Water-in-oil type sunscreen cosmetic

A technology of water-in-oil type cosmetics, which is applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc. It can solve the problems of cosmetics that are difficult to spread, and achieve the effect of easy spreading, not easy to white, and excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~10

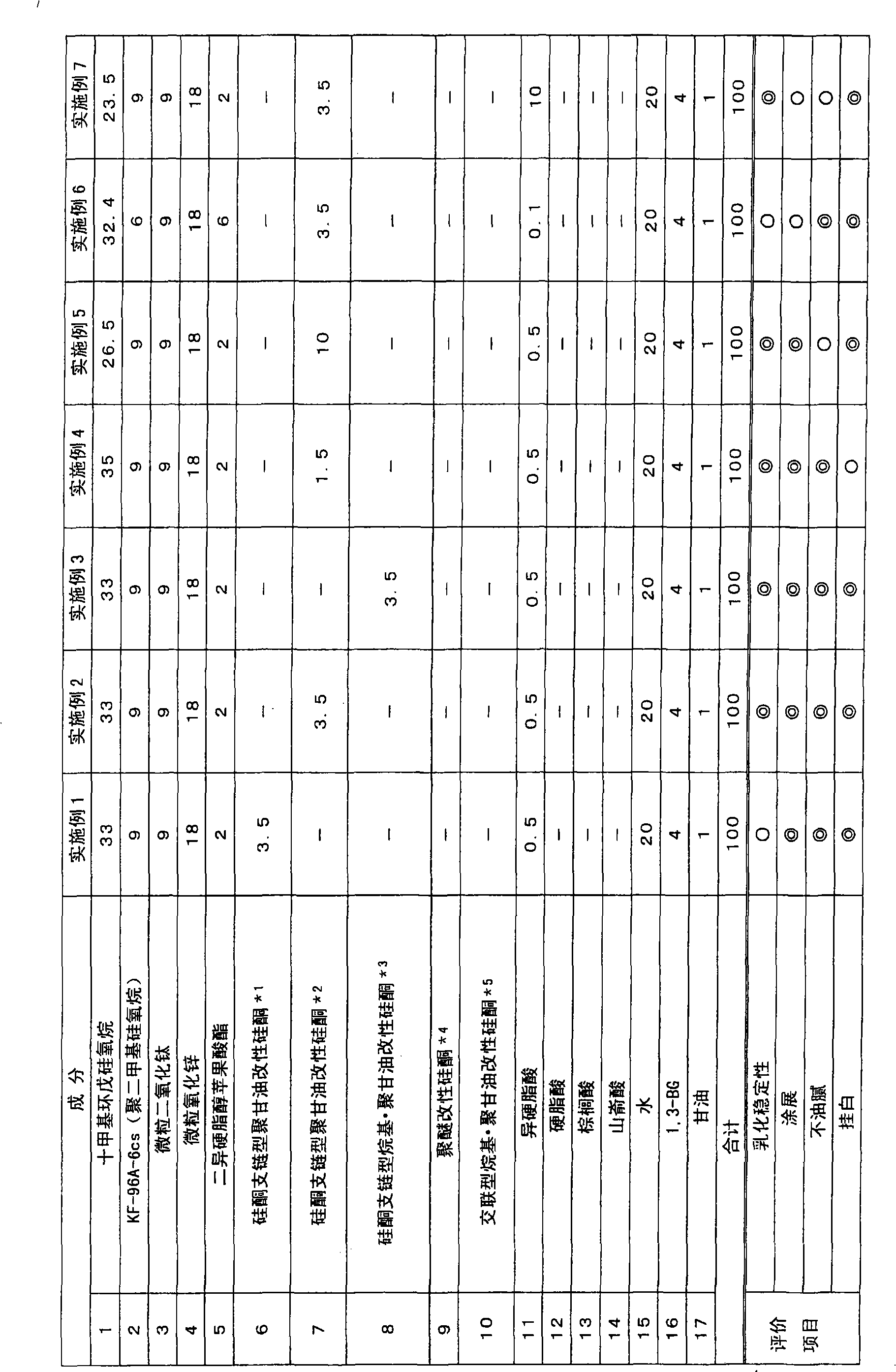

[0056] Water-in-oil type sunscreen cosmetics having the compositions shown in Tables 1 to 2 were prepared by the following production methods, respectively. The items "emulsion stability", "spreading", "non-greasy", and "whitening" of the obtained water-in-oil type sunscreen cosmetics were evaluated and judged by the test methods and judgment criteria shown below. The judgment results of these items are shown in Tables 1-2. In addition, unless otherwise specified, the unit of each component in the table is mass % based on the total amount of cosmetics.

[0057] Table 1

[0058]

[0059] Table 2

[0060]

[0061]

[0062] (1) Mix ingredients 2, 3, 6-10 uniformly according to the ratios shown in Table 1-2 with a three-roll machine to obtain mixture A.

[0063] (2) On the other hand, components 1, 4, 5, and 11-14 (heating and melting solid fatty acids) were uniformly mixed in the proportions shown in Tables 1-2 with a homomixer to obtain mixture B.

[0064] (3) Mix th...

Embodiment 8

[0130] (Example 8) sunscreen

[0131] (ingredients) (mixing ratio (mass%))

[0132] 1. Methyl polytrimethicone 20.0

[0133] 2. Particulate Titanium Dioxide 10.0

[0134] 3. Microparticle zinc oxide 12.0

[0135] 4. Diisostearyl malate 2.0

[0136] 5. Silicone branched polyglycerol modified silicone *2 3.0

[0137] 6. Isostearic acid 0.5

[0138] 7. Polymethyl methacrylate 5.0

[0139] 8. KSG-16 9.0

[0140] 9. KP-545 7.0

[0141] 10. Water 25.3

[0142] 11. Glycerin 5.0

[0143] 12.1, 3-BG 1.0

[0144] 13. Methylparaben 0.2

[0145]

[0146] (1) Components 1 to 3 were uniformly mixed with a three-roll machine to obtain a mixture A.

[0147] (2) On the other hand, components 4 to 9 were uniformly mixed with a homomixer to obtain a mixture B.

[0148] (3) Mix the mixture A and mixture B obtained above with a homomixer to obtain an oil phase mixture C.

[0149] (4) On the other hand, component 13 was heated and dissolved in component 12, and components 10 a...

Embodiment 9

[0153] (Example 9) (makeup primer)

[0154] (ingredients) (mixing ratio (mass%))

[0155] 1. Decamethylcyclopentasiloxane 23.0

[0156] 2. Phenyl trimethicone 4.0

[0157] 3. Particulate Titanium Dioxide 2.0

[0158] 4. Particulate Zinc Oxide 10.0

[0159] 5. Triisocapryl 7.0

[0160] 6. Silicone branched polyglycerol modified silicone *3 2.0

[0161] 7. Polyether modified silicone *4 1.5

[0162] 8. Isostearic acid 0.5

[0163] 9. Polymethyl methacrylate 6.0

[0164] 10. KSG-16 6.0

[0165] 11. Octyl Methoxycinnamate 6.0

[0166] 12. Talc 1.0

[0167] 13. Mica 1.0

[0168] 14. Water 21.8

[0169] 15. Glycerin 2.0

[0170] 16. DPG 4.0

[0171] 17.1, 3-BG 2.0

[0172] 18. Methylparaben 0.2

[0173]

[0174] (1) Mix components 2-5 uniformly with a three-roll machine to obtain a mixture A.

[0175] (2) On the other hand, components 1 and 6 to 13 were uniformly mixed with a homomixer to obtain a mixture B.

[0176] (3) Mix the mixture A and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com