Composite material pre-impregnation rubber belt hot-pressing and lapping device based on rollers

A composite material and overlapping device technology, which is applied in the field of composite material winding and laying molding, can solve the problems of complex process, occurrence of doped materials, low efficiency of prepreg tape, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Describe the present invention below in conjunction with specific embodiment:

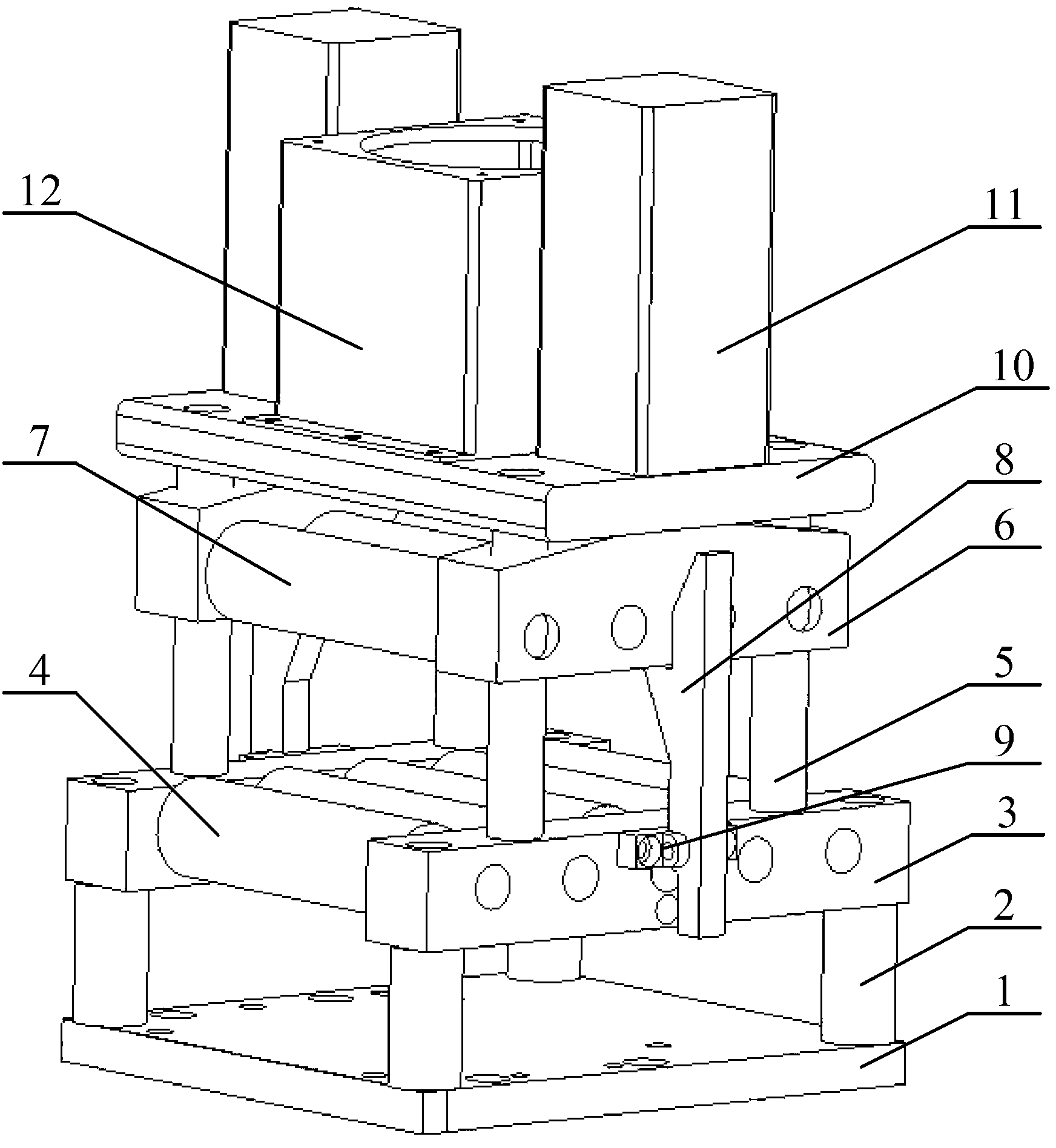

[0016] A roller-based composite material prepreg tape hot-press lapping device in this embodiment consists of a bottom plate 1 , a lower guide roller mechanism, an upper guide roller mechanism, a top plate 10 , a cylinder 11 and a hot air barrel 12 .

[0017] The bottom plate is a rectangular steel plate, which is the supporting mechanism of the whole device. There are two threaded holes on the long sides on both sides, which are used for fixed connection with the external body through bolts. Four countersunk through holes are evenly distributed on the four corners of the bottom plate, which are used for fixing with the lower guide pillars in the lower guide roller mechanism.

[0018] Described lower guide roller mechanism is made up of lower guide pillar 2, two lower guide roller frames 3 and several lower guide rollers 4. The lower guide column is a low cylindrical steel material, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com