Full-automatic swing arm sucker type label suturing machine

A labeling machine and sucker-type technology, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc., can solve the problems of complicated structure, inconvenient application of automatic packaging and sealing machinery, etc., and achieve complex structure, simple and practical structure, and stable quantity reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

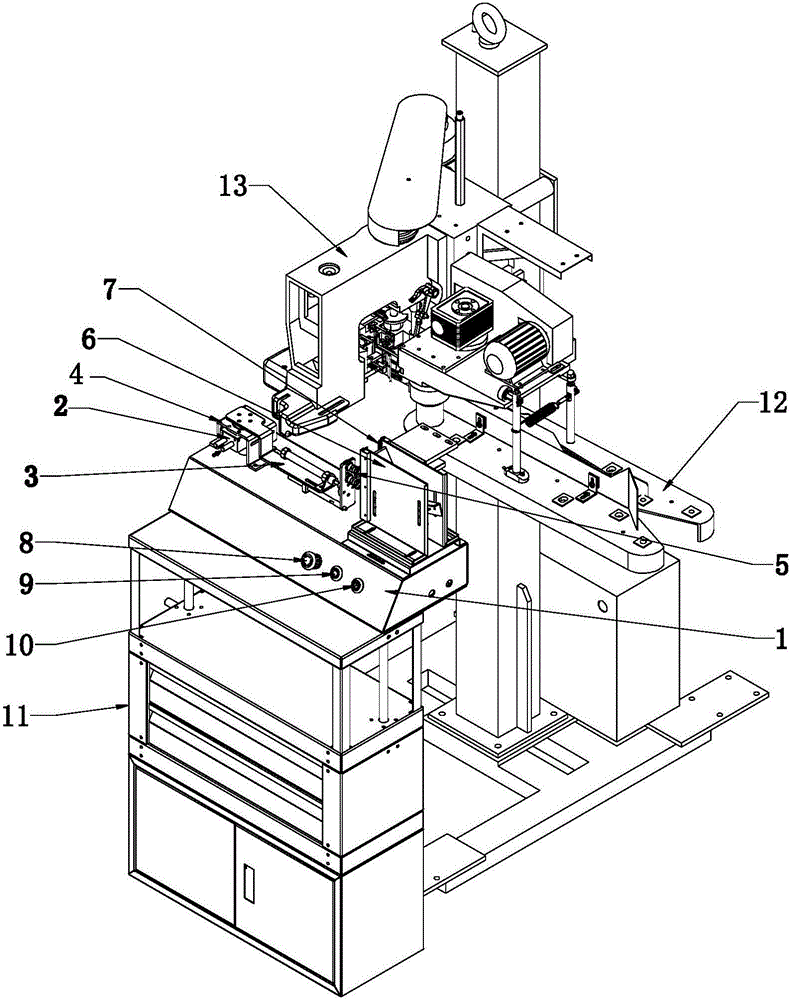

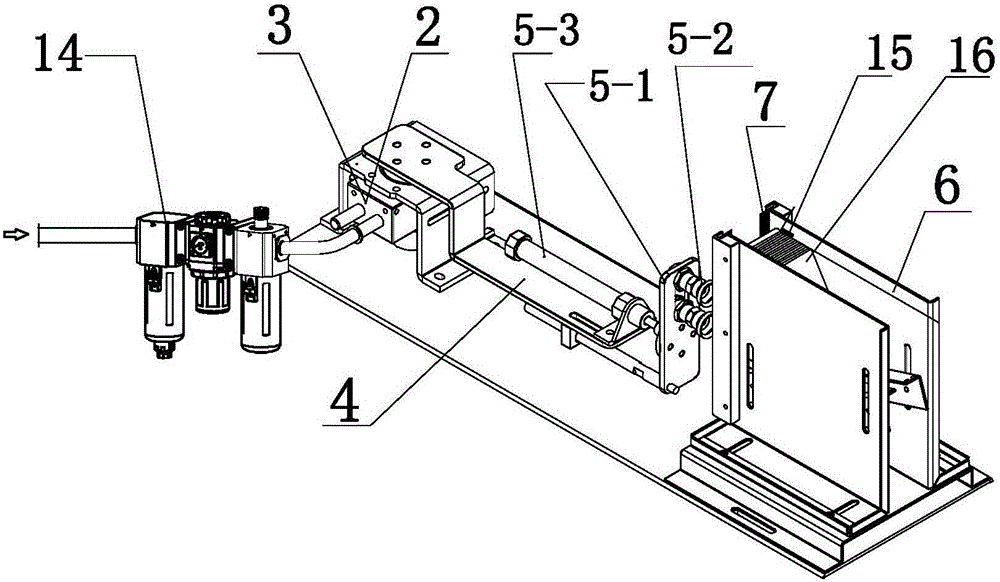

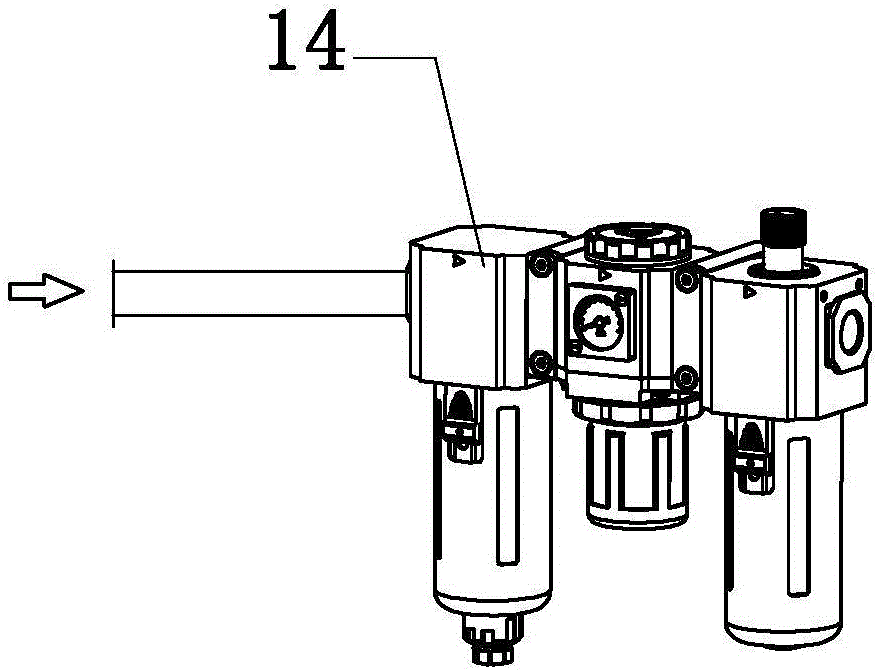

[0019] Such as Figure 1-Figure 3 In the illustrated embodiment, the present invention is provided with: a labeling machine main body, a vacuum suction mechanism 5, a label storage bin 6, an automatic controller, and a rotating swing arm mechanism 2. The main body of the labeling machine is a label machine base 9 equipped with a vacuum suction mechanism 5 , label storage compartment 6, the main body 11 of the automatic swing arm suction cup type sewing label machine of the rotary swing arm mechanism 2, the rotary swing arm mechanism 2 is composed of the swing arm and the automatic controller connected by the rotary cylinder 4, the automatic controller is connected and Control the rotary cylinder 4, one end of the swing arm is connected to the top of the rotary cylinder 4, and the top of the swing arm body is connected with a vacuum suction mechanism 5, and the vacuum suction mechanism 5 is respectively matched and connected to suck the label 16 installed in the label storage bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com