A kind of side chain dopamine functionalized polyurethane coating and its preparation method and application

A technology of polyurethane coatings and dopamine, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor bonding effect on the surface of flexible substrates, unfavorable long-term use of coatings, etc., to achieve preparation The method is simple and feasible, the cost is low, and the effect of good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation of the natural rubber and the surface treatment method of the natural rubber are carried out according to the method described in Example 1 in the patent application 201110073775.8 A surface treatment method for improving the bonding performance of vulcanized natural rubber.

[0071] In the embodiment, the adhesion force of the side chain dopamine functionalized polyurethane coating on the surface of natural rubber is measured by the pulling method, with reference to GB / T 5210, the test area is a circular area with a diameter of 20mm, and the pulling rate is set to 0.2MPa / s. Five different regions were tested for each sample, and the average value was taken as the test result.

[0072] In the examples, the molecular weight of side chain dopamine functionalized polyurethane is measured by gel permeation chromatography, and polystyrene with narrow distribution is used as standard sample.

[0073] Refer to GB / T 21886-2008 for the anti-bacterial adhesion t...

Embodiment 1

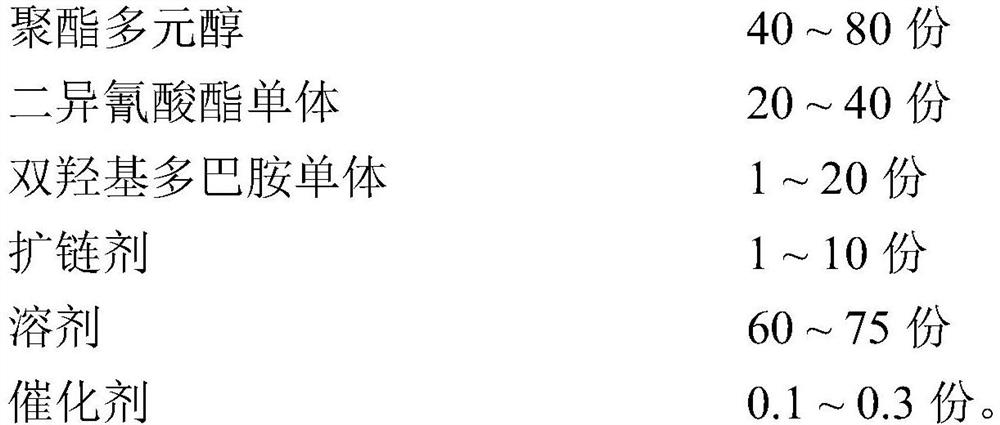

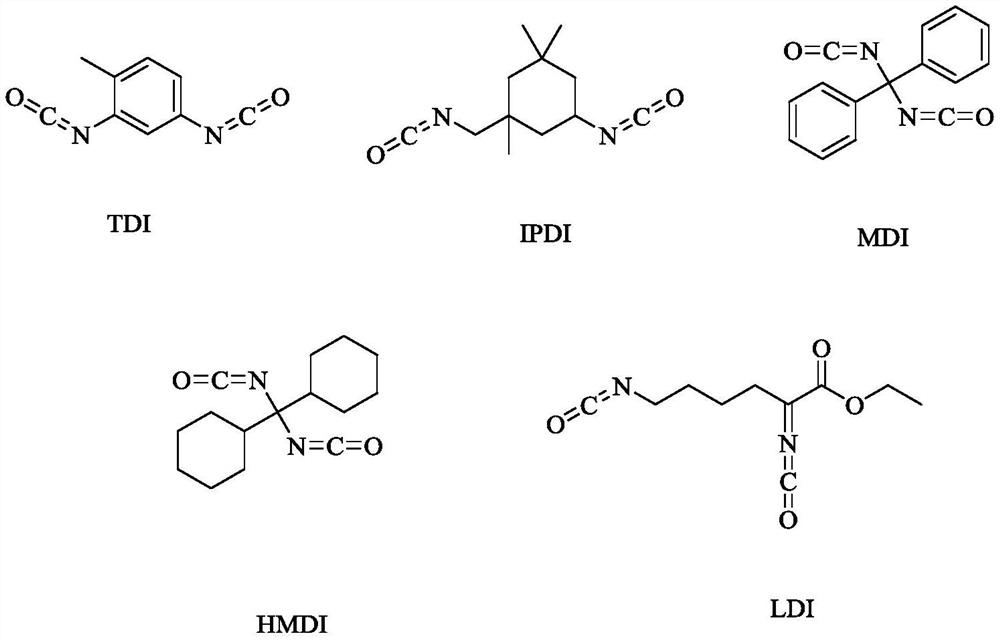

[0078] A preparation method for side chain dopamine functionalized polyurethane coating, comprising the steps of:

[0079] (1) In the reactor, 25 parts by weight of 2,2-dimethylolpropionic acid, 25 parts by weight of 2,2-dimethoxypropane and 0.5 parts by weight of p-toluenesulfonic acid are added to 50 parts by weight of acetone , reacted at 25°C for 5 hours, neutralized with sodium bicarbonate after the reaction and dried by suction to obtain the product intermediate monomer P1; 40 parts by weight of the product intermediate monomer P1, 30 parts by weight of N-hydroxysuccinimide, 50 parts by weight of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride was added to 50 parts by weight of dichloromethane, reacted at 0°C for 2 hours and then reacted at 25°C Under reaction for 24 hours, after the completion of the reaction, extract with 10wt% sodium bicarbonate aqueous solution, concentrate and dry to obtain the intermediate product P2; 50 parts by weight of the intermedia...

Embodiment 2

[0091] A preparation method for side chain dopamine functionalized polyurethane coating, comprising the steps of:

[0092] (1) In the reactor, 25 parts by weight of 2,2-dimethylolpropionic acid, 25 parts by weight of 2,2-dimethoxypropane and 0.5 parts by weight of p-toluenesulfonic acid are added to 50 parts by weight of acetone , reacted at 25°C for 5 hours, neutralized with sodium bicarbonate after the reaction and dried by suction to obtain the product intermediate monomer P1; 40 parts by weight of the product intermediate monomer P1, 30 parts by weight of N-hydroxysuccinimide, 50 parts by weight of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride was added to 50 parts by weight of dichloromethane, reacted at 0°C for 2 hours and then reacted at 25°C Under reaction for 24 hours, after the completion of the reaction, extract with 10wt% sodium bicarbonate aqueous solution, concentrate and dry to obtain the intermediate product P2; 50 parts by weight of the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com