Patents

Literature

53results about How to "Frequency controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

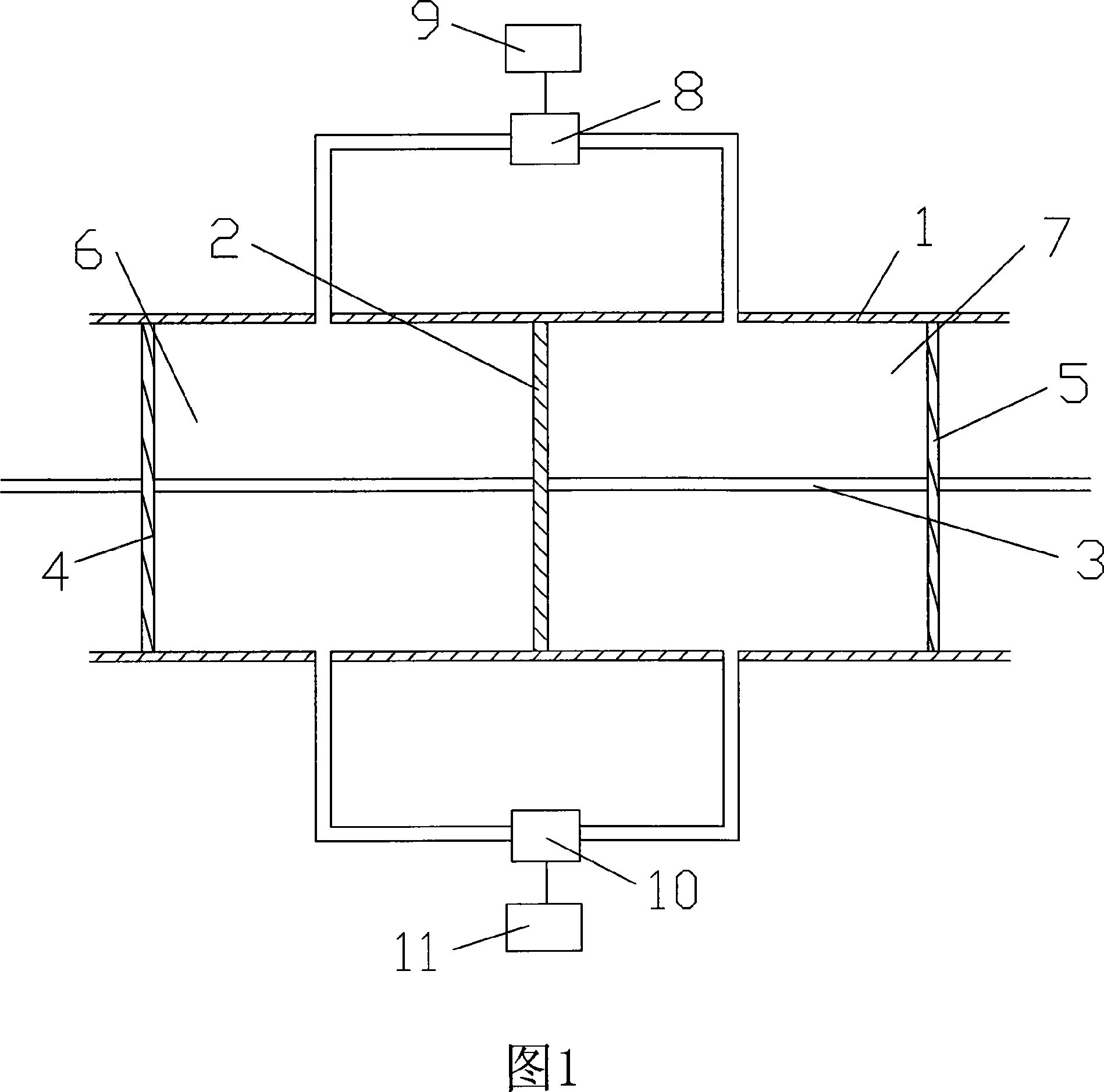

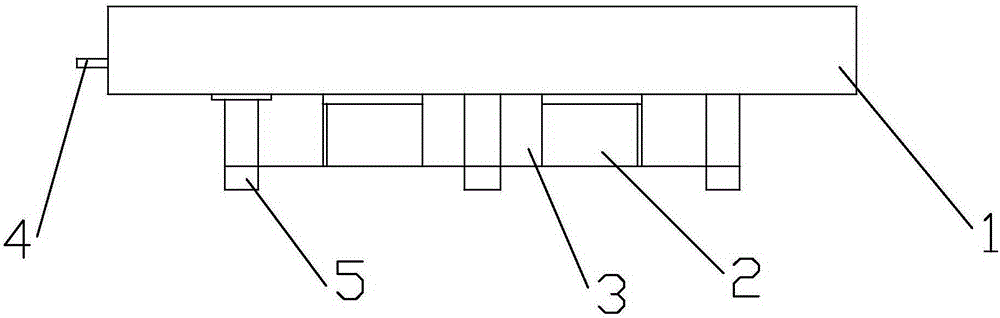

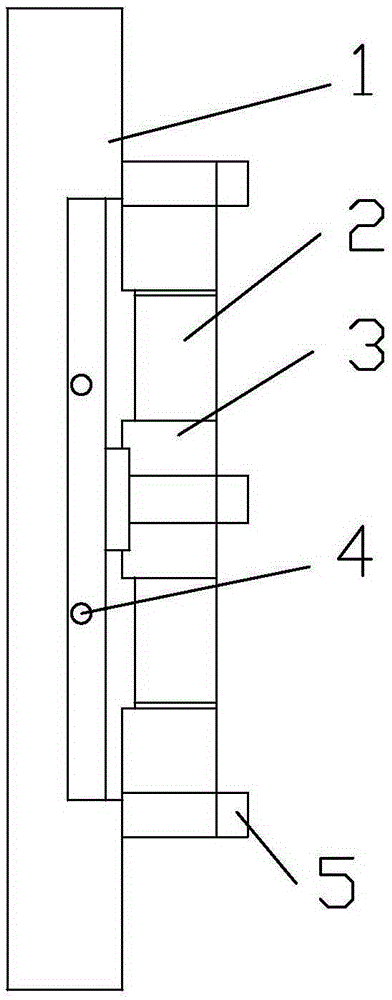

Experimental method of simulating dynamic and static load and device thereof

InactiveCN101532931AOvercome gradationOvercome sizeFluid pressure measurement by electric/magnetic elementsMaterial strength using tensile/compressive forcesExperimental methodsData acquisition

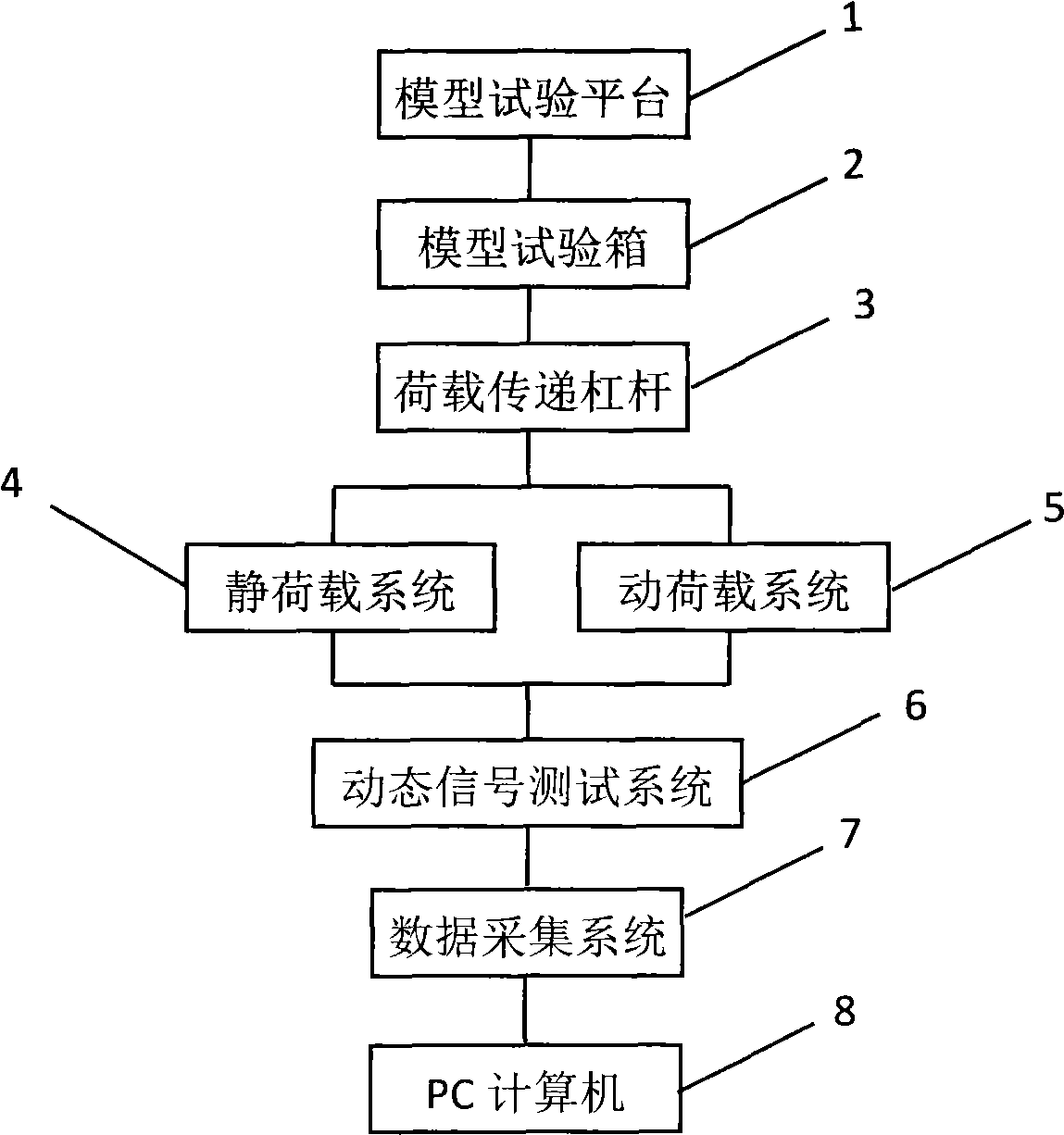

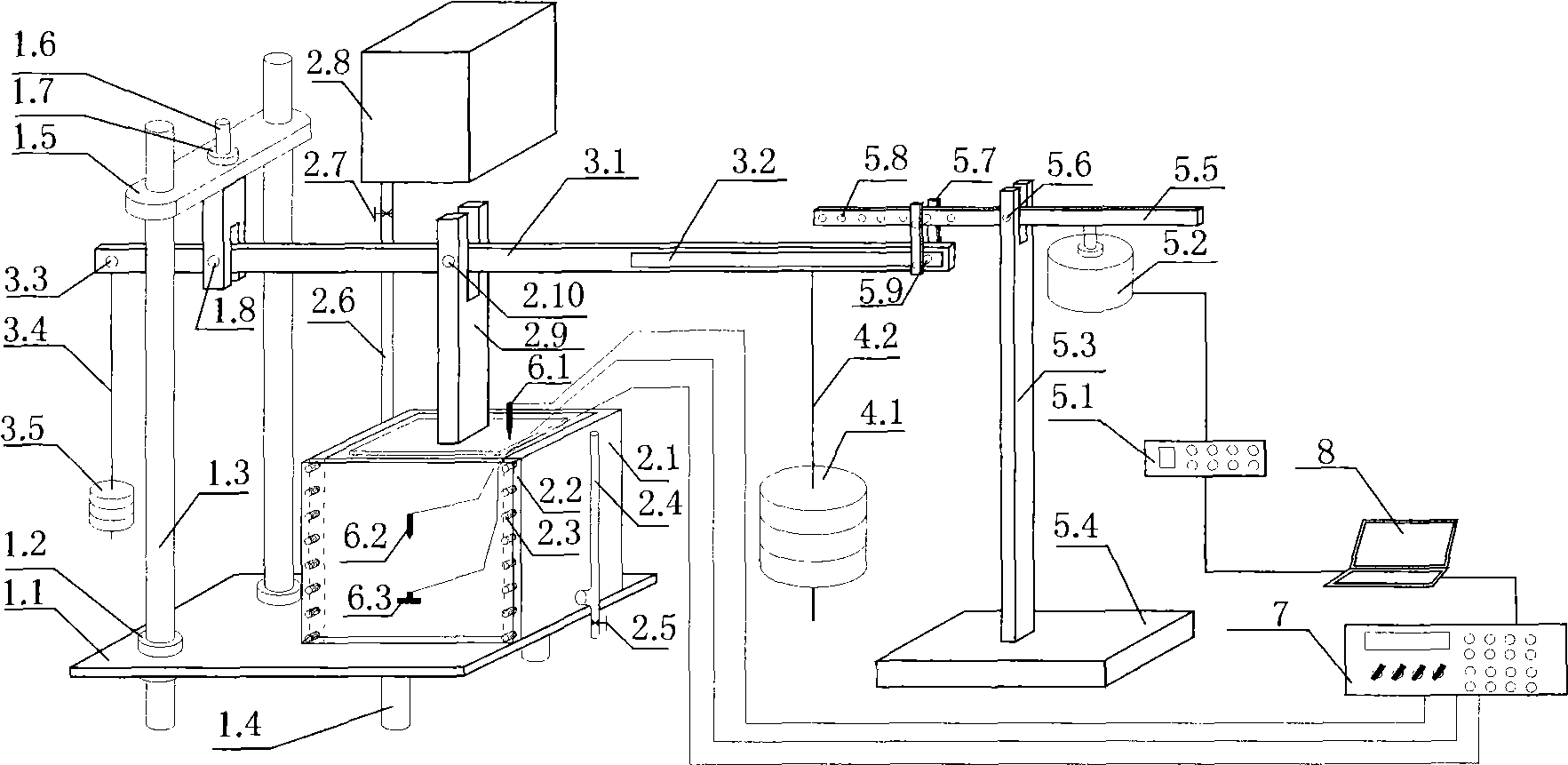

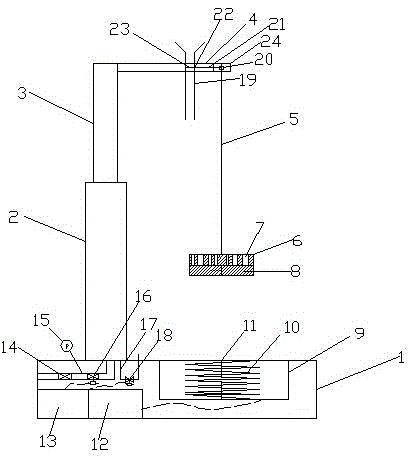

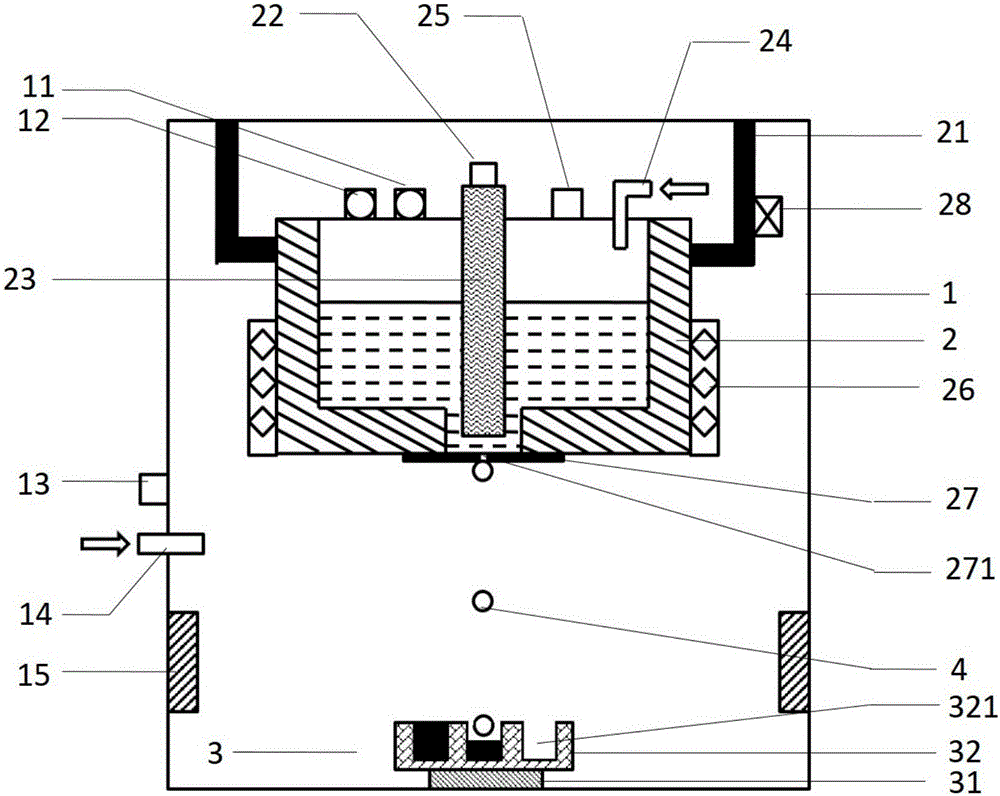

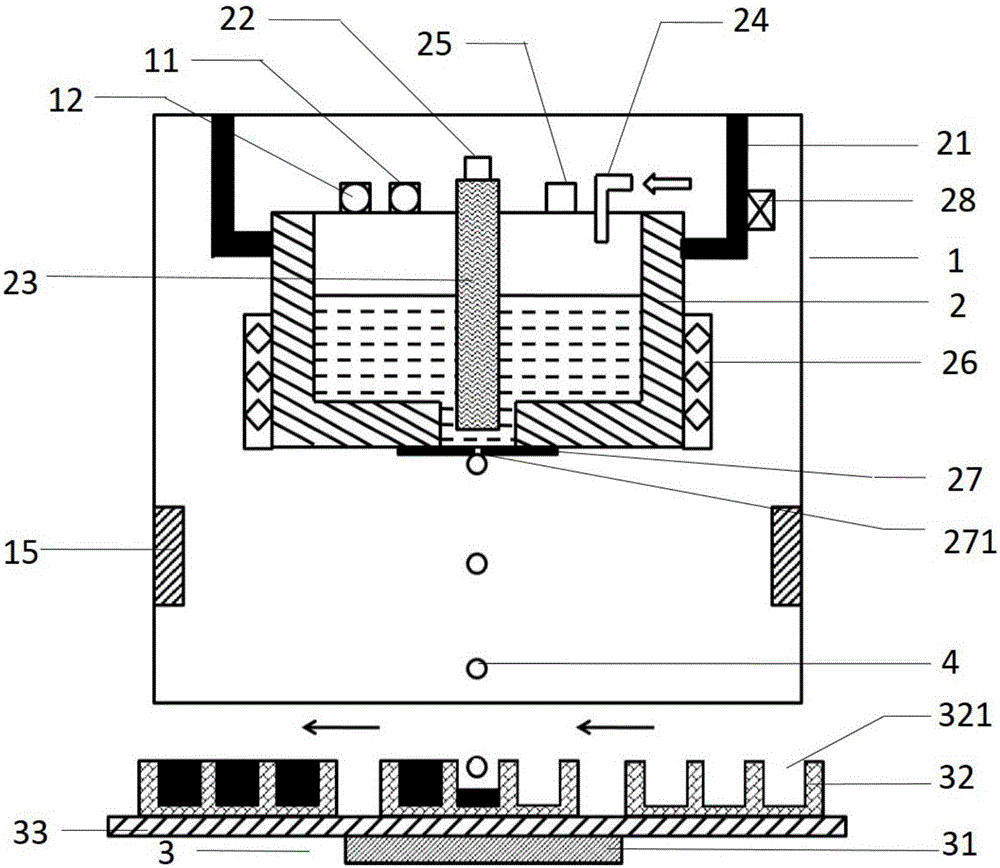

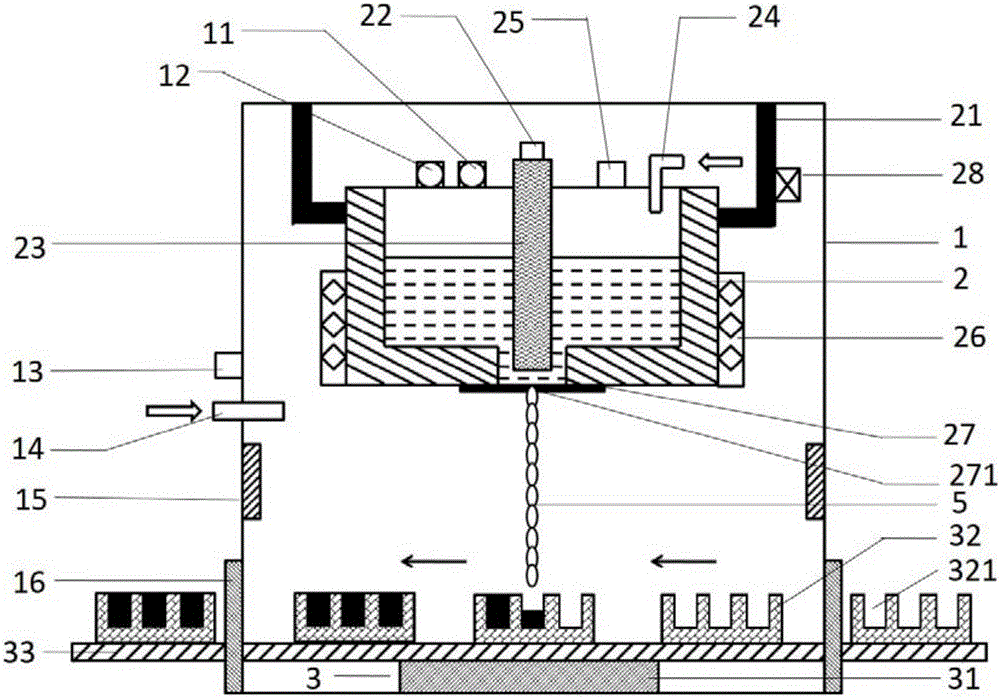

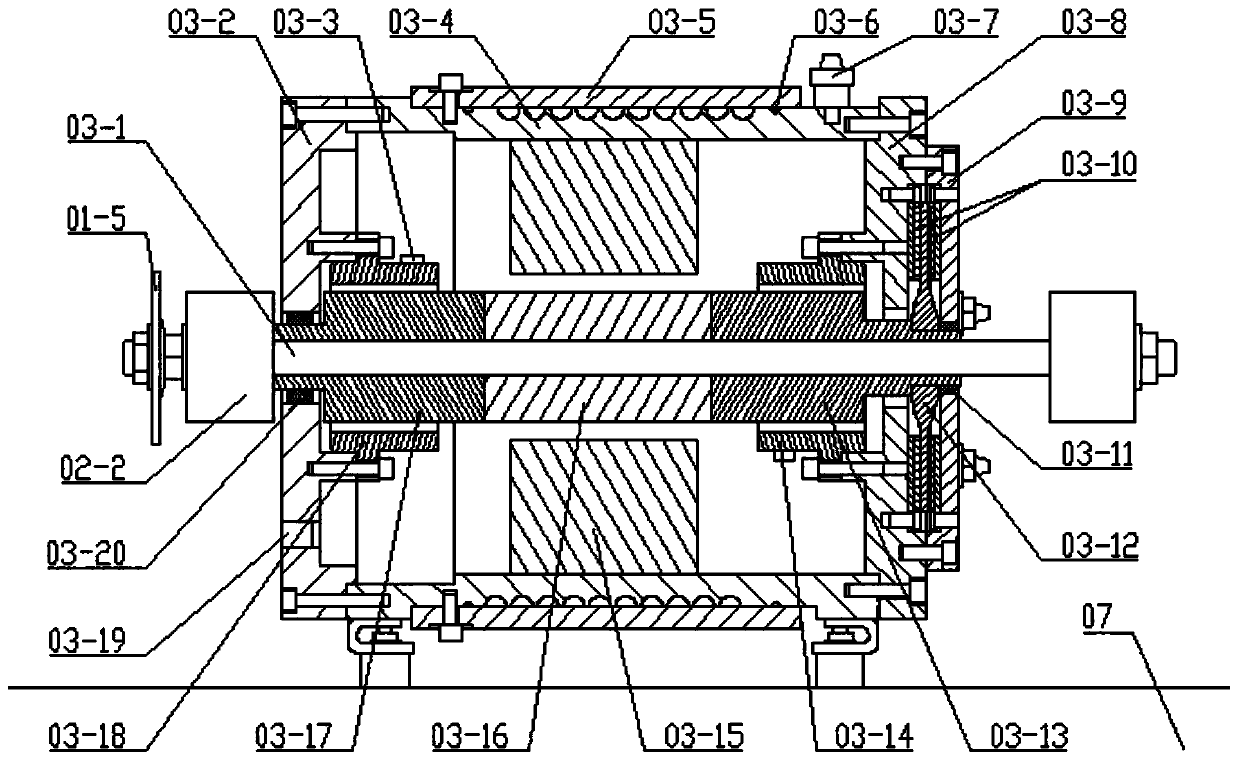

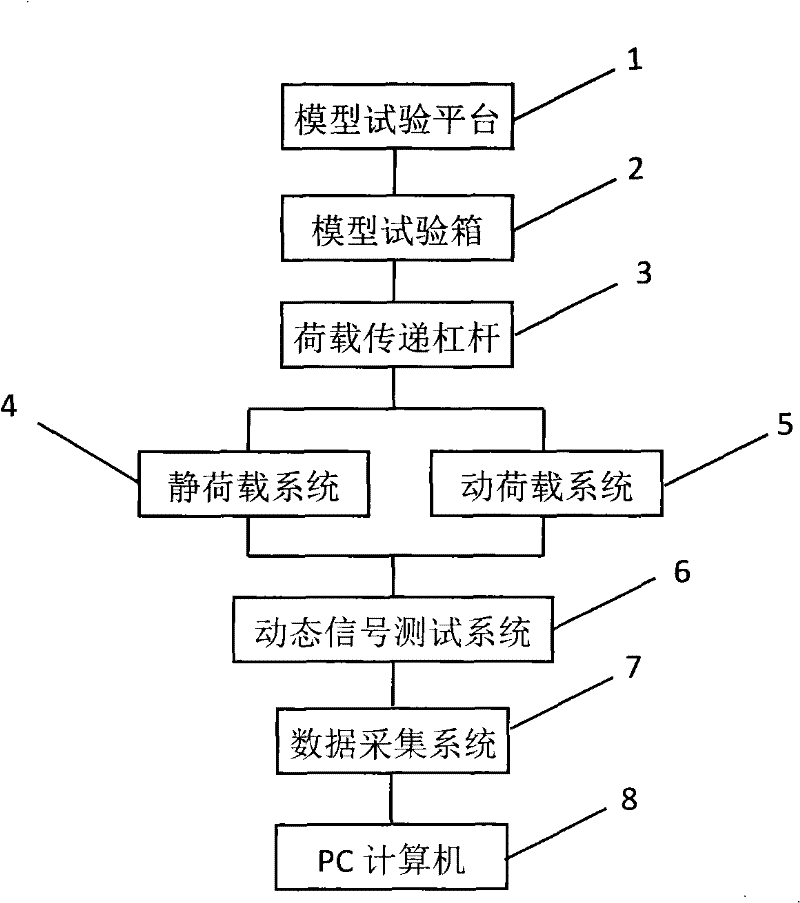

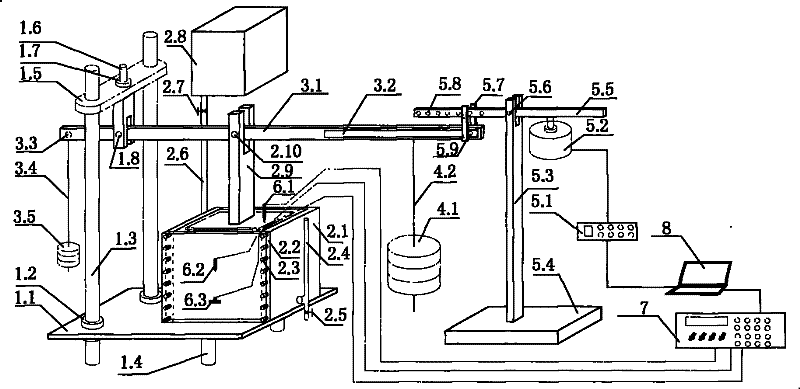

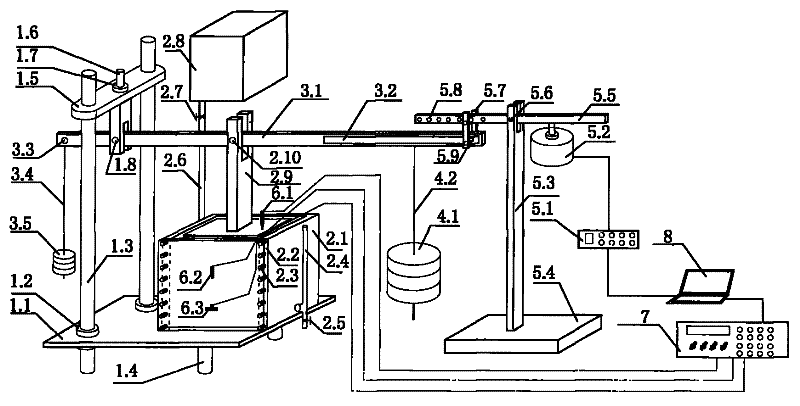

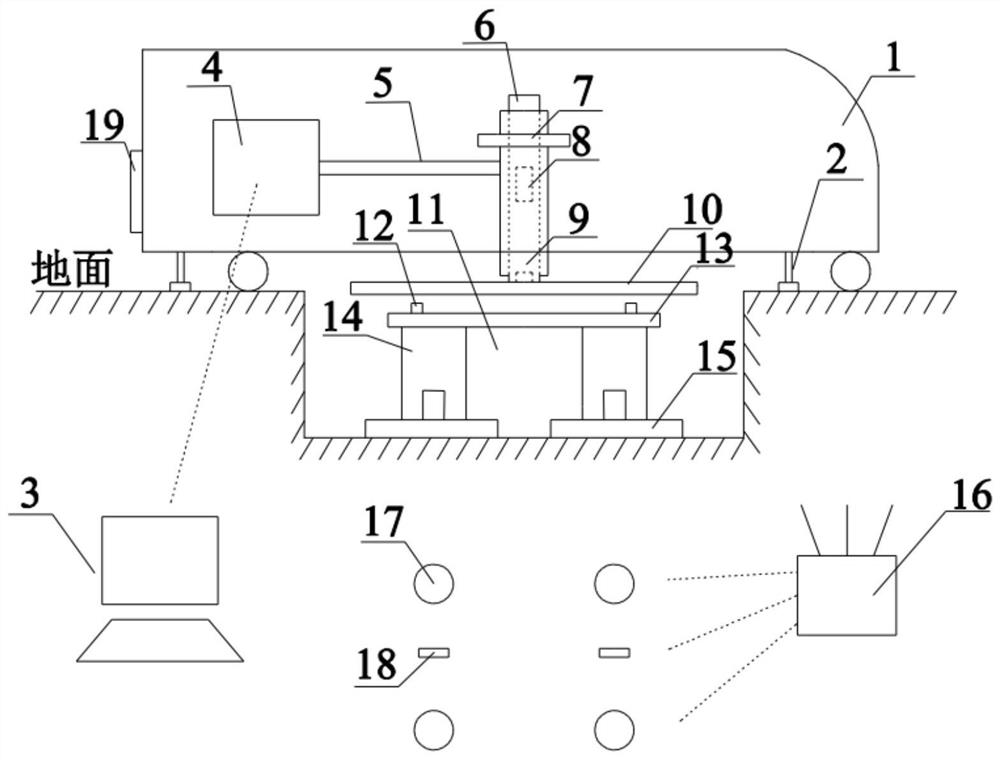

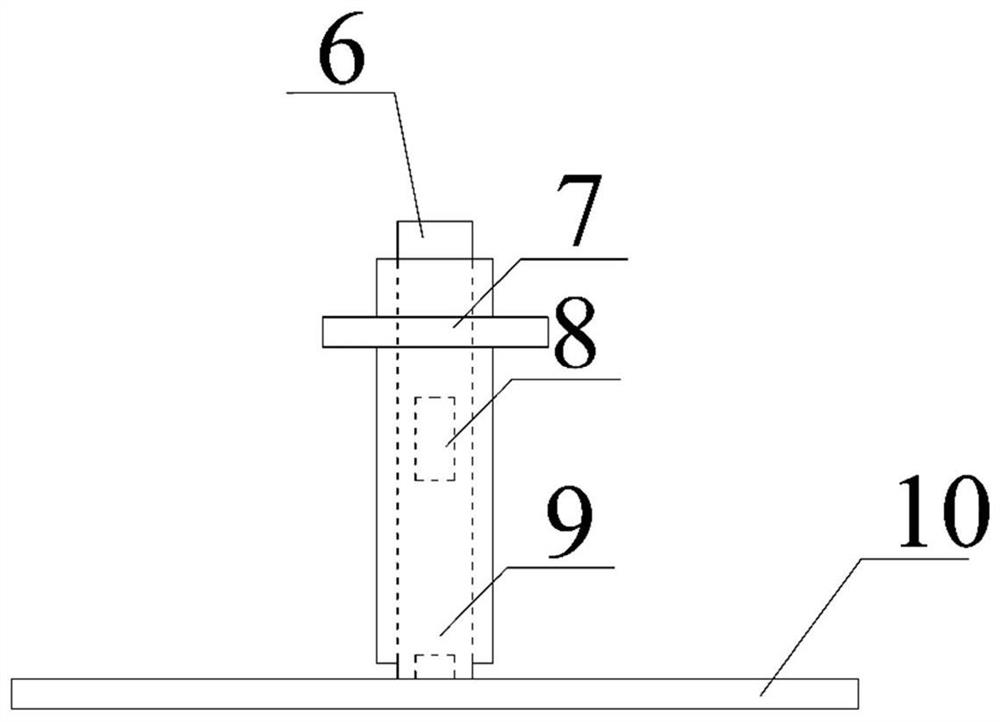

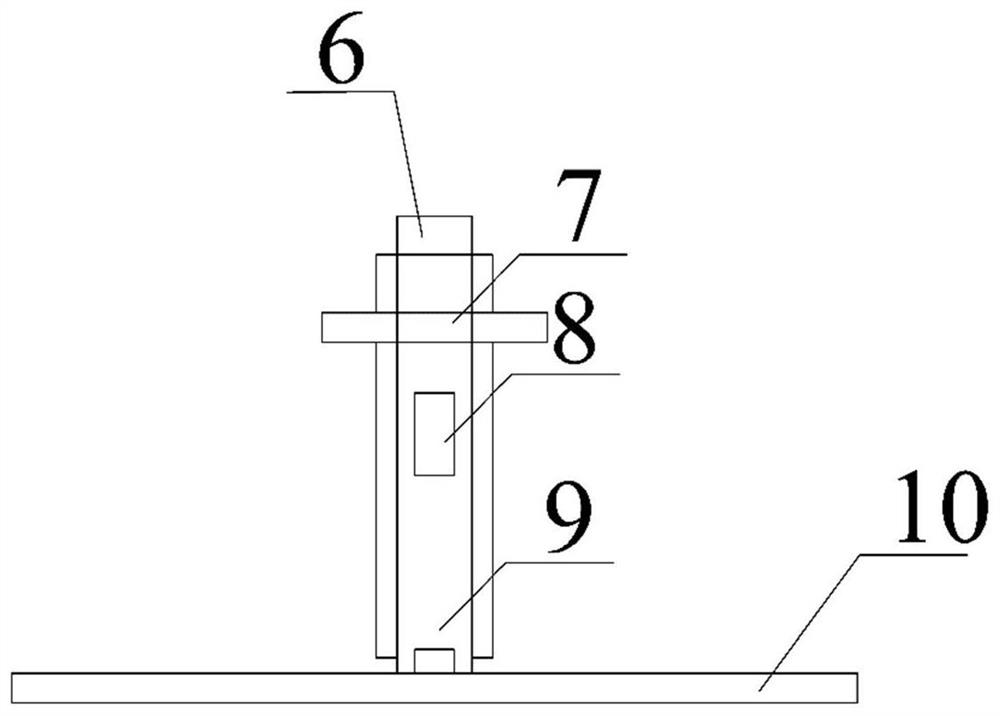

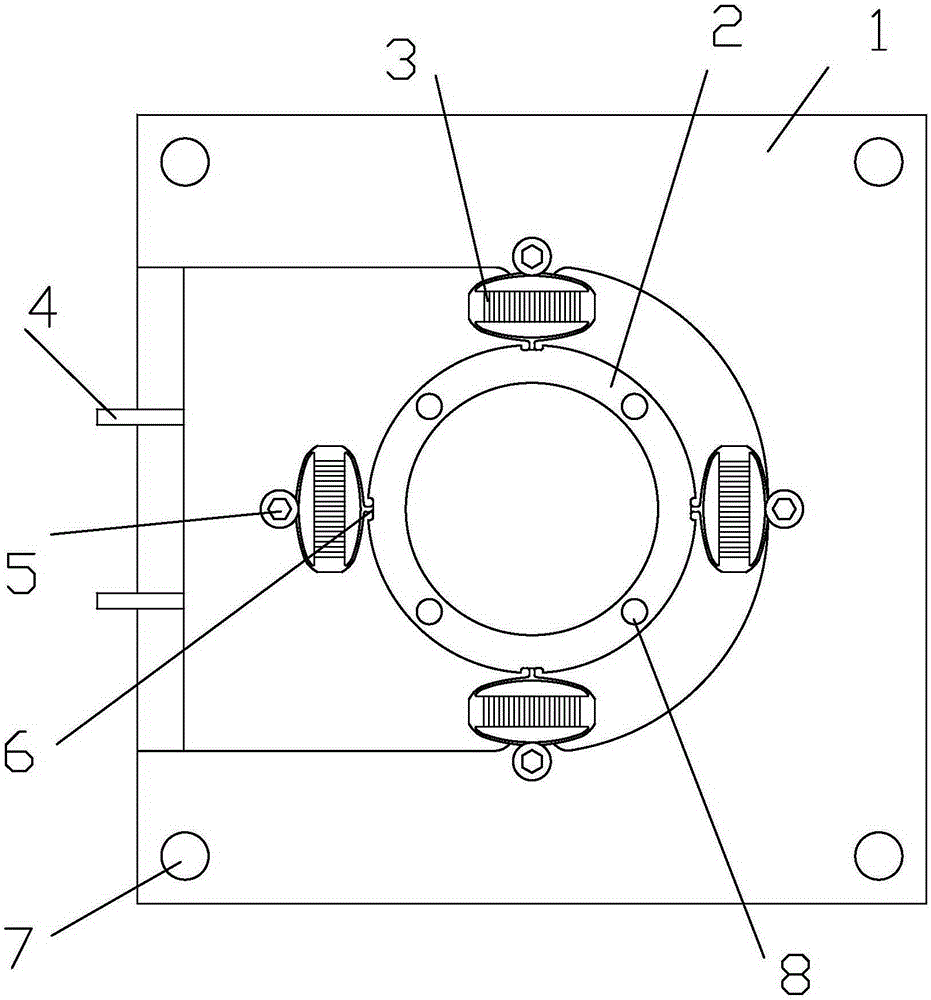

The invention discloses an experimental method of simulating dynamic and static load and a device thereof, relating to indoor model experimental technique of geotechnical engineering. The structure of the device is as follows: a model experimental platform (1), a model experimental box (2) and a load transmitting lever (3) are sequentially connected; the load transmitting lever (3) is respectively connected with a static load system (4) and a dynamic load system (5) which are respectively connected with a dynamic signal testing system (6); the dynamic signal testing system (6), a data acquisition system (7) and a computer (8) are sequentially connected. The device caries out dynamic and static load experiments on different structure models, and can monitor and collect non-linear properties of deformation and stress of gneiss under complex load condition in real time. The device has intuitional testing principle, simple structure, high precision, good stability, easy operation, convenient detachment and no high technical requirement to mounting and testing workers.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Two-fluid jet system

InactiveCN102527541AExtended service lifeSimplified implementation pathLiquid spraying apparatusPhysicsPowder metallurgy

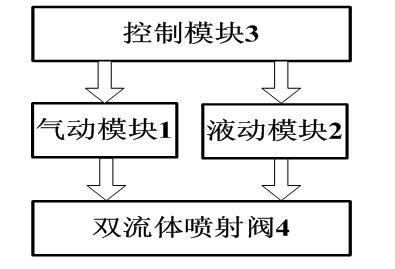

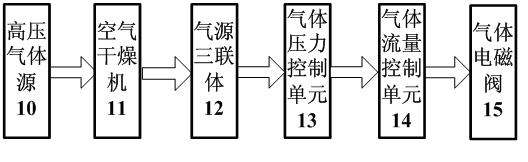

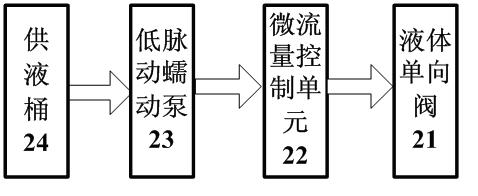

The invention relates to a two-fluid jet system, which comprises a pneumatic module, a hydraulic module, a control module and a two-fluid jet valve, wherein the control module is respectively connected with a gas pipe and a liquid pipe of the two-fluid jet valve through the pneumatic module and the hydraulic module. The two-fluid jet system is based on the microchannel gas-liquid flow movement principle, namely the control module is used for controlling gas-liquid flow velocity ratio or flow ratio of the pneumatic module and the hydraulic module, so that liquid jet of slug flow is realized in a microchannel. The two-fluid jet system is applicable to fluid jet in the fields of semiconductor film preparation, composite preparation, electronic package, MEMS (micro-electromechanical systems), spraying, ink jet, powder metallurgy, biomedicine, food processing, welding, combustion, chemical engineering and the like.

Owner:SHANGHAI UNIV

Measuring device of soil conductivity and method

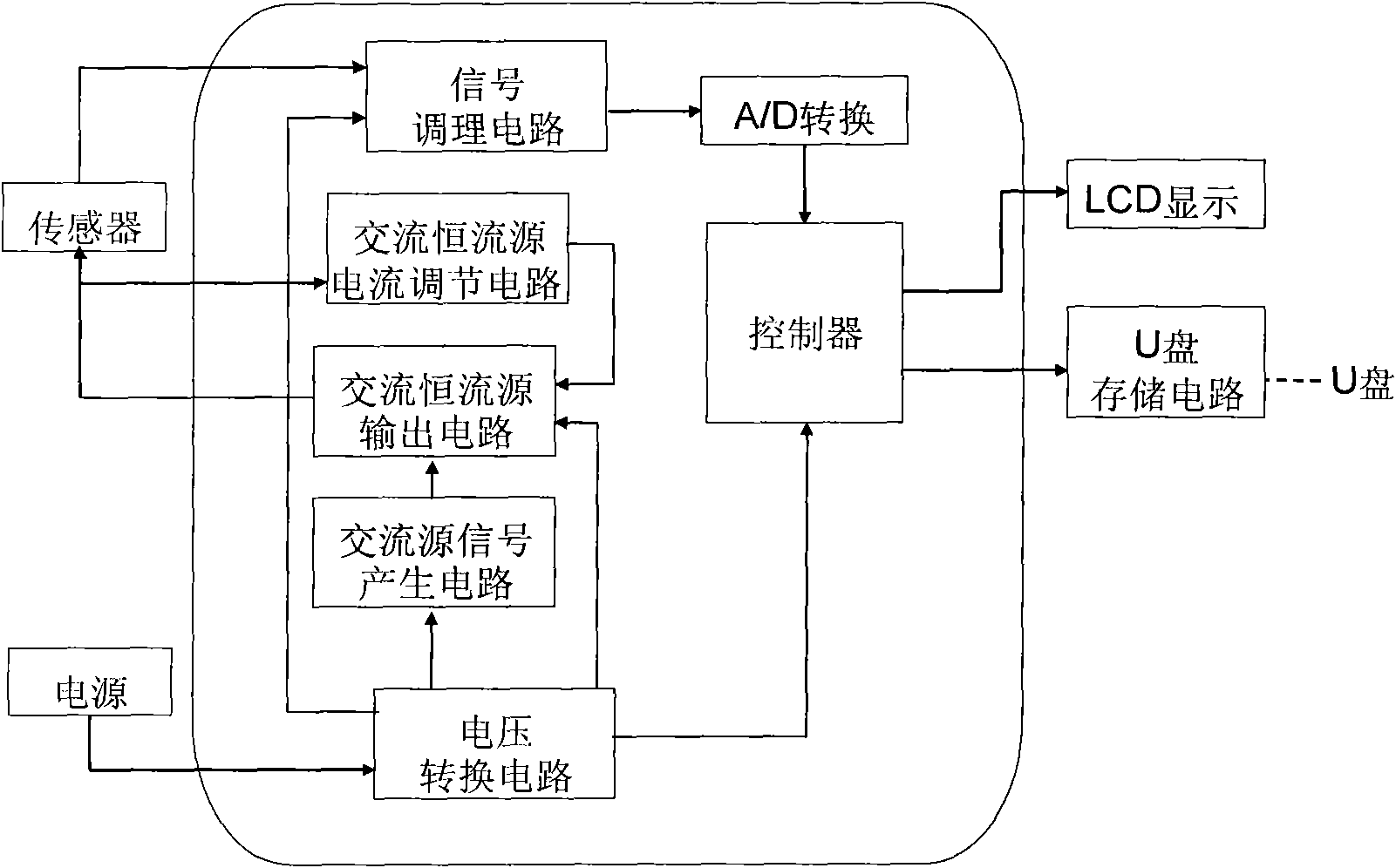

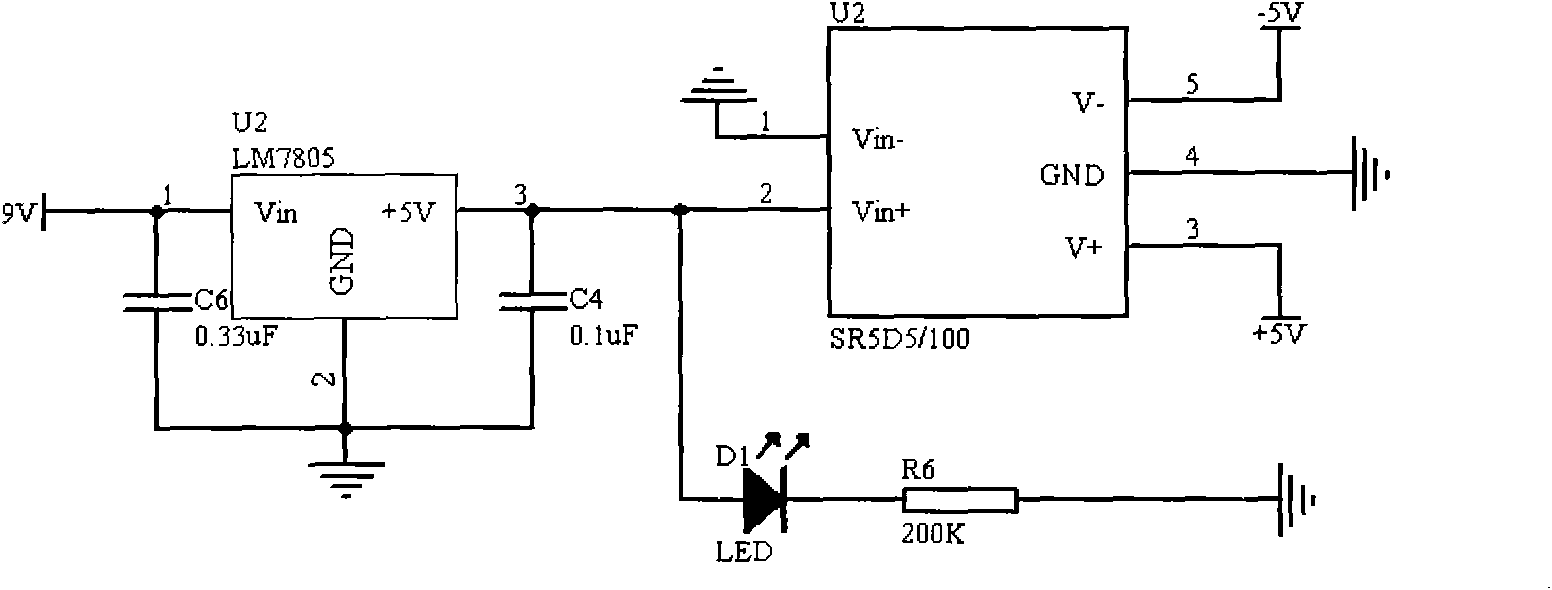

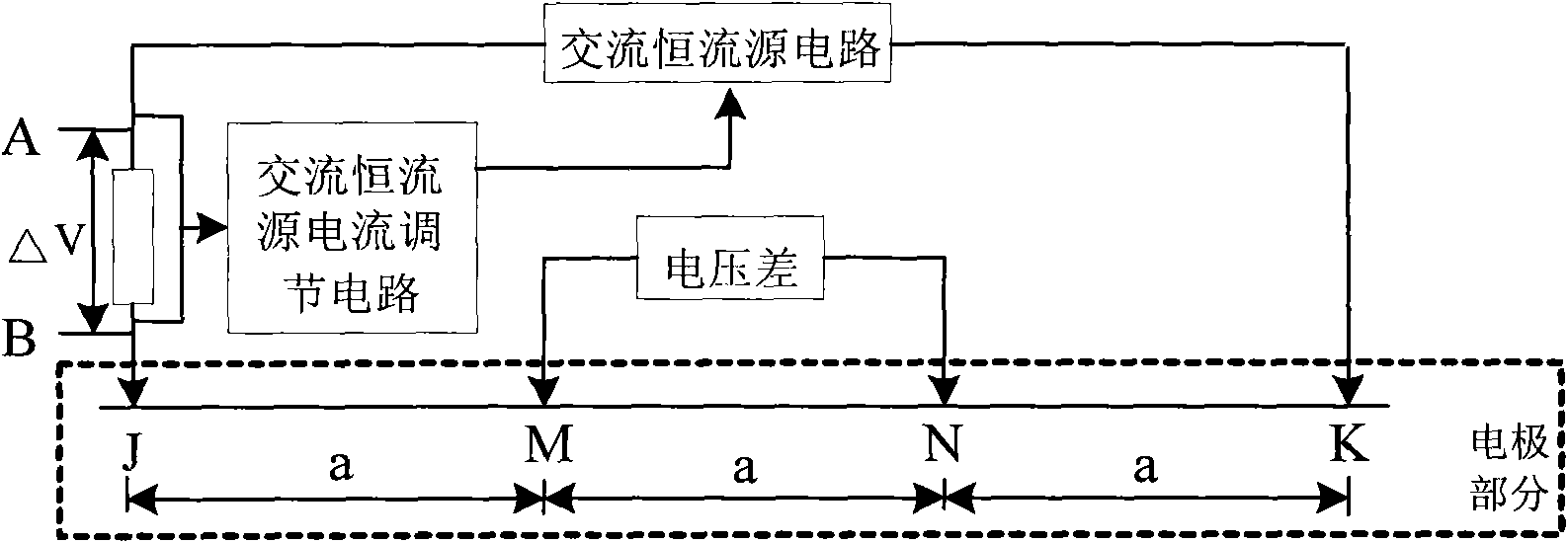

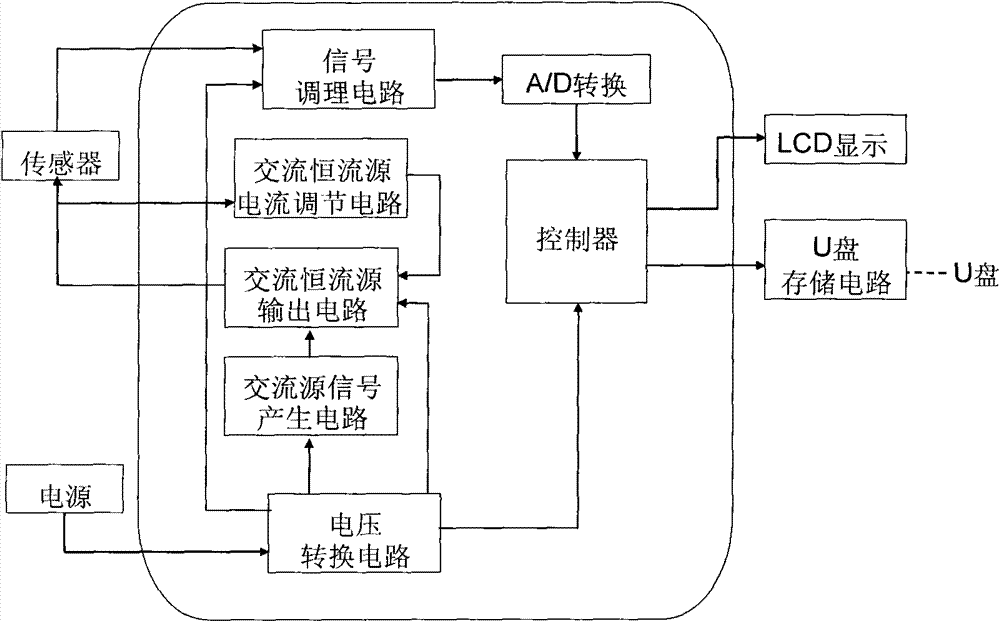

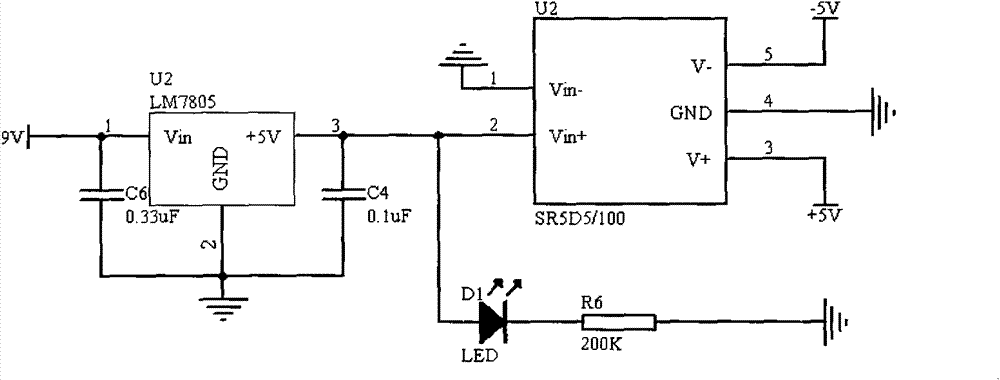

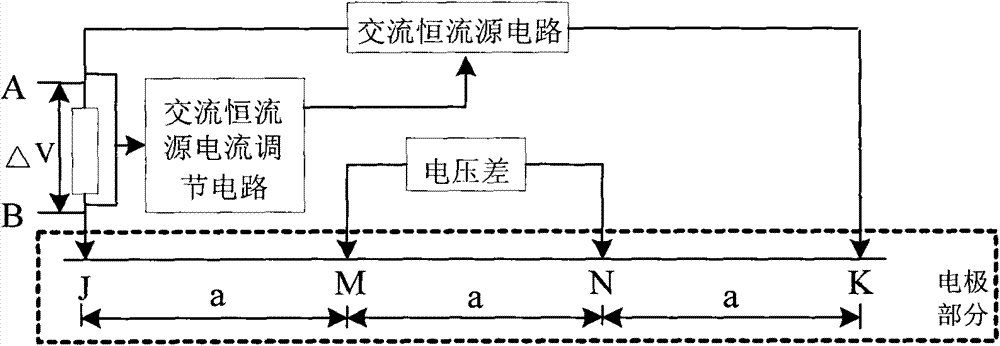

InactiveCN101609058AAvoid polarizationAdjustable sizeMaterial resistanceData displayData acquisition

The invention discloses a measuring device of soil conductivity, mainly comprising a sensor unit and a data acquisition and processing unit; the sensor unit mainly comprises electrodes which are configured in a linear equal interval manner; the data acquisition and processing unit mainly comprises a voltage conversion circuit, a signal conditioning circuit, an analog-to-digital converter, a data controller and a liquid crystal display circuit, and also comprises a alternating-current source signal generating circuit, an alternating-current constant current source output circuit and an alternating-current constant current source regulating circuit. According to the measuring device of soil conductivity, the invention also discloses a measuring method of soil conductivity. The invention can regulate the size of exciting current input into the soil at any time according to soil characteristics of the measured farmland so as to guarantee that the sensor works at the linear area under any soil condition, has high measuring accuracy and also has the function of data display and storage.

Owner:CHINA AGRI UNIV

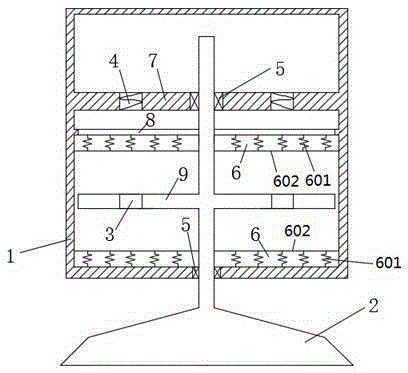

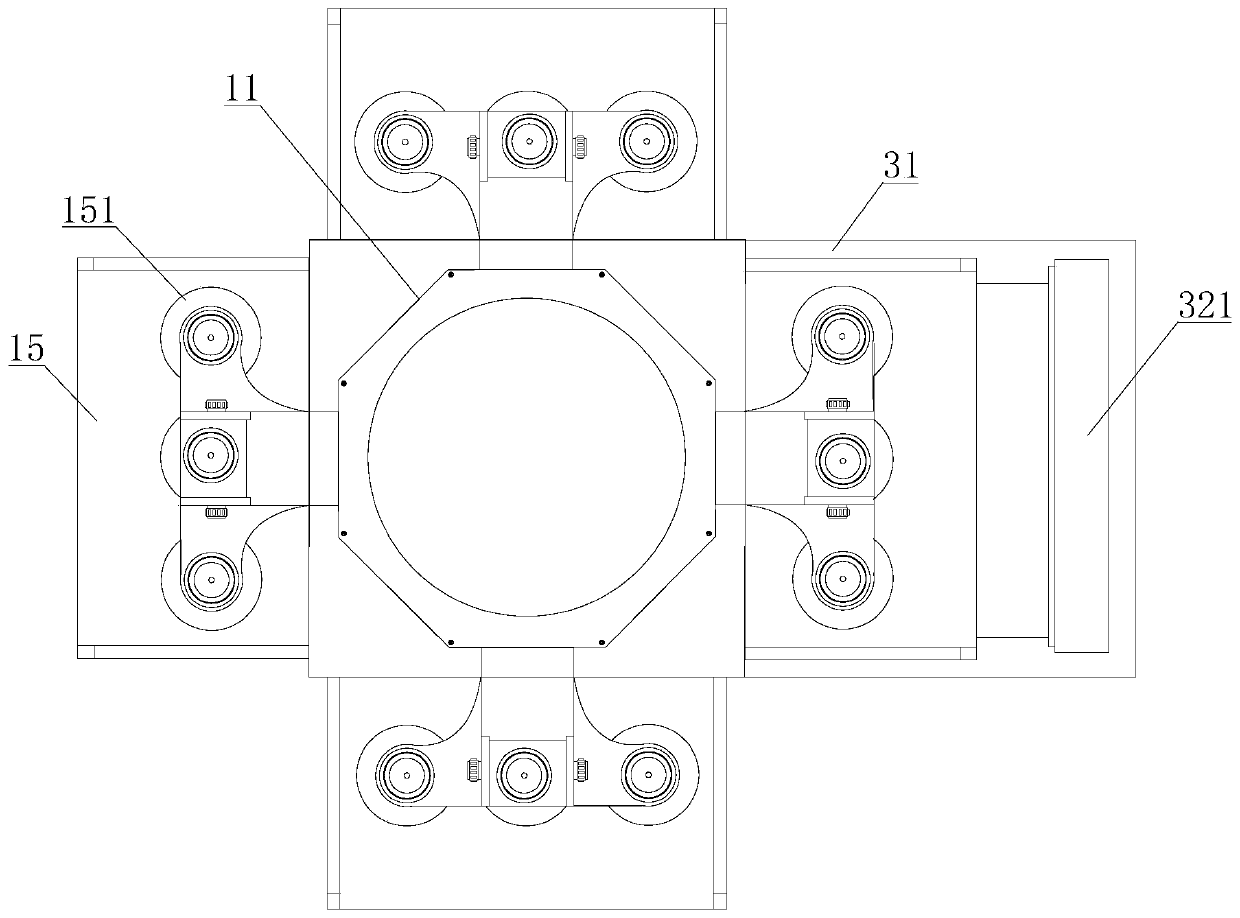

Sand-packed model pipe full-automatic compacting device

InactiveCN105464653AReduce labor intensityImprove work efficiencyConstructionsBorehole/well accessoriesHydraulic cylinderMagnetic poles

The invention discloses a sand-packed model pipe full-automatic compacting device. The sand-packed model pipe full-automatic compacting device comprises a pedestal, a hydraulic cylinder, a hydraulic push rod, a connecting rod, a straight rod and a compacting block. The upper end of the hydraulic cylinder is provided with the hydraulic push rod, the connecting rod is horizontally vertical to the hydraulic push rod, the end of the connecting rod is fixedly connected with an automatic sand-pack tunnel, the interior of the pedestal is provided with an electromagnet, an electromagnet pulse controller, a hydraulic control circuit board, a hydraulic input pipe and a hydraulic output pipe, and the hydraulic input pipe and the hydraulic output pipe are arranged under the hydraulic cylinder and are connected with the hydraulic cylinder. The and-packed model pipe full-automatic compacting device is advantaged in that the pulse controller is used for controlling two poles of the electromagnet to change; when the upward magnetic pole of the electromagnet is opposite to the downward magnetic pole of the compacting block, the compacting block is attracted downwards through a principle that unlike poles attract each other to carry out a compacting process; when the upward magnetic pole of the electromagnet is the same as the downward magnetic pole of the compacting block, the compacting block is pushed up through a principle that two like magnetic poles repel each other; and the sand-packed model pipe full-automatic compacting device replaces manual compacting operation, the labor intensity is reduced, and the work efficiency is improved.

Owner:QIDONG JOYSON TOYS CO LTD

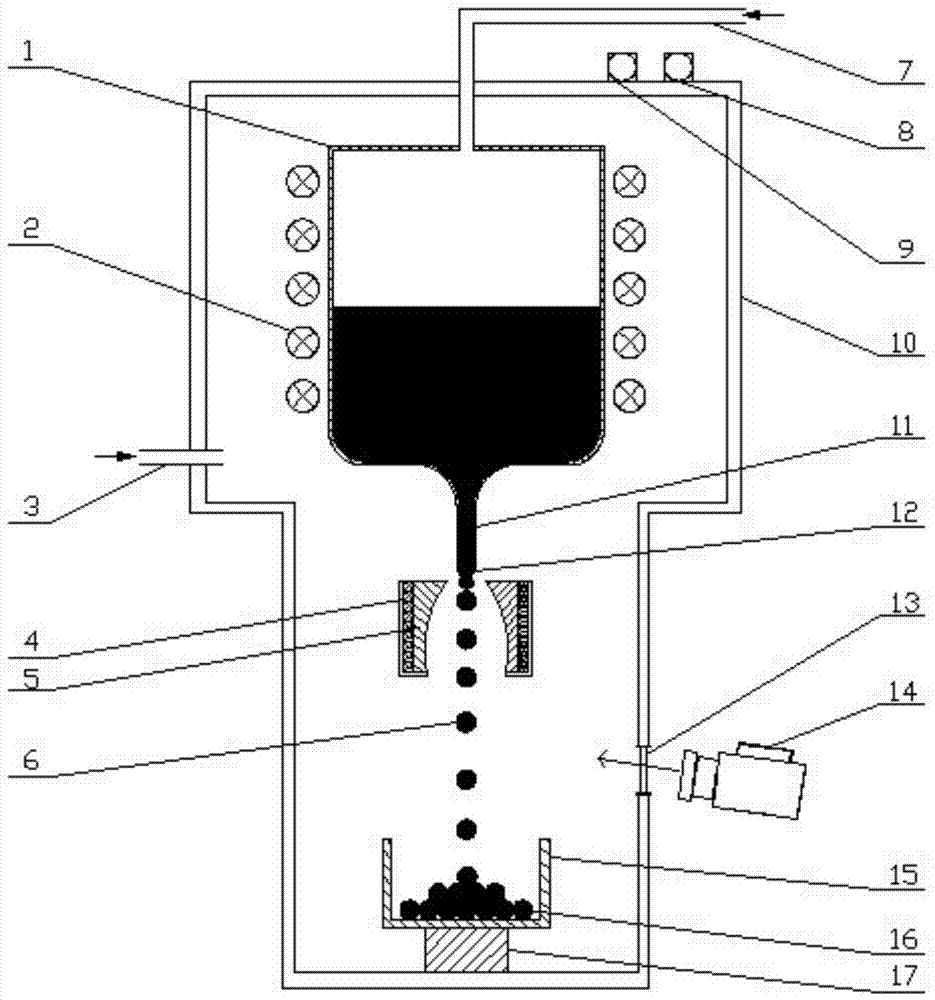

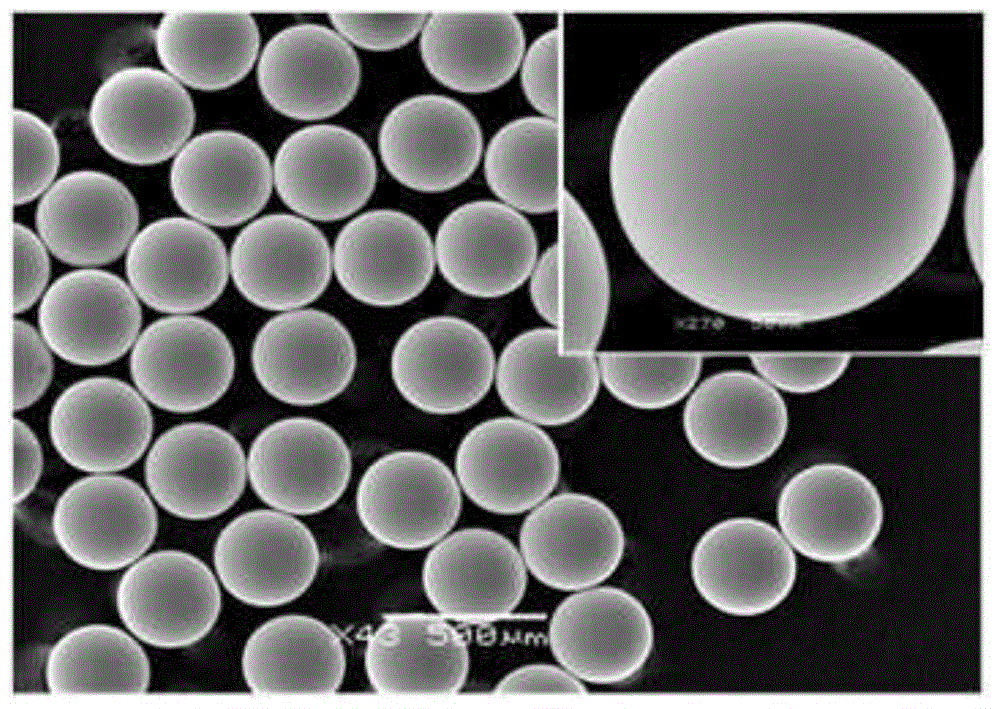

Device and method for manufacturing uniform spherical micro-particles

The invention discloses a device and a method for manufacturing uniform spherical micro-particles. The device comprises a crucible, an induction heater, an induction coil, a concentrator, a mechanical pump, a diffusion pump, a cavity, a high-speed camera and a collector. The device and the method have the advantages that capillary jet flow is cut by the aid of electromagnetic force to manufacture the uniform spherical micro-particle, metal materials molten in the crucible are ejected from small holes in the bottom of the crucible under the effect of pressures to form the capillary jet flow, the electromagnetic force is generated by the induction coil and acts on the capillary jet flow via the concentrator, sausage-shaped liquid droplet strings are gradually formed by the capillary jet flow under the disturbance effects of surface tension and the electromagnetic force and can be ultimately dispersed to form liquid droplets with consistent sizes and equal distances, and metal particles can be formed by the liquid droplets in containerless solidification procedures; the metal particles manufactured by the aid of the method are uniform in particle size (the relative deviation of the particle sizes is smaller than 1.8%) and are high in sphericity, and manufacturing materials can be prevented from being polluted by the crucible in the solidification procedures.

Owner:DALIAN UNIV OF TECH

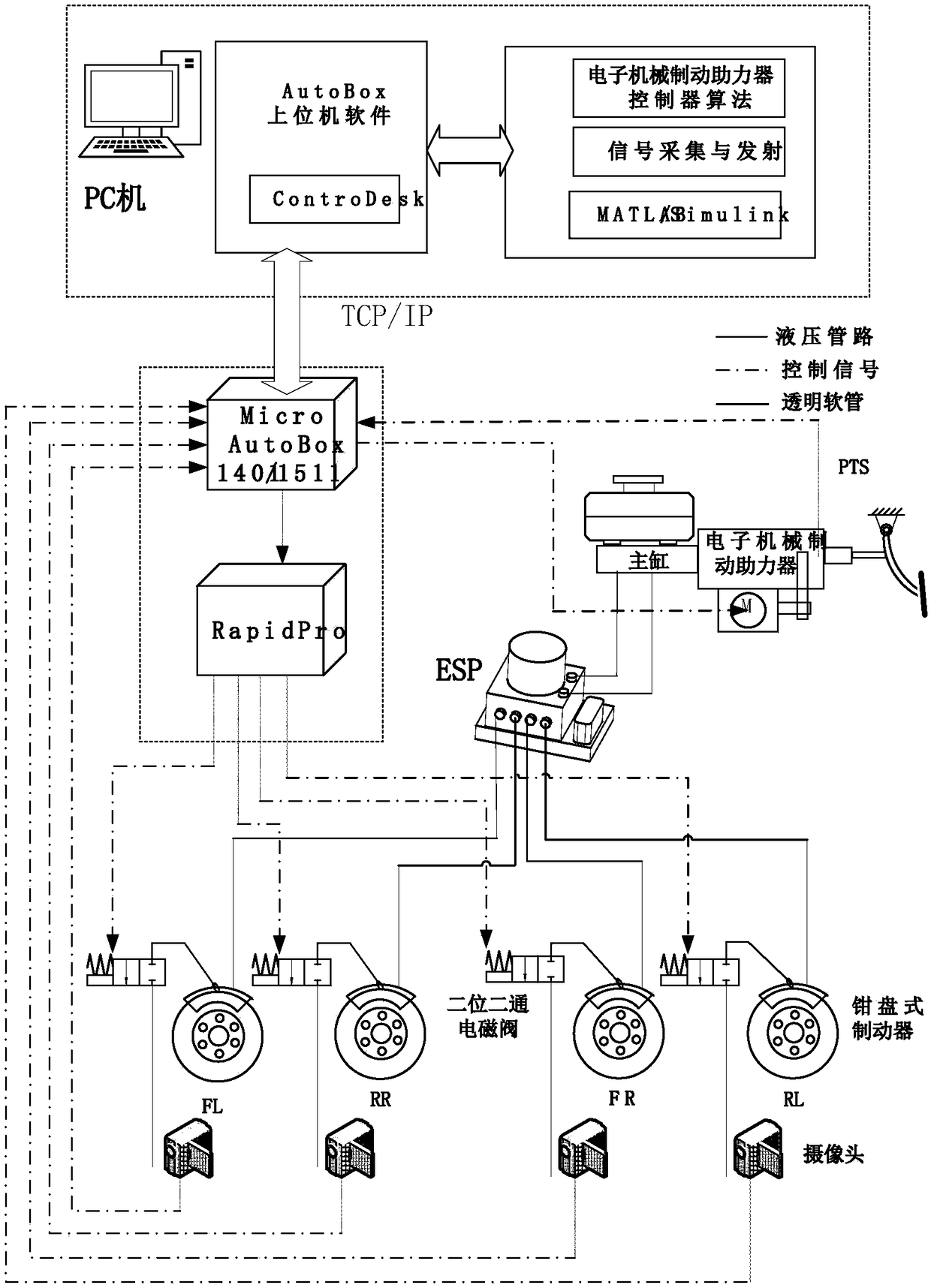

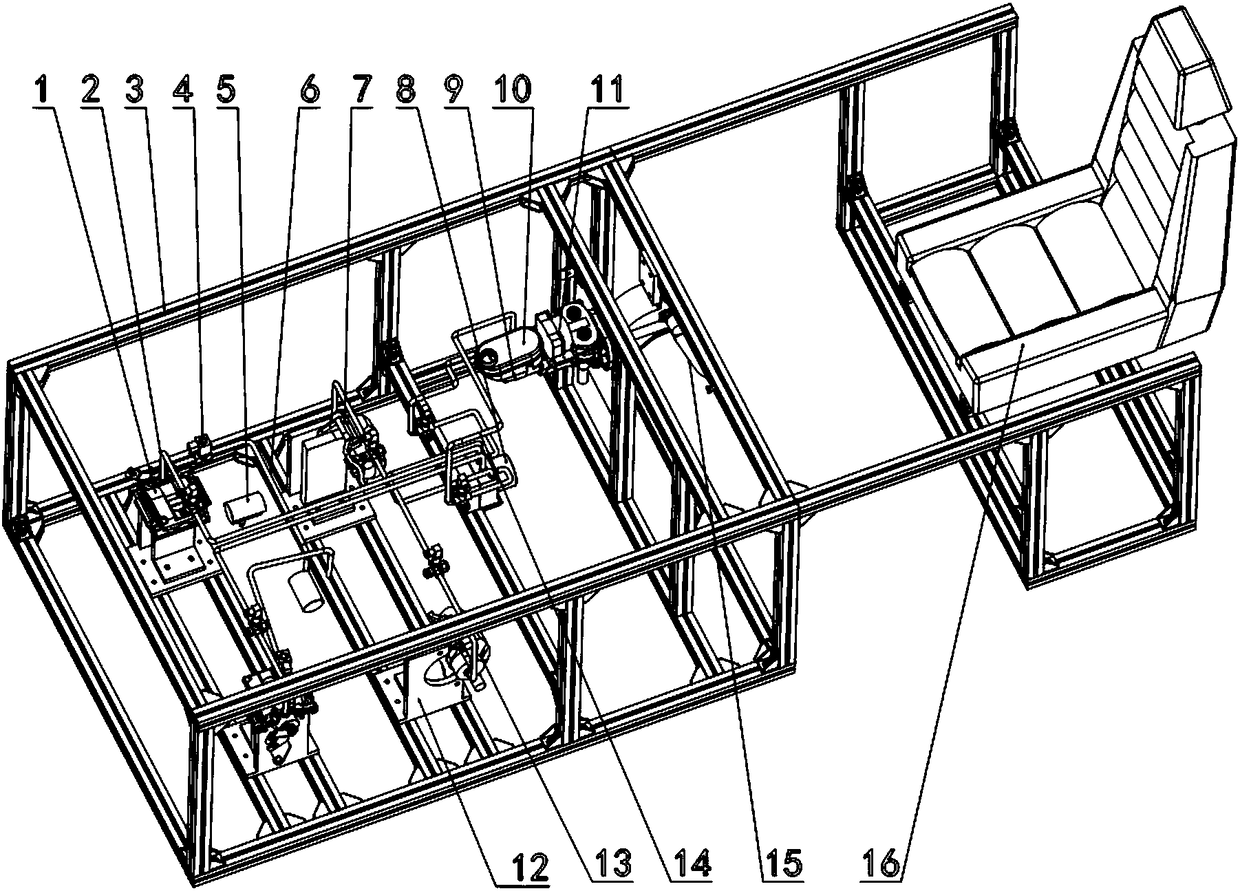

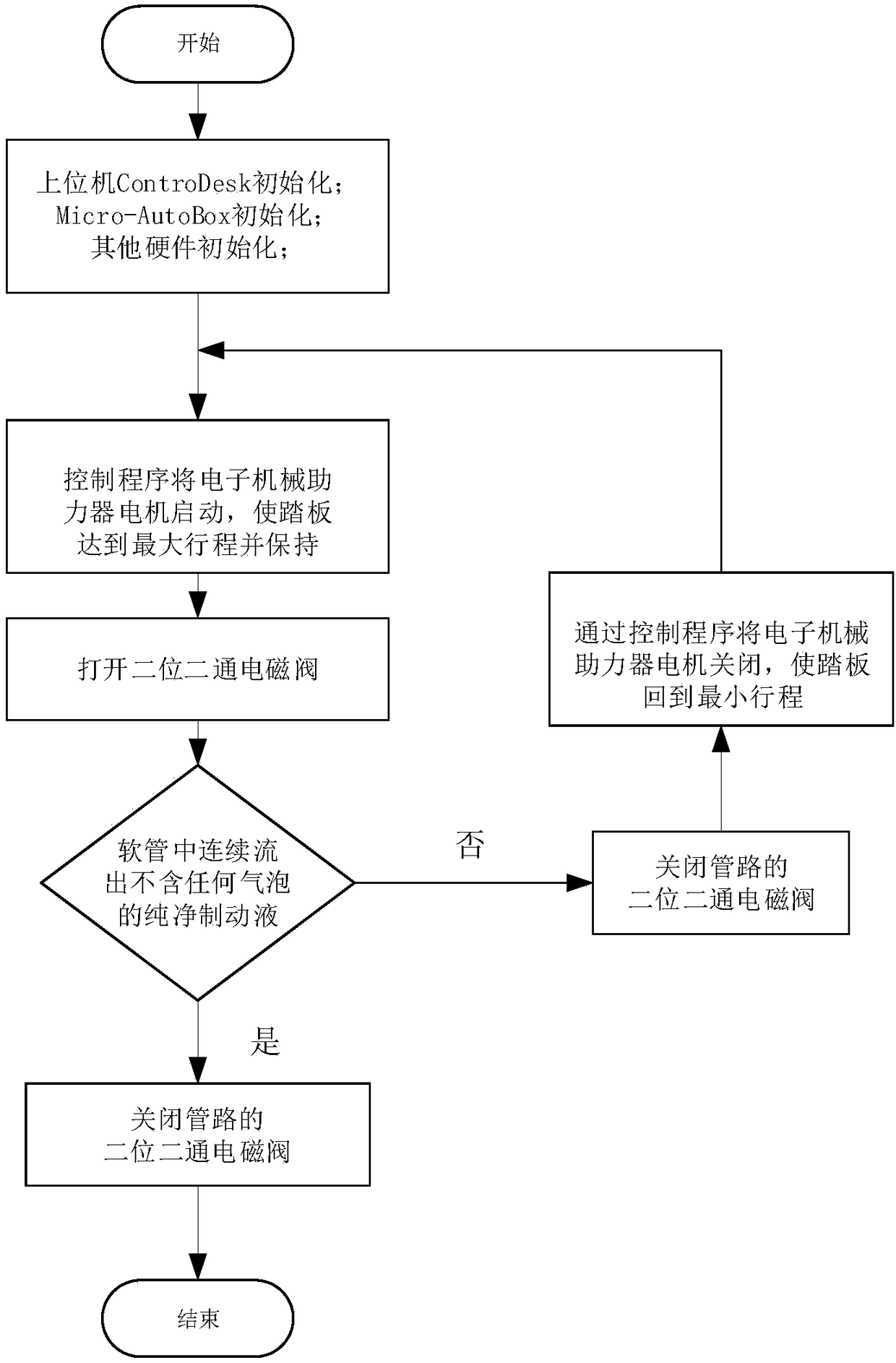

Hydraulic system automatic exhausting device and method for electro-hydraulic brake test bed

InactiveCN108167270ASolve the problem of high braking labor intensityControllable strokeFluid-pressure actuator testingFluid-pressure actuator componentsSolenoid valveElectro hydraulic

The invention belongs to a brake hydraulic pipeline exhausting method and particularly relates to a hydraulic system automatic exhausting device and method for an electro-hydraulic brake test bed. Thedevice comprises a front brake wheel cylinder, a test bed body, a transparent hose, a rear brake wheel cylinder, a vehicle electronic stabilization system, a brake master cylinder, a liquid storage pot, an electronic mechanical brake booster, a support, a brake pedal, an adjustable seat, a signal acquisition and transmission platform, a PC, brake master cylinder hydraulic pipelines, two-positiontwo-way solenoid valves, caliper disk brakes and brake wheel cylinder hydraulic pipelines. The device automatically judges the exhausting completion moment through recognition processing according tothe state, acquired by cameras, of brake fluid discharged from the transparent hose, controls rotation of a motor through an ECU of the mechanical brake booster to achieve operations of treadling a pedal and loosening the pedal by simulating a person. The device can be more accurate, efficient, convenient and thorough in automatic exhausting control. The problems that time and labor are wasted, exhausting is incomplete and brake fluid corrodes operators can be solved.

Owner:JILIN UNIV

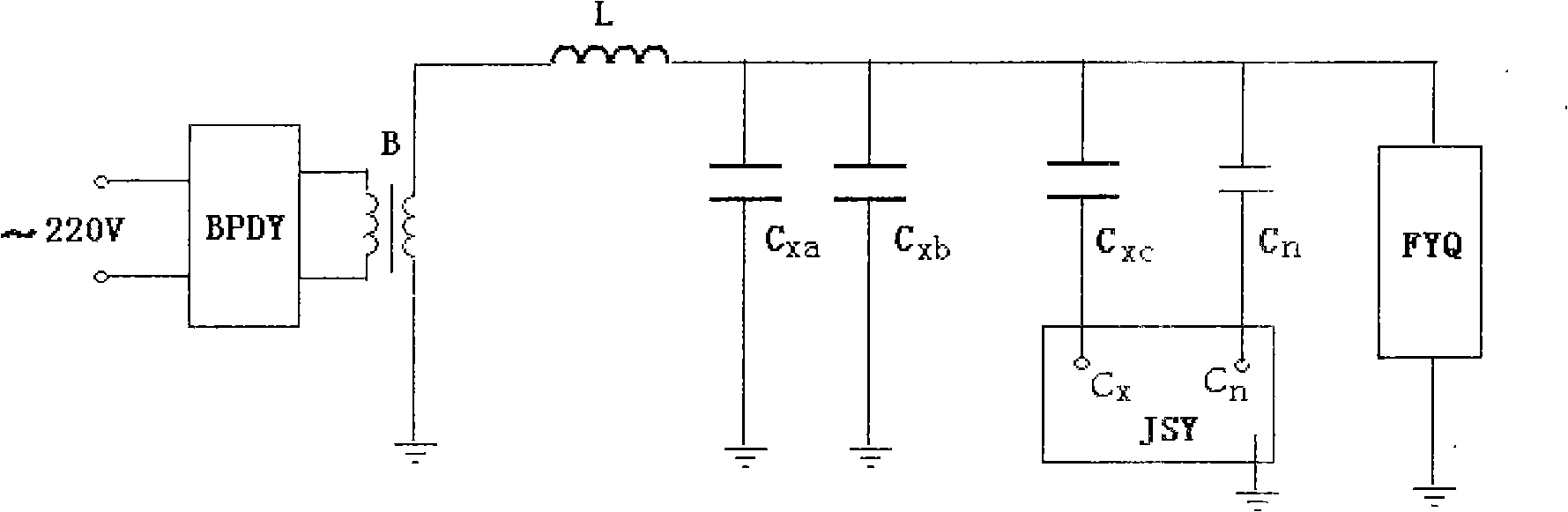

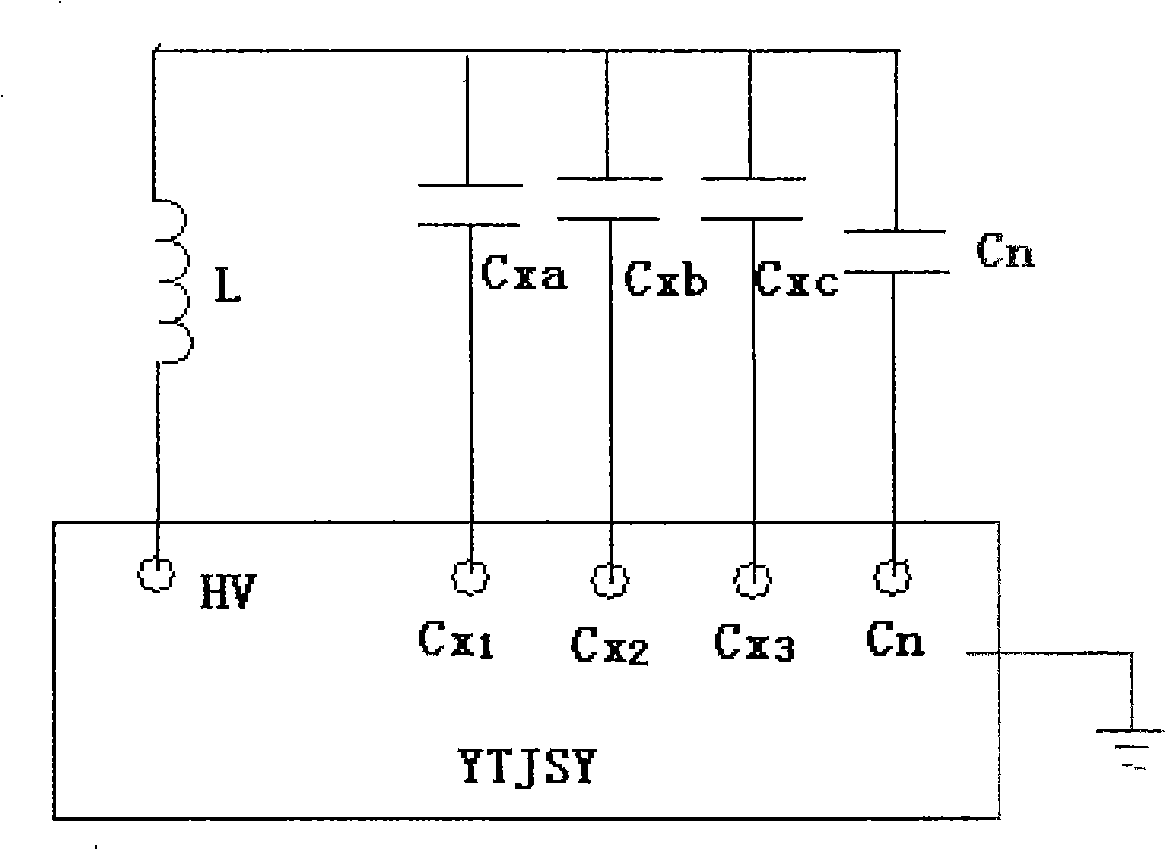

Method for testing capacitance type mutual inductor on site high voltage dielectric loss

ActiveCN101303380ASolve the problem of insufficientReduce capacityResistance/reactance/impedenceElectrical testingCapacitanceDielectric loss

The invention relates to a testing method for the field high-voltage dielectric dissipation of capacitive transformers, which adopts a frequency modulation series resonance set-up and a cordwood reactance for lap join compensation, three phases are connected in parallel and pressured at the same time, and the three phases are measured one by one or at the same time, thereby overcoming a plurality of defects of the testing power of the traditional method of large volume, cumbersome equipment, troublesome operations and certain influence on the onsite safe operation, etc. The whole testing device has the advantages of less parts, small volume, light weight and functions of anti-interference and testing three to-be-tested devices at the same time, thus being suitable for application on site.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Electromagnetic pile driver

The invention discloses an electromagnetic pile driver which comprises a fixed disc, electromagnets arranged in the fixed disc, a movable disc, closed coils and an electromagnetic hammer formed on the movable disc, wherein the closed coils are arranged on the movable disc and correspond to the electromagnets. Electric energy is adopted as the energy source by the pile driver, the electromagnets are arranged in the fixed disc, the closed coils are arranged in the movable disc, the electromagnetic hammer is connected to the movable disc, and the intensity of the electromagnets is changed according to the Lenz law to achieve piston movement of the movable disc, so that precise control over the pile driving force and frequency is achieved; meanwhile, energy is saved, emission is reduced, and noise is lowered.

Owner:江苏易琥珀智能科技有限公司

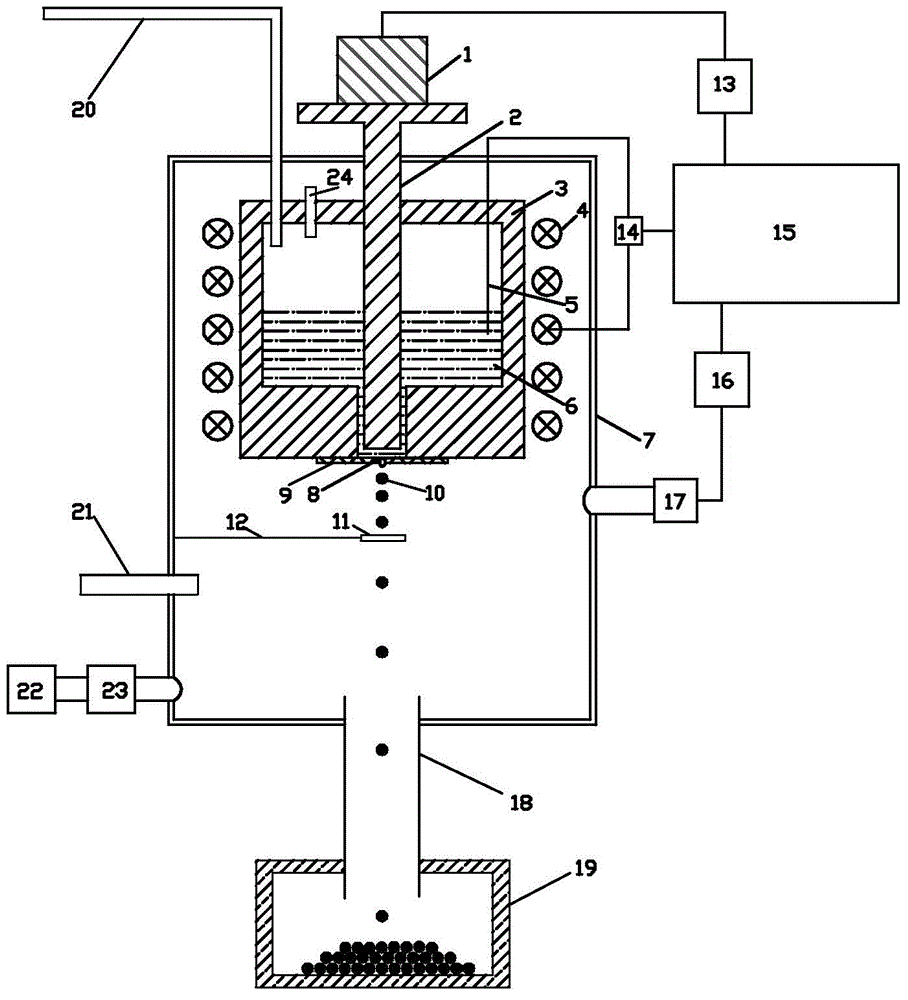

Method and device for manufacturing metallic glass particles

ActiveCN104096845AConsistent thermal stateAvoid uncontrollable factors such as heterogeneous nucleationElectricityDifferential pressure

The invention discloses a method and a device for manufacturing metallic glass particles, and belongs to the field of technologies for manufacturing metallic glass. The method includes generating stable differential pressures of 0-50KPa for metal melts in molten states under a vacuum condition; generating certain pulse signals for a piezoelectric ceramic to act on the metal melts; ejecting tiny liquid droplets from a hole in the bottom of a crucible; quickly cooling and solidifying the tiny liquid droplets without containers to form the spherical metallic glass particles. The device comprises a vacuum chamber. A particle collecting device is mounted at the bottom of the vacuum chamber, a liquid droplet ejecting system is mounted on the top of the vacuum chamber and is positioned right above the particle collecting device, and an image acquiring system is connected onto the vacuum chamber of a vacuum system. The method and the device have the advantages that the metallic glass particles are manufactured by a pulse hole ejecting process, the tiny liquid droplets are quickly solidified without the containers, accordingly, the particles with uniform and consistent particle sizes and high sphericity can be obtained, the particle sizes can be controlled, the manufacturing efficiency is high, and problems of low cooling speed, uneven particle size distribution, inconsistent thermal history and the like of an existing technology for manufacturing metallic glass particles can be solved.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

Controllable gas vibrating system

The controllable gas vibrating system includes one exciting barrel, one piston, one guide bar, two baffle plates separately on two ends of the exciting barrel to form one sealed space together with the exciting barrel, ball valves, two motors and one control system to control the rotation of the motors. The piston is set on the guide bar for sliding relatively to the guide bar and inside the sealed space to separate the sealed space into one right gas chamber and one left gas chamber with ball valve controlled gas inlet and gas outlet each. The controllable gas vibrating system has controllable vibrating frequency, low cost and use convenience.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

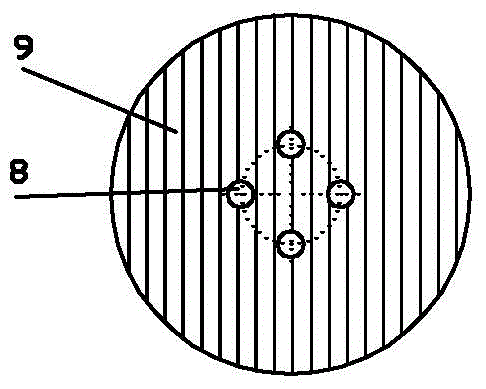

Medium loading adjustable filter, design method thereof, and adjustable duplexer

The invention discloses a medium loading adjustable filter which comprises a rectangular waveguide, a tuning medium piece, and a driving mechanism. The cavity is divided into a plurality of resonant cavities by a set of partition walls arranged in the cavity and parallel to the E face, the wide edge pipe wall of one side of the rectangular waveguide is provided with at least one slit correspondingto the position of each resonant cavity, the slit is distributed along the bisector of the E face, and the length direction of the slit is parallel to the E face, the tuning medium piece is a comb-shaped structure with a set of comb teeth pieces, the length and the thickness of each comb tooth piece are the same, all the comb teeth pieces of the comb-shaped structure can be inserted into the cavity of the rectangular waveguide without friction through the slit at the same time, the number of the comb teeth pieces inserted into each resonant cavity is the same; and the driving mechanism is used for driving the tuning medium piece and adjusting the insertion depth. The invention further discloses a design method of the filter and an adjustable duplexer. According to the invention, the electrical performance is better, the structure is simpler, and the production cost is lower.

Owner:PIVOTONE COMM TECH

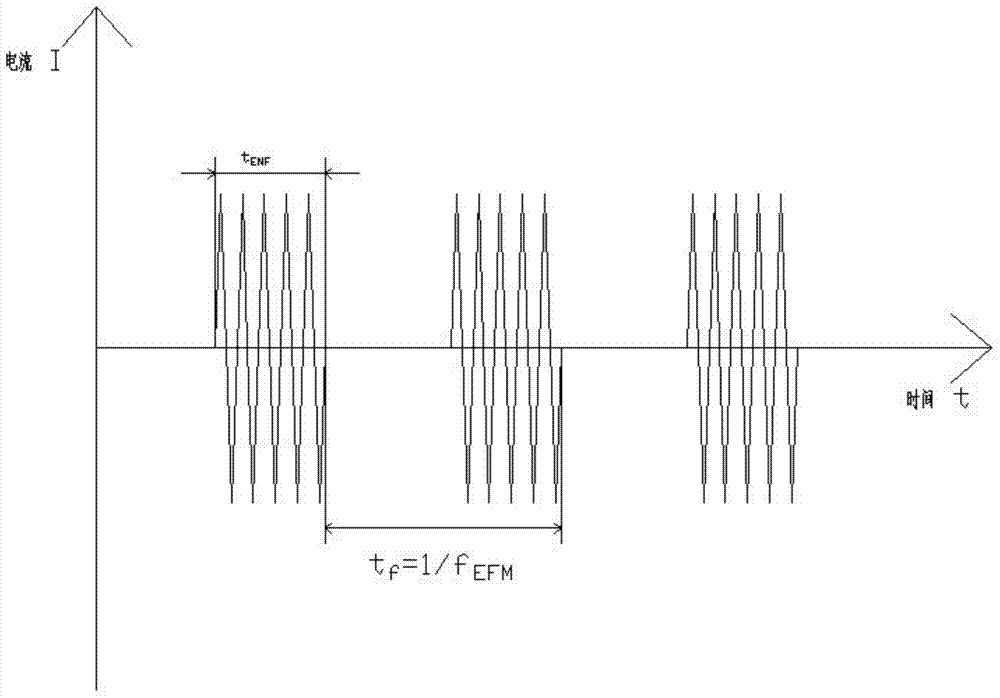

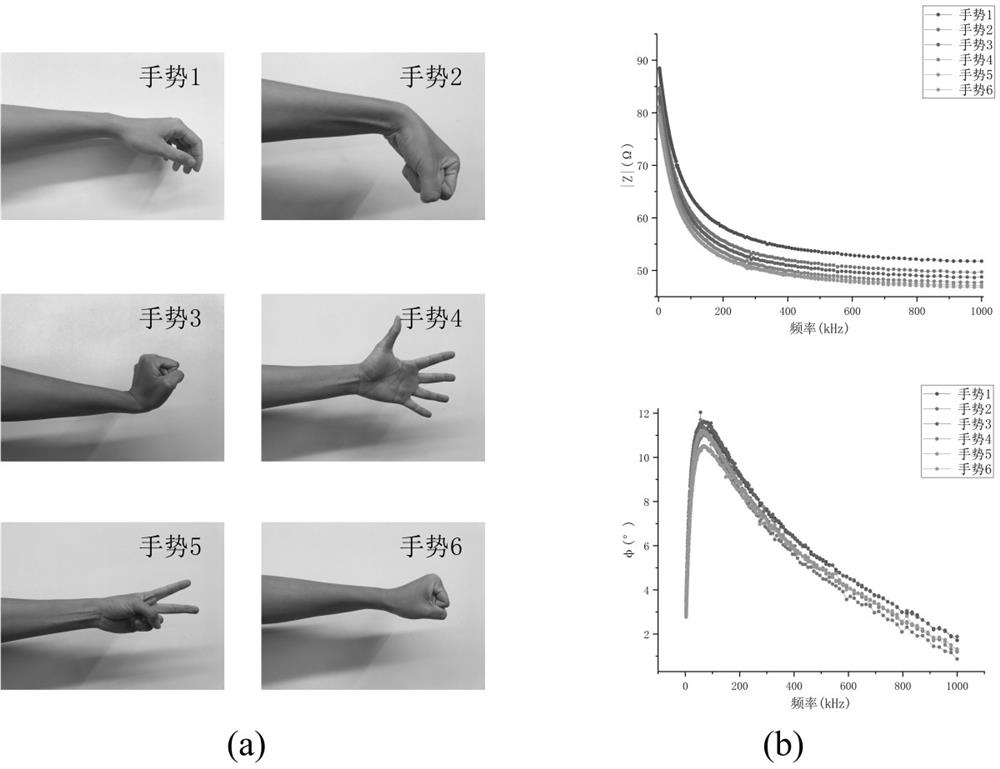

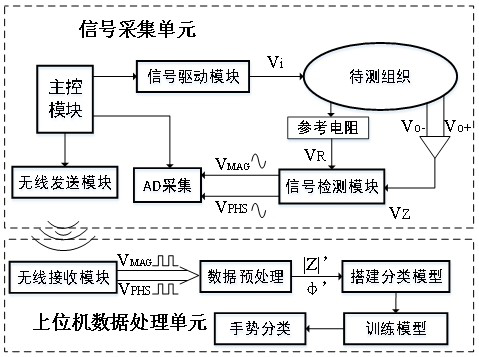

Gesture recognition system and method based on muscle electrical impedance signals

PendingCN112101298AHigh shrinkage sensitivityHigh sensitivityCharacter and pattern recognitionNeural architecturesMuscle contractionWireless transmission

The invention relates to a gesture recognition system based on muscle electrical impedance signals. The gesture recognition system comprises a signal acquisition unit and an upper computer data processing unit, the signal acquisition unit comprises a main control module, a signal driving module, a signal detection module, an AD acquisition module and a wireless communication module; the main control module is connected with the signal driving module, the AD acquisition module and the wireless communication module; the signal detection module is respectively connected with an electrode and theAD acquisition module; the wireless communication module is connected with an upper computer through wireless transmission and transmits collected signals to the upper computer for processing. The system and method can directly reflect the intrinsic state of the muscle, has good sensitivity to low-speed movement, and is high in muscle contraction sensitivity, good in robustness, large in signal amplitude, controllable in frequency and simple in preprocessing.

Owner:FUZHOU UNIV

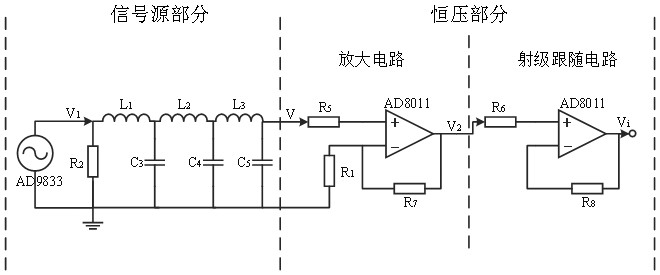

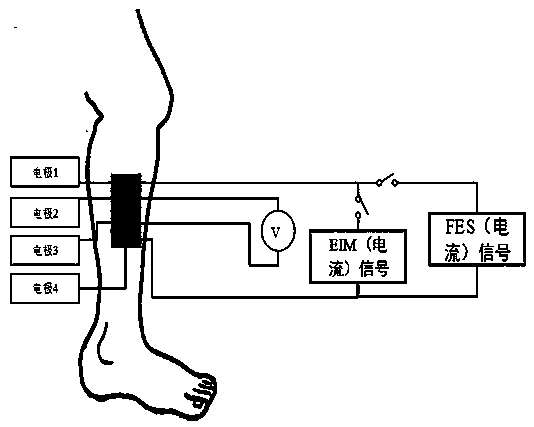

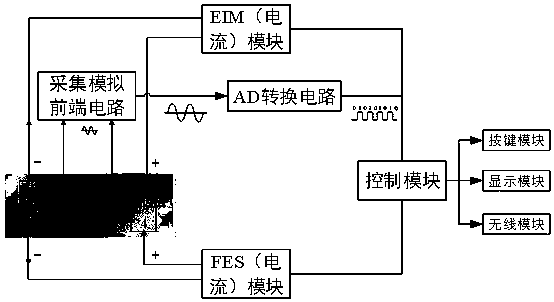

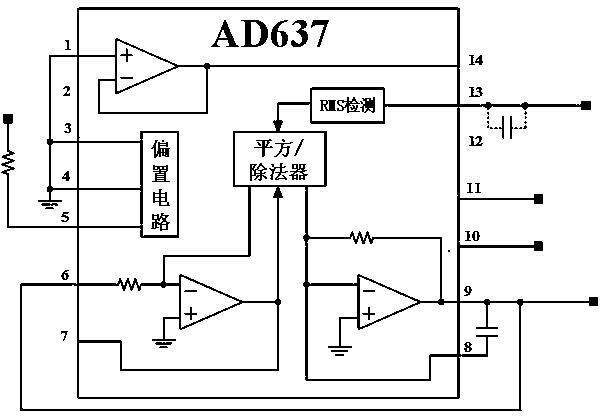

Electrical stimulation system with fatigue evaluation function

PendingCN110522999ALess susceptible to interferenceIncrease amplitudeElectrotherapyDiagnostic recording/measuringElectricityMultiplexing

The invention provides an electrical stimulation system with a fatigue evaluation function. The electrical stimulation system comprises a multiplexing electrode slice, an EIM excitation current module, an FES stimulation current module, a control module and an acquisition module, and the multiplexing electrode slice is connected with the EIM excitation current module, the FES stimulation current module and the acquisition module respectively. The EIM excitation current module is used for generating an excitation current signal; the FES stimulation current module is used for generating FES stimulation signals. The electrical stimulation system has the advantages of being simple in feedback control process, stable in measurement process during resting, good in robustness and not prone to being disturbed by external factors, the amplitude of the feedback signals is large, the frequency is controllable, and preprocessing is simple. According to the scheme, on the basis of the electrical stimulation system, an EIM detection link is added, the stimulated local muscle fatigue state is fed back to the system in real time, excessive treatment caused by muscle fatigue is avoided, and the rehabilitation effect is improved.

Owner:FUZHOU UNIV

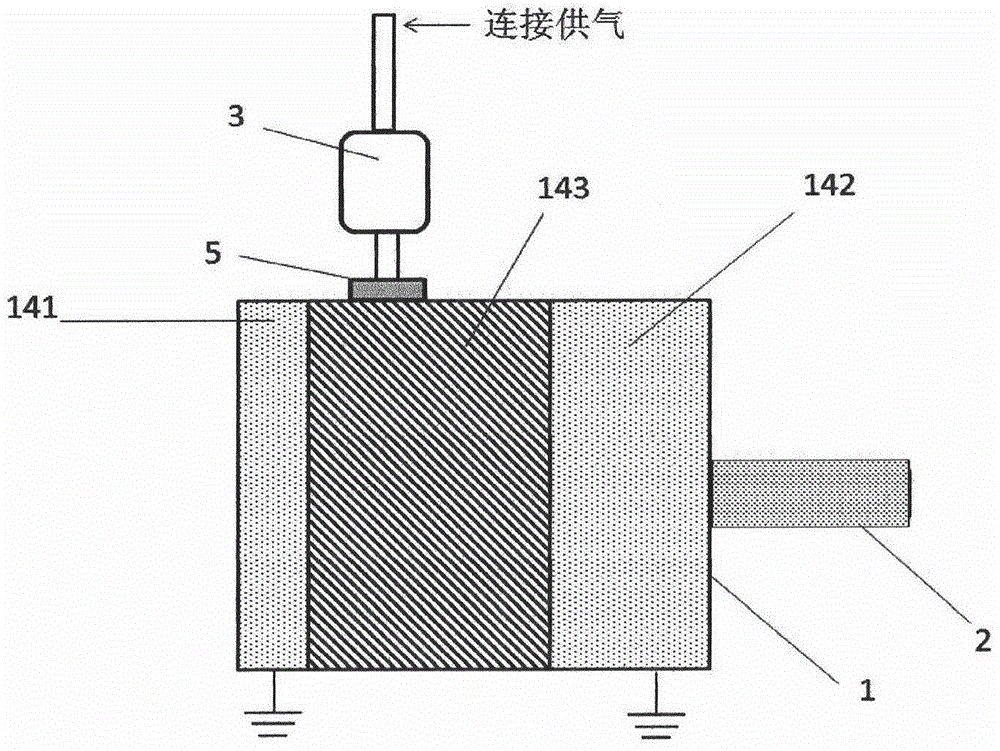

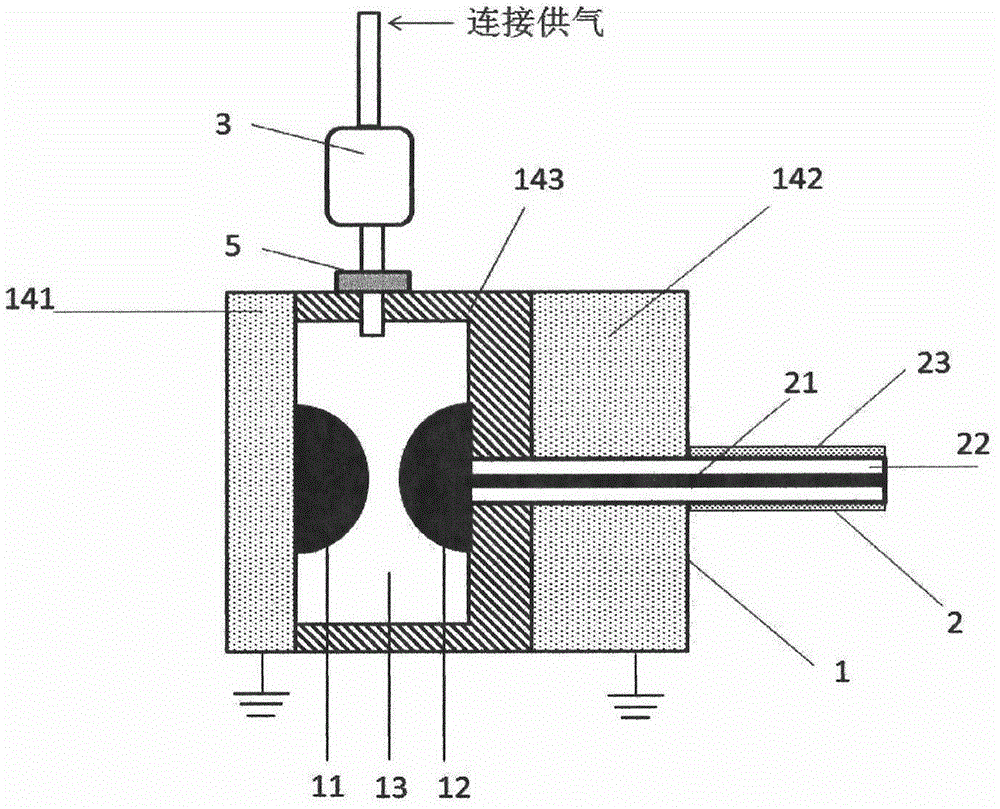

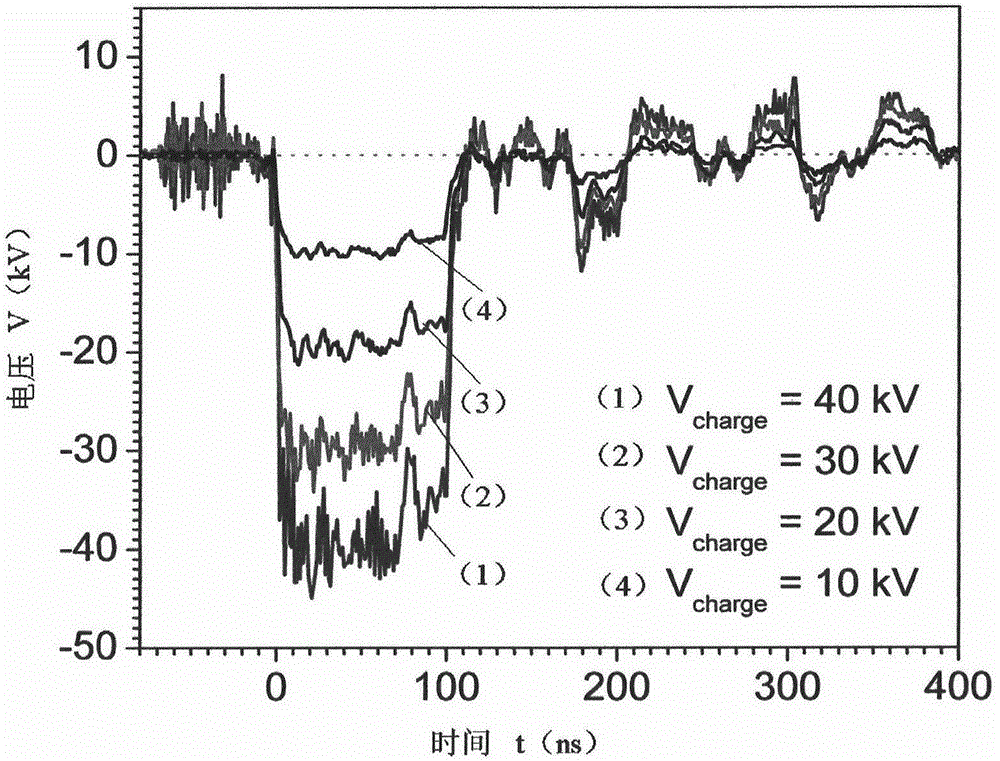

Gas spark gap switch for nanosecond pulse generator

InactiveCN104953470AReduce coupling capacitanceAdjustable electrode spacingSpark gaps with auxillary triggeringCapacitanceEngineering

The invention provides a gas spark gap switch for a nanosecond pulse generator. The gas spark gap switch comprises a coaxial cable, a high-voltage spark discharge electrode, a grounding spark discharge electrode and an electronic gas pressure controller, wherein the coaxial cable is arranged on one side of a gas cavity, the high-voltage spark discharge electrode and the grounding spark discharge electrode are arranged in the gas cavity, the high-voltage spark discharge electrode is connected with the coaxial cable, the grounding spark discharge electrode is connected with a ground electrode, and the electronic gas pressure controller is used for controlling spark discharge and extinguishing of the high-voltage spark discharge electrode and the grounding spark discharge electrode by controlling gas pressure in the gas cavity. The switch is integrally of a coaxial structure and has characteristic impedance matched with a pulse forming network, electrode spacing is adjustable, the switch is low in coupling capacitance, spark inductance and spark resistance, high in repetition frequency and wide in adjustable puncture voltage range, generated nanosecond pulse rising edge is rapid, the shape of nanosecond pulse is close to ideal rectangular pulse, and spark discharge is controlled by the gas pressure controller.

Owner:庄杰 +1

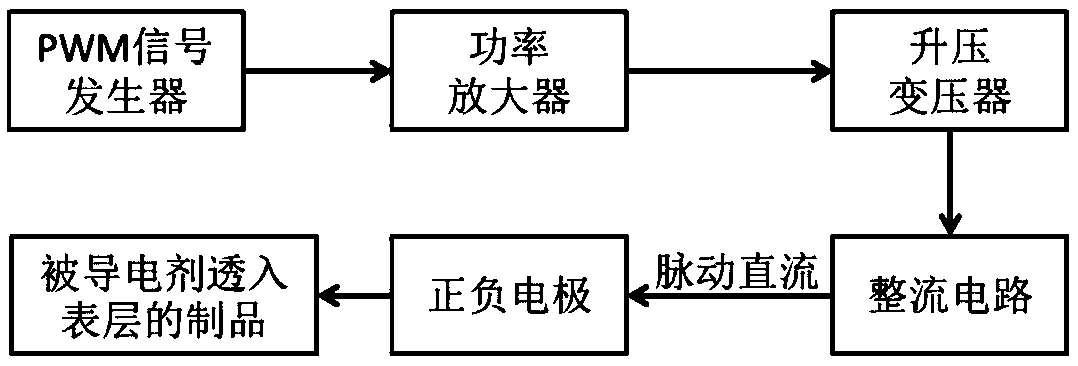

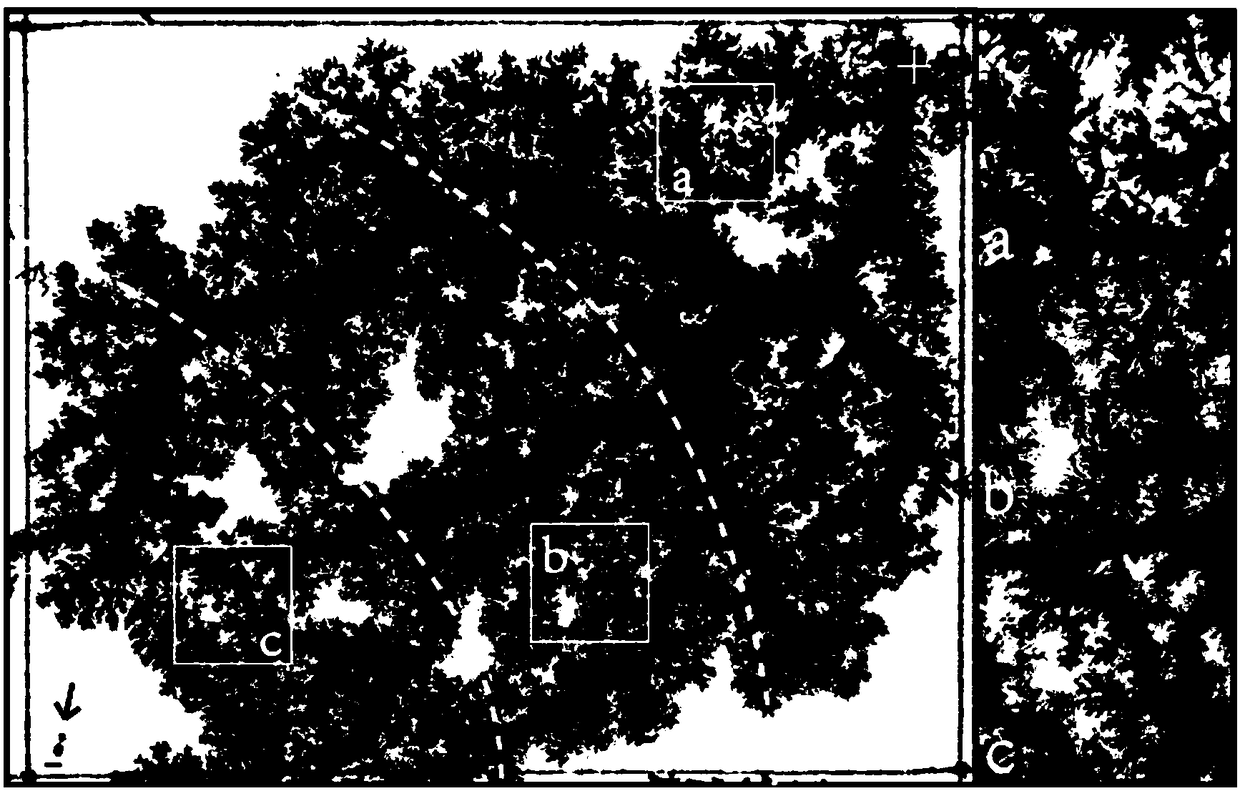

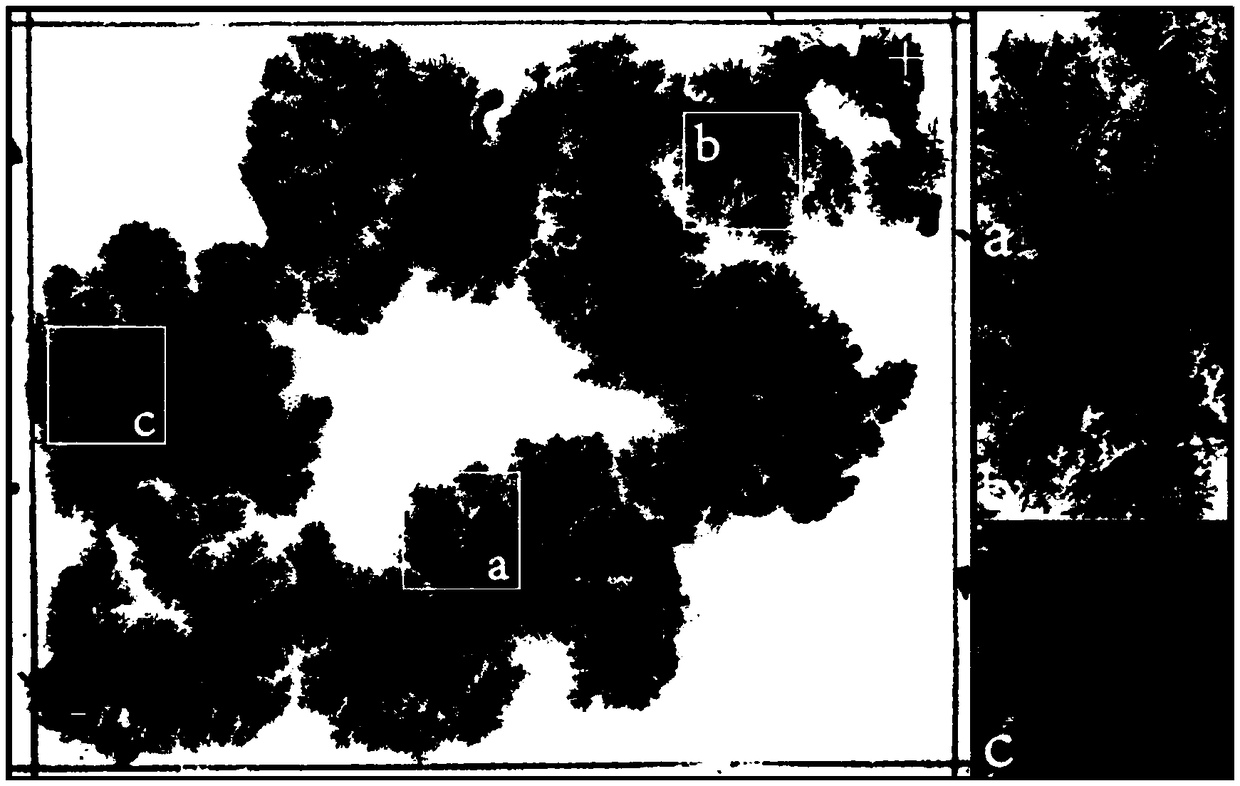

Method and device for obtaining high-voltage electricity surface unipolar discharging trace

ActiveCN108638726AAvoid self-healing phenomenonReduce weightSpecial ornamental structuresTransformerOperability

The invention provides a method and device for obtaining a high-voltage electricity surface unipolar discharging trace. Through cooperation of a conductive additive, the unipolar discharging trace canbe obtained on the surface of a product through pulse direct current. In the method and the device, a PWM signal generator generates a drive signal, a direct-current pulse voltage is obtained by stimulating a boosting transformer and a rectifying circuit through a power amplifier, the voltage is transmitted to a positive electrode and a negative electrode, the positive electrode and the negativeelectrode are then placed on the product where the conductive additive permeates the surface layer, surface discharging is conducted from an anode or a cathode, and the unipolar discharging trace is left on the surface layer of the product. The macroscopic pattern of the discharging trace has fractal features and can be used for artistic creation, fractal picture template manufacture and craft manufacture. Compared with a method and device for obtaining a discharging trace by applying the industry alternating-current high voltage on the surface of a wet material, the method has the beneficialeffects that unipolar control is achieved, operability is high and pattern continuity is ensured; and the device has the beneficial effects that the device is easy to obtain and the structure is simple.

Owner:BEIJING UNIV OF TECH

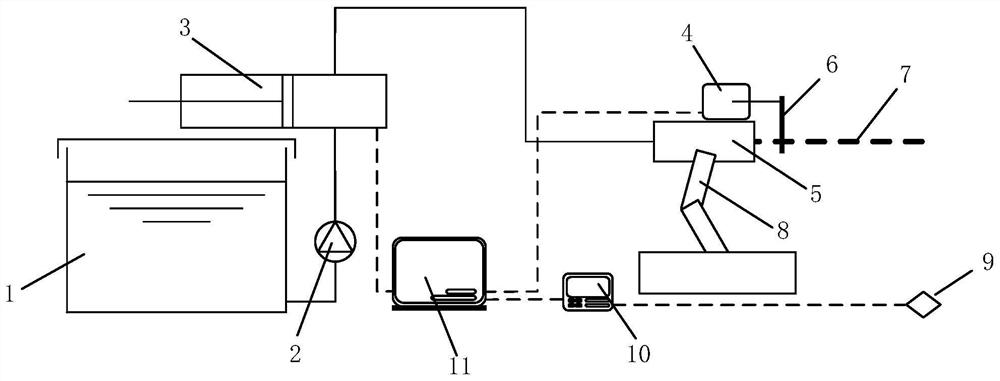

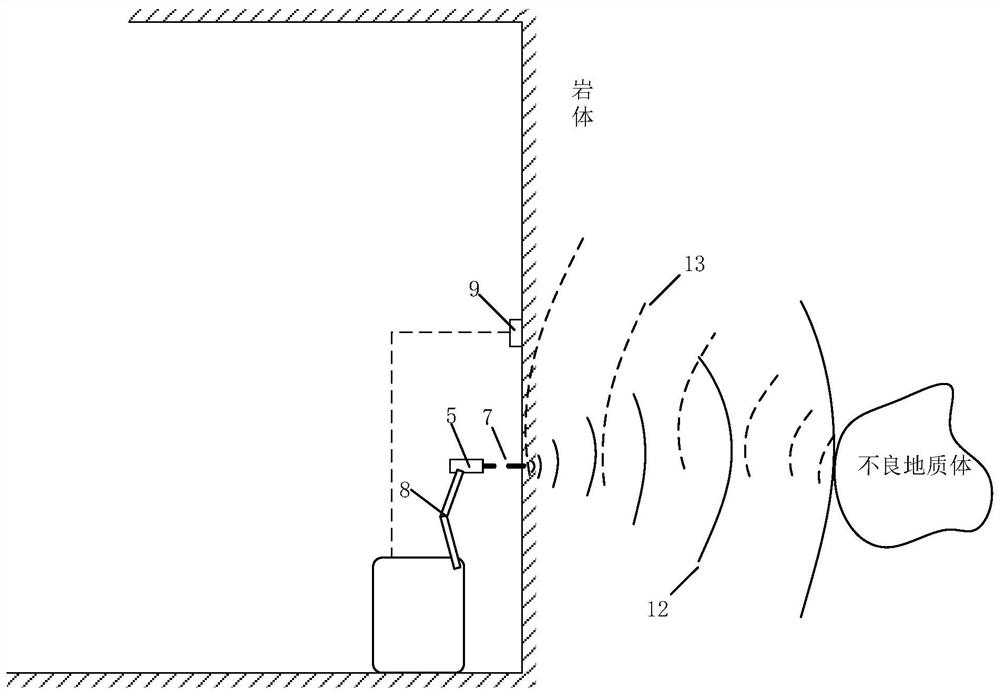

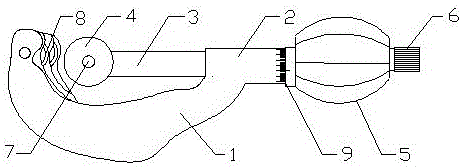

High-pressure pulsed water jet controllable active seismic source advanced detection device and application method

ActiveCN110632645BWide variety of sourcesNo explosive effectSeismic signal receiversReflected wavesData acquisition

The invention provides a high-pressure pulsed water jet controllable active seismic source advanced detection device and its use method. The detection device includes a water tank, a water supply pump, a supercharger, a servo motor, a convergent nozzle, a receiving sensor and a seismic wave data acquisition instrument, and the water supply pump is respectively Connect the water tank and the supercharger, the supercharger is connected to the convergent nozzle, the output shaft of the servo motor is connected to the block; the receiving sensor is connected to the seismic wave data acquisition instrument, the water supply pump pumps the water in the water tank into the supercharger, and the supercharger is pressurized The high-pressure water jet is formed, the servo motor drives the block to rotate, and the block is cut off to form a high-voltage pulse jet beam. The high-voltage pulse jet beam hits the working surface to generate shocking seismic waves, and receives the reflected waves from the sensor. The seismic wave data acquisition instrument collects the reflected waves in real time and transmits them to the smart terminal. , the intelligent terminal analyzes the reflected waves and judges the characteristics of bad geological bodies. The invention has the beneficial effects of scientific principle, safety and high efficiency, energy saving and environmental protection, and good application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Jiggle corrosion abrasion-micro amplitude collision abrasion test machine

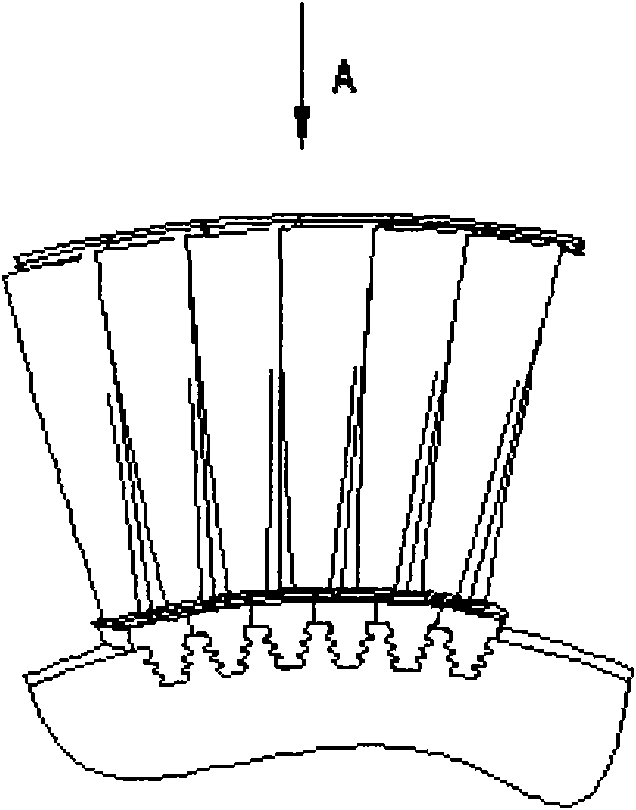

ActiveCN101666731AEasy to replaceAchieve displacementGas-turbine engine testingInvestigating abrasion/wear resistanceAviationIndustrial gas

The invention provides a jiggle corrosion abrasion-micro amplitude collision abrasion test machine. The test machine consists of a main machine and a system, wherein the system comprises a measurementcontrol system and a cooling system; the main machine comprises a device base, a driving motor, an eccentric wheel mechanism, a lever-type swinging-arm mechanism and an electric heating furnace; thelever-type swinging-arm mechanism drives a shaft pin of a rolling bearing serving as a rotating center, and is arranged on the device base through front and rear brackets with balls; a frequency-variable motor enables the lever-type swinging-arm mechanism to produce reciprocating swing by using the shaft pin as the center and using a pin roller bracket as a plane through an eccentric wheel which is arranged at the shaft end and provided with the rolling bearing; each part is lubricated by lubricating grease; and a hole at the bottom of the electric heating furnace enables the lower part of a swinging-arm test section to be supported on the pin roller bracket. The test machine is used for representing the jiggle corrosion abrasion and micro amplitude collision abrasion work properties of crowned turbine blades, blades with various intermediate damping tables and blade vibration damping device and the like in the power mechanical devices in aviation, ship, industrial gas turbine and steam turbine and the like, and can be applied to the similar machinery.

Owner:HARBIN GUANGHAN GAS TURBINE

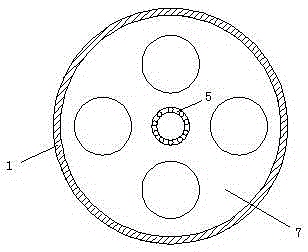

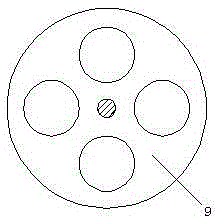

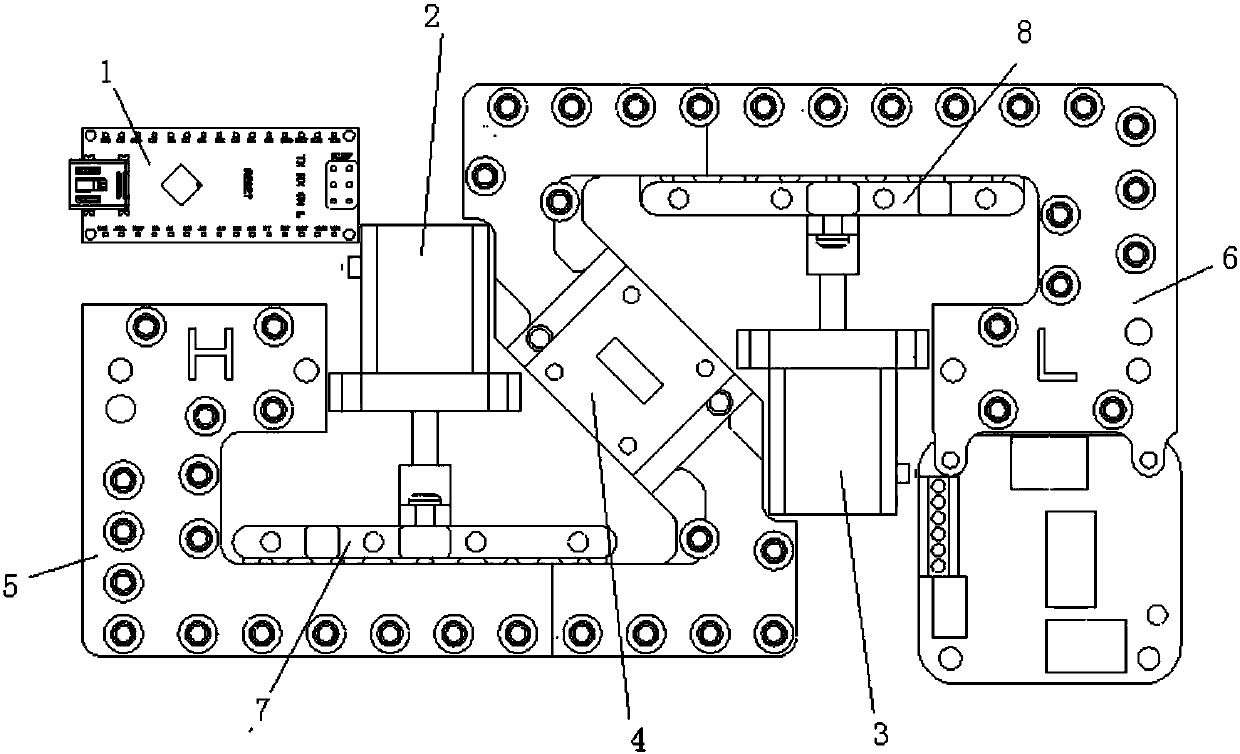

Method and device for filling of vertical through hole

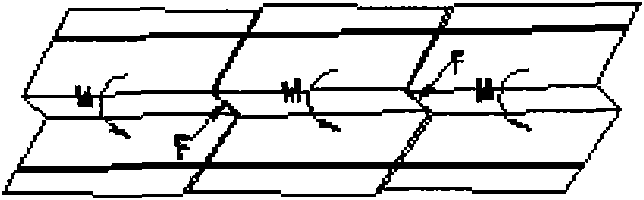

ActiveCN105671473AHigh dimensional accuracyFrequency controllableMolten spray coatingSemiconductor/solid-state device manufacturingLiquid lineLiquid jet

The invention discloses a method and device for filling of a vertical through hole. The device comprises a metal liquid jetting device and a filling working zone, and is characterized in that a crucible is of a cylindrical structure with the center line as an axis and connected with the upper portion of a cavity through a crucible support connected with a three-dimensional motion controller, and cavity temperature controllers for maintaining the temperature of the cavity are further arranged on the two sides of the middle portion of the cavity; and the filling working zone comprises a substrate used for receiving even liquid drops or stead flow liquid lines jetted out from the metal liquid jetting device and a substrate bearing part used for containing the substrate. The invention further discloses the method for filling of the vertical through hole through the above device. According to the method and device, as the metal liquid jetting device is cooperated with a working table of the filling working zone, uniform liquid drops can be formed, the frequency is controllable, the stead flow liquid lines can also be formed, metallization filling of the vertical through hole is achieved, the size accuracy is high, the porosity is low, the filling efficiency is high, the cost is low, the process is simple, and automatic production can be achieved.

Owner:DALIAN UNIV OF TECH

Automatic glue brushing device for plastic bottleneck

InactiveCN111111998APrevent collapseGuaranteed not to dropLiquid surface applicatorsCoatingsAdhesive glueBrush device

The invention discloses an automatic glue brushing device for a plastic bottleneck. The device comprises a control console mechanism, a glue brushing mechanism and a glue bonding mechanism. A container is firmly clamped through elastic restoring force of an elastic clamping ring, it is ensured that the container does not fall down, the device stability is improved, a plastic bottle to be sealed isplaced under the brush coating mechanism, a bending arm is pressed down to drive brush discs to stretch into the container containing glue to be dipped with glue and then lifted, the brush discs dipped with glue are driven by a rotating shaft to be moved to the portion above the bottleneck of the plastic bottle to be sealed, the bending arm is pushed down so that the brush discs brush glue to thebottleneck and then lifts the bottleneck, a STM32F407 type single-chip microcomputer inside an electric control box achieves the controllable frequency in the glue brushing process, the intelligent degree is increased, another set of brush discs are pushed down to be dipped with glue while the brush discs brush glue to the bottleneck of the plastic bottle, then the glue brushing process is performed repeatedly, by arranging four sets of brush discs, the glue brushing working efficiency is improved, the working time is shortened, the workloads of workers are reduced, and the practicability isimproved.

Owner:长兴新亚环保机械科技股份有限公司

Transverse defect verification method in eddy current testing and pipe cutting device with vernier adjustment knob

InactiveCN106680365AImprove accuracyLow costMaterial magnetic variablesEddy-current testingEngineering

The invention discloses a transverse defect verification method in eddy current testing, comprising the following steps: adopting an eddy current testing detection flow line; determining the position of a flaw on a steel wire; determining the initial scale of a flaw of the pipe cutting device with the vernier adjustment knob; determining the depth of the flaw on the steel wire; determining the length of the flaw on the steel wire; starting a drawing device for drawing the steel wire, and starting a flaw detection device to carry out flaw detection; if the flaw detection device can detect the flaw position and alarm for stoppage, proving that the flaw detection device satisfies requirements on sensitivity; and if the flaw detection device cannot detect the flaw position, proving that the flaw detection device is insufficient in sensitivity and needs repair. The transverse defect verification method adopts an on-line flaw cutting and on-line verification scheme, the flaw is cut with the pipe cutting device during the production process of the steel wire, the length and depth of the flaw are determined, then a detector is used for detecting the flaw for verifying the sensitivity of the detector, and the method is quick, high in accuracy, lower in cost and flexible and convenient in use due to controllable verification frequency and controllable defect size.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

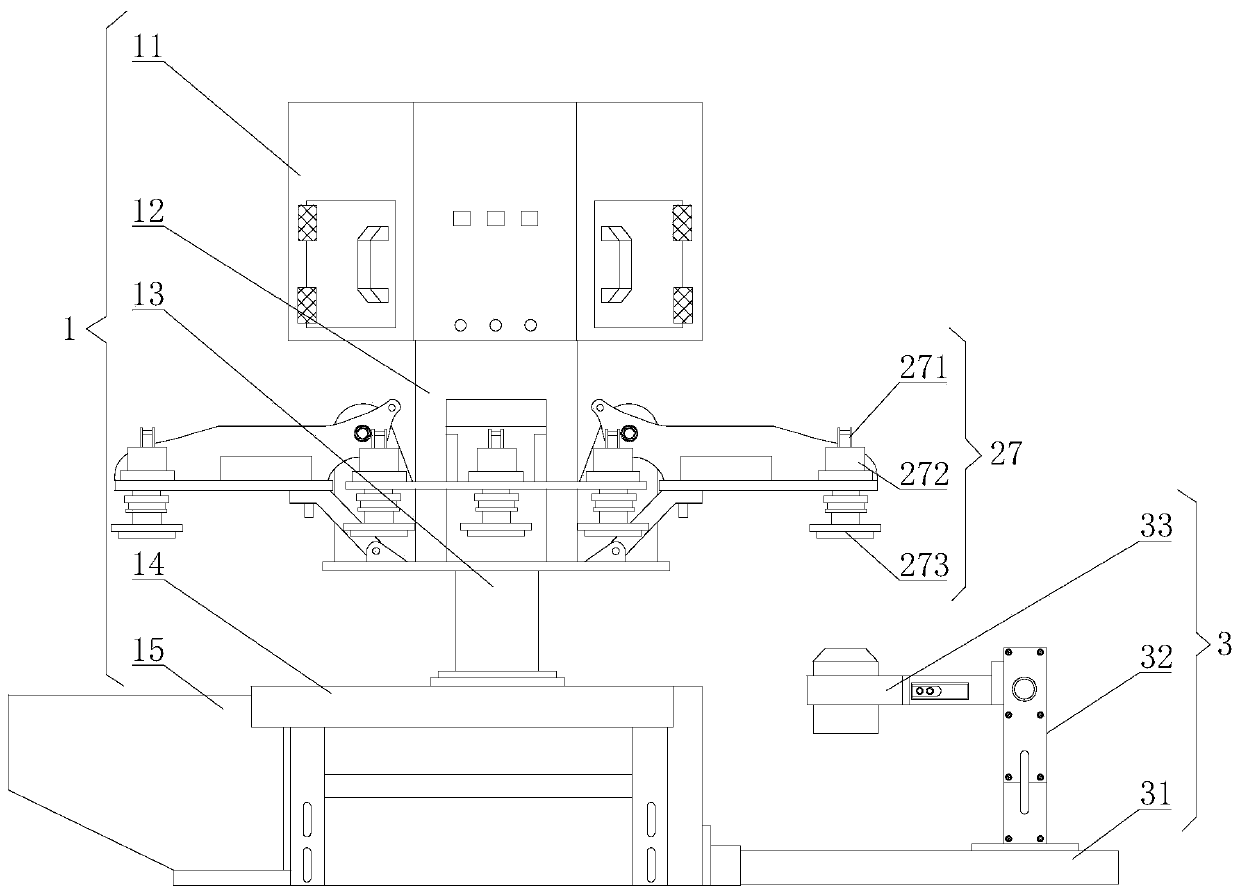

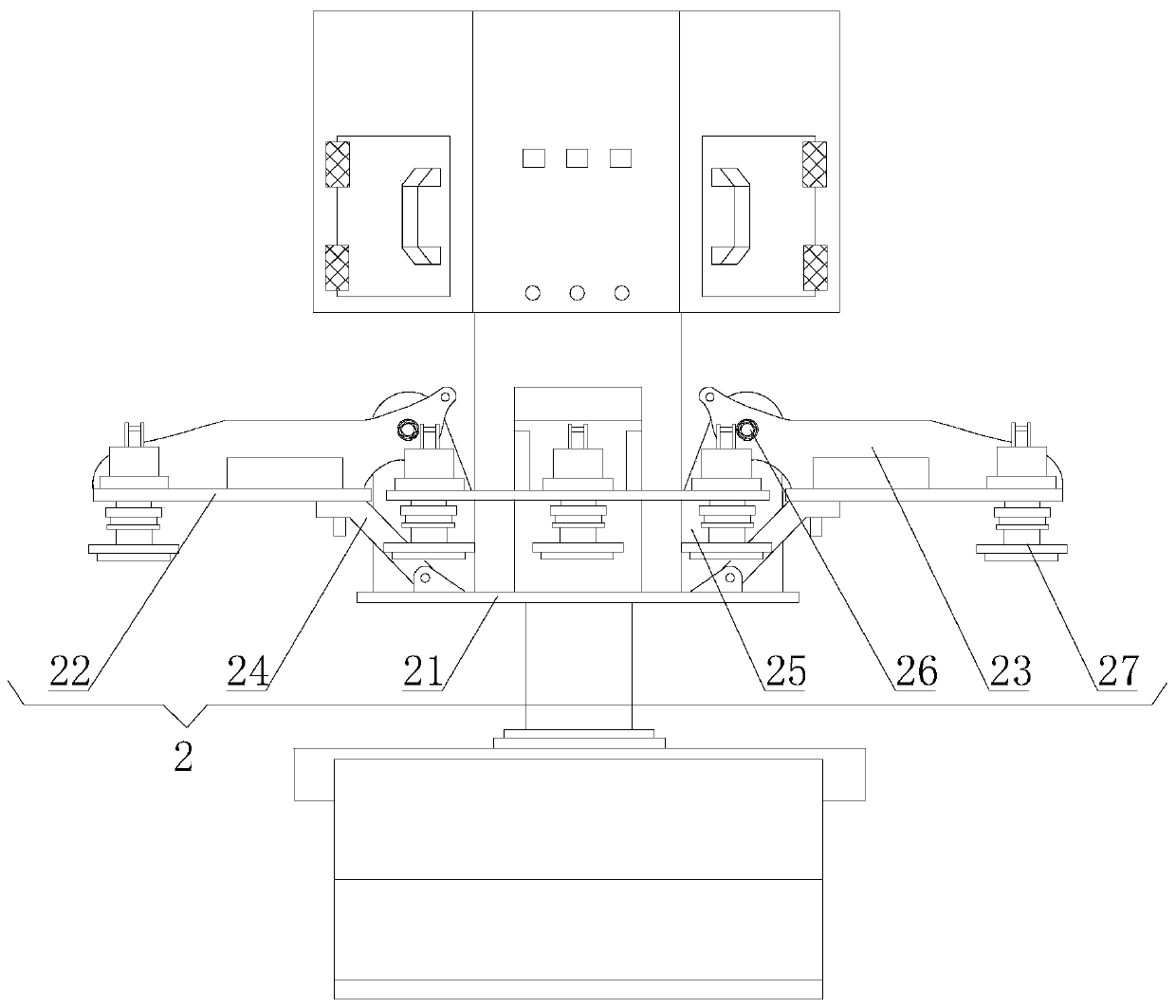

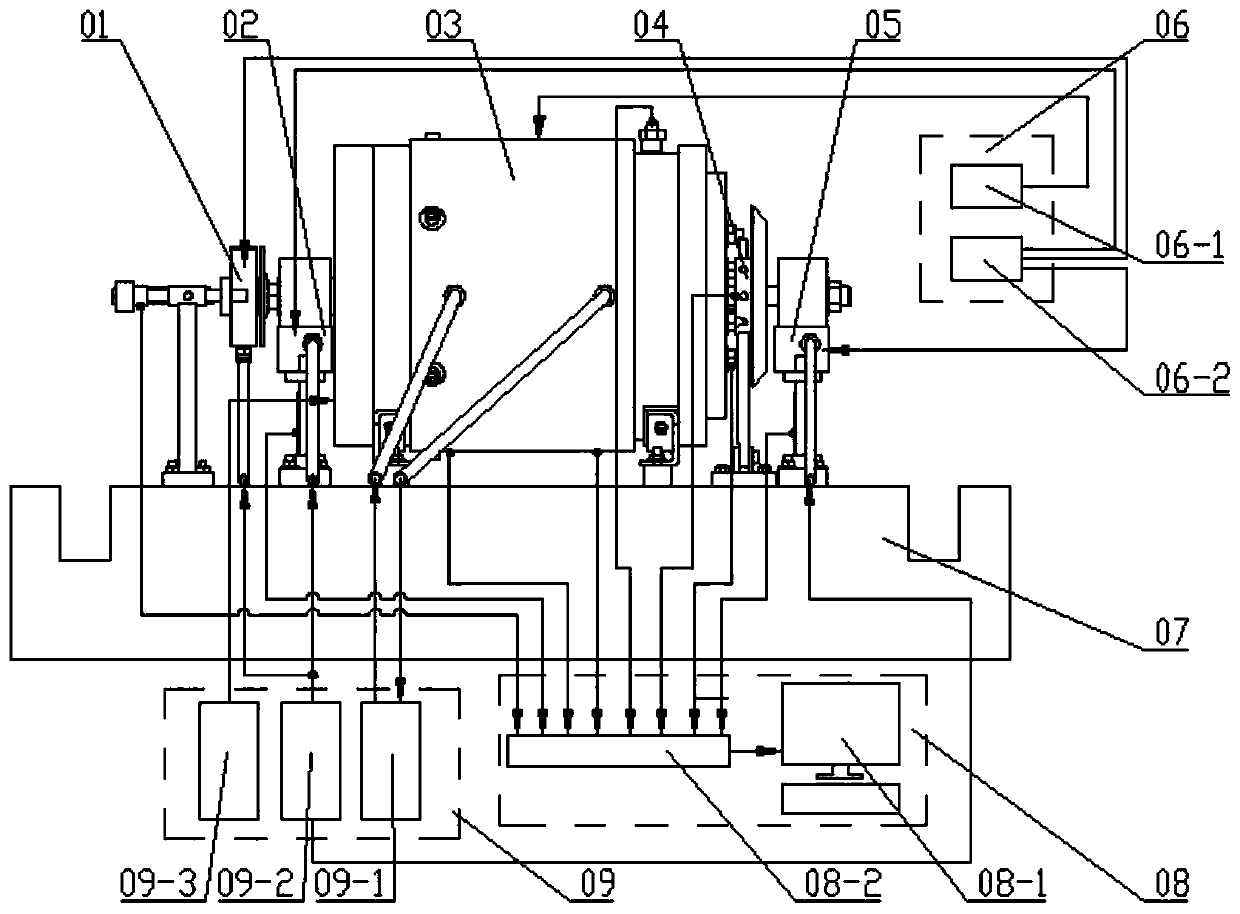

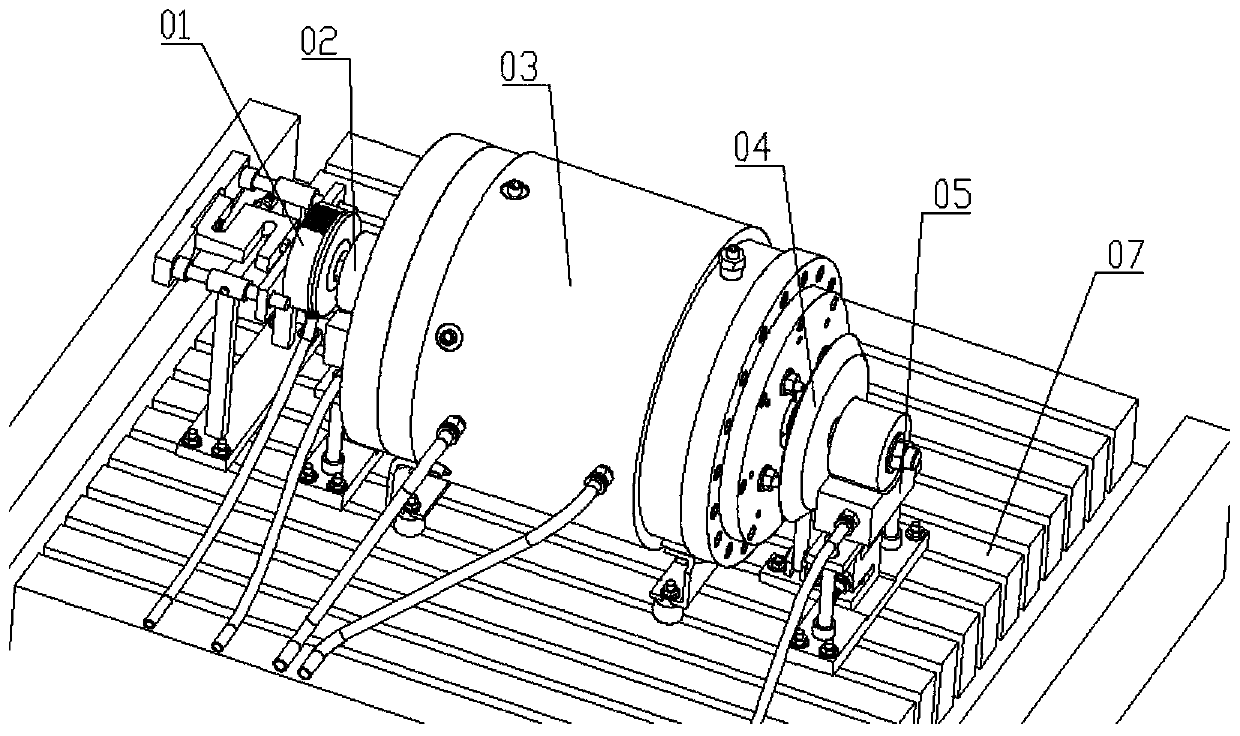

Foil gas bearing comprehensive experiment table device and experiment method

PendingCN110823573AAvoid influenceStable static load sizeMachine bearings testingExperimental DevicesMechanical engineering

The invention relates to the technical field of foil gas bearing load loading experiment devices, and specifically relates to a foil gas bearing comprehensive experiment table device that comprises anaxial load loading unit, a radial load loading unit, a rotor system experiment table main body unit, a sensor unit and a base; the axial load loading unit, the radial load loading unit, the rotor system experiment table main body unit and the sensor unit are fixedly connected with the base; a rotating shaft penetrates through the rotor system experiment table main body unit, the rotating shaft isrotatably connected with the rotor system experiment table main body unit, and the axial load loading unit and the radial load loading unit respectively apply axial and radial loads to the rotating shaft. The invention also provides a fail gas bearing comprehensive experiment method. The characteristics of the foil gas bearing under different loads and different medium environments are researchedby changing the loads and the gas medium. The loading process is free of friction, small in vibration, stable and reliable in static load and controllable in dynamic load size and frequency.

Owner:中船重工(重庆)西南装备研究院有限公司

Experimental method of simulating dynamic and static load and device thereof

InactiveCN101532931BOvercome sizeFrequency controllableFluid pressure measurement by electric/magnetic elementsMaterial strength using tensile/compressive forcesExperimental methodsClassical mechanics

The invention discloses an experimental method of simulating dynamic and static load and a device thereof, relating to indoor model experimental technique of geotechnical engineering. The structure of the device is as follows: a model experimental platform (1), a model experimental box (2) and a load transmitting lever (3) are sequentially connected; the load transmitting lever (3) is respectively connected with a static load system (4) and a dynamic load system (5) which are respectively connected with a dynamic signal testing system (6); the dynamic signal testing system (6), a data acquisition system (7) and a computer (8) are sequentially connected. The device caries out dynamic and static load experiments on different structure models, and can monitor and collect non-linear properties of deformation and stress of gneiss under complex load condition in real time. The device has intuitional testing principle, simple structure, high precision, good stability, easy operation, convenient detachment and no high technical requirement to mounting and testing workers.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Measuring device of soil conductivity and method

InactiveCN101609058BAvoid polarizationAdjustable sizeMaterial resistanceData displayData acquisition

The invention discloses a measuring device of soil conductivity, mainly comprising a sensor unit and a data acquisition and processing unit; the sensor unit mainly comprises electrodes which are configured in a linear equal interval manner; the data acquisition and processing unit mainly comprises a voltage conversion circuit, a signal conditioning circuit, an analog-to-digital converter, a data controller and a liquid crystal display circuit, and also comprises a alternating-current source signal generating circuit, an alternating-current constant current source output circuit and an alternating-current constant current source regulating circuit. According to the measuring device of soil conductivity, the invention also discloses a measuring method of soil conductivity. The invention canregulate the size of exciting current input into the soil at any time according to soil characteristics of the measured farmland so as to guarantee that the sensor works at the linear area under any soil condition, has high measuring accuracy and also has the function of data display and storage.

Owner:CHINA AGRI UNIV

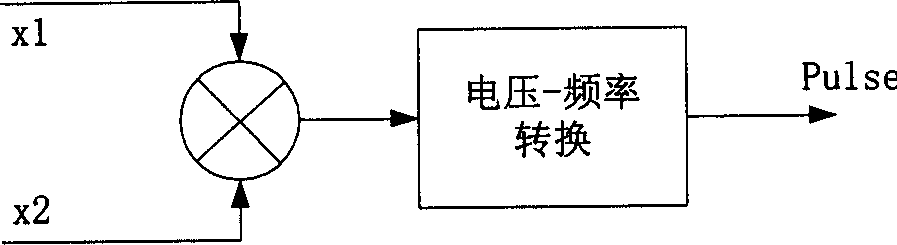

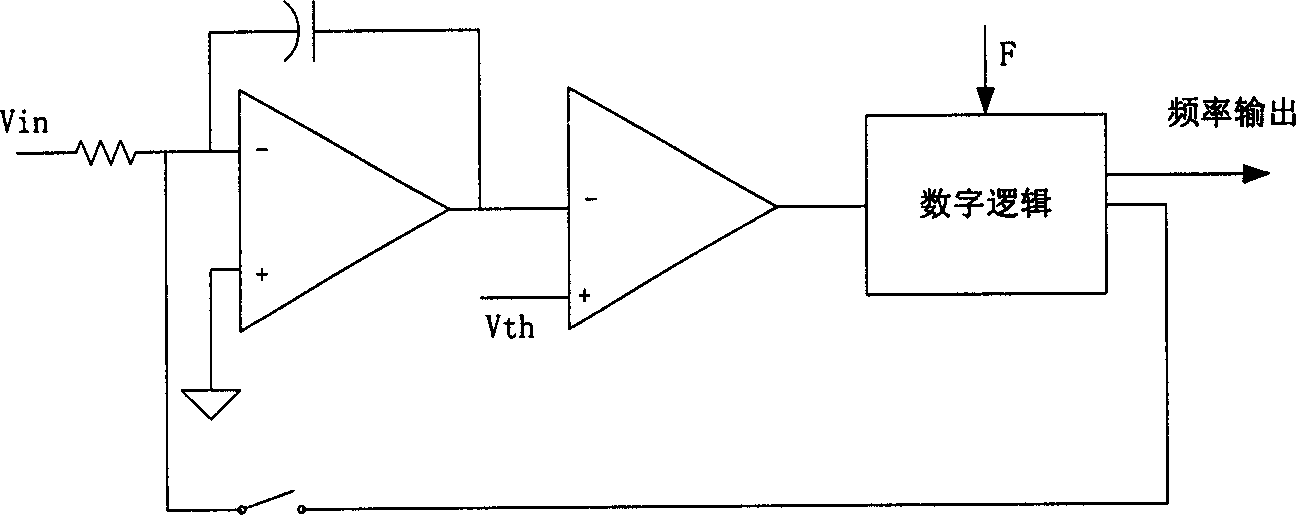

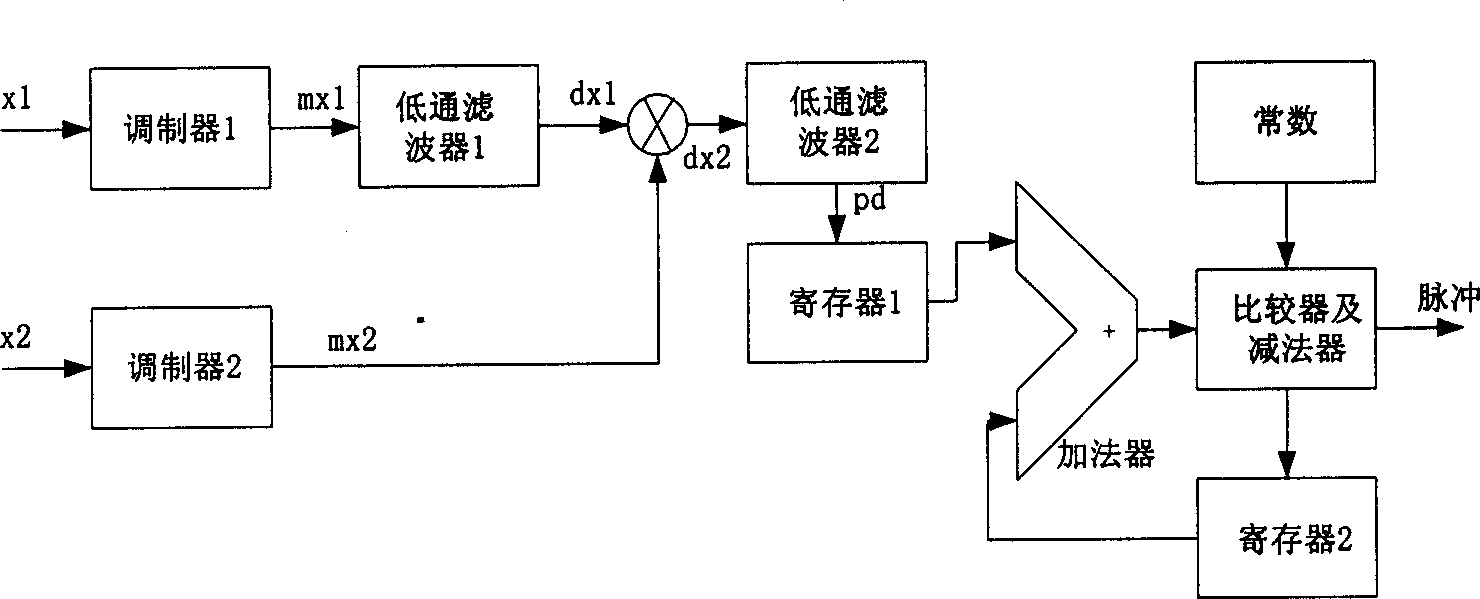

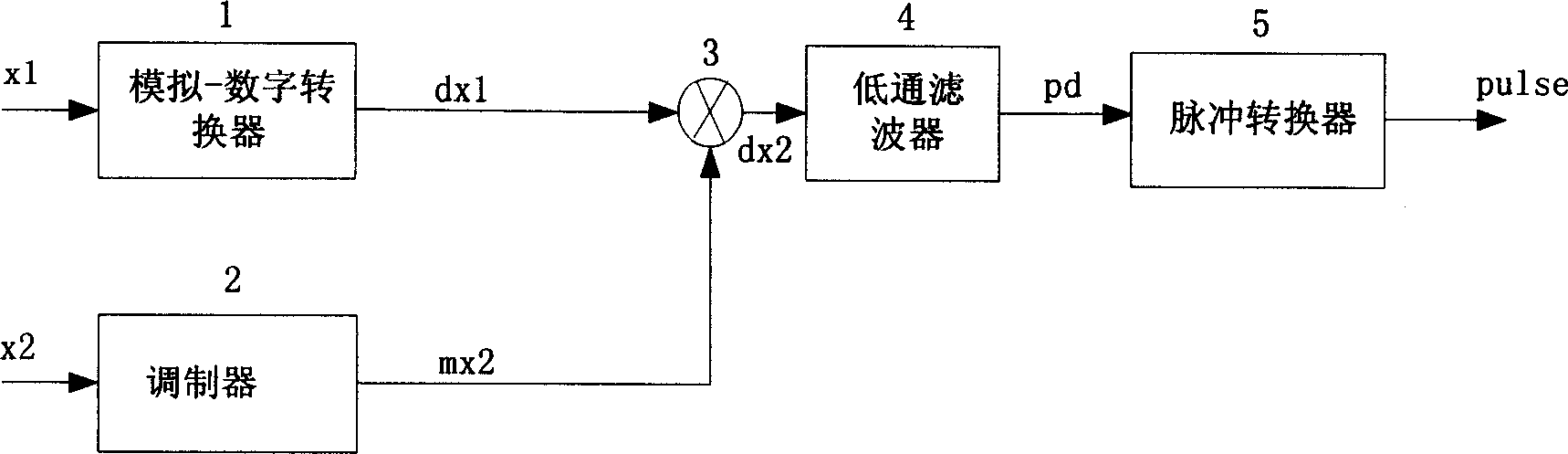

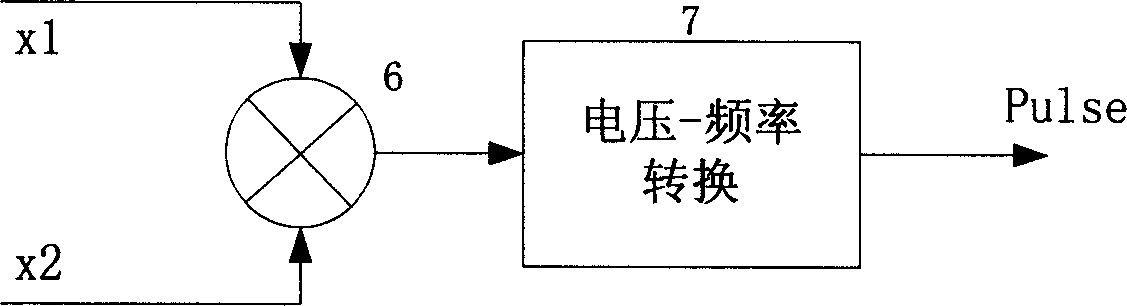

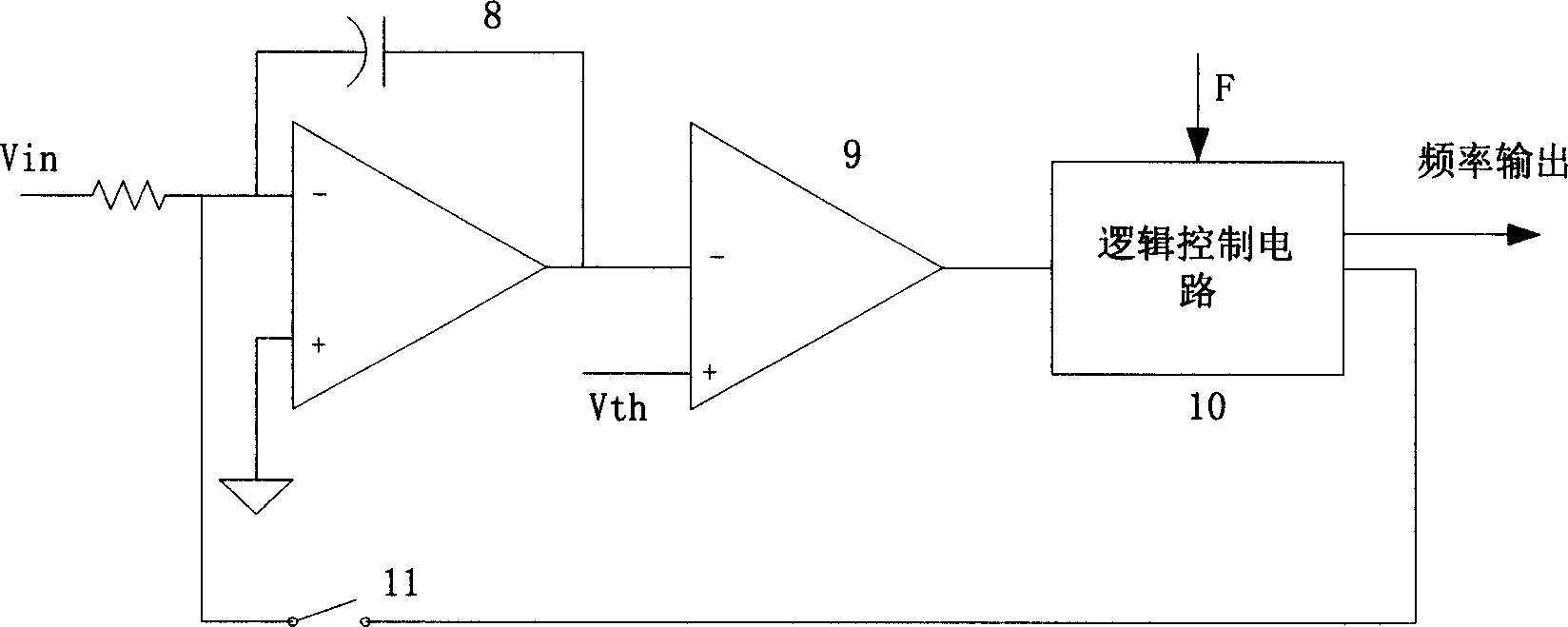

Product-to-pulse conversion method and circuit

A conversion method and circuit from product to pulse applies analog signal product to be converted to certain frequency output pulse in stead of analog circuit existed in present technique. It is made by converting the product of two analog signal into a certain frequency output pulse with the pulse frequency relating to the big or small or signal product, converting analog signal into digital signal 1 and modulated signal 2 by analog-digital converter and modulator, multi plying digital signal, with modulated signal 2 by multiplier to create digital signal 2 which being filtered for product, converting the product into a certain frequency pulse signal by product-pulse converter. The sampling frequency of two route analog signal can be different as well as the working frequency of product-pulse converter and the output frequency of product also can be different.

Owner:SHANGHAI FUDAN MICROELECTRONICS GROUP

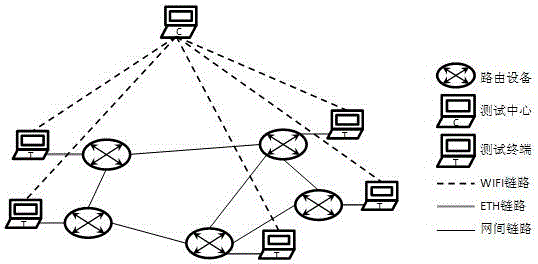

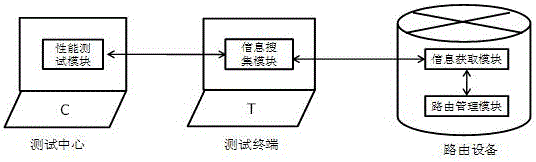

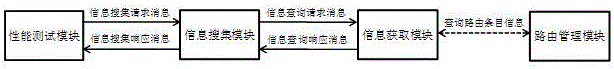

Method, system and device of communication network distributed routing protocol convergence time test

InactiveCN106506258AWide coverageIncrease automation and accuracyData switching networksTest objectNetwork level

The present invention discloses a method, system and device of a communication network distributed routing protocol convergence time test. The method comprises: obtaining the routing entry information of each node in a routing management module in a communication network, performing statistics and analysis, and dynamically measuring and calculating the convergence time of the distributed routing. The present invention is characterized in that: a system-level and network-level communication network routing protocol convergence time test method, system and device are provided. The test method has universality and can perform convergence time test of a plurality of distributed routing protocols such as RIP, OSPF, EIGRP and the like. The test object coverage range is wide to perform test of a plurality of network nodes at the same time, and the frequentness gathered through routing information is controllable so as to improve the test accuracy and the automation degree. The WIFI link transmission test information is employed so as not to influence the routing protocol performance caused by extra bandwidth consumption introduced by the test network.

Owner:CHONGQING JINMEI COMM

Product-to-pulse conversion method and circuit

InactiveCN1169291CImprove application flexibilityFrequency controllableElectric pulse generatorLow-pass filterEngineering

A conversion method and circuit from product to pulse applies analog signal product to be converted to certain frequency output pulse in stead of analog circuit existed in present technique. It is made by converting the product of two analog signal into a certain frequency output pulse with the pulse frequency relating to the big or small or signal product, converting analog signal into digital signal 1 and modulated signal 2 by analog-digital converter and modulator, multi plying digital signal, with modulated signal 2 by multiplier to create digital signal 2 which being filtered for product, converting the product into a certain frequency pulse signal by product-pulse converter. The sampling frequency of two route analog signal can be different as well as the working frequency of product-pulse converter and the output frequency of product also can be different.

Owner:SHANGHAI FUDAN MICROELECTRONICS GROUP

Device and method for in-situ testing of soil dynamic stress-strain curve

ActiveCN112730116BReduce distractionsShorten the test cycleMaterial strength using repeated/pulsating forcesSoil scienceData acquisition

The invention discloses a dynamic stress-strain curve in-situ test device, which includes a movable system, a dynamic response system, a load servo system and a data acquisition system. The device of the invention is powered by a hydraulic source, and can operate at preset frequencies, amplitudes, The vertical dynamic load is applied to the rigid plate of the vibrator under the number of loading cycles, thereby spreading into the foundation soil. After the pre-embedded sensor senses the measured information, it is converted into a fixed form of signal output by the data acquisition system, which can be analyzed and processed. The working method provides a new method for the field test problem of soil dynamic stress-strain curve.

Owner:NANJING HYDRAULIC RES INST

Two-dimensional piezoelectric vibration platform

InactiveCN103817064BLow frequency controllableFrequency controllableMechanical vibrations separationEngineeringActuator

The invention discloses a two-dimension piezoelectric vibration platform which is characterized in that four piezoelectric stack actuators are symmetrically arranged on upper, lower, left and right sides, wherein the external sides of the piezoelectric stack actuators are fixed on a base plate through screws; hex screws are adopted as the screws; internal sides of the piezoelectric stack actuators are respectively connected with a disc which is located in a middle position through flexible hinges; at least three thread holes are arranged in the disc; four uniformly distributed thread holes are arranged in the disc in the embodiment; a mounting hole is arranged in the base plate; piezoelectric input and output ports are arranged on one side of the base plate and are respectively connected with the piezoelectric stack actuators through leads. The two-dimension piezoelectric vibration platform has the advantages of simple structure, low frequency, controllable vibration frequency, amplitude and waveform, and capability of realizing two-dimension vibration of a workpiece; the efficiency of the applied piezoelectric stack actuators is higher than the efficiency of a single chip; the two-dimension piezoelectric vibration platform has a simple structure, is easy to control and is convenient to produce, so that the two-dimension piezoelectric vibration platform is fit for popularization in the fields of vibration milling or other vibration screening, and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

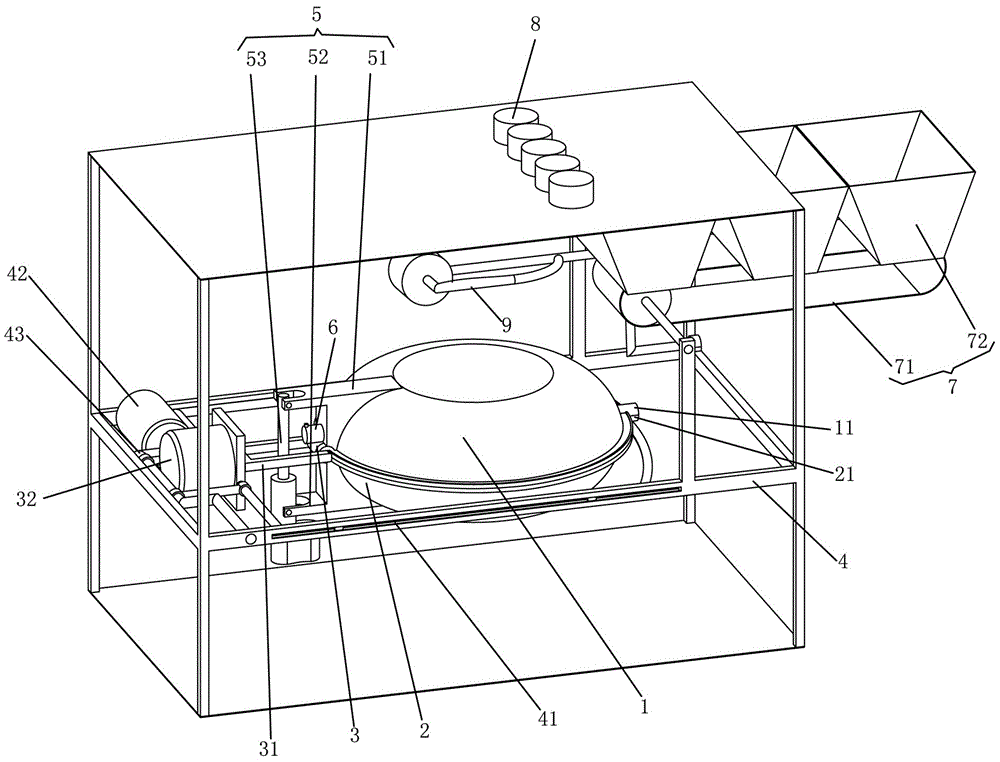

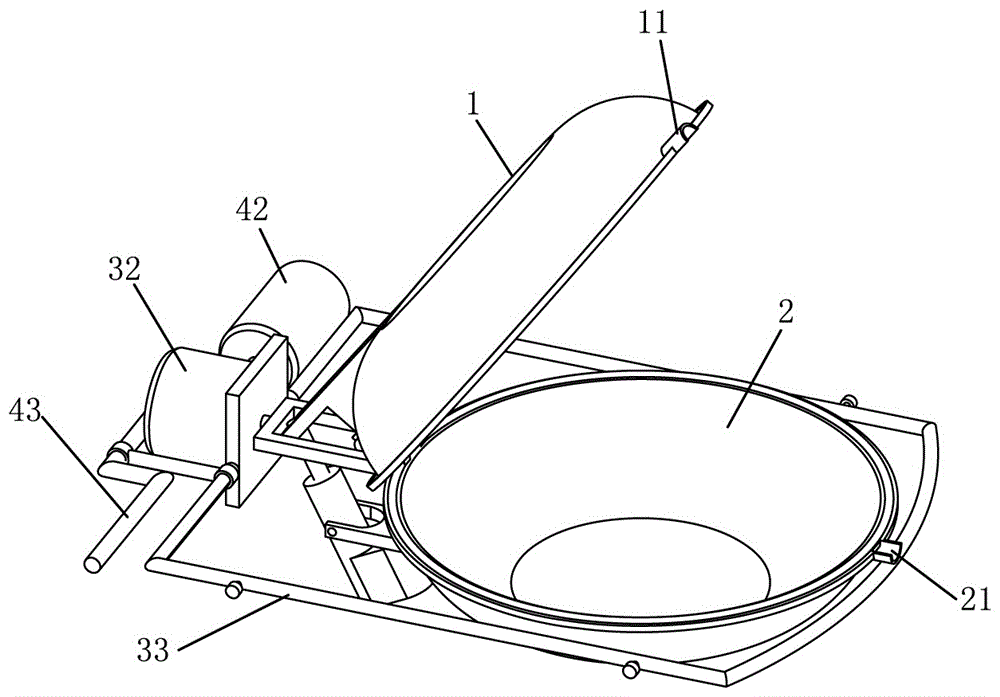

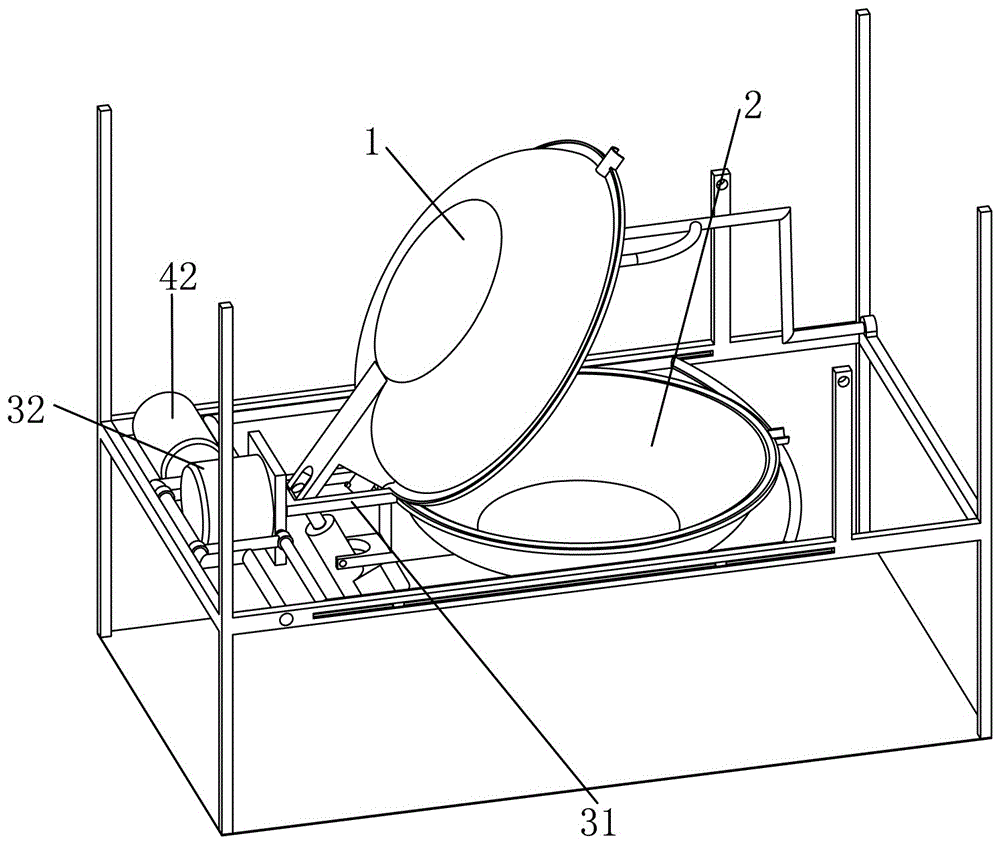

An automatic cooking pot and its automatic cooking system

The invention relates to the technical field of woks used in kitchens, in particular to an automatic wok and an automatic stir-frying system. The technical defects that a dish fried by an existing automatic stir-frying device is poor in mouthfeel, and oil fumes cannot be exhausted in time are overcome. The automatic wok comprises a first wok body and a second wok body which cover each other correspondingly, are turned over and heated alternately and serve as wok covers for each other, and one side of the first wok body and one side of the second wok body are hinged through a hinge mechanism. As the two wok bodies are adopted, cover each other correspondingly, are turned over and heated alternately and serve as the wok covers for each other, and in the alternating process of the two wok bodies, food materials are turned over synchronously, directly and sufficiently at the controllable frequency and heated uniformly, the food materials are not prone to breaking and have a good mouthfeel, and labor is saved. The automatic wok is particularly suitable for continuously stir-frying vegetables in a restaurant for a long time, capable of carrying out perfect stir-frying and being heated uniformly and high in steaming and stir-frying efficiency.

Owner:杨斌

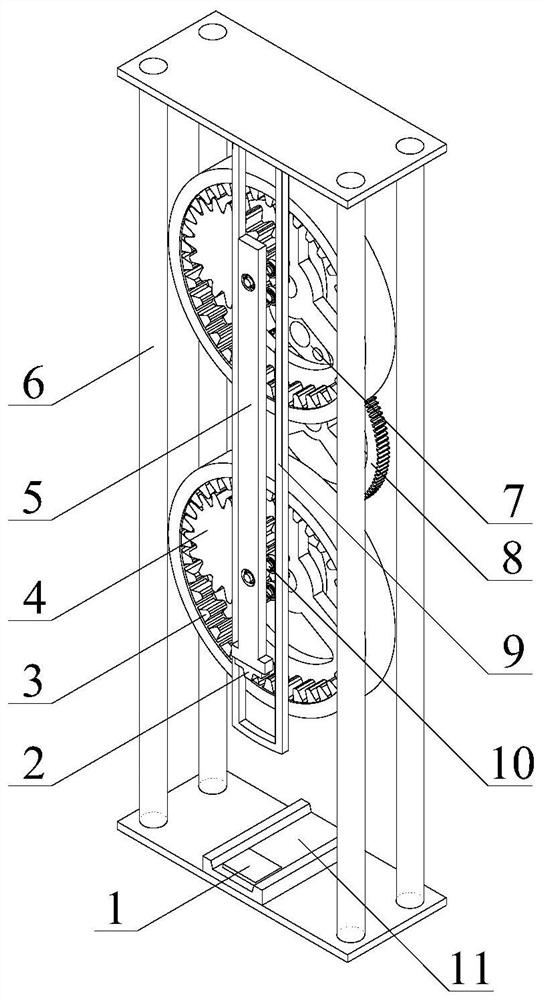

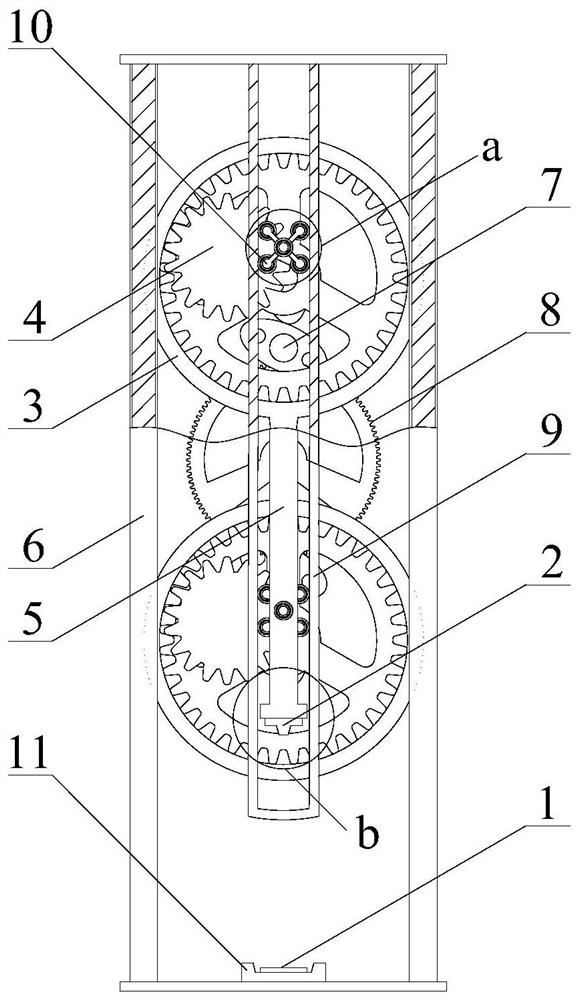

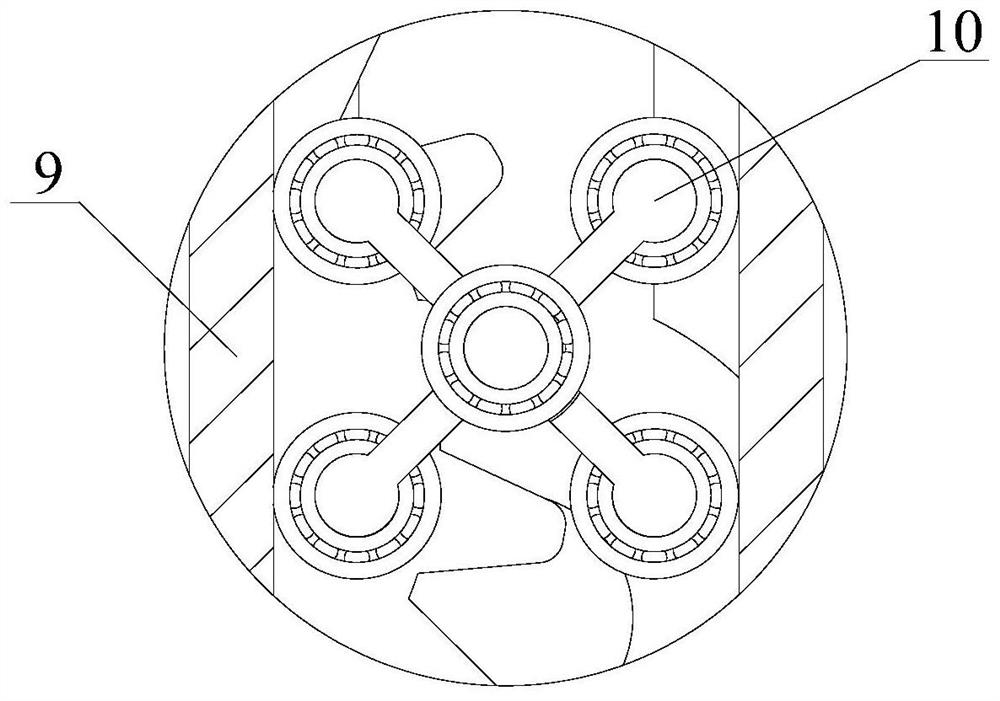

A test device and method for applying continuous impact load

ActiveCN109001061BAdjustable sizeAdjustable frequencyMaterial strength using repeated/pulsating forcesGear driveGear wheel

The invention discloses a test device for applying continuous impact load and a method thereof, which comprises an internal gear, an external gear, a guide bearing group, a guide rail, an impact rod, an action head, an elliptical gear group and a power gear. The top of the guide rail is fixed on the overall support, and the test piece is placed in the test bench at the bottom. The power gear drives the elliptical gear set, and transmits power through the internal gear, external gear and guide bearing set. The impact rod and the action head reciprocate vertically along the guide rail to exert continuous impact load on the specimen. The ratio of the inner diameter of the internal gear to the outer diameter of the external gear is 2:1, and the hypocycloid trajectory of any given point on the external gear is linear reciprocating motion. The variable rotation speed can be obtained by adjusting the meshing mode of the elliptical gear set, thereby realizing the continuous application of impact loads of different sizes and frequencies; the invention has simple structure, convenient operation, and safe and controllable operation.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com