Ultralow temperature nano antifreezing isolating emulsion, and preparation method thereof

An ultra-low temperature, milk isolation technology, applied in coatings and other directions, can solve the problems of high labor and material resources to clean frozen cars, hidden dangers of railway traffic safety, affecting the efficiency of unloading, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

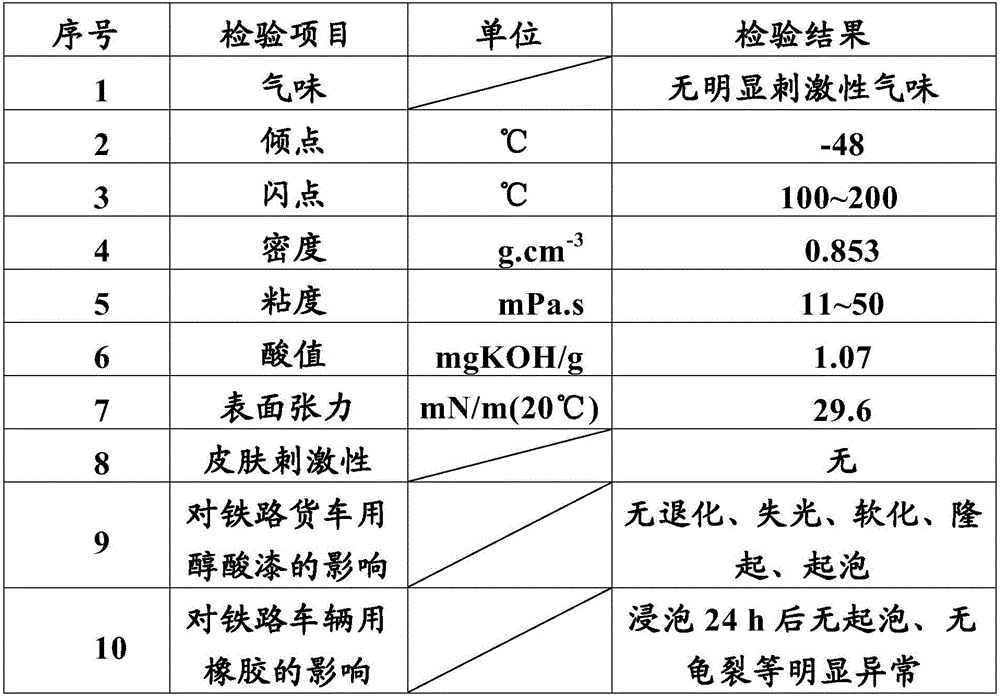

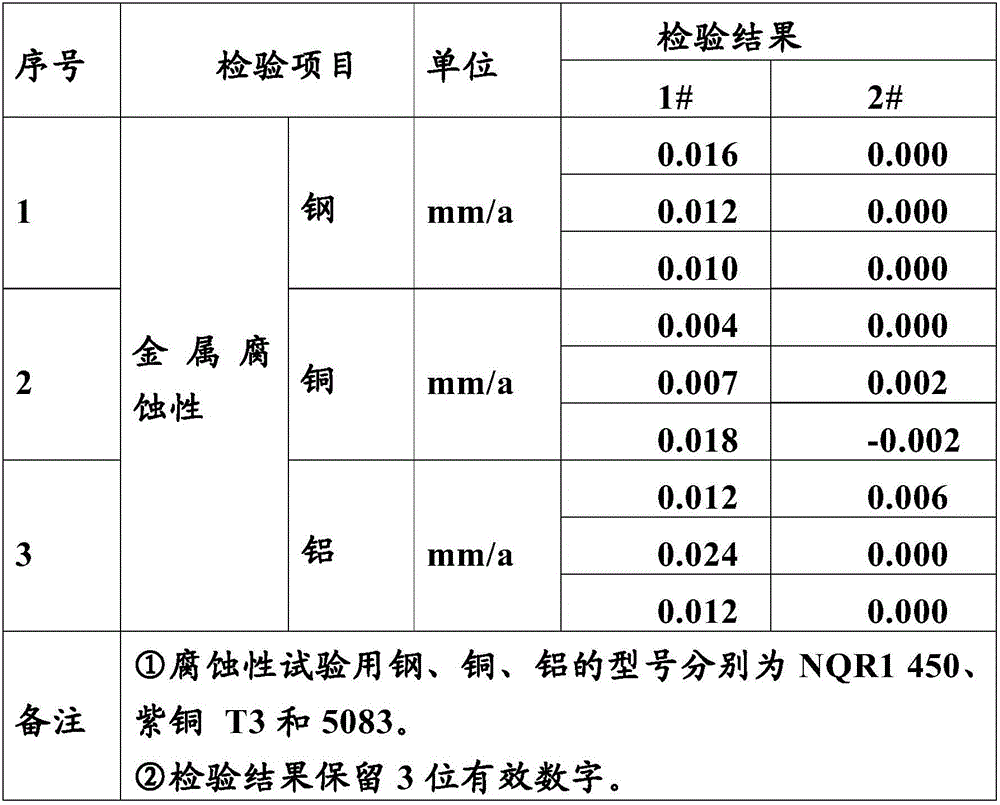

[0035] The present invention proposes an ultra-low temperature nano-antifreeze isolation emulsion, which still has high stability and excellent anti-corrosion performance at ultra-low temperatures, so as to effectively solve the problem of frozen trains.

[0036] Specifically, the ultra-low temperature nano antifreeze isolation emulsion includes 100 parts by weight of mineral oil and / or bio-oil, 0.1-1 part by weight of auxiliary agent A, 1-2 parts by weight of auxiliary agent B and 13-50 parts by weight of water.

[0037] The auxiliary agent A includes ethylene / vinyl acetate copolymer, acrylate polymer, maleic anhydride copolymer, polyoxyethylene alkylamine or a mixture of any two or more of the above. The auxiliary agent B includes sorbitol fatty acid ester, polyglycerol fatty acid ester, polyoxyethylene fatty acid ester, isostearic acid monoglyceride, monoalkenyl succinimide, polyalkenyl succinimide Or a mixture of any two or more of the above types. The auxiliary agent A i...

Embodiment 2

[0050] Another object of the present invention is to provide a method for preparing an ultra-low temperature nano antifreeze isolation emulsion, said preparation method comprising the following steps:

[0051] 1) Add 0.1-1 parts by weight of auxiliary agent A and 1-2 parts by weight of auxiliary agent B to 100 parts by weight of mineral oil and / or bio-oil, and stir evenly, wherein the auxiliary agent A includes ethylene / vinyl acetate copolymerization acrylate polymer, maleic anhydride copolymer, polyoxyethylene alkylamine or a mixture of any two or more of the above, the auxiliary agent B includes sorbitol fatty acid ester, polyglycerin fatty acid ester, poly Oxyethylene fatty acid ester, monoglyceride isostearate, monoalkenyl succinimide, polyalkenyl succinimide or a mixture of any two or more of the above;

[0052] 2) Increase the rotating speed and stir, and add 13 to 50 parts by weight of water;

[0053] 3) After stirring for 20 min, the mixture turns white or light yello...

Embodiment 3

[0059] The difference between this example and Example 2 is that in this example, 35kg of mineral oil is added to the reaction vessel, 0.15kg of acrylate polymer and 0.4kg of polyglycerol fatty acid ester are added respectively, the speed is set at 500r / min, and the mixture is stirred evenly . Then increase the rotation speed to above 3000r / min, then add 10kg of water, and stir for 20 minutes, and the system turns white or light yellow, and the ultra-low temperature nano antifreeze isolation emulsion is obtained.

[0060] The main technical indicators of the ultra-low temperature nano antifreeze isolation emulsion prepared by the above preparation method are: viscosity 13.7mPa·s, pour point -43°C, good performance at ultra-low temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com