Water-based plaster

一种水性贴剂、水性的技术,应用在酸性共聚物粘合剂、粘合剂类型、无机非有效成分等方向,能够解决膏体延展不均匀、延展膏体的时间仅限于短时间、水性粘附基质粘度升高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the water-soluble patch provided by the present invention is not particularly limited, and it can be prepared according to known preparation methods. For example, a water-based patch can be formed by spreading the adhesive matrix composed of the above-mentioned matrix components on a support, and covering the surface of the water-based matrix with a plastic film.

[0053] As the plastic film covering the substrate on the support body, polyethylene, polypropylene, polyester, and polyvinyl chloride can be used alone or in combination, and silicone treatment, corona discharge, etc. Thin films for processing, embossing, plasma processing, etc.

[0054] Examples of the support include porous bodies such as polyethylene, polypropylene, polyvinyl chloride, polyester, nylon, and polyurethane, foams, woven fabrics, non-woven fabrics, and films or sheets with porous bodies, foams, and woven fabrics. Cloth, laminated products of nonwoven fabrics, etc., p...

Embodiment 1

[0061] Add 2.5 g of purified water to 1.1 g of loxoprofen sodium hydrate, stir and dissolve, as the main drug solution. Next, add 25g 70% D-sorbitol solution, 3g kaolin, 0.5g titanium oxide, 0.5g tartaric acid, 0.06g edetate sodium hydrate, 5.0g 20% polyacrylic acid aqueous solution, 2.5g 33% Polyvinyl alcohol aqueous solution, 1.0 g of methyl acrylate·2-ethylhexyl acrylate copolymer resin emulsion, and the balance (appropriate amount) of purified water were mixed.

[0062] To this solution, a solution obtained by dissolving 0.1 g of methylparaben and 0.05 g of propylparaben in a mixed solvent of 1.0 g of propylene glycol and 0.5 g of peppermint oil was added, and mixed until uniform. Then add the dispersion obtained by dispersing 4.0g sodium carmellose, 5.0g sodium polyacrylate, 0.25g hydroxypropyl cellulose, and 0.09g aluminum dihydroxide glycerin in 20g concentrated glycerin to the solution, evenly mix. Finally, the main drug solution and 3.0 g of isostearic acid were a...

Embodiment 2-7

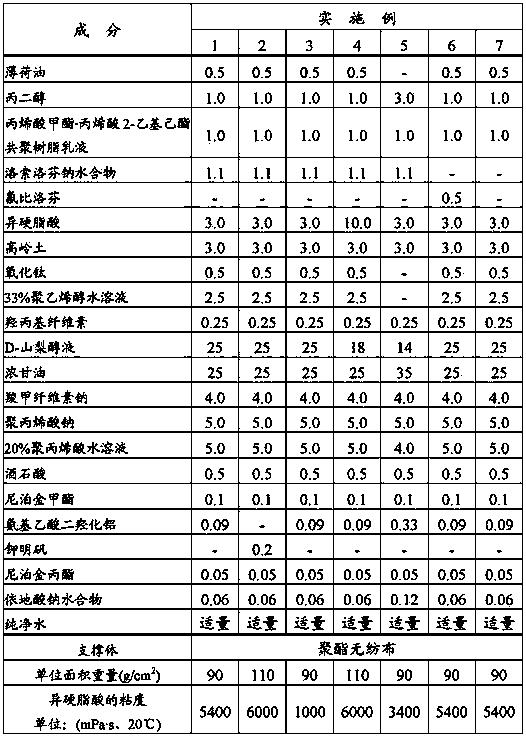

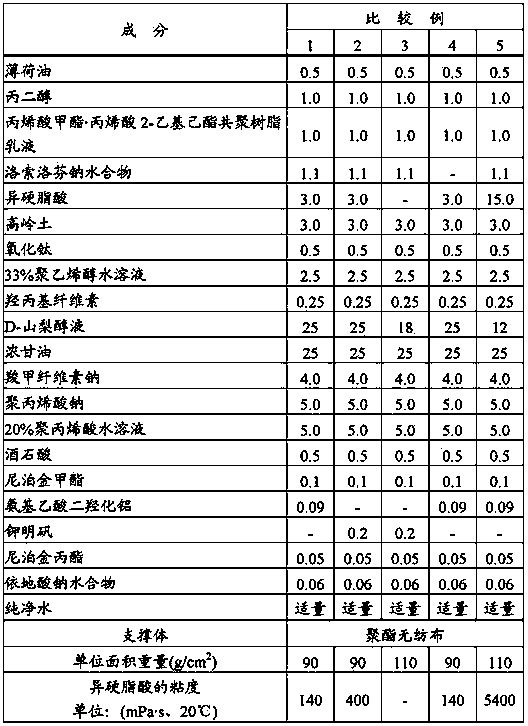

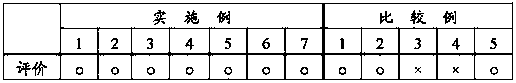

[0064] According to the mixing formula (unit: weight %) shown in the following Table 1, the water-based patch of each example was prepared in the same manner as in Example 1.

[0065] It should be noted that the formulation of the above-mentioned Example 1 is also described in Table 1.

[0066] [Table 1]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com