A test device and method for applying continuous impact load

A technology of impact load and test device, applied in the direction of measurement device, application of repetitive force/pulse force test material strength, instrument, etc., can solve the problem of not being able to clearly provide the structural fatigue damage of the specimen, and difficult to realize the continuous application of impact load, etc. To achieve the effect of diversification, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

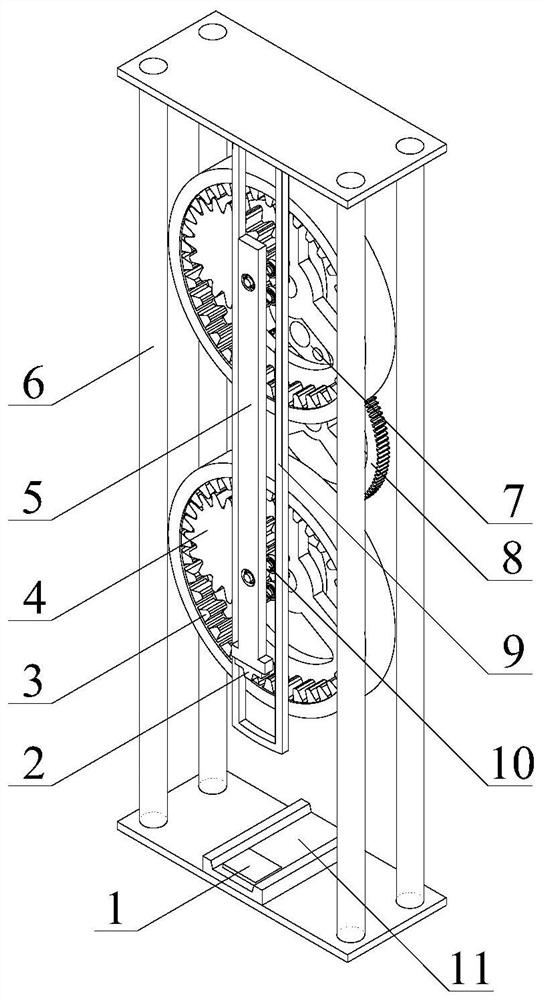

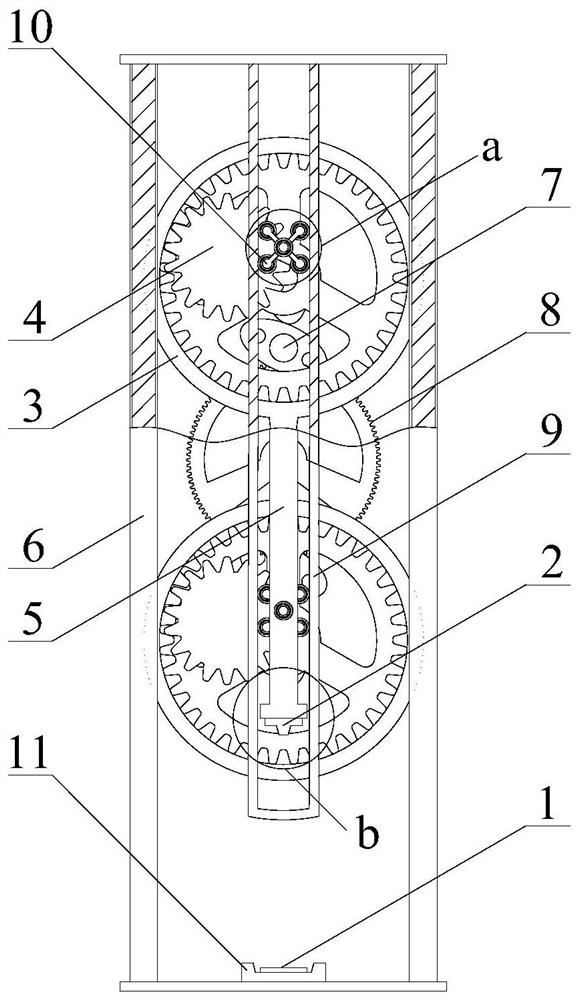

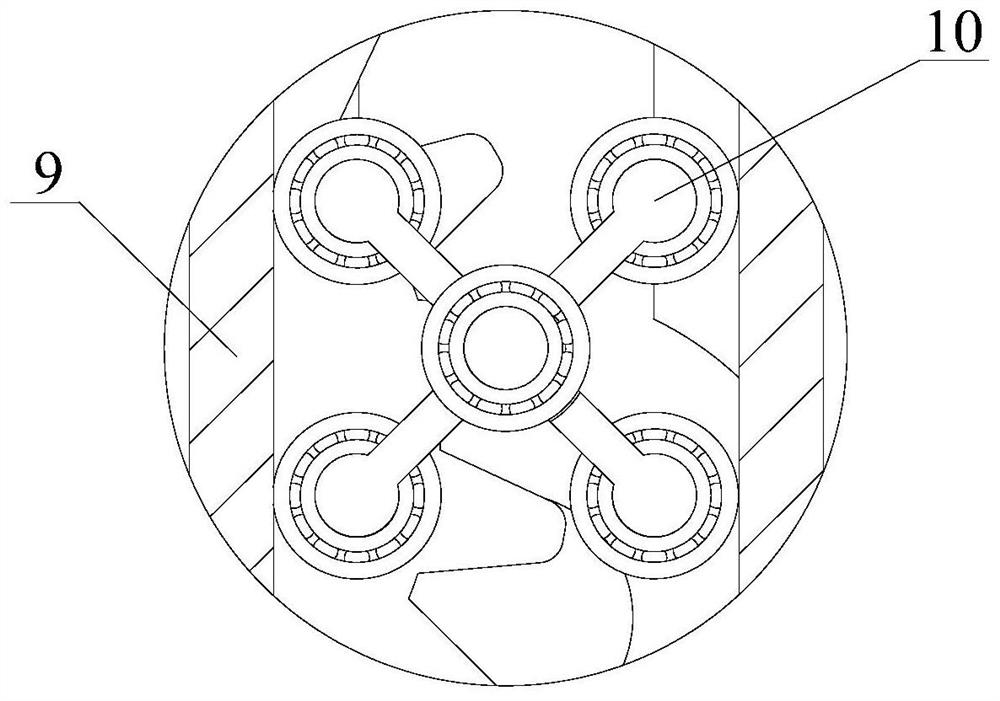

[0029] figure 1 It is a structural schematic diagram of an embodiment of the test device for applying continuous impact load in the present invention. figure 2 for figure 1 A front view, partially in section, of one embodiment is shown. Such as figure 1 with figure 2 As shown, the device of the embodiment of the present invention includes an internal gear 3 , an external gear 4 , a guide bearing set 10 , a rail member 9 , an impact rod 5 , an oval gear set 7 , a power gear 8 , and a test piece 1 . The integral support 6 is a frame structure, including an upper platform and a lower platform parallel to each other, a vertical support for connecting and fixing the upper platform and the lower platform; It consists of vertically arranged steel parts; the test bench 11 is fixed on the lower platform. The elliptical gear set 7 is respectively connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com