Electromagnetic pile driver

An electromagnetic pile driver, electromagnet technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

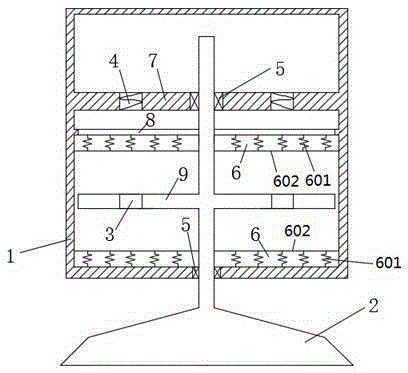

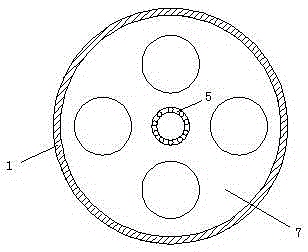

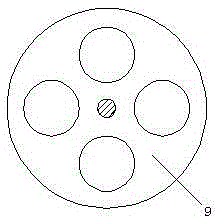

[0020] An electromagnetic pile driver, comprising: a fixed disk 7, an electromagnet 4 placed in the fixed disk 7, a moving disk 9, a closed coil 3 arranged on the moving disk 9 and corresponding to the electromagnet 4, formed on Electromagnetic hammer 2 on the moving disk 9. When the electromagnet 4 in the fixed disc 7 is passed to the alternating current of the set frequency, the magnetic poles and the magnetic field size of the electromagnet 4 in the fixed disc 7 will be periodic changes, and the closure in the movable disc 9 will The coil 3 will change the magnetic flux according to the change of the magnetic field of the electromagnet 4 in the fixed disk 7. According to Lenz's law, a circular current will be generated in the coil to form a magnetic field to hinder this change. When the magnetic field of the electromagnet 4 is strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com