A kind of side chain epoxy functionalized polyurethane coating and its preparation method and application

A polyurethane coating and functionalization technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of ensuring the flexibility of flexible substrates, affecting the normal use of marine facilities, and reducing the service life of materials and other problems, to achieve the effect of simple and feasible preparation method, low cost and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation of the natural rubber and the surface treatment method of the natural rubber are carried out according to the method described in Example 1 in the patent application 201110073775.8 A surface treatment method for improving the bonding performance of vulcanized natural rubber.

[0057] In the embodiment, the adhesion of side chain epoxy functionalized polyurethane coating on the surface of natural rubber is measured by pulling method, with reference to GB / T 5210, the test area is a circular area with a diameter of 20mm, and the pulling rate is set to 0.2MPa / s. Five different regions were tested for each sample, and the average value was taken as the test result.

[0058] In the examples, the molecular weight of the side-chain epoxy-functionalized polyurethane resin was measured by gel permeation chromatography, and polystyrene with narrow distribution was used as the standard sample.

[0059] The anti-bacterial adhesion test of side-chain epoxy-functiona...

Embodiment 1

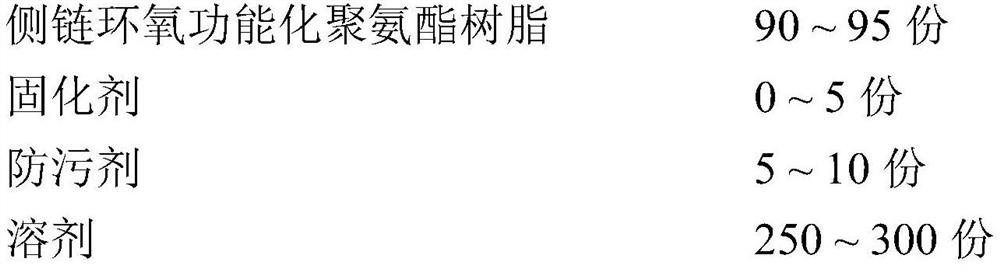

[0064] A preparation method for side chain epoxy functionalized polyurethane coating, comprising the steps of:

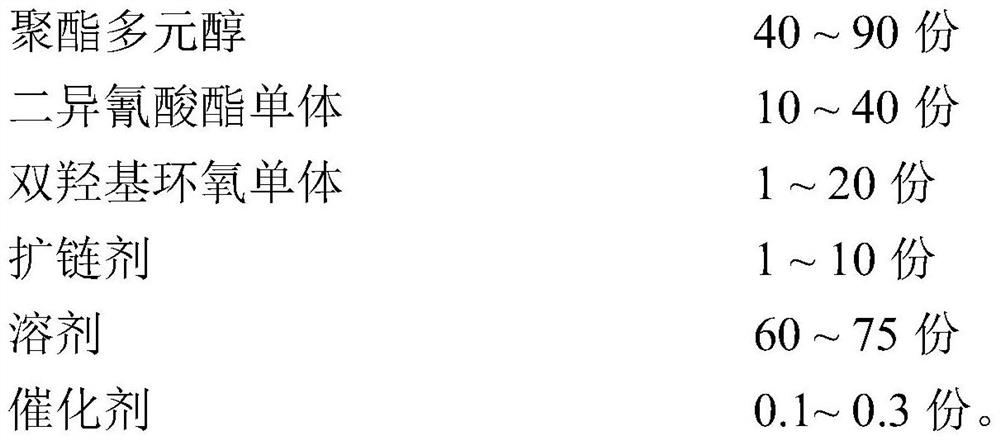

[0065] (1) In the reactor, add 43.2 parts by weight of α-thioglycerol, 56.8 parts by weight of glycidyl methacrylate, 2 parts by weight of benzoin dimethyl ether, and 40 parts by weight of tetrahydrofuran. The intensity is 100mW / cm 2 ) reacted for 40 minutes under curing to obtain a dihydroxy epoxy monomer;

[0066] (2) In a reaction vessel under a nitrogen atmosphere, add 60 parts by weight of polycaprolactone diol (molecular weight 2000g / mol), 23.55 parts by weight of isophorone diisocyanate and 40 parts by weight of tetrahydrofuran and react for 1 hour at 70°C , to obtain a polyurethane prepolymer, add 15 parts by weight of dihydroxy epoxy monomer, 0.2 parts by weight of dibutyltin dilaurate, 1.45 parts by weight of 1,4-butanediol and 20 parts by weight of tetrahydrofuran and react at 80°C for 3 hours After the reaction, the side chain epoxy functionalized poly...

Embodiment 2

[0078] A preparation method for side chain epoxy functionalized polyurethane coating, comprising the steps of:

[0079] (1) In the reactor, add 43.2 parts by weight of α-thioglycerol, 56.8 parts by weight of glycidyl methacrylate, 2 parts by weight of benzoin dimethyl ether, and 40 parts by weight of tetrahydrofuran. The intensity is 100mW / cm 2 ) reacted for 40 minutes under curing to obtain a dihydroxy epoxy monomer;

[0080] (2) In the reaction vessel of nitrogen atmosphere, add 60 parts by weight of polyethylene adipate (molecular weight 2000g / mol), 25.83 parts by weight of isophorone diisocyanate and 40 parts by weight of tetrahydrofuran react at 70 DEG C for 1 hours, to obtain a polyurethane prepolymer, then add 10 parts by weight of dihydroxy epoxy monomer, 0.2 parts by weight of dibutyltin dilaurate, 4.17 parts by weight of 1,4-butanediol and 20 parts by weight of tetrahydrofuran react at 80 ° C for 3 Hour, after reaction finishes, obtain side chain epoxy functionaliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com