Patents

Literature

49results about How to "Guaranteed non-stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

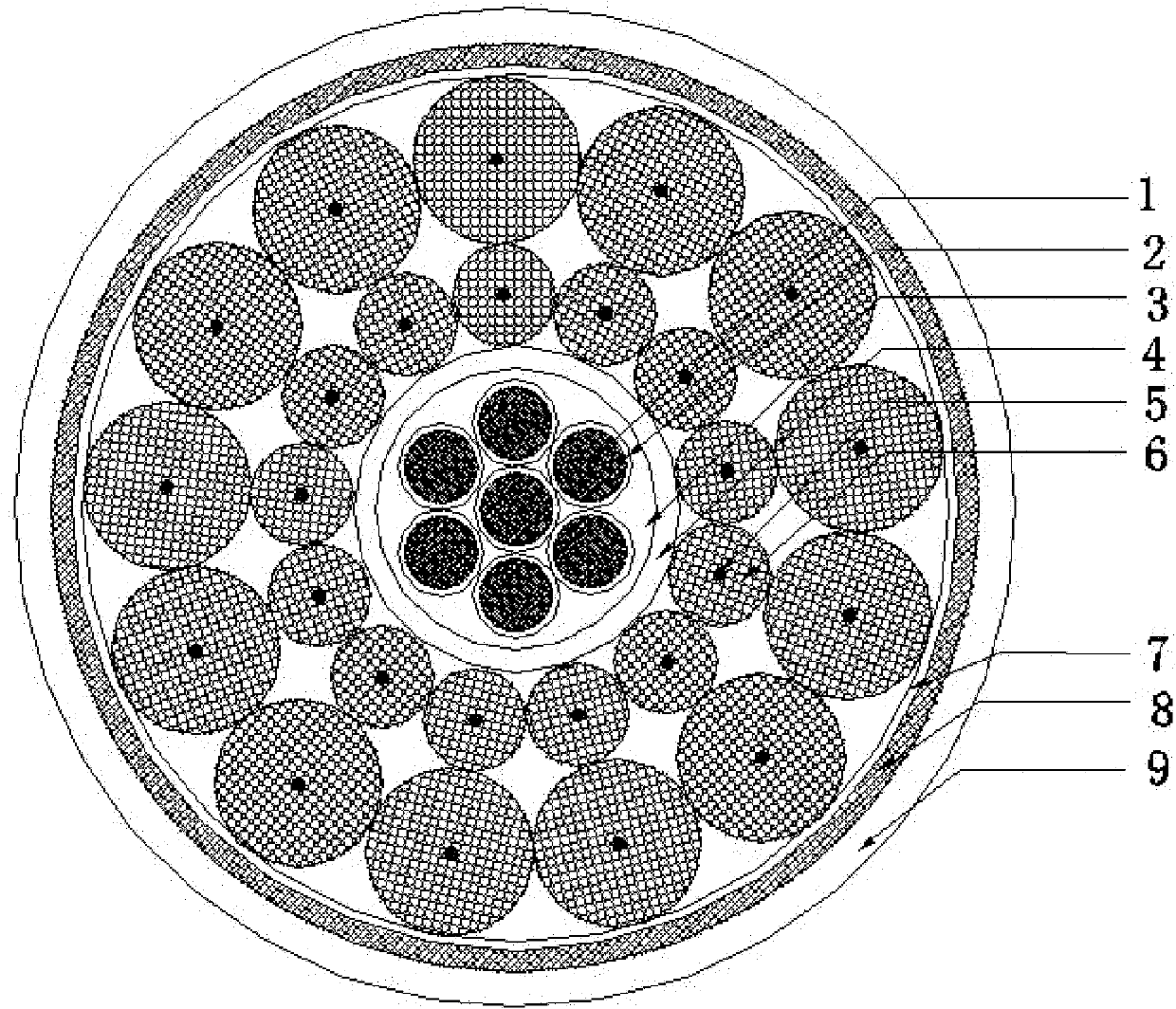

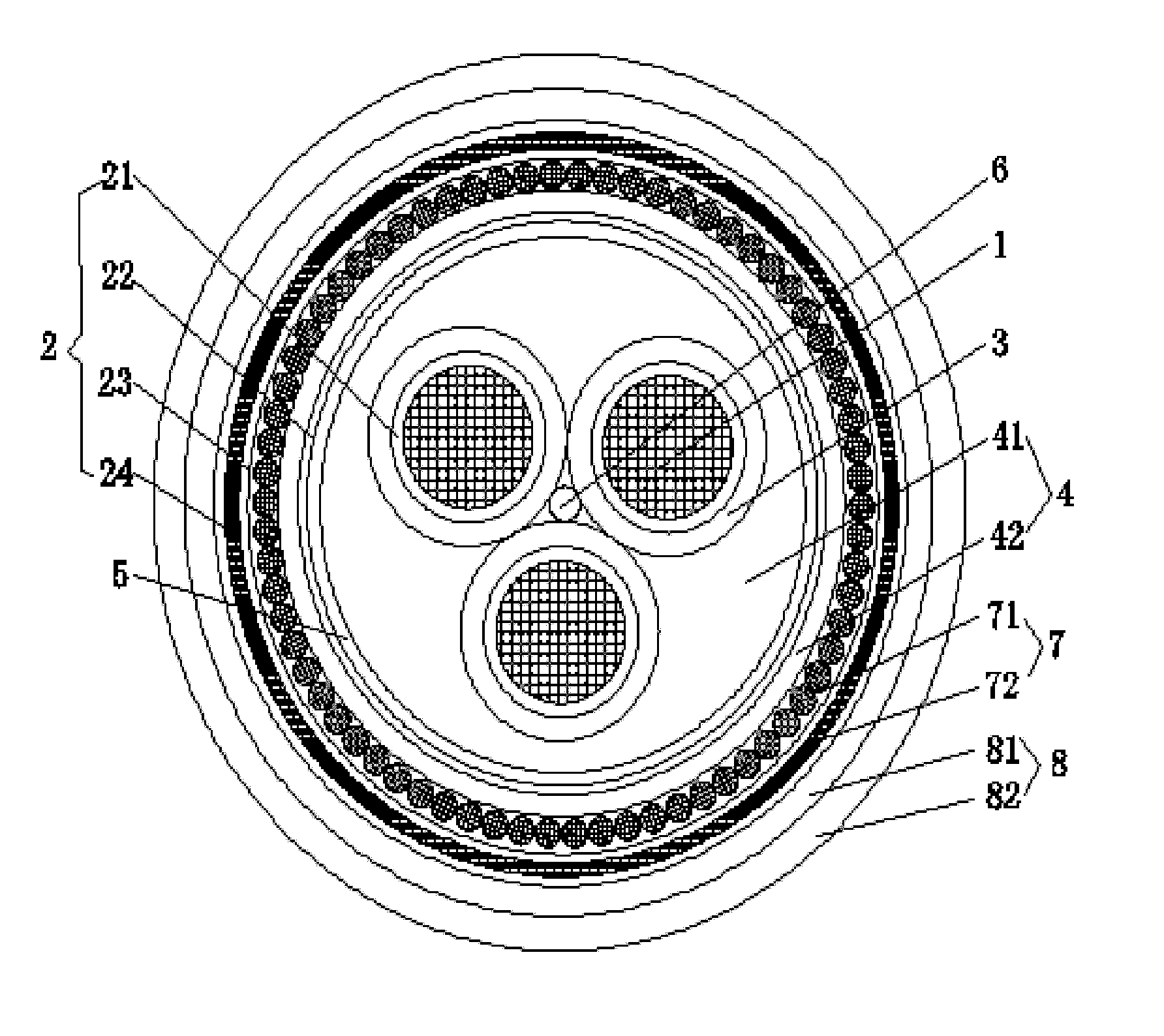

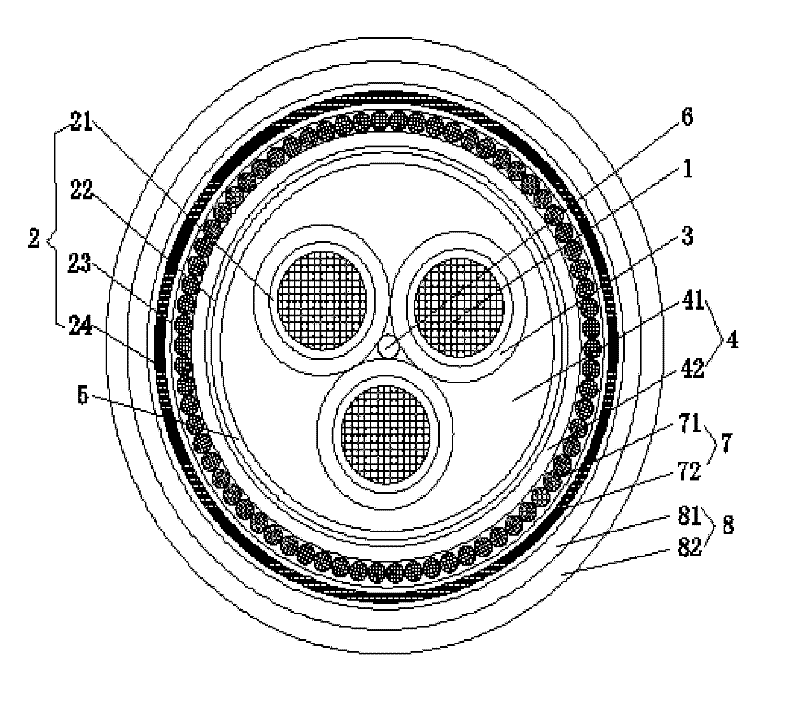

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

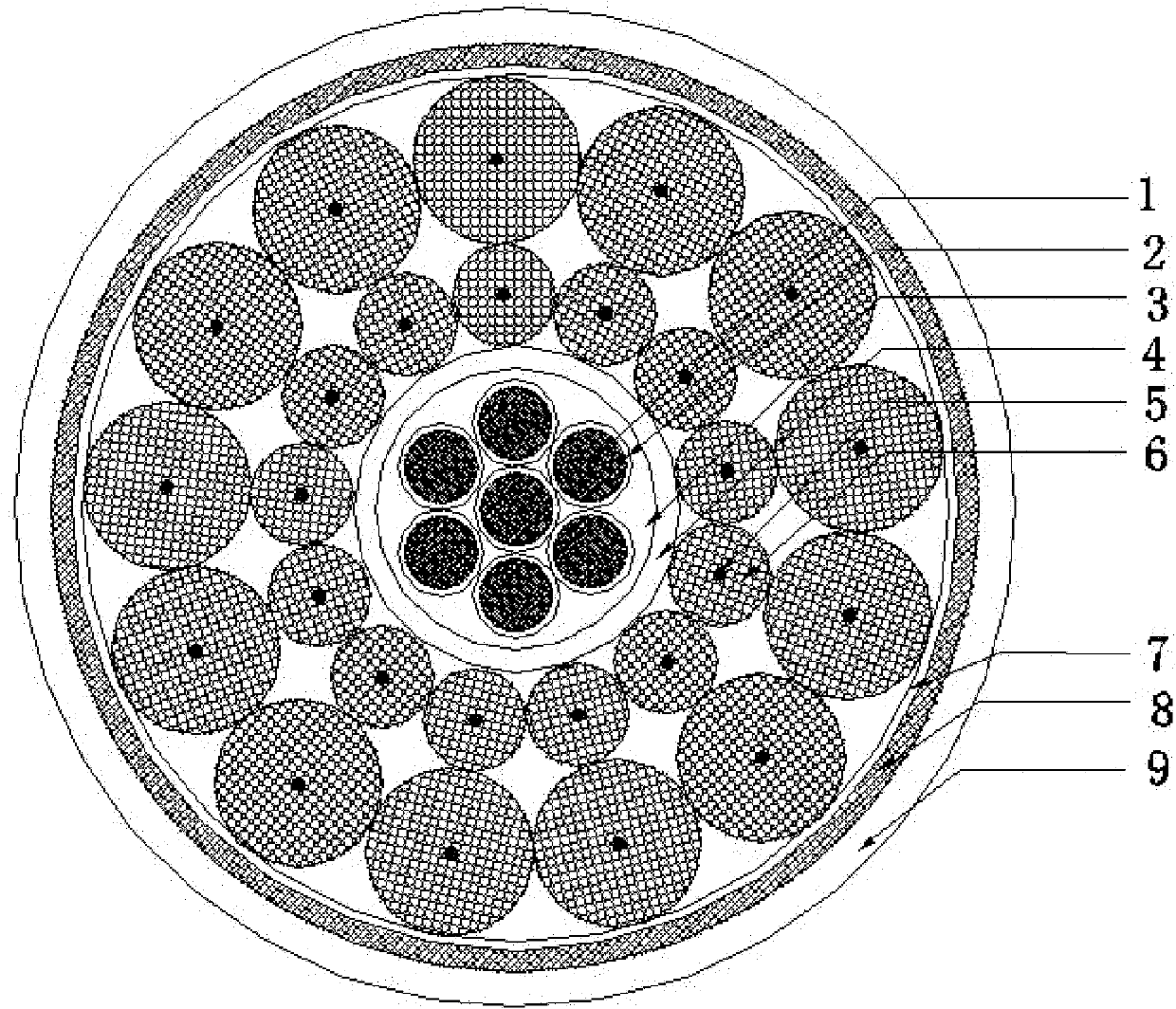

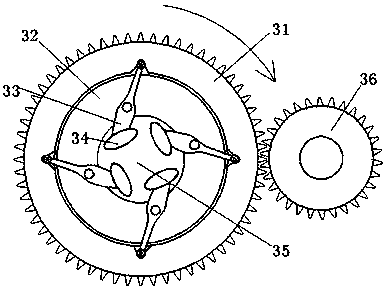

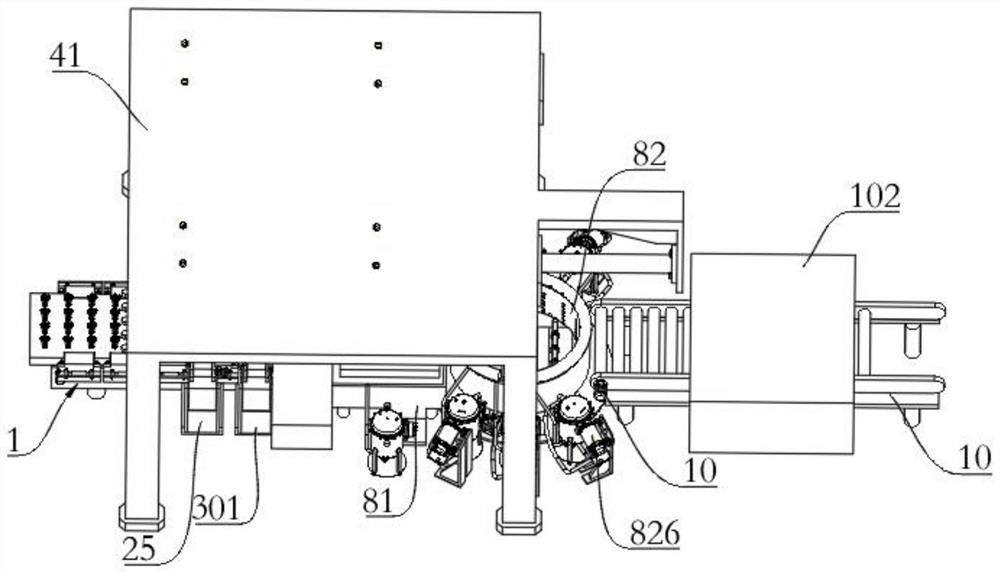

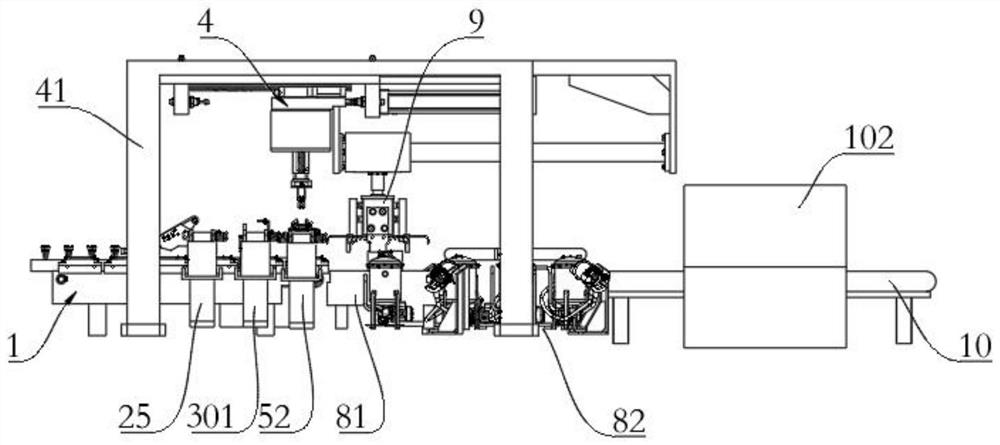

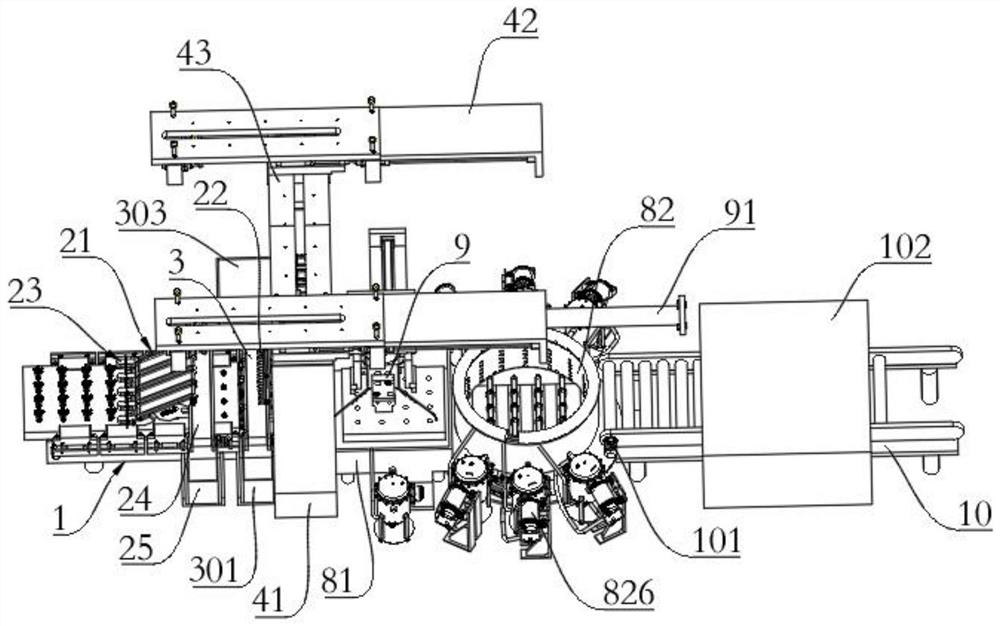

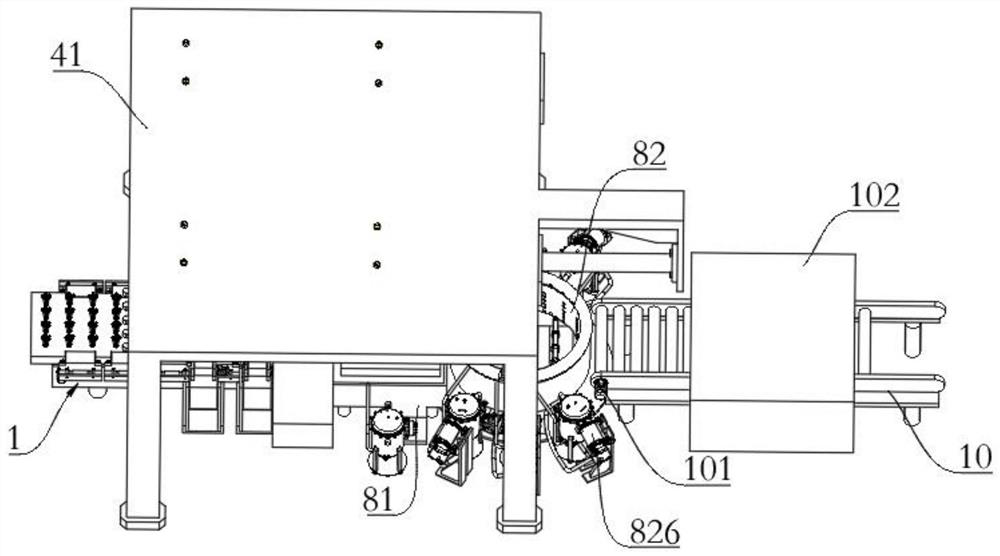

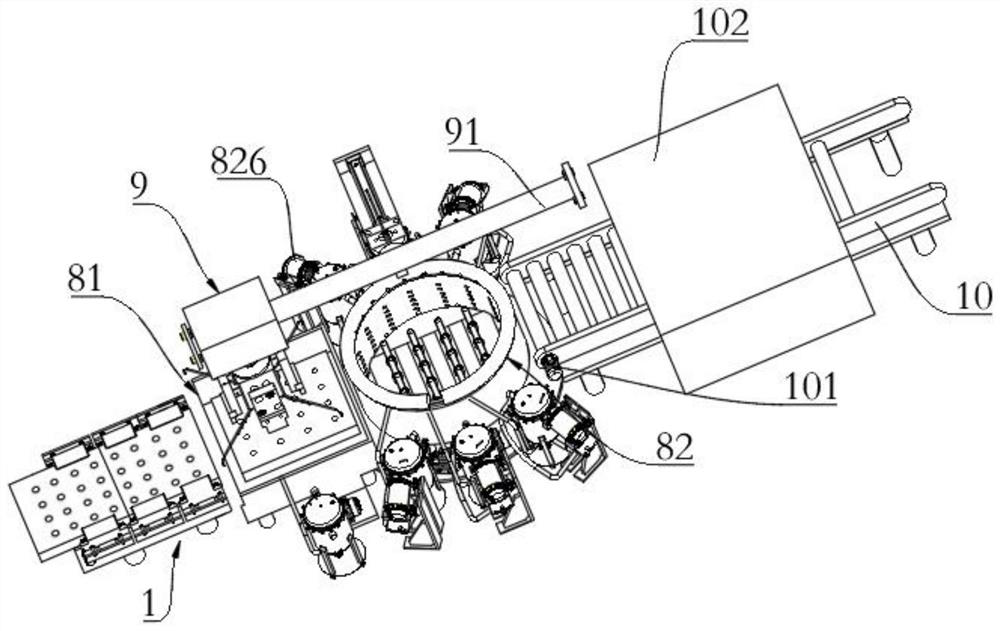

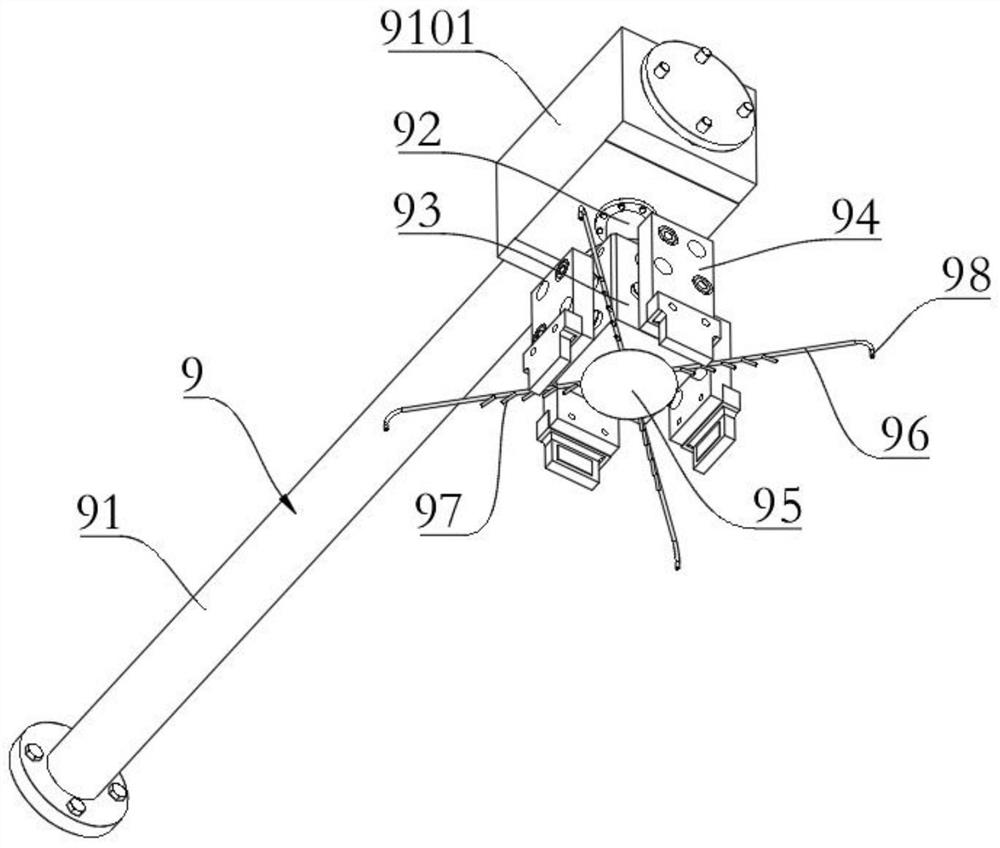

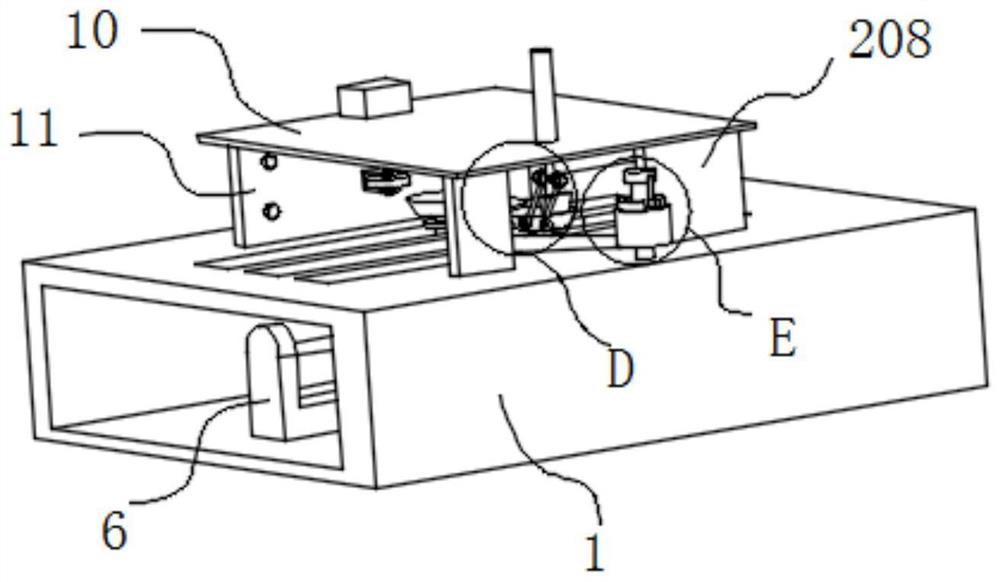

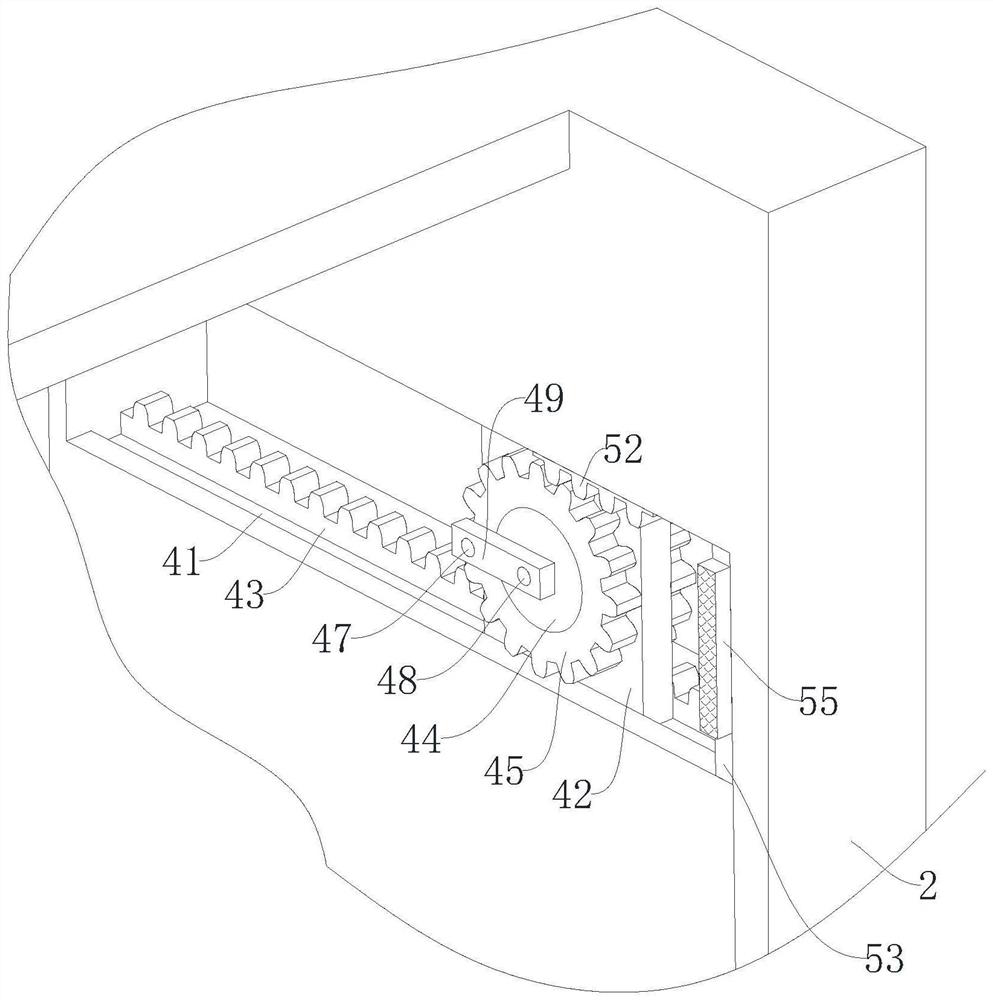

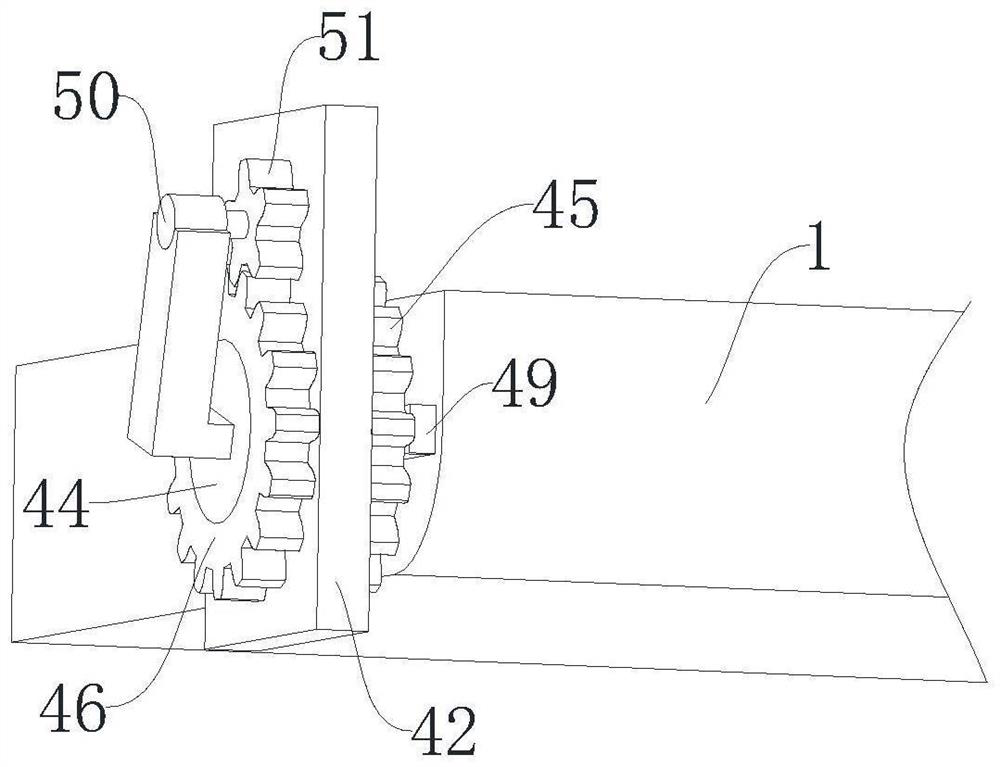

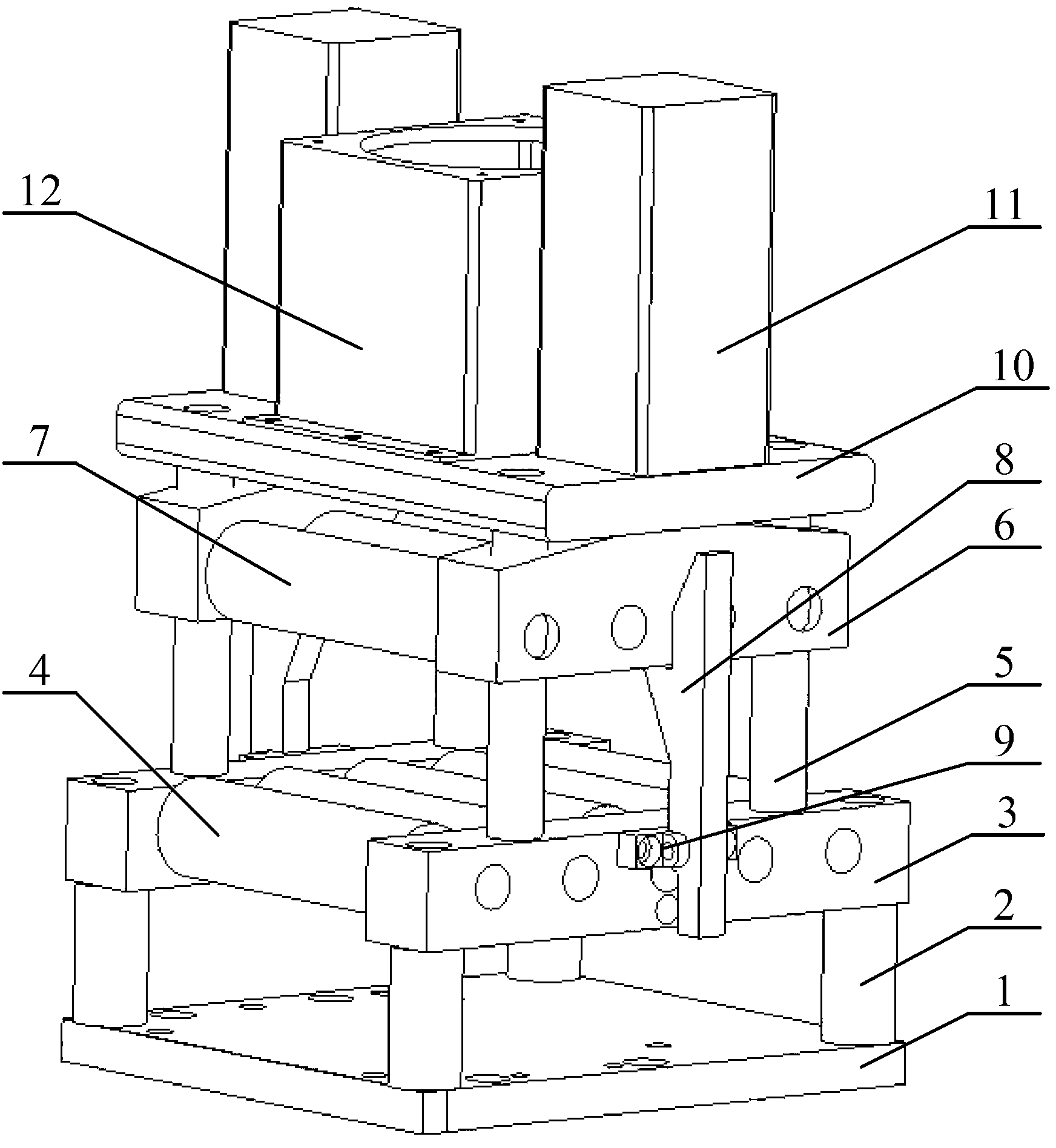

Automatic crisp fried cake forming machine

InactiveCN107751281AEasy to shapeFast formingDough-sheeters/rolling-machines/rolling-pinsDough mixing/kneading machinesEngineeringConveyor belt

The invention discloses an automatic crisp fried cake forming machine. A kneading assembly is arranged at the output end of a cake crust forming assembly; a finished crisp fried cake forming assemblyis arranged at the output end of the kneading assembly; an auxiliary material blanking assembly is arranged on the cake crust forming assembly; and the cake crust forming assembly comprises a cake crust forming conveyor belt, multiple groups of forming wheel assemblies and an oiling assembly. The forming machine disclosed by the invention is convenient and rapid to form, and with the adoption of stepped forming, the formed crisp fried cake has high quality. During forming, the cake crust is gradually formed by utilizing the multiple groups of forming wheels, and chopped green onion and other auxiliary materials are spread, and a pressing plate is utilized for pressing downwards once, so that the subsequent auxiliary materials are prevented from dropping. Then, the kneading assembly is utilized for performing repeated kneading, so that the chewy property of the cake is improved, the cake is formed into the finished product again after kneading, and therefore, the taste of the crisp fried cake is greatly improved. In addition, the oiling assembly is arranged on each pressing wheel, so that the cake and the oil can be well mixed, the performance of the crisp fried cake is improved, and the cake can be prevented from being stuck to one another.

Owner:栗永伟

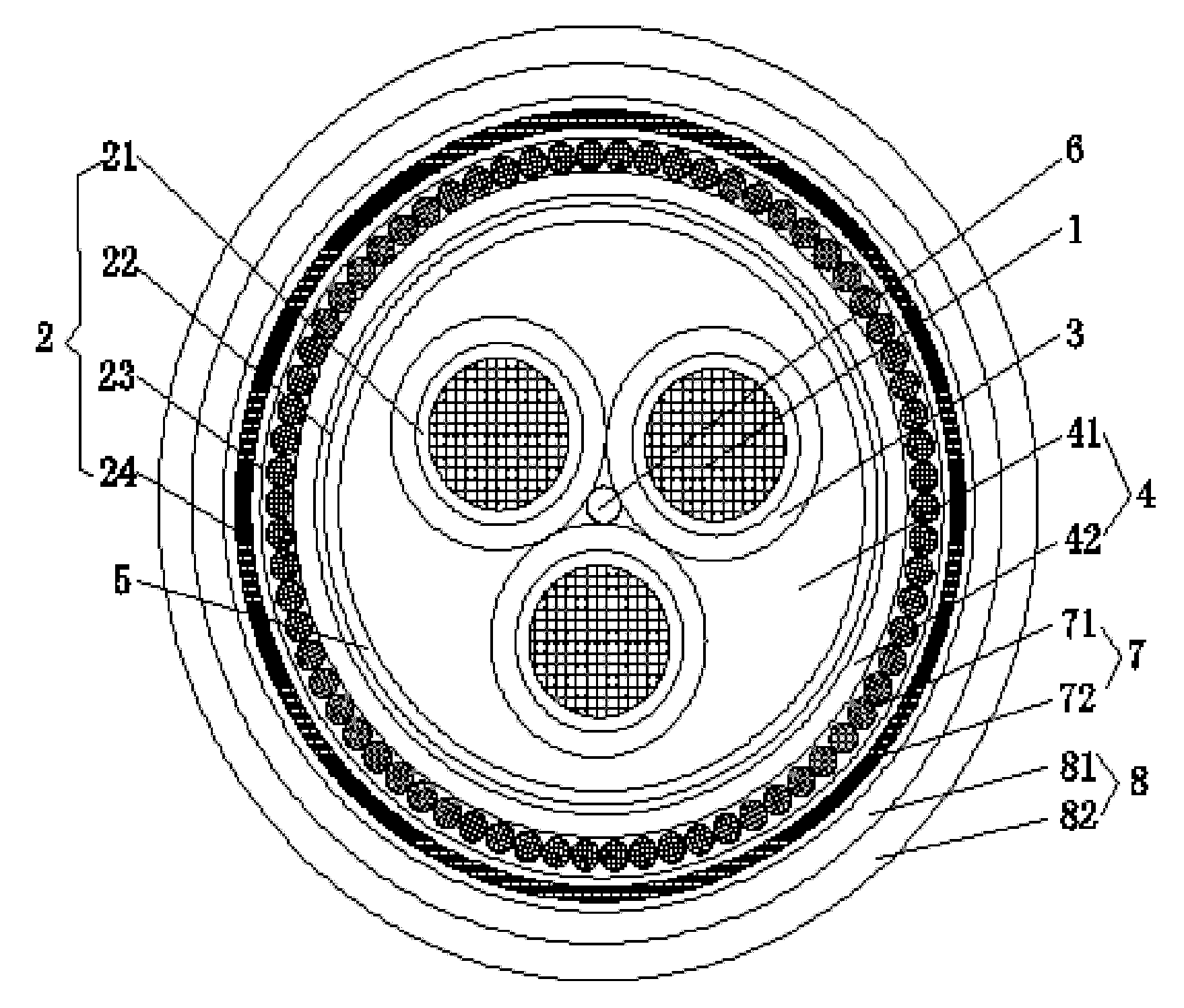

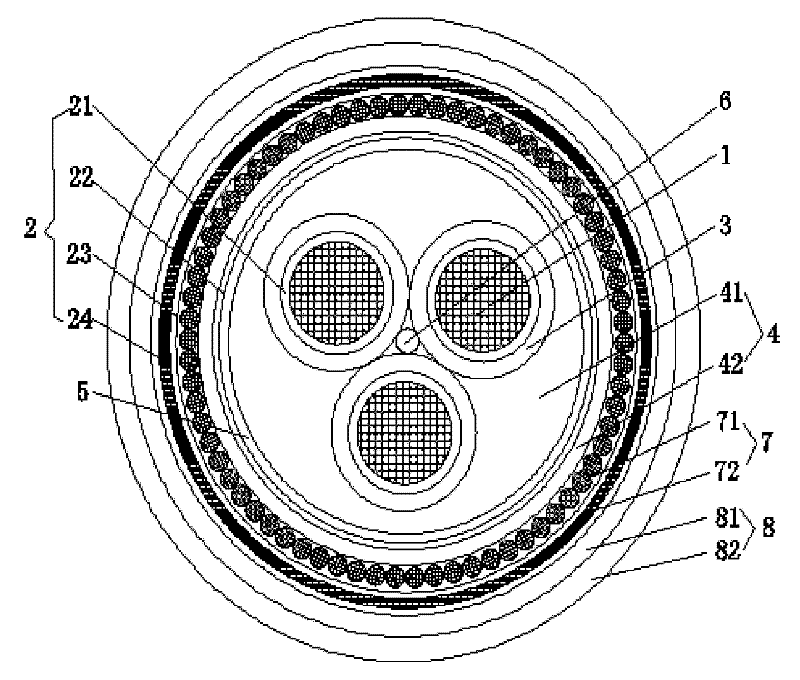

Cable for shallow sea wind power generation

ActiveCN101937738AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFlexible cablesElectricityElectrical conductor

The invention discloses a cable for shallow sea wind power generation, which comprises a conductor, water-blocking tapes, an insulating layer and lining layers, wherein, the first water-blocking tape and the extruded insulating layer are wrapped sequentially outside the conductor to form insulating wire cores, and a plurality of insulating wire cores are twisted together to form a cable core; the first lining layer and the second water-blocking tape are wrapped sequentially outside the cable core; and the insulating layer and the first lining layer are formed by extruding a thermoplastic elastomer (TPE). In the invention, the insulating layer is made of a thermoplastic olefin (TPO) material in the TPE and the first lining layer is made of a thermoplastic starch (TPS) material in the TPE, wherein, the TPE has good electrical property, good mechanical property, excellent low-temperature bending property and excellent torsion resistance, high long-term working temperature up to 125 DEG C, better water resistance and excellent salt-fog resistance, and especially the TPE can still maintain good flexibility at -60 DEG C; and TPO has more excellent electrical property, and TPS has better water resistance than that of the TPO.

Owner:FAR EAST CABLE +2

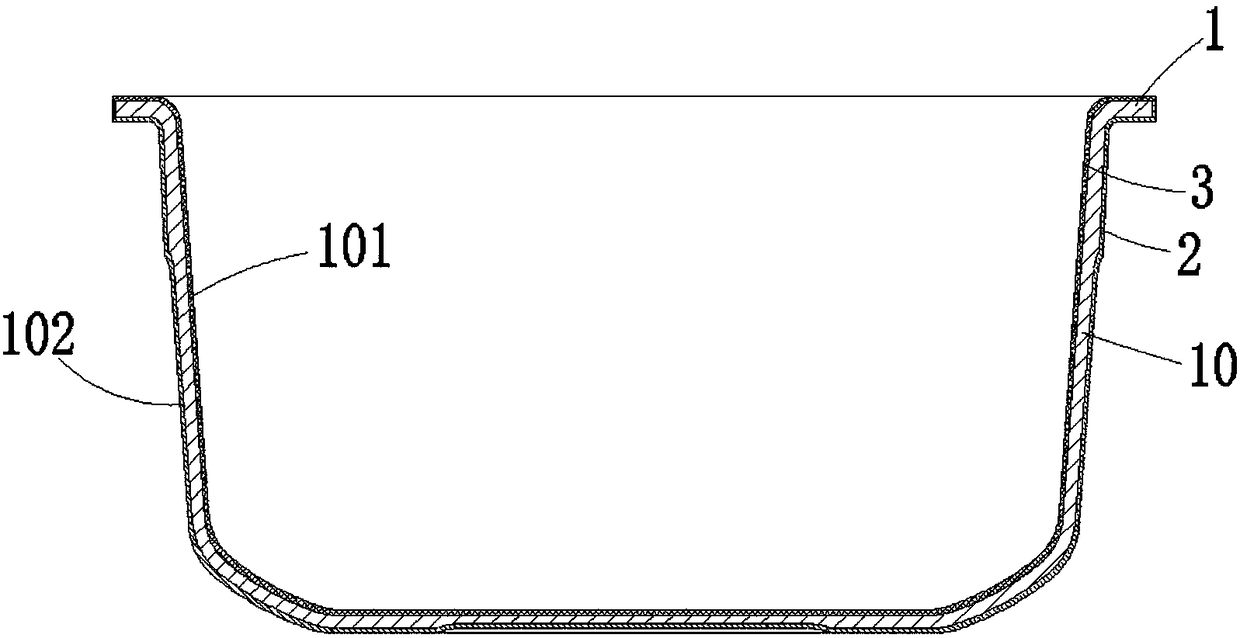

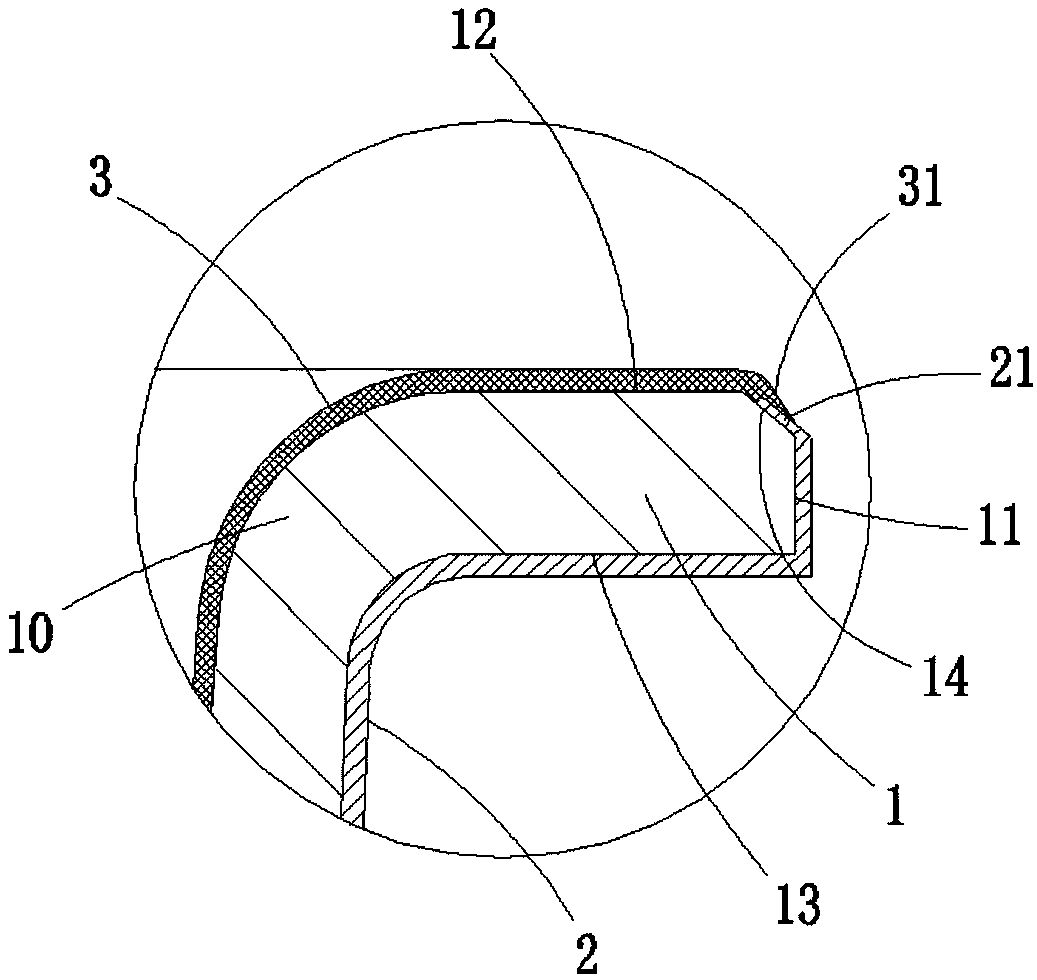

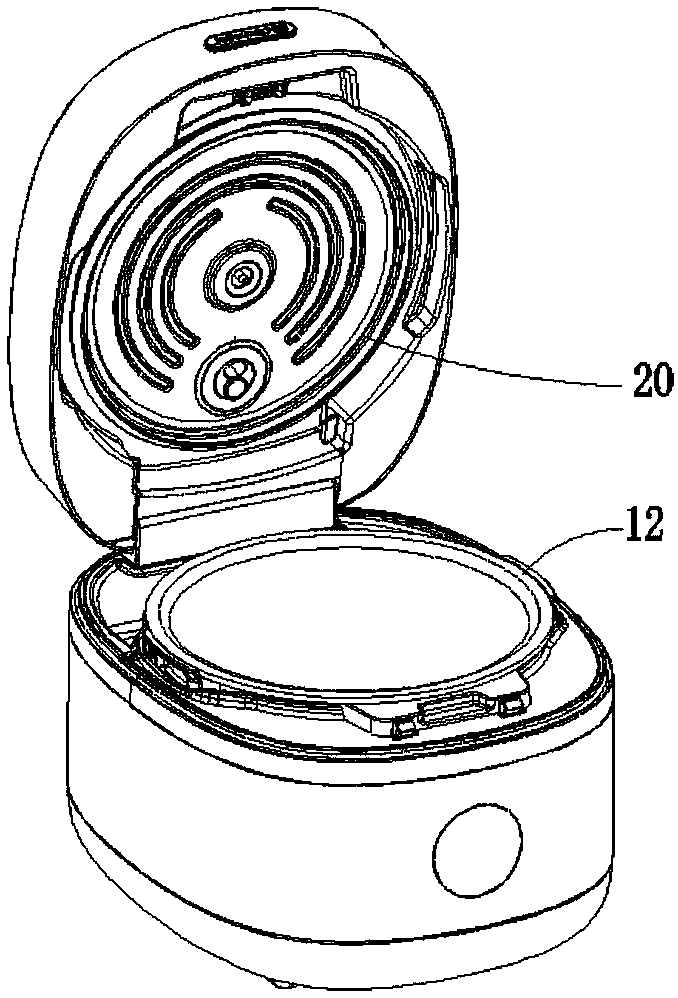

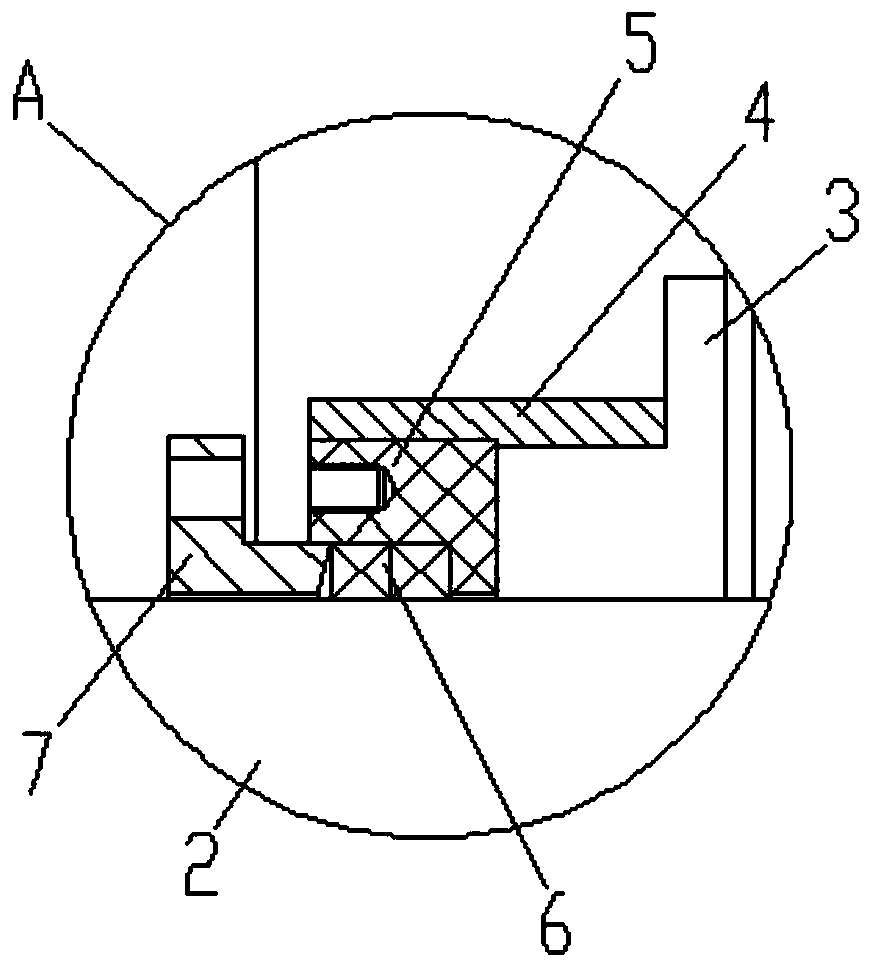

Enamel inner container for cooking utensil

ActiveCN108158387AGuaranteed non-stickImprove corrosion resistanceCooking-vessel materialsCooking vessel constructionsMaterials scienceFlange

The invention provides an enamel inner container for a cooking utensil. The enamel inner container comprises a cast iron container body, an enamel glaze layer is sintered on the outer surface of the cast iron container body, a non-stick coating is sprayed to the inner surface of the cast iron container body, an opening of the cast iron container body is provided with an outward radial flange, theenamel glaze layer and the non-stick coating both extend to the flange, corners are formed between the top face of the flange and the outer end face of the flange and between the bottom face of the flange and the outer end face of the flange respectively, and the joint between the enamel glaze layer and the non-stick coating is located at one corner. The inner and outer surfaces of the inner container are provided with the non-stick coating and the enamel glaze layer respectively, and the container has the advantages of having few flaws, and being attractive in appearance and good in touch.

Owner:JOYOUNG CO LTD

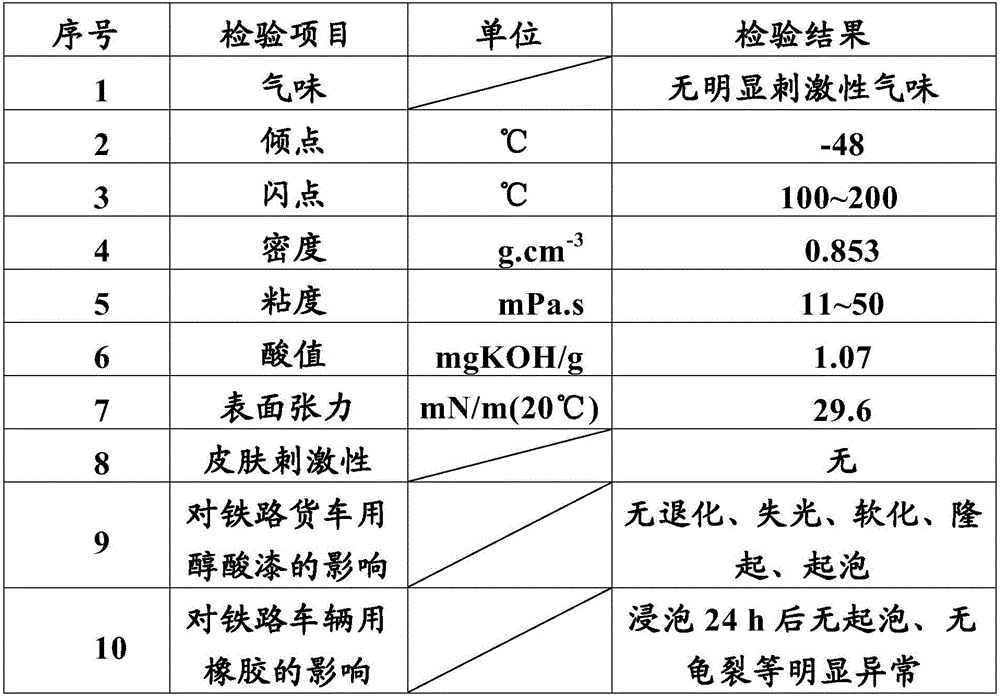

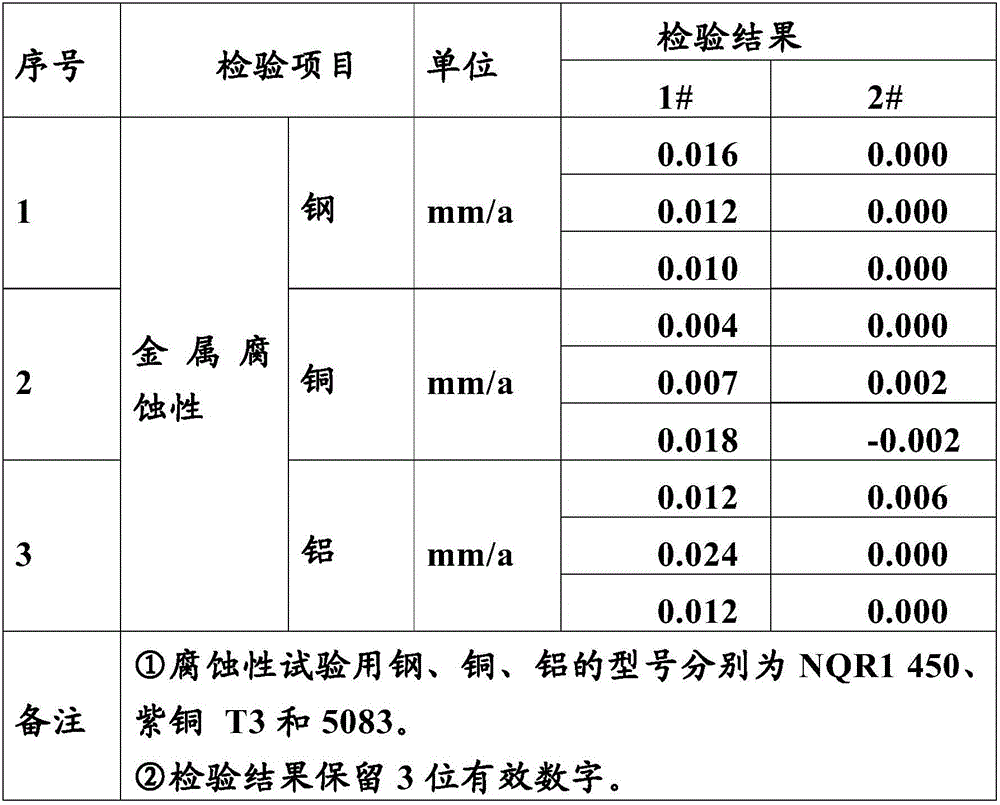

Ultralow temperature nano antifreezing isolating emulsion, and preparation method thereof

The invention relates to an ultralow temperature nano antifreezing isolating emulsion, and a preparation method thereof. The ultralow temperature nano antifreezing isolating emulsion comprises, by weight, 100 parts of a mineral oil and / or a biological oil, 0.1 to 1 part of an accessory ingredient A, 1 to 2 parts of an accessory ingredient B, and 13 to 50 parts of water; the accessory ingredient A comprises ethylene / vinyl acetate copolymer, an acrylate polymer, a maleic anhydride copolymer, polyoxyethylene alkyl amine, or a mixture of three or more ingredients selected from the above; and the accessory ingredient B comprises a sorbitol fatty acid ester, a polyglycerol fatty acid ester, a polyoxyethylene fatty acid ester, an isostearic acid monoglyceride, a monoolefine succinimide, a polyene succinimide, or a mixture of three or more ingredients selected from the above. The ultralow temperature nano antifreezing isolating emulsion is an oil substance, is low in pour point and corrosivity, is hydrophobic, and is capable of avoiding freezing of coal conveyors effectively.

Owner:北京首创大气环境科技股份有限公司

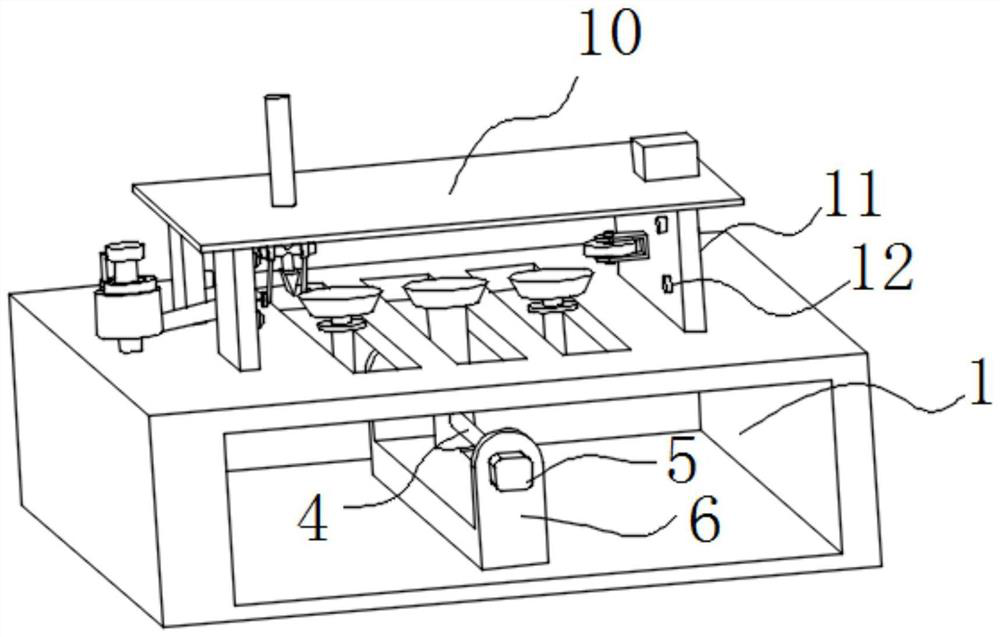

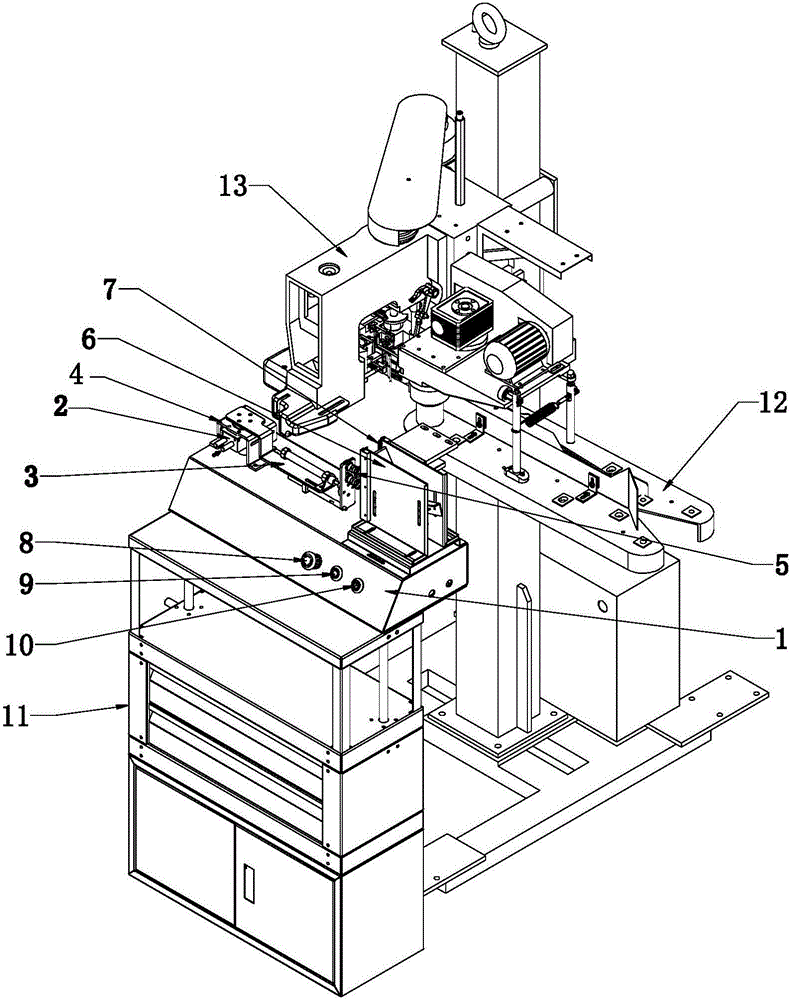

Facility agriculture vegetable hydroponic planting integrated harvesting and recycling system and method thereof

ActiveCN112586173AReduce manufacturing costImprove harvesting efficiencyMowersCleaning using toolsAgricultural engineeringAgricultural science

The invention discloses a facility agriculture vegetable hydroponic planting integrated harvesting and recycling system and a method thereof. The system comprises a field planting plate conveying device, a harvesting device is erected above the middle of the field planting plate conveying device, a seedling pulling assembly is installed at the input end of a slope conveying device, and a cutting knife assembly is arranged below the seedling pulling assembly; a plurality of field planting plate positioning devices which are arranged in parallel are installed at the side, facing the field planting plate conveying device, of a frame body of a root system conveying belt, a field planting basket conveying belt and a sponge conveying belt are arranged at the outer side of the root system conveying belt in parallel, and a clamping and moving device is erected above a field planting basket separating device and a sponge separating device; and a preliminary cleaning device is placed at the output end of the planting plate conveying device, a rubber particle cleaning device is placed at one side of a cleaning pool, and a roller shaft conveyor used for outputting planting plates is installedat one side of the rubber particle cleaning device. The facility agriculture vegetable hydroponic planting integrated harvesting and recycling system can complete hydroponic vegetable harvesting, field planting plate cleaning and recycling work.

Owner:赵宝明

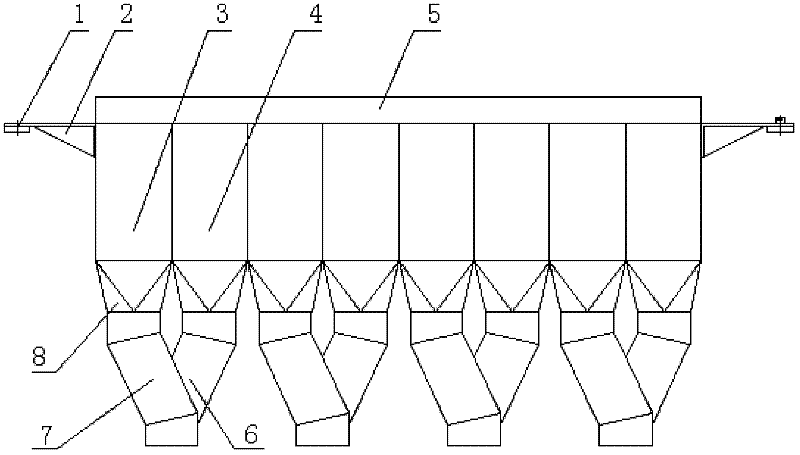

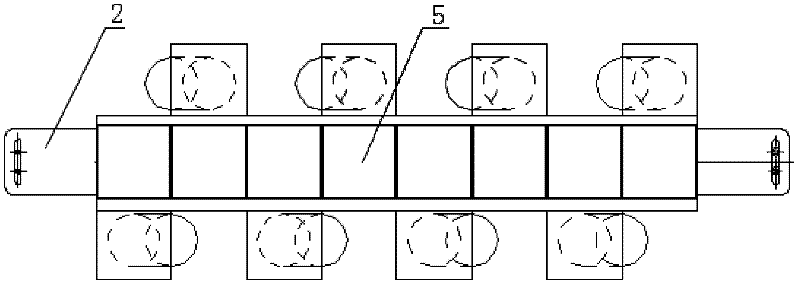

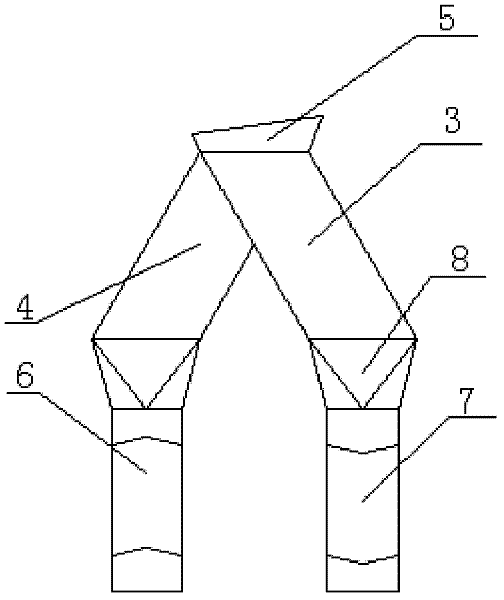

Parallel noodle-falling bucket device in production line for fresh wet rice noodles

InactiveCN102514760AGuaranteed non-stickFast and orderly accessPackagingProduction lineManufacturing engineering

The invention relates to a parallel noodle-falling bucket device in a production line for fresh wet rice noodles, composed of a material-receiving bucket, material-leaking buckets and brackets, wherein the charge holes of one group of the material-leaking buckets are arrayed and fixedly installed on the lower part of the material-receiving bucket; two adjacent material-leaking buckets in the group of the material-leaking buckets compose the material-leaking buckets in the same row; the discharge holes of the material-leaking buckets in the same row are located in a list parallel to the front and rear lists; and the brackets are symmetrically and fixedly installed at the both sides of the material-receiving bucket. The parallel noodle-falling bucket device disclosed by the invention is reasonable in structure, ingenious in design, efficiently improved in the layout rationality of production line for rice noodles, increased in the production efficiency of production line for rice noodles, easy in operation and low in cost. A material-receiving bucket device with high innovativeness in production for fresh wet rice noodles is provided.

Owner:SHENGCHANGDA MACHINERY TIANJIN

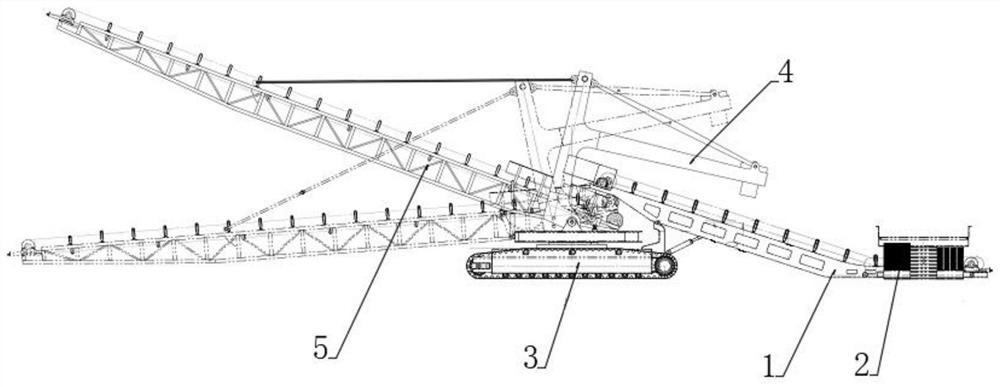

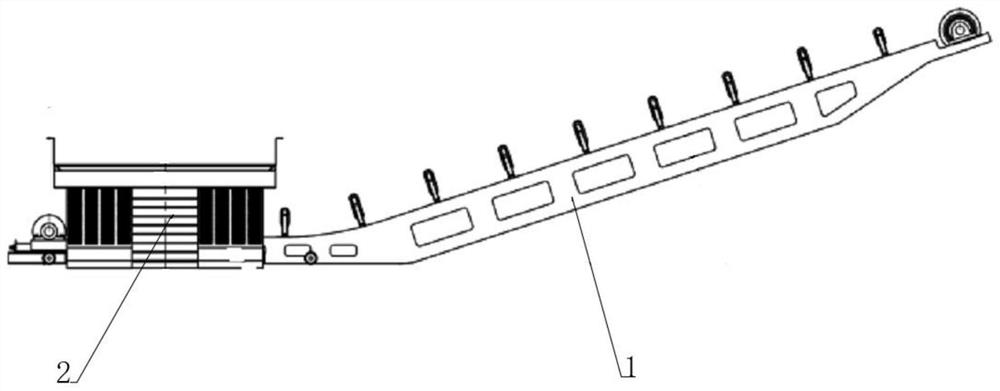

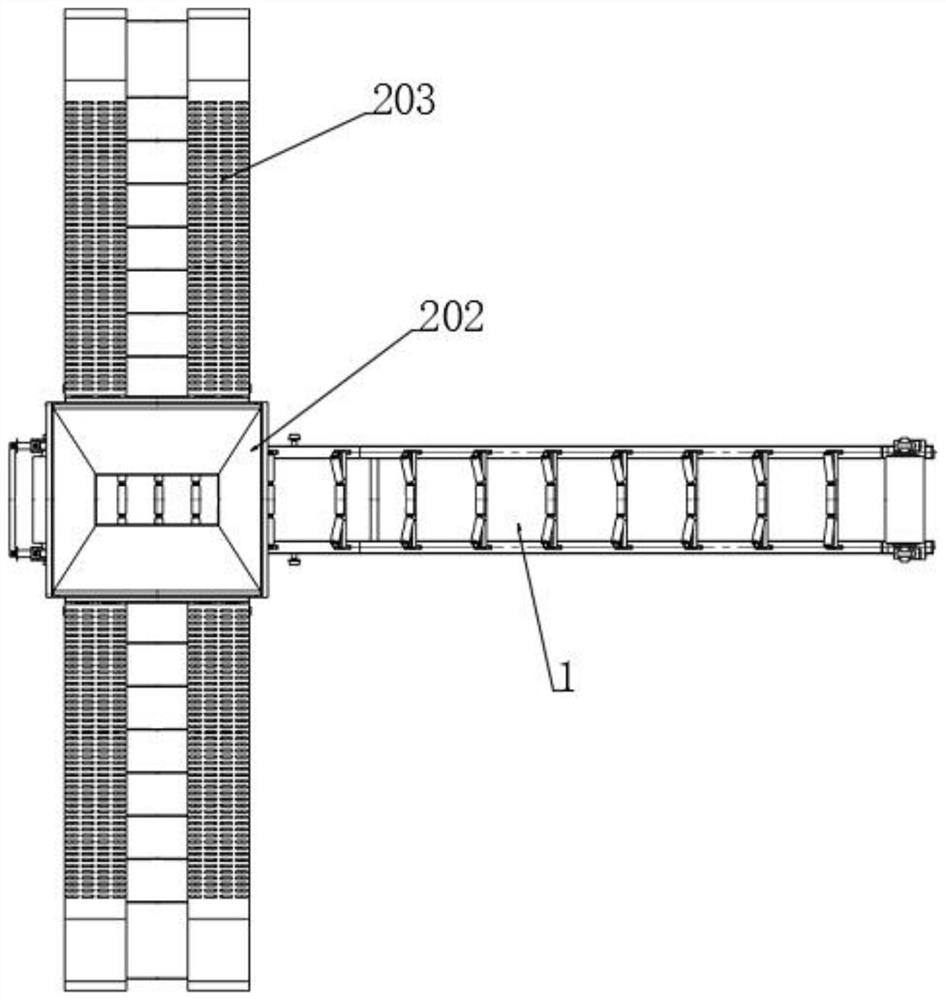

Crawler belt moving type automatic feeding machine facilitating concentrated material stacking in harbor district

InactiveCN113003252AStrong wear resistanceReduce maintenanceConveyorsSupporting framesCantileverBelt conveyor

The invention discloses a crawler belt moving type automatic feeding machine facilitating concentrated material stacking in a harbor district, and belongs to the technical field of feeding machine equipment. A cantilever feeding belt conveyor, a feeding mechanism, a rotation driving mechanism and a cantilever discharging belt conveyor are matched, and a feeding platform is in mechanical buckle type connection with the cantilever feeding belt conveyor during operation and is driven by a walking mechanism. When the feeding machine is transferred, the feeding mechanism can be tripped, a platform slope plate is lifted up during transferring, discharging is conducted through the cantilever discharging belt conveyor, and the feeding machine has the advantages of being high in production efficiency, large in stacking height, large in stacking radius, high in abrasion resistance, small in maintenance amount and the like; and meanwhile, the feeding speed and the discharging speed are high, operation is convenient, and moving is made free. The requirement for frequent stockpiling operation of a port wharf can be effectively met to a certain degree, the problems that the sites are scattered, dirty and disordered due to the fact that stockpiling is large in occupied area and difficult to stack high in the harbor district are effectively solved, and the stockpiling environment of the harbor district is effectively improved.

Owner:WENZHOU CITY HUADA ELECTRIC POWER & METALLURGICAL EQUIP CO LTD +1

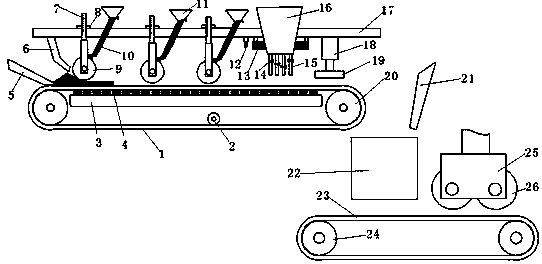

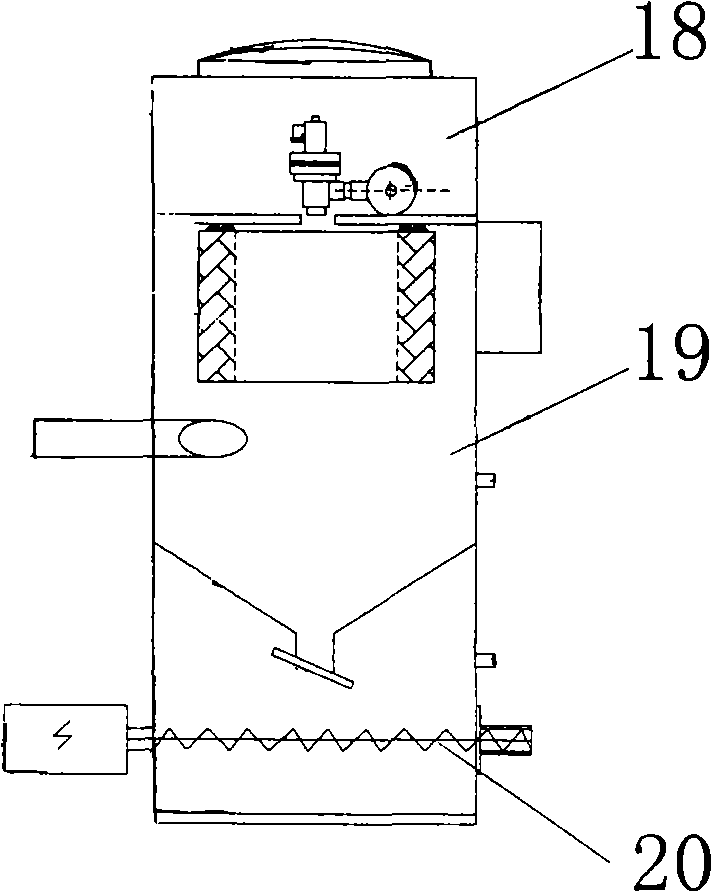

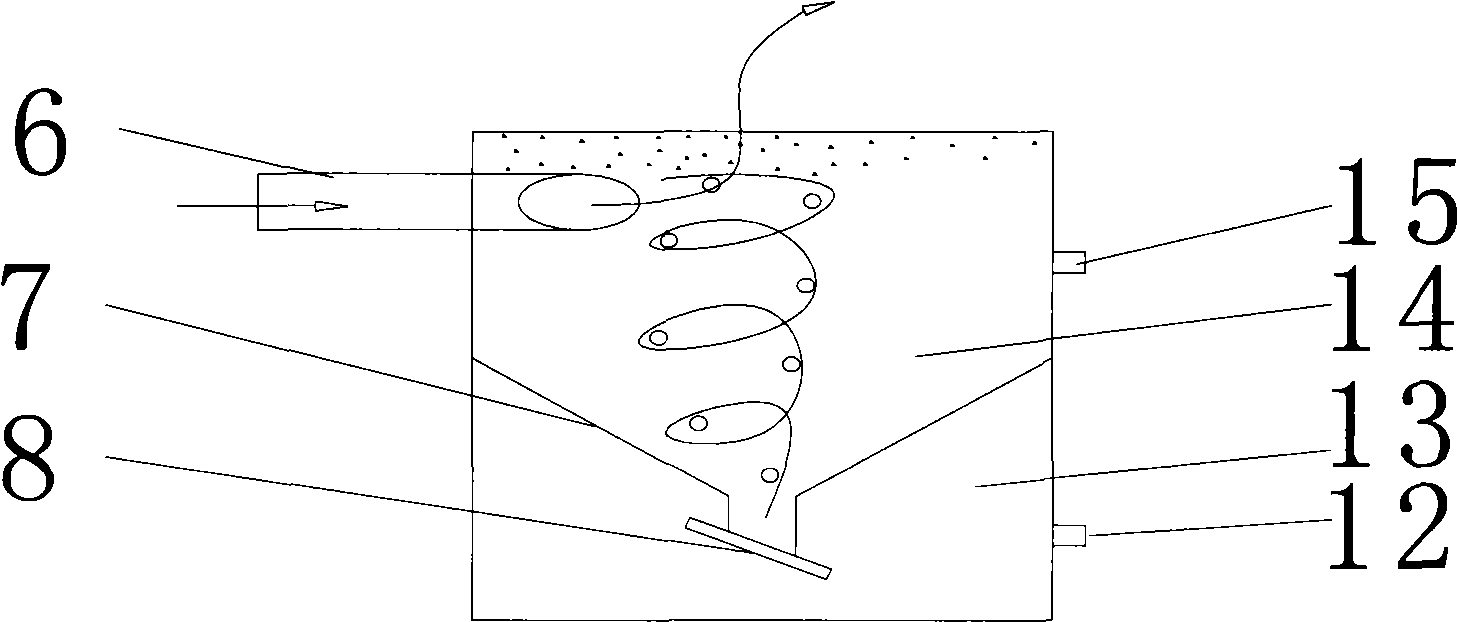

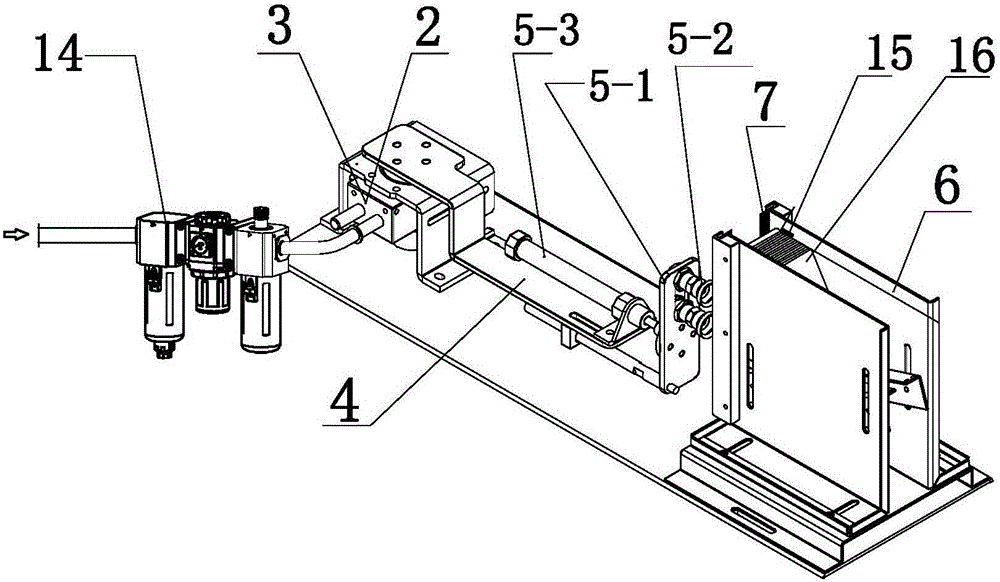

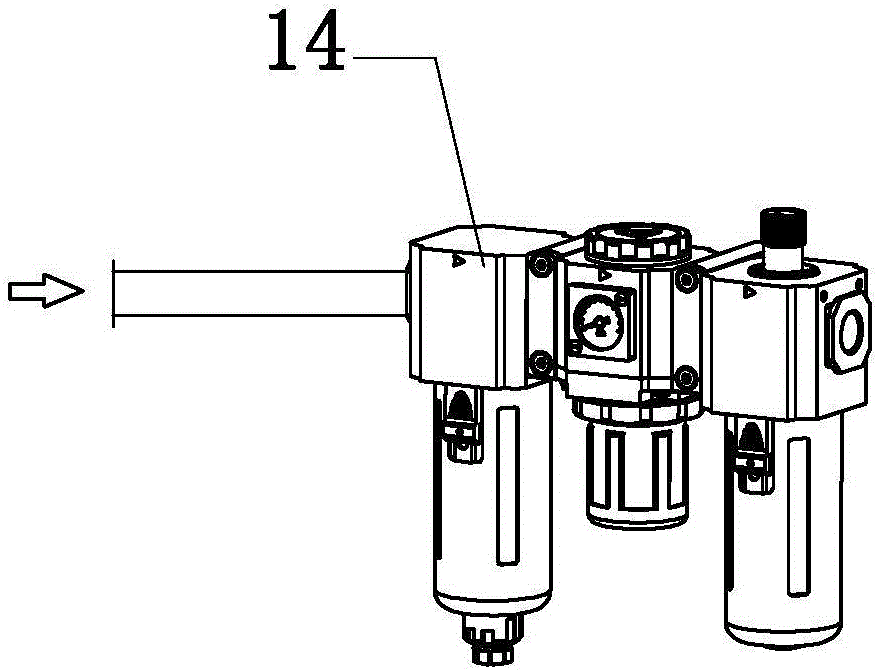

Vacuum feed device

InactiveCN101531414AGuaranteed quantitative dosingGuaranteed non-stickWater/sewage treatment by flocculation/precipitationEngineeringMechanical engineering

The invention provides a vacuum feed device. The device is characterized by comprising a vacuum separating device, a bin storage device and a material conveying device which are connected in sequence. The device has the advantages that: as thread pitch of a feed screw and rotating speed of a motor are determined, quantitative feed of a material is ensured in unit time; a back flowing device is added to ensure that the material is prevented from adhering on a filter, thereby achieving integration of loading and accurate feed, meanwhile, the device has a special effect on a material with large adherence, and solves the never solved problem of PAM feed in the water treatment industry because of large adherence; in PLC, the rotating speed of the motor can be changed through setting parameters so as to change the volume of feed amount, thereby achieving that integration of vacuum loading and material accurate feed is completely controlled by PLC, greatly reducing man power, and improving the production efficiency.

Owner:SHANGHAI OD WATER TREATMENT SCI & TECH

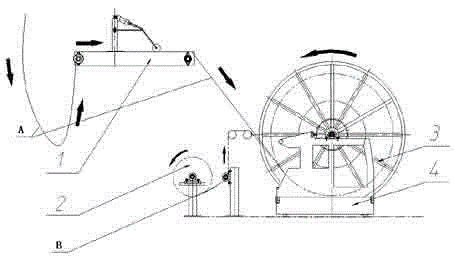

Cushion rubber coiling device for tire production

The invention provides a cushion rubber coiling device for tire production. The cushion rubber coiling device comprises a cushion rubber transition device, a cloth liner unwinding device, a spool and a cushion rubber coiling cart, the cushion rubber transition device receives semi-finished cushion rubber and conveys the same to the spool, the cloth liner unwinding device outputs cloth liners to the spool which is arranged on the cushion rubber coiling cart, and the spool has rotational degree of freedom relative to the cushion rubber coiling cart and drives the cushion rubber and the cloth liners to enter the spool at the same linear speed in a coiling manner when rotating. The cushion rubber coiling device has the advantages that the cushion rubber is outputted synchronously without adhesion and warping and few in conveying cut surfaces being coiled by the spool, quality of the cushion rubber is effectively guaranteed, and production efficiency is improved.

Owner:SAILUN GRP CO LTD

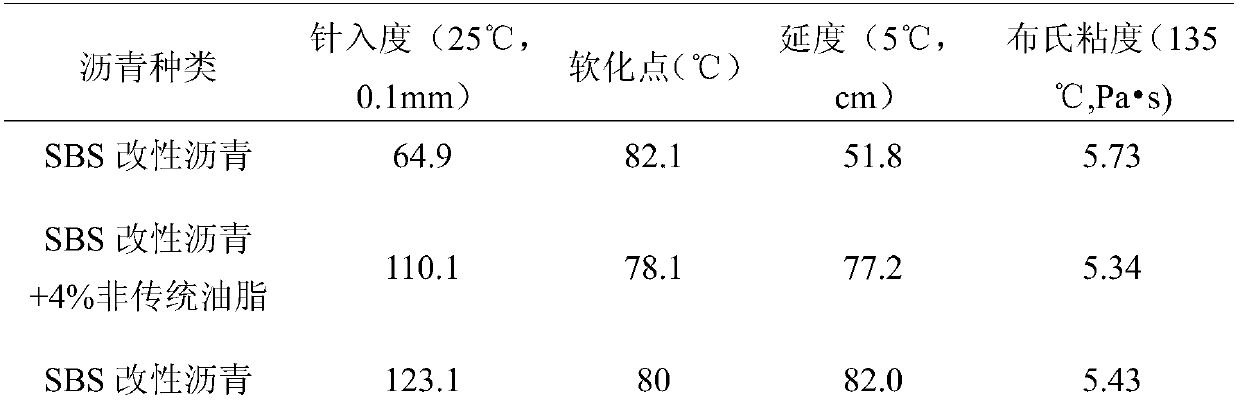

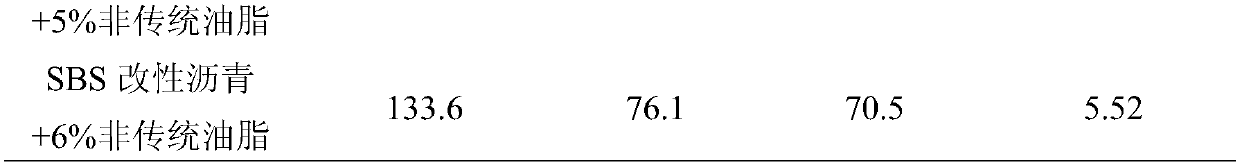

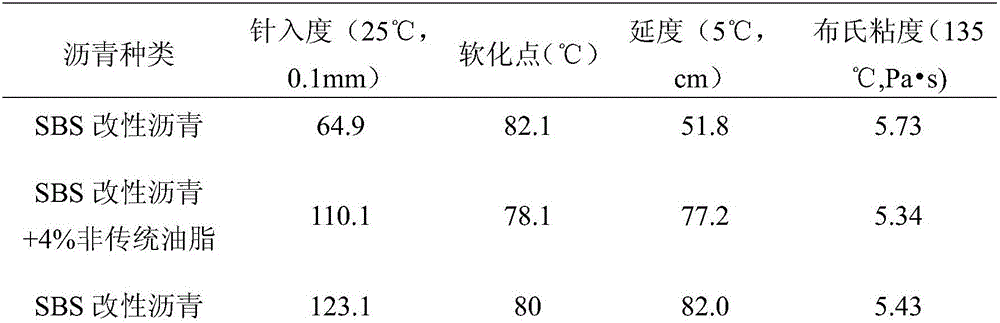

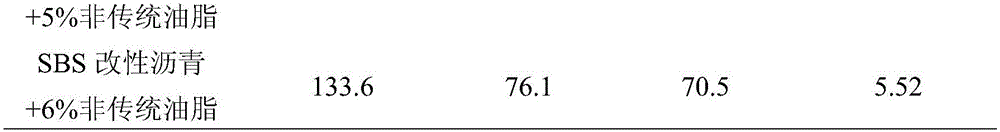

A kind of non-traditional grease release agent for asphalt pavement construction machinery and preparation method thereof

The invention belongs to the field of unconventional grease recycled isolation agents for asphalt pavement construction machines, and relates to an unconventional grease isolation agent for asphalt pavement construction machines. The unconventional grease isolation agent for asphalt pavement construction machines is composed of unconventional grease, an emulsifier and water, wherein emulsified oil is prepared from unconventional grease and the emulsifier, and the isolation agent is prepared from the emulsified oil and water; the emulsified oil comprises 80-90wt% of the unconventional grease and 10-20wt% of the emulsifier; and the isolation agent comprises 25-40wt% of the emulsified oil and 60-75wt% of water. The preparation method realizes recycling of the unconventional grease and reduces the production cost, and the isolation agent prepared in the invention has stable performances, cannot dissolve asphalt, and has a good isolation effect.

Owner:WUHAN UNIV OF TECH

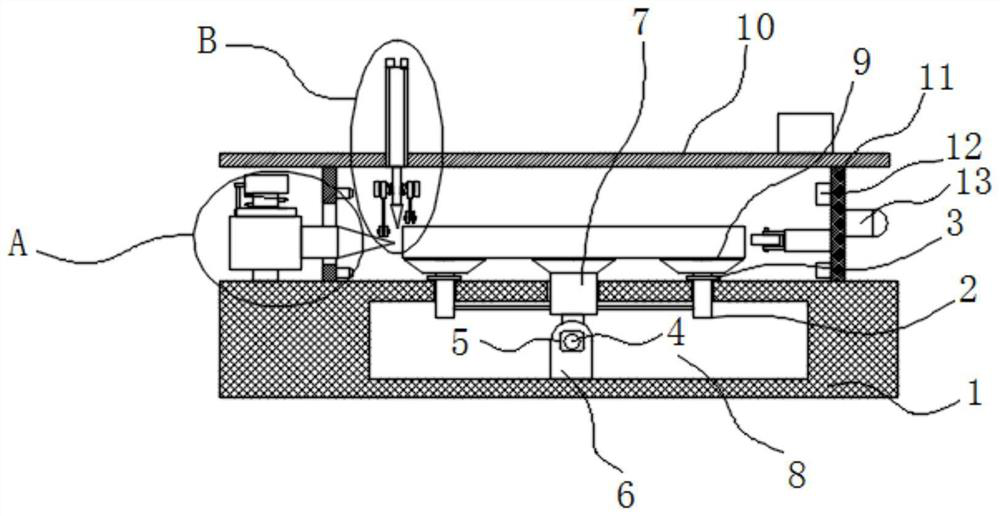

Automatic field planting plate cleaning system and method for facility ecological agriculture hydroponic planting

ActiveCN112588661AClean upSo as not to damageCleaning using toolsCleaning using liquidsEnvironmental resource managementEngineering

The invention discloses an automatic field planting plate cleaning system and method for facility ecological agriculture water culture plant. The automatic field planting plate cleaning system comprises a field planting plate conveying belt, a preliminary cleaning device is placed at the output end of the field planting plate conveying belt, an equipment top frame is erected above a cleaning pool,and a four-claw clamping device is installed on the equipment top frame; and a rubber particle cleaning device is placed on one side of the cleaning pool and comprises a water pool and a plurality ofrotary sponge rods vertically and rotationally installed in the water pool, a plurality of sewage outlet pipelines are arranged on the water pool in a communicating mode, the sewage outlet pipelinescommunicate with a cleaning roller assembly, sewage in the cleaning roller assembly is input into a second filter through a pipeline, and a roller shaft conveyor used for outputting field planting plates is installed on one side of the rubber particle cleaning device. In the step of cleaning the field planting plates, a mode of primarily cleaning and then cleaning the field planting plates with the rubber particles is adopted, it is guaranteed that the field planting plates are cleaned up, the rubber particles can strike the field planting plates and adsorb dirty impurities, and the field planting plates cannot be damaged.

Owner:赵宝明

Wafer processing equipment

ActiveCN114227961ARealize pressing and fixingNo tear damageFinal product manufactureSemiconductor/solid-state device manufacturingWaferStructural engineering

The invention belongs to the technical field of semiconductor processing, and particularly relates to wafer processing equipment which comprises a movable frame, a driven rod, a limiting plate, a light receiver and a warning lamp, under the cooperation of a first reed, a roller on one side is attached to the surface of a wafer to press and fix the wafer, and a roller on the other side presses waste materials to guarantee that the waste materials are not damaged after cutting. Waste materials are not adhered, meanwhile, it is guaranteed that the cutting side is not deformed, it is guaranteed that tearing damage does not exist in the wafer cutting process, the integrity of the wafer is guaranteed, the cutting yield is improved, needle head swinging is achieved, the inner wall of a notch of an electrode ring makes contact with an electrode ball, an alarm can be powered on, an alarm can be given out, and meanwhile an alarm signal is transmitted into a PLC processor. A shutdown command is issued through the PLC processor, shutdown operation is achieved, scrapped wafers are processed, meanwhile, equipment is maintained, the accuracy of follow-up operation is guaranteed, the cutting quality of the wafers is guaranteed, the yield is improved, the cutting stability is monitored, and the production efficiency can be improved.

Owner:江苏威森美微电子有限公司

Rapid-granulating and curing process of natural rubber

The invention provides a method for quickly granulating and solidifying natural rubber latex. The invention is characterized in that the method comprises the steps as follows: the natural rubber latex is dropped into an alcoholic solution containing polyvinyl alcohol and calcium ions at room temperature; the latex surface is solidified and is automatically granulated and sedimentated in the alcoholic solution; latex particles are separated; and the separated latex particles are dried. The method can quickly acquire rubber particles with smooth, round and non-adhesive surfaces, has no pollution during the whole production process, and ensures that the production quality meets rubber processing requirements, thereby the method is the latest domestic natural rubber solidification technology.

Owner:刘结平

Totally-synthetic high-speed copper drawing fluid

The invention relates to a totally-synthetic high-speed copper drawing fluid, which comprises, by mass percentage, 5-10% of triethanolamine, 5-9% of amide caproic acid triethanolamine salt, 8-15% of polyethylene glycol, 0.5-3.0% of special amine, 0.5-2.0% of disodium EDTA, 0.1-0.5% of T706, 3.0-6.0% of diglycol, 3.0-6.0% of polyether 1740, 1.5-4.0% of sebacic acid, 6.0-12.0% of diethanolamine, 0.5-1.5% of an MBM bactericide, and 0.03-0.15% of an antifoaming agent, with the balance being water. The fluid gives off faint smell, and is excellent in lubricity, cleaning ability and copper corrosioninhibition performance. During high-speed drawing of copper wires, the liquid protects a die and cone pulley from being attached with copper powder and copper sludge, so that the service life of thedie and cone pulley is greatly prolonged.

Owner:天津市澳路浦润滑科技股份有限公司

New energy electric vehicle high-definition display screen

InactiveCN114863815ADoes not occupy a fixed spaceGuaranteed non-stickCleaning using toolsVehicular energy storageDriver/operatorNew energy

The invention relates to the technical field of automobile display screens, in particular to a new energy electric automobile high-definition display screen which comprises a display screen body, a containing bin, a cleaning unit and a transmission unit. When drivers with different heights watch the screen, the screen can reflect light. An exposed display screen and a peripheral structure thereof are easy to accumulate dust, are inconvenient to clean, are easy to scratch the screen and influence the service life of the display screen; the display screen can be controlled to go in and out of the containing bin through the transmission unit, the display screen can be adjusted to a proper angle when going out of the bin, a driver can conveniently watch the display screen, and space can be saved by storing the display screen when not used; the display screen located in the containing bin can be cleaned through the cleaning unit, and meanwhile dust on the left side wall and the right side wall of the display screen is cleaned when the display screen enters and exits from the containing bin.

Owner:梁中相

Full-automatic swing arm sucker type label suturing machine

PendingCN106801302AUnified positionSimple structureWork-feeding meansPulp and paper industryIndustrial sewing machine

The invention provides a full-automatic swing arm sucker type label suturing machine, belonging to automatic label connecting machinery. The full-automatic swing arm sucker type label suturing machine aims at solving the problems that an automatic label packaging and connecting machine is separated from an industrial sewing machine, has a complex structure, and is inconvenient to use when matched with an automatic packaging and sealing machine. A full-automatic swing arm sucker type label suturing machine main body is adopted by the invention, a rotational swing arm mechanism is formed by connecting a rotational air cylinder respectively with a swing arm and an automatic controller, the automatic controller is connected with and controls the rotational air cylinder, one end of the swing arm is connected with the top of the rotational air cylinder, a swing arm body is provided and connected with a vacuum absorbing mechanism, the vacuum absorbing mechanism respectively matches, connects and adsorbs labels packaged in a label storage bin, and the absorbed labels are matched with and connected to a label suturing presser foot of the industrial sewing machine positioned behind a packaging bag traction flanging machine. The full-automatic swing arm sucker type label suturing machine has a simple and practical structure, and is suitable for matching and connecting the suturing labels of auto-complete packaging bags after the industrial sewing machine and the traction flanging machine perform automatic packaging and sealing.

Owner:HEBEI QINGXIAN QINGGONG SEWING MACHINE

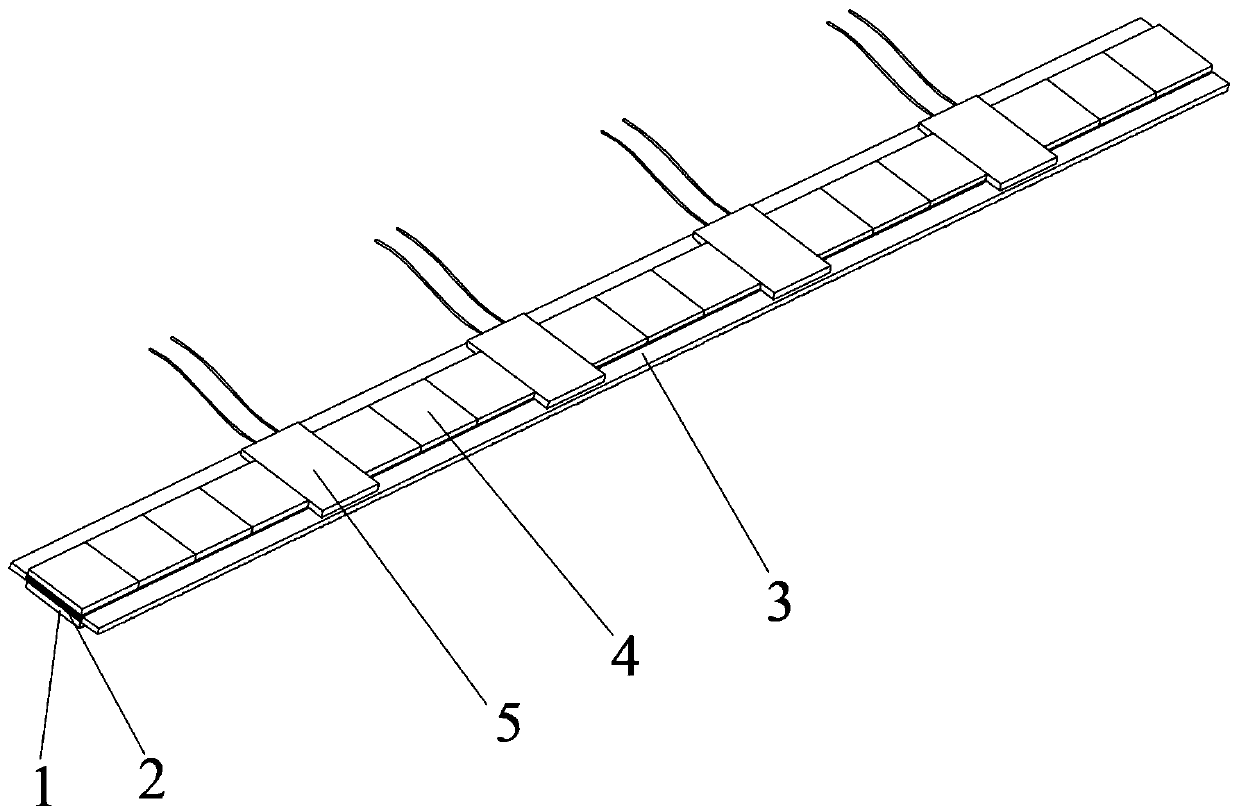

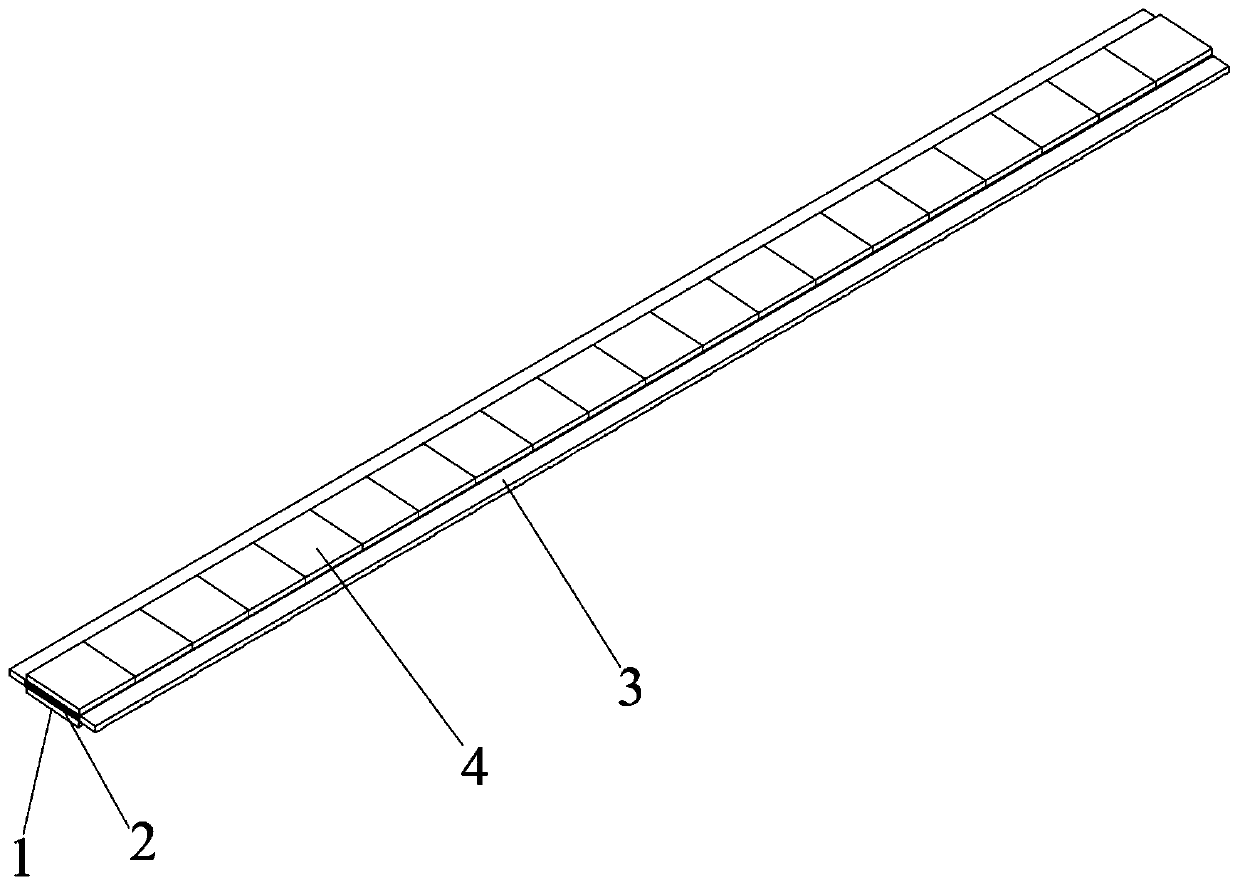

Auxiliary strain gauge adhering device

The invention provides an auxiliary strain gauge adhering device, and belongs to the technical field of component testing. The auxiliary strain gauge adhering device comprises an upper isolation film,an adhesive layer, thin film scale bars, a lower isolation film, and a strain gauge, and is characterized in that the upper isolation film is located at the outermost layer and is adhered and fixed to the adhesive layer; the lower isolation film is located at the bottom layer and is also adhered and fixed to the adhesive layer; the upper isolation film is a monolithic isolation film; the lower isolation film is a small grid-shaped isolation film; the adhesive layer is sandwiched between the upper isolation film and the lower isolation film; and the upper isolation film and the lower isolationfilm can be peeled off. The thin film scale bars with scales are arranged at the two sides of the adhesive layer; and the thin film scale bars are transparent thin film and have no adhesive. The backof the strain gauge is adhered and fixed to the adhesive layer by peeling off the lower small grid-shaped isolation film. The adhesive layer, the upper isolation film and the lower isolation film areall flexible materials. The auxiliary strain gauge adhering device is used for the testing of component strain or deformation.

Owner:SOUTHWEST JIAOTONG UNIV +1

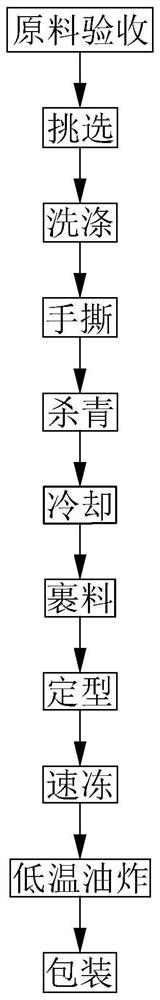

Low-temperature preparation method of fruit and vegetable crisp chips

InactiveCN113498857AReduce dropReduce pollutionFood ingredientsFood coatingProcess engineeringBiology

The invention relates to the field of processing of fruit and vegetable crisp chips, in particular to a low-temperature preparation method of fruit and vegetable crisp chips, which comprises the following steps: step 1, checking and accepting raw materials; step 2, selecting; step 3, washing; step 4, tearing with hands; step 5, performing fixation; step 6, cooling; step 7, wrapping the materials; wrapping the surfaces of the oyster mushrooms with seasonings; step 8, shaping; fixing the seasonings on the oyster mushrooms; step 9, quick-freezing; step 10, frying at low temperature; and step 11, packaging and warehousing. Before low-temperature frying, the seasoning is coated on the fruit and vegetable crisp chips and is fixed on the fruit and vegetable crisp chips, so that the probability that the seasoning falls off from the fruit and vegetable crisp chips can be greatly reduced, the taste of the fruit and vegetable crisp chips is kept unchanged, and environmental pollution to a workshop caused by the fact that the seasoning falls on the ground is reduced.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

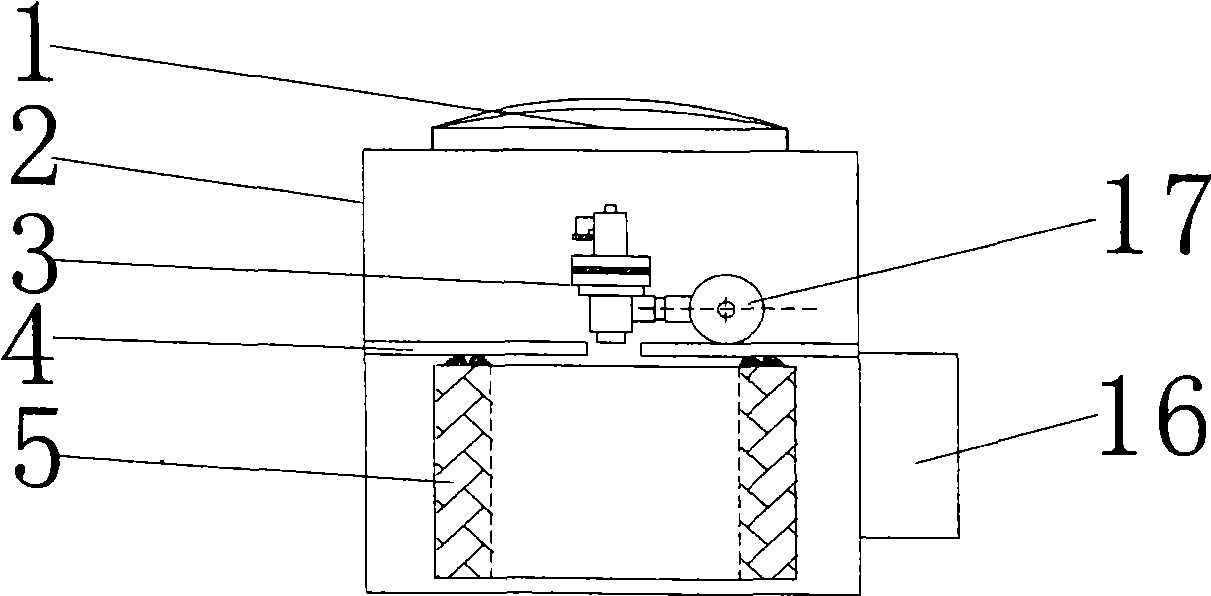

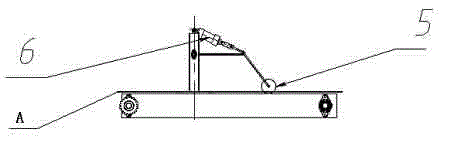

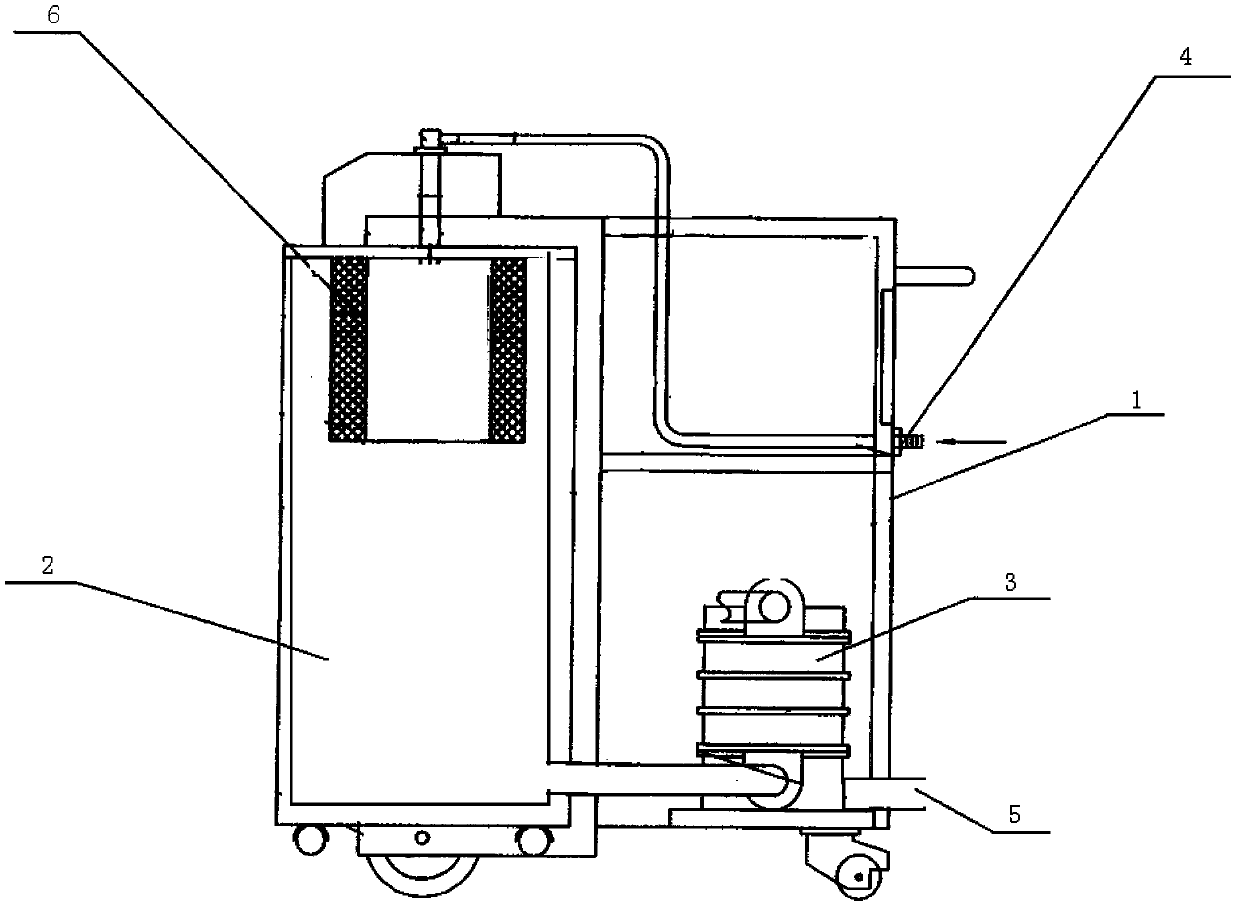

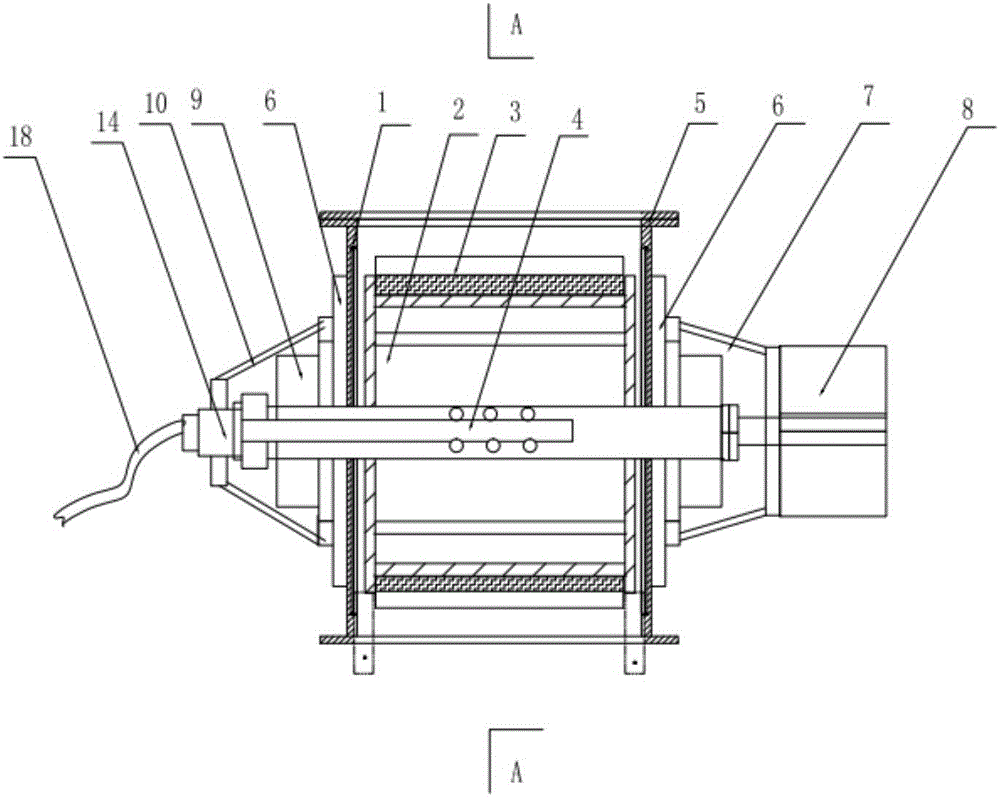

High temperature dust collector

InactiveCN103387326AHigh temperature resistantEasy to cleanGlass furnace apparatusEngineeringTemperature resistance

The invention provided with a high temperature dust collector. The high temperature dust collector comprises a body (1) and an air chamber (2) arranged in the body (1), a fan (3), an air inlet pipe (4), an air outlet pipe (5) and a metal screen (6), wherein the air inlet pipe (4), the air chamber (2), the fan (3) and the air outlet pipe (5) are successively connected, and the metal screen (6) is arranged between the air inlet pipe (4) and an air inlet of the air chamber (2). The high temperature dust collector provided by the invention has the characteristics that a filter bag which is made of a metal material is adopted to replace the traditional filter bag, the high temperature dust collector is high temperature resistance and is easy to clean, and the application range is wide.

Owner:HUAERRUN GLASS IND

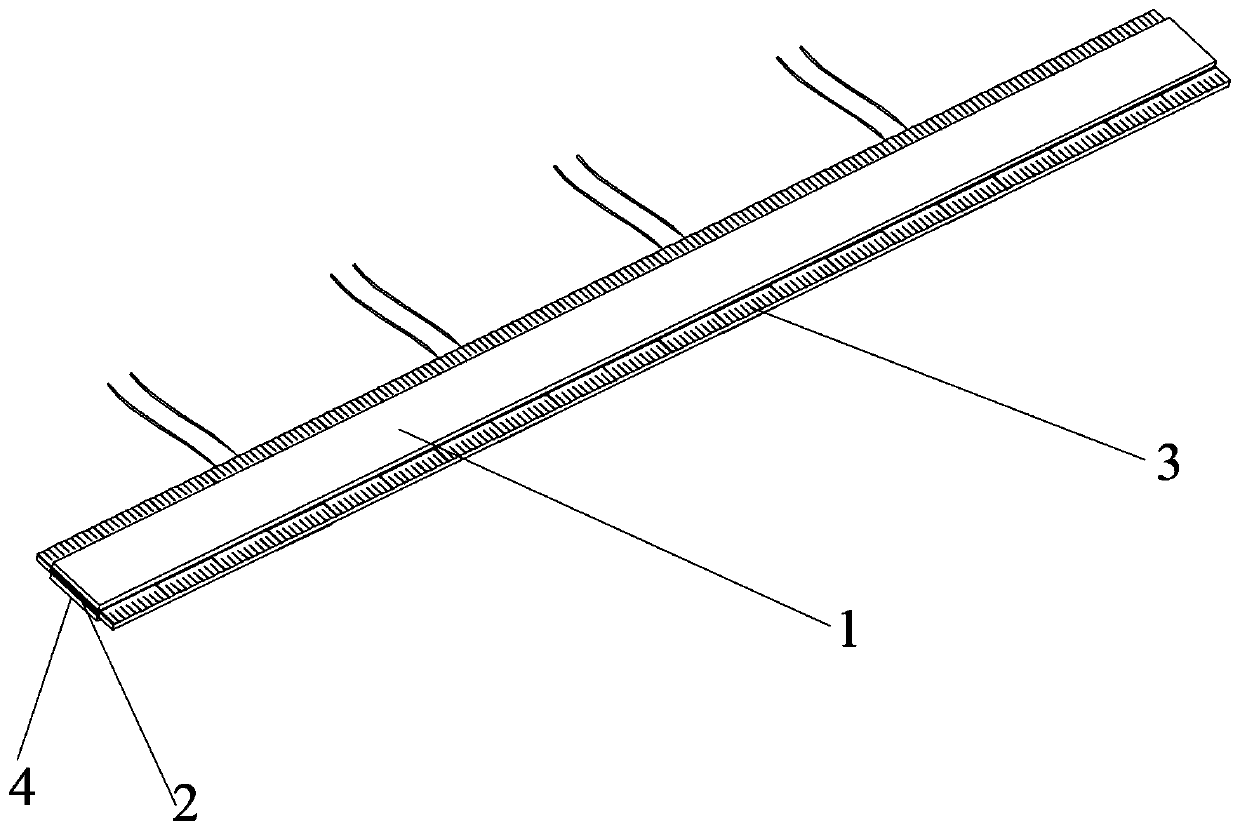

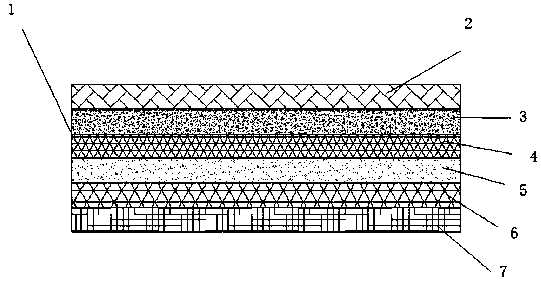

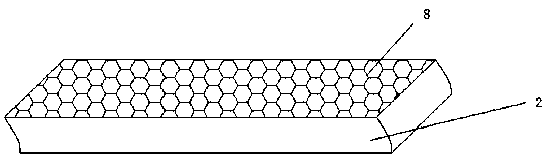

High-temperature-resistant polytetrafluoroethylene material filter material base cloth

InactiveCN109367171AGuaranteed non-stickPromote circulationSynthetic resin layered productsFiltration separationYarnFiber

The invention discloses a high-temperature-resistant polytetrafluoroethylene material filter material base cloth, which comprises a base cloth body. The high-temperature-resistant polytetrafluoroethylene material filter material base cloth has the advantages that by arranging a first polytetrafluoroethylene weaving layer and a second polytetrafluoroethylene weaving layer, alkali resistance and acid resistance of the overall base cloth are guaranteed, and high-temperature resistance, low-temperature resistance, non-stickiness and the like are achieved; the first polytetrafluoroethylene weavinglayer and the second polytetrafluoroethylene weaving layer are provided with a plurality of ventilating small holes correspondingly, and thus air circulation in the overall base cloth is facilitated;by arranging a first bamboo fiber yarn weaving layer and a second bamboo fiber yarn weaving layer, good performance such as good gas permeability and instantaneous water absorbability, and high abrasion resistance, antibacterial and bacteriostatic properties, deodorization property and ultraviolet prevention are achieved; by arranging a polytetrafluoroethylene mesh weaving layer, the first bamboofiber yarn weaving layer and the second bamboo fiber yarn weaving layer are layered; and by arranging a fluorocarbon resin film layer, it is guaranteed that when the surface layer is affected by the outside, performance such as non-stickiness and self-cleanliness can be maintained, overall environmental protection is achieved, practicality is high, and the high-temperature-resistant polytetrafluoroethylene material filter material base cloth can be applied to more fields.

Owner:江苏宏纬工业用布有限公司

A kind of production method of fishing rod film

The invention relates to a production method of a fishing rod film. The method comprises the following steps: selecting polypropylene of which the isotacticity is over 96 percent for serving as a major raw material, adding 0.5-3 percent by mass of anti-blocking agent, 0.5-3 percent by mass of slip agent and 0.5-3 percent by mass of high-temperature-resistant aid into the polypropylene raw material, and mixing uniformly; adding the mixed raw materials into an extruder, forming three layers of stretched films through co-extrusion and stretching, and performing eight segments of preheating, four segments of stretching, two segments of sizing and two segments of cooling in two areas. The fishing rod film can be prevented from being bonded during hot molding at the high temperature below 150 DEG C, does not contract transversely, is combined firmly on a cloth layer, does not contain air bubbles, is easy to peel after cooling and molding, can be applied to manufacturing of various products such as ball arms and ski sticks, and is wide in application.

Owner:YANTAI TIANSU PACKAGING MATERIAL CO LTD

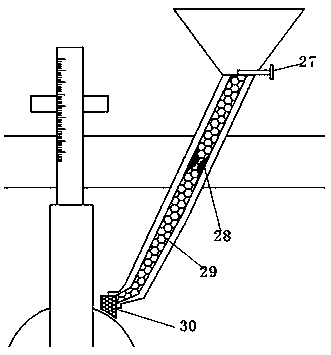

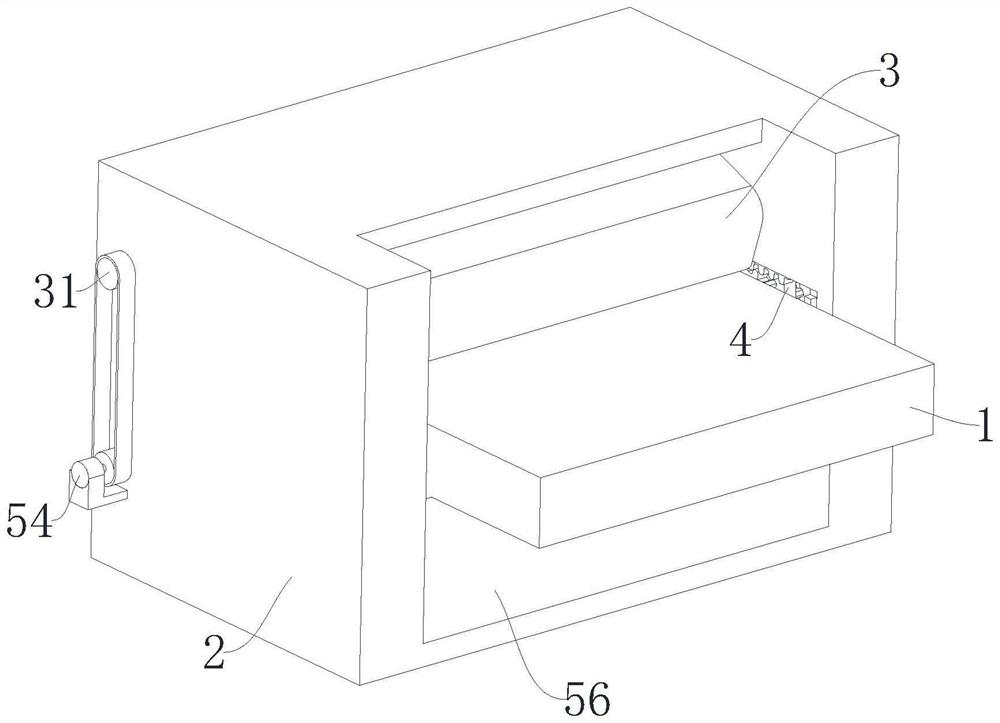

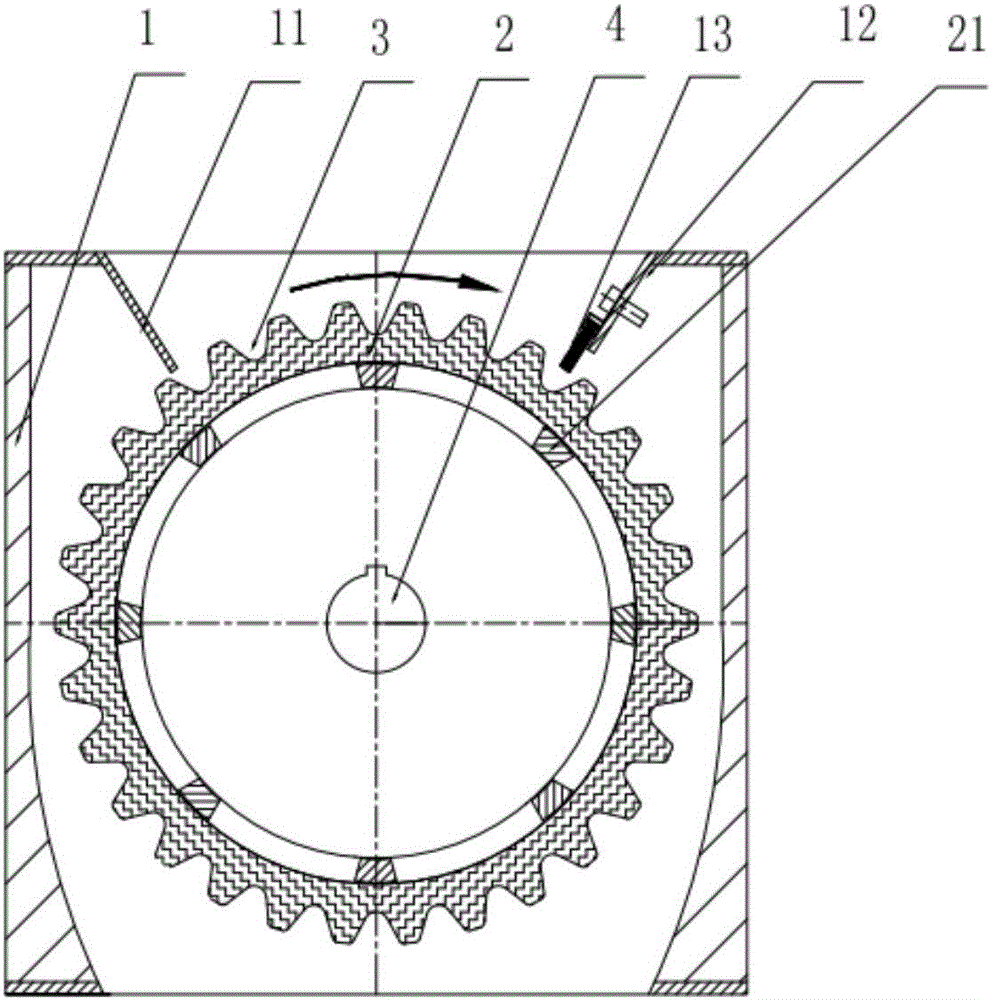

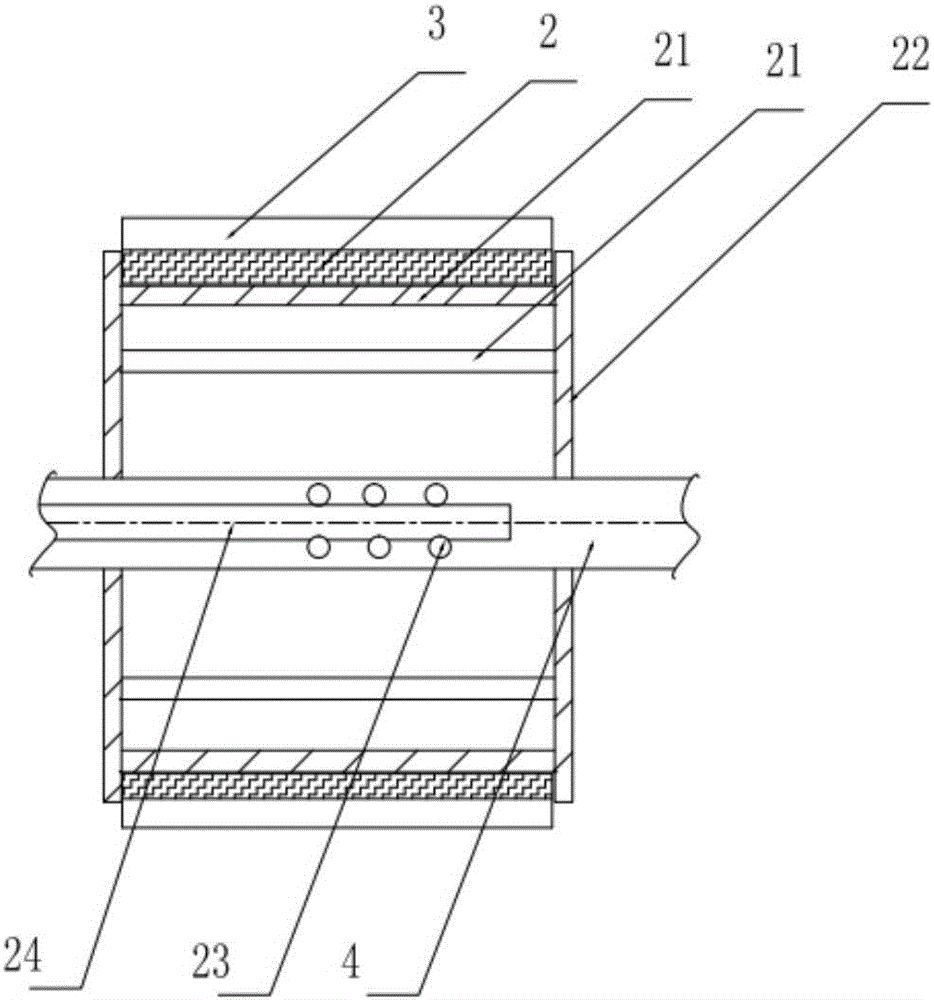

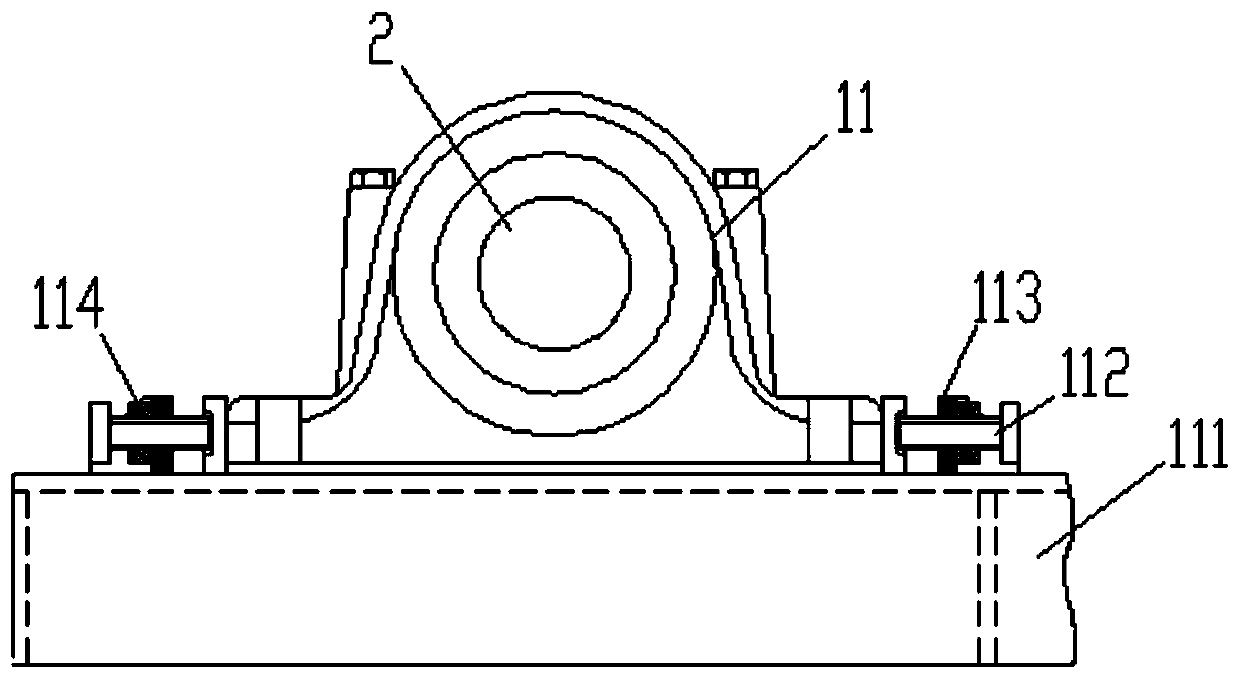

Particle material metering device

ActiveCN106482817AGuaranteed non-stickSolve the problem of random error in measurementWeighing apparatus detailsSolid materialDrive shaftPulp and paper industry

The invention relates to a particle material metering device. The metering device comprises a casing and a roller arranged in the casing, the casing is provided with a feed port and a discharge port, the roller comprises a roller body and a driving shaft, and the roller is mounted on the casing via the rotating shaft; the roller comprises two side plates and a squirrel-cage-type skeleton arranged on the side plates; the squirrel-cage-type skeleton is provided with a groove drum, a metering groove is arranged in the external of the groove drum, and the groove drum is made of a microporous ventilating material; and the side plates and the groove drum form a sealed cavity; one end of the rotating shaft is provided with a deceleration motor, the other end of the rotating shaft is provided with a rotating joint, the driving shaft is internally provided with a blind hole, an air channel through which the blind hole is communicated with the cavity is arranged in the driving shaft, the rotating joint comprises a fixed end and a hollow rotation shaft, and the hollow rotation shaft is connected with the rotating shaft, and enables that the rotating joint is communicated with the blind hole. The particle material metering device has the advantages that the material does not stick to the metering groove, and metering accuracy is further ensured.

Owner:烟台中正新技术有限公司

Unconventional grease isolation agent for asphalt pavement construction machines, and preparation method thereof

The invention belongs to the field of unconventional grease recycled isolation agents for asphalt pavement construction machines, and relates to an unconventional grease isolation agent for asphalt pavement construction machines. The unconventional grease isolation agent for asphalt pavement construction machines is composed of unconventional grease, an emulsifier and water, wherein emulsified oil is prepared from unconventional grease and the emulsifier, and the isolation agent is prepared from the emulsified oil and water; the emulsified oil comprises 80-90wt% of the unconventional grease and 10-20wt% of the emulsifier; and the isolation agent comprises 25-40wt% of the emulsified oil and 60-75wt% of water. The preparation method realizes recycling of the unconventional grease and reduces the production cost, and the isolation agent prepared in the invention has stable performances, cannot dissolve asphalt, and has a good isolation effect.

Owner:WUHAN UNIV OF TECH

Production method of steamed caramel melon seeds

The invention relates to the technical field of the production of foods, in particular to a production method of steamed caramel melon seeds. The melon seeds are made from the following raw materialsin parts by weight: 50-60 parts of sunflower seeds, 1-4 parts of star aniseeds, 2-4 parts of fennel seeds, 1-4 parts of cinnamon bark, 10-15 parts of brown sugar, 4-7 parts of table salt, 3-5 parts ofmint and 2-5 parts of tartaric acid. The production method of the melon seeds comprises several following steps of (1) steaming medicines, performing deslagging, and performing soaking; (2) performing baking; and (3) packaging finished products. According to the melon seeds provided by the invention, the defects that existing melon seeds provided by the prior art are uneven in raw and cooked conditions, are not easy to preserve and single in taste can be effectively overcome.

Owner:山丹县精海农副产品加工有限责任公司

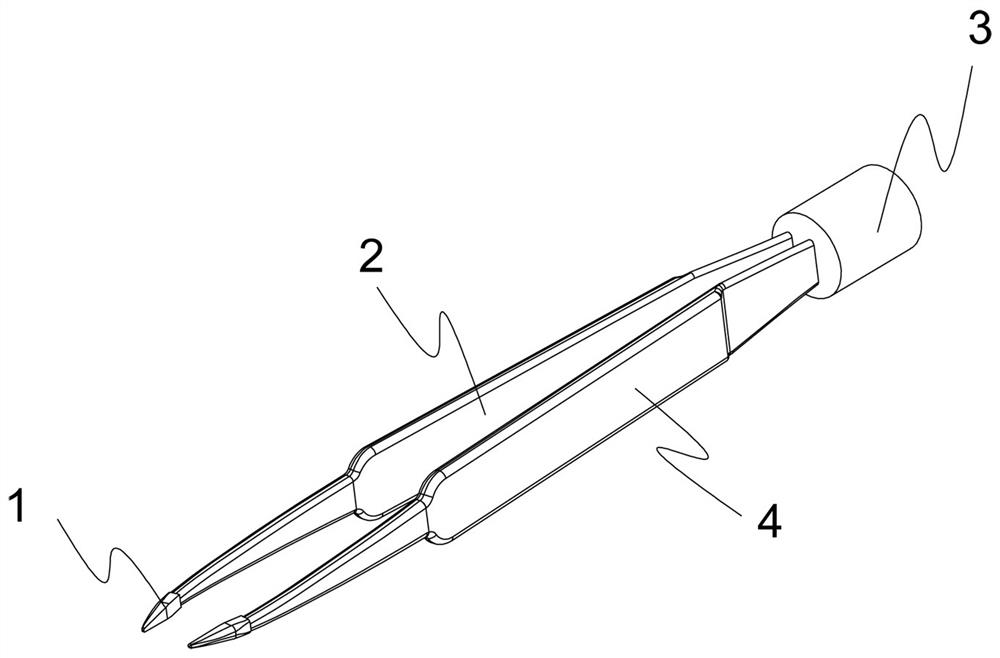

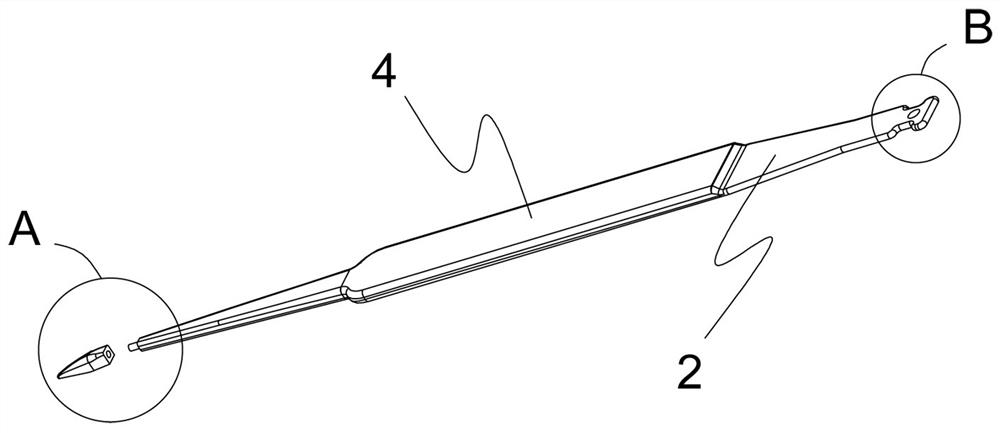

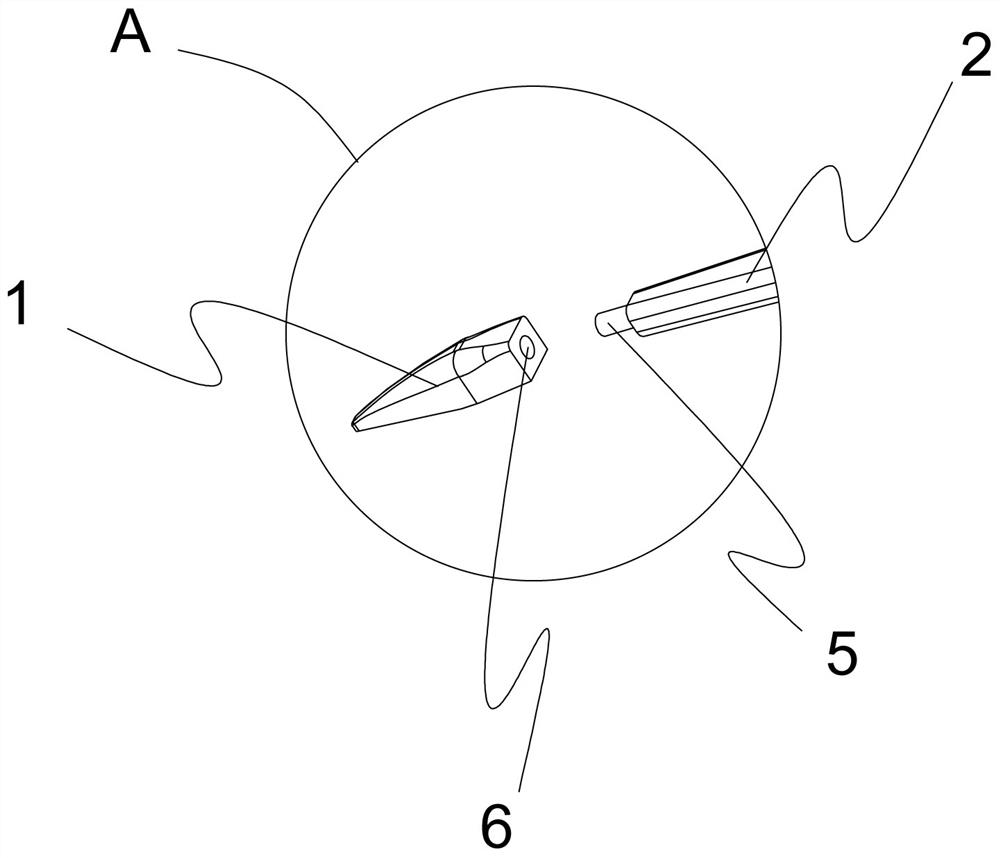

Non-stick electro-coagulation forceps

PendingCN111643185AGuaranteed electrical and thermal conductivityGuaranteed non-stickSurgical instruments for heatingSurgical forcepsForcepsEngineering

The invention discloses a pair of non-stick electro-coagulation forceps. The forceps comprise two forceps bodies and a tail connector, the forceps bodies are fixedly connected with the tail connector,forceps tips are further fixedly connected to the ends, away from the tail connector, of the forceps bodies, electric conduction and heat conduction channels are laid on the forceps bodies, one end of each electric conduction and heat conduction channel is directly connected with the corresponding forceps tip, and the other end of the electric conduction and heat conduction channel extends to thetail part, away from the corresponding forceps tip, of the corresponding forceps body and used for enabling the electric conduction and heat conduction channel to directly contact with a power wire in the tail connector. The forceps tips and the tail connector are directly switched on through the electric conduction and heat conduction channels, the overall electric conduction and heat conductionperformance of the electro-coagulation forceps is guaranteed, and a non-stick effect of a product is guaranteed.

Owner:ZHEJIANG SHUYOU SURGICAL INSTR

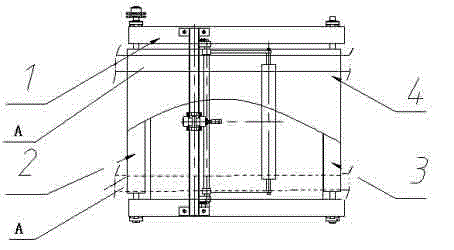

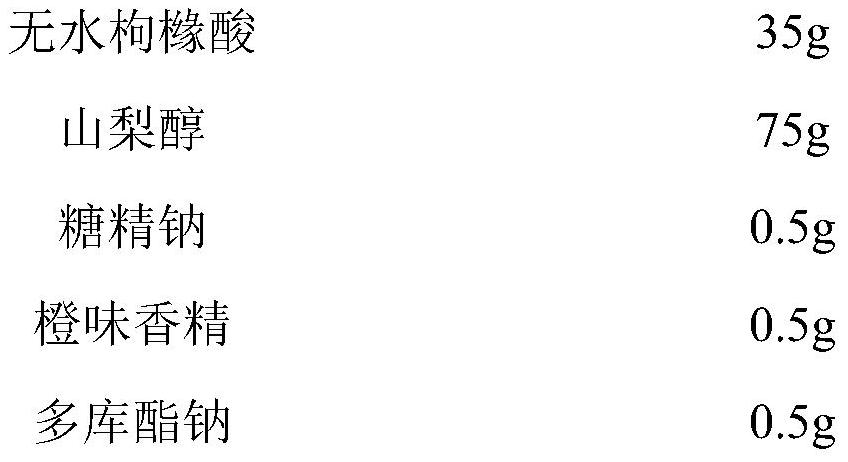

Composite material pre-impregnation rubber belt hot-pressing and lapping device based on rollers

The invention designs a composite material pre-impregnation rubber belt hot-pressing and lapping device based on rollers. The composite material pre-impregnation rubber belt hot-pressing and lapping device consists of a base plate, a lower guide roller mechanism, an upper guide roller mechanism, a top plate, two driving mechanisms and a hot air barrel, wherein the lower guide roller mechanism consists of lower guide columns, two lower guide roller frames and a plurality of lower guide rollers; the upper guide roller mechanism consists of upper guide columns, two upper guide roller frames and a plurality of upper guide rollers; a hot air opening is formed in the middle of the top plate; the two driving mechanisms and the hot air barrel are fixedly arranged on the top plate; driving rods of the two driving mechanisms penetrate through the top plate and then are fixedly and respectively connected with the corresponding upper guide roller frames; and the driving mechanisms drive the upper guide roller frames to move along the upper guide columns. The lower guide rollers of the composite material pre-impregnation rubber belt hot-pressing and lapping device are made of polytetrafluoroethylene which has the characteristics of acid / alkaline resistance and resistance to various organic solvents, so that the outer sides of the guide rollers cannot be stuck with adhesives; and when the upper guide rollers and the lower guide rollers are used for extruding rubber belts, the rubber belts can be fully stuck to each other when moving, and air in a stuck part is filtered, so that the quality of a coiled product is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

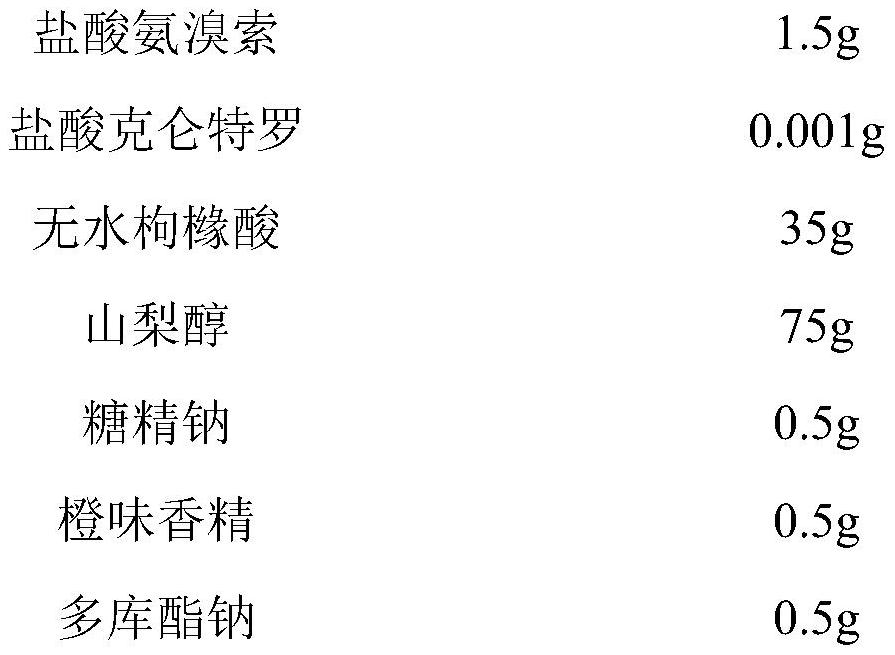

Ambroxol hydrochloride compound effervescent tablet and preparation method thereof

ActiveCN113975259AImprove stabilityImprove uniformityOrganic active ingredientsInorganic non-active ingredientsPolyethylene glycolTableting

The invention relates to an ambroxol hydrochloride compound effervescent tablet which comprises acid particles, alkali particles and polyethylene glycol, the acid particles are prepared from the following components in parts by weight: 1.5 parts of ambroxol hydrochloride, 0.001 part of clenbuterol hydrochloride, 15 to 45 parts of an acid disintegrating agent, 50 to 100 parts of sorbitol, 0.3 to 0.8 part of saccharin sodium, 0.3 to 0.8 part of essence and 0.1 to 1 part of docusate sodium; the alkali particles are sodium bicarbonate particles, potassium bicarbonate particles or sodium carbonate particles with the particle size of 20 to 40 meshes. The ambroxol hydrochloride compound effervescent tablet prepared by the invention is non-sticky in the tabletting process, rapid in effervescence dissolution, rich in bubbles, clear in solution after effervescence, free of residues, good in taste and good in patient compliance, and is especially suitable for children.

Owner:NANJING HEALTHNICE MEDICAL TECH +2

Air-tight sealing device of head of belt conveyor

The invention discloses an air-tight sealing device of a head of a belt conveyor applied to the field of belt conveying. The device structurally comprises a fixing plate, a sealing pipe, a sealing gasket and a sealing cover, wherein the fixing plate, the sealing pipe, the sealing gasket and the sealing cover are sequentially arranged; the end face of one end of the sealing pipe is coaxially weldedto the side face of the fixing plate, the sealing gasket is sleeved with the other end of the sealing pipe, the outer surface of the sealing gasket and the inner surface of the sealing pipe are welded and positioned, the inner surface of the sealing gasket is provided with an inner ring groove facing the sealing cover, one end of the sealing cover is internally sleeved with the inner ring groove,the space among the sealing cover, the sealing gasket and a shaft is filled with sealing filler in the inner ring groove, a gas ring cavity is defined by the fixing plate, the sealing pipe, the sealing gasket, the sealing filler and the shaft, and one side of the sealing pipe is provided with an air inlet. According to the device, dust is prevented from passing through the connecting gap betweenthe shaft and the shell through the gas pressure, so that the sealing operation to the connecting gap is realized, the auxiliary circumferential positioning for the shaft can be realized through the flow of circumferential air pressure, the equipment connecting quality is further improved, the connecting relative friction force is reduced, and the matched driving effect is improved.

Owner:JIANGSU JIANGDA MACHINERY

Cable for shallow sea wind power generation

ActiveCN101937738BImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFlexible cablesElectricityElectrical conductor

The invention discloses a cable for shallow sea wind power generation, which comprises a conductor, water-blocking tapes, an insulating layer and lining layers, wherein, the first water-blocking tape and the extruded insulating layer are wrapped sequentially outside the conductor to form insulating wire cores, and a plurality of insulating wire cores are twisted together to form a cable core; thefirst lining layer and the second water-blocking tape are wrapped sequentially outside the cable core; and the insulating layer and the first lining layer are formed by extruding a thermoplastic elastomer (TPE). In the invention, the insulating layer is made of a thermoplastic olefin (TPO) material in the TPE and the first lining layer is made of a thermoplastic starch (TPS) material in the TPE, wherein, the TPE has good electrical property, good mechanical property, excellent low-temperature bending property and excellent torsion resistance, high long-term working temperature up to 125 DEG C, better water resistance and excellent salt-fog resistance, and especially the TPE can still maintain good flexibility at -60 DEG C; and TPO has more excellent electrical property, and TPS has betterwater resistance than that of the TPO.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com