Cable for shallow sea wind power generation

A cable and shallow sea technology, which is applied in the field of cables for shallow sea wind power generation, can solve the problems of complex structure and insufficient bending resistance, and achieve the effects of excellent electrical performance, high production efficiency and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

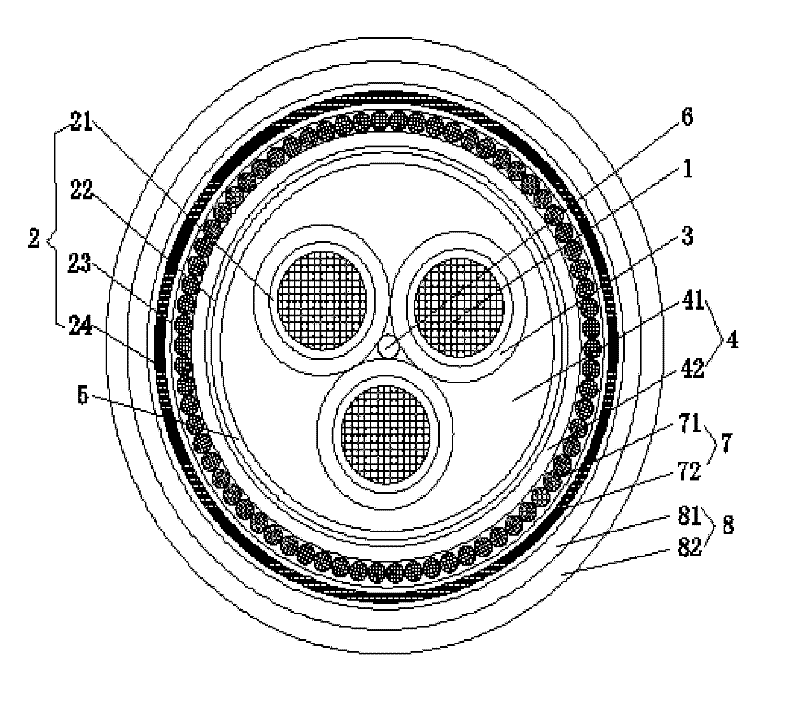

[0035] See figure 1 , a cable for shallow sea wind power generation in this embodiment is particularly suitable for use in water situations, and can also be used underwater, including a conductor 1, a water blocking tape 2, an insulating layer 3, an inner lining 4, a rubber strip 6 and a shielding Layer 5. The first water blocking tape 21 and the extruded insulation layer 3 are wrapped around the conductor 1 to form an insulated wire core, and multiple insulated wire cores are stranded to form a cable core; the first inner lining layer 41 and the shielding layer 5 are wrapped around the cable core in turn , the second water blocking strip 22 , and the second inner lining layer 42 .

[0036] Conductor 1 is made of tinned annealed copper wire; the pitch ratio of strands made of copper wire is 15 to 18 times;

[0037] The insulating layer 3 and the first inner lining layer 41 are extruded from TPO material in TPE, and the second inner lining layer 42 is extruded from TPS materi...

Embodiment 2

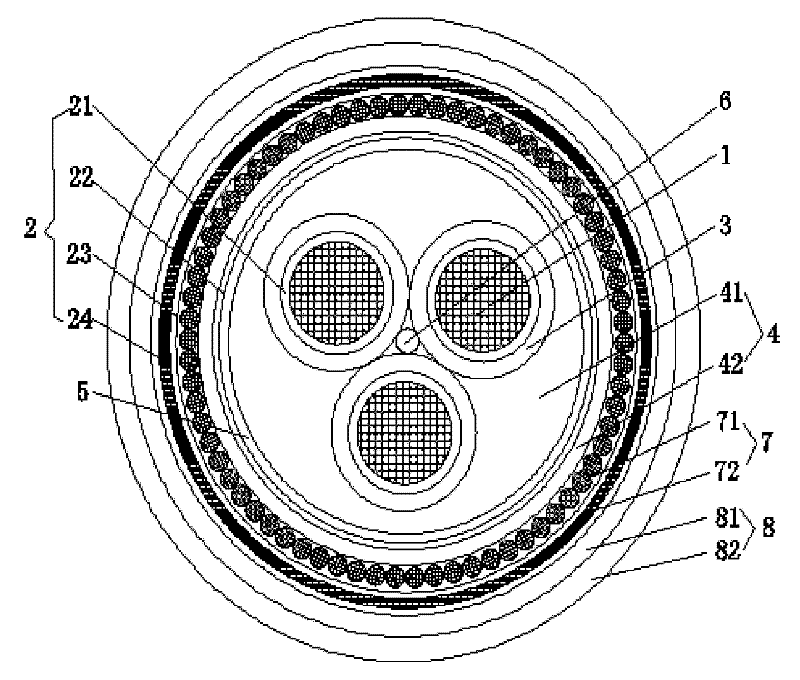

[0043] still see figure 1 , this embodiment 2 increases the armor layer 7 and the outer sheath 8 on the basis of the embodiment 1, in order to meet the requirements of wear resistance and tensile resistance during long-term underwater use. Specifically, its structure is as follows: the conductor 1 is wrapped around the first water blocking tape 21 and the insulating layer 3 is wrapped in turn to form an insulated wire core, and multiple insulated wire cores are stranded to form a cable core; rubber strips are filled in the gaps of the insulated wire cores 6. Wrap the first inner lining layer 41, the first inner lining layer 41, the shielding layer 5, the second water blocking tape 22, the second inner lining layer 42, the first armor layer 71, and the third inner lining layer 41 in sequence outside the cable core. The water blocking tape 23 , the second armor layer 72 , the fourth water blocking tape 24 and the outer sheath 8 .

[0044] The first armor layer 71 adopts aviation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com