Two-dimensional piezoelectric vibration platform

A technology of electric vibration and platform, applied in the direction of fluid using vibration, etc., can solve the problems of reducing surface roughness, deteriorating processing quality, and vibration waveform can not be controlled arbitrarily according to needs, and achieve the effect of simple structure and good vibration processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

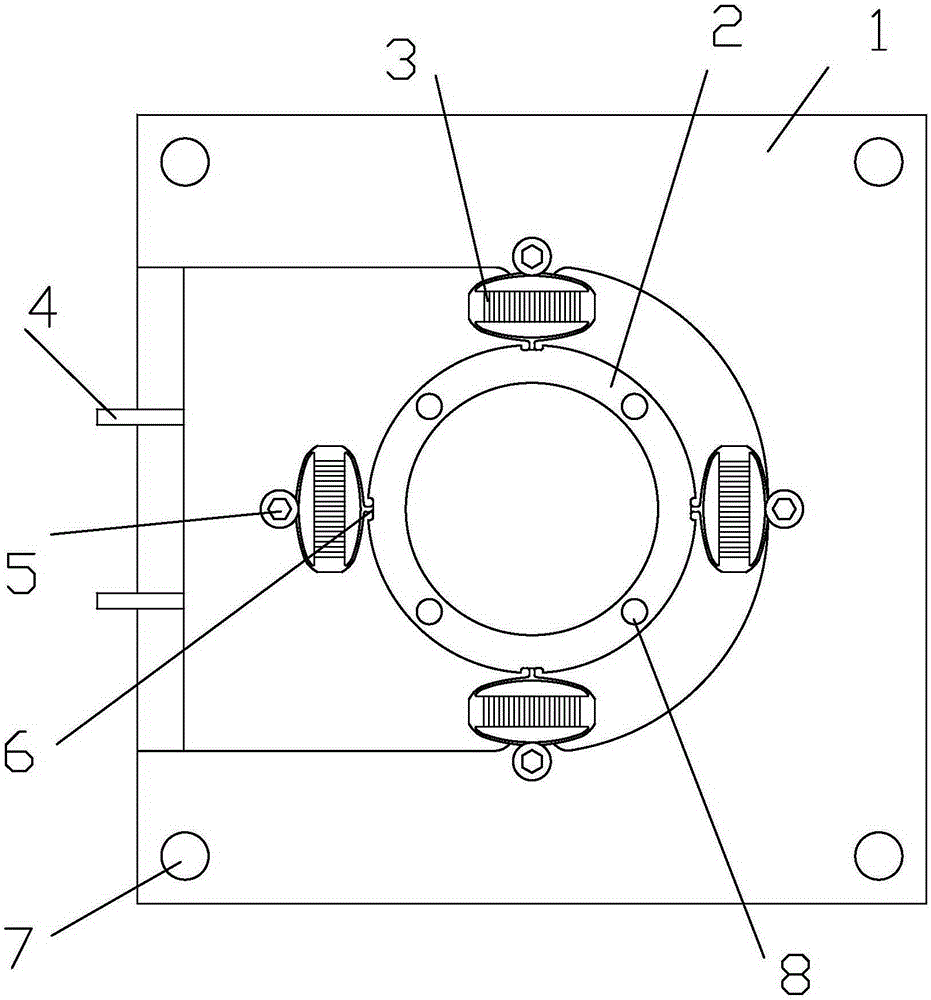

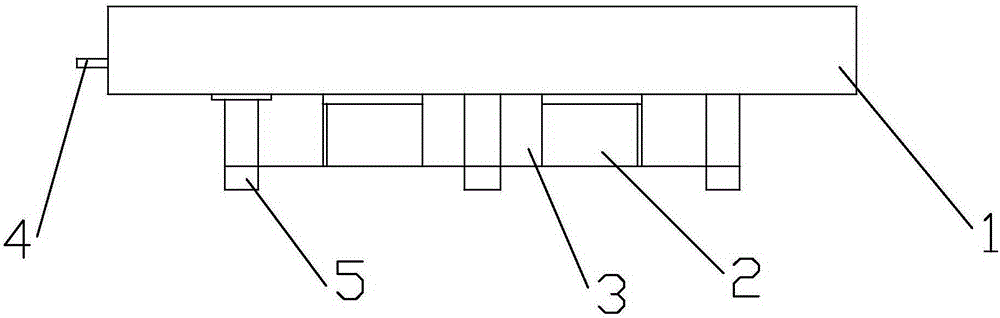

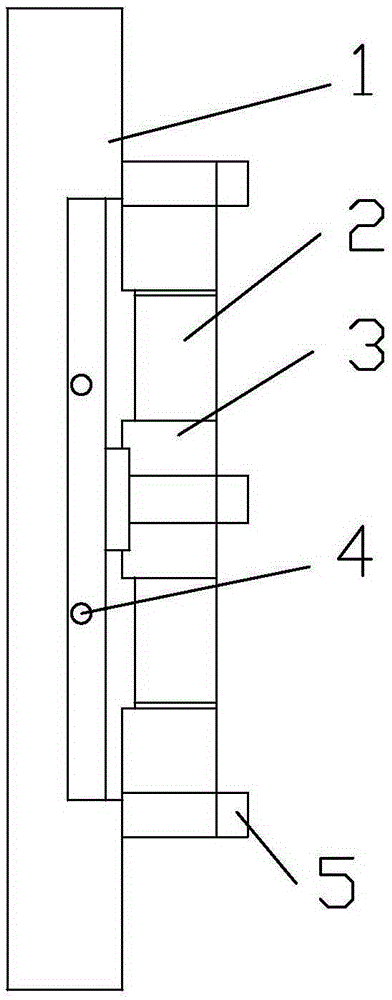

[0012] attached figure 1 It shows a schematic structural diagram of the present invention, which uses a piezoelectric actuator to drive the workpiece to vibrate, thereby realizing vibration cutting.

[0013] The piezoelectric input and output ports receive vibration signals of different waveforms. For this two-dimensional piezoelectric vibration platform, four piezoelectric stack actuators 3 are arranged symmetrically up and down, left and right, and their respective outer sides are fixed on the bottom plate 1 with screws 5 . In this case, screw 5 is a hexagonal screw. The inner sides of the piezoelectric stack actuators 3 are respectively connected to the disc 2 at the middle position through flexible hinges 6 . The disk 2 is provided with at least three threaded holes 8 . In this case, the threaded holes provided on the disc 2 are 4 evenly distributed. Mounting holes 7 are provided on the base plate 1 , and piezoelectric input and output ports 4 are provided on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com