Method and device for filling of vertical through hole

A technology of vertical through-holes and injection devices, which is applied in metal material coating technology, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of long time, difficult to fill micro-holes, complicated process, etc., and achieve low porosity, Uniform composition and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

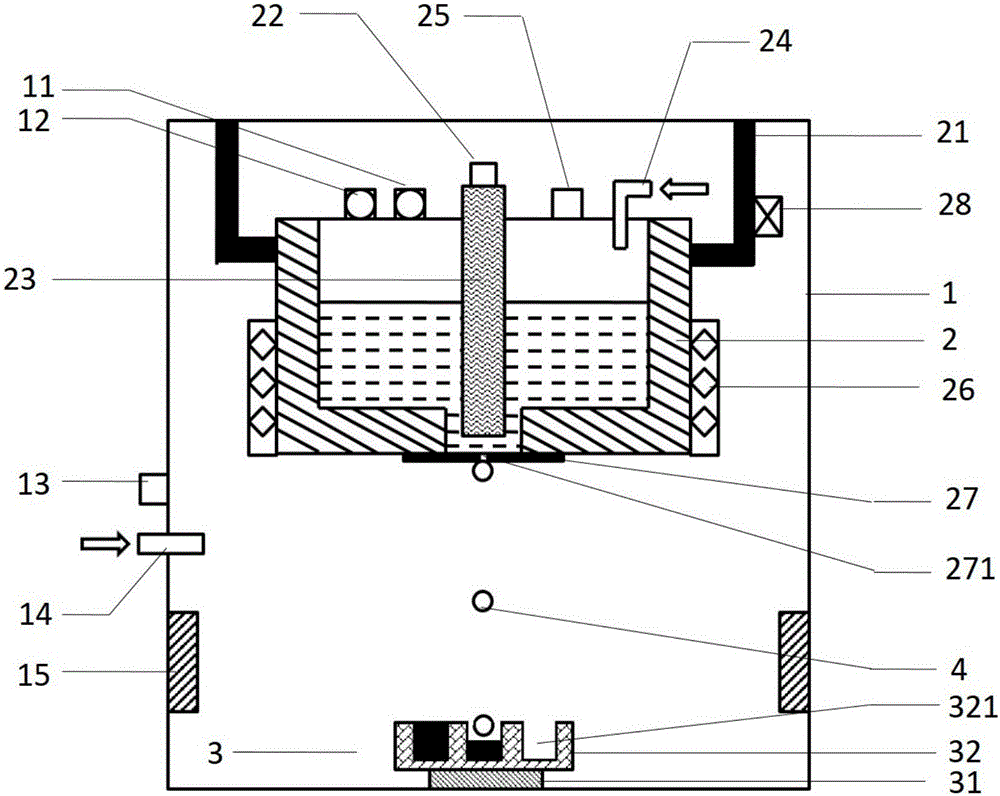

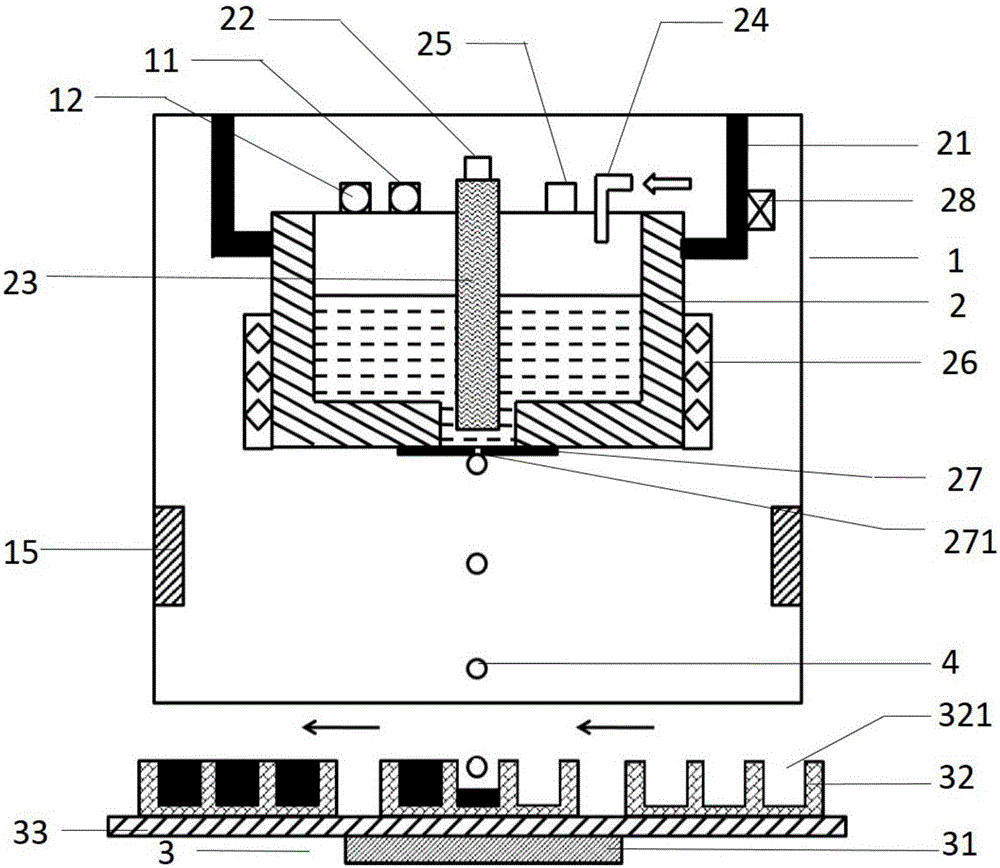

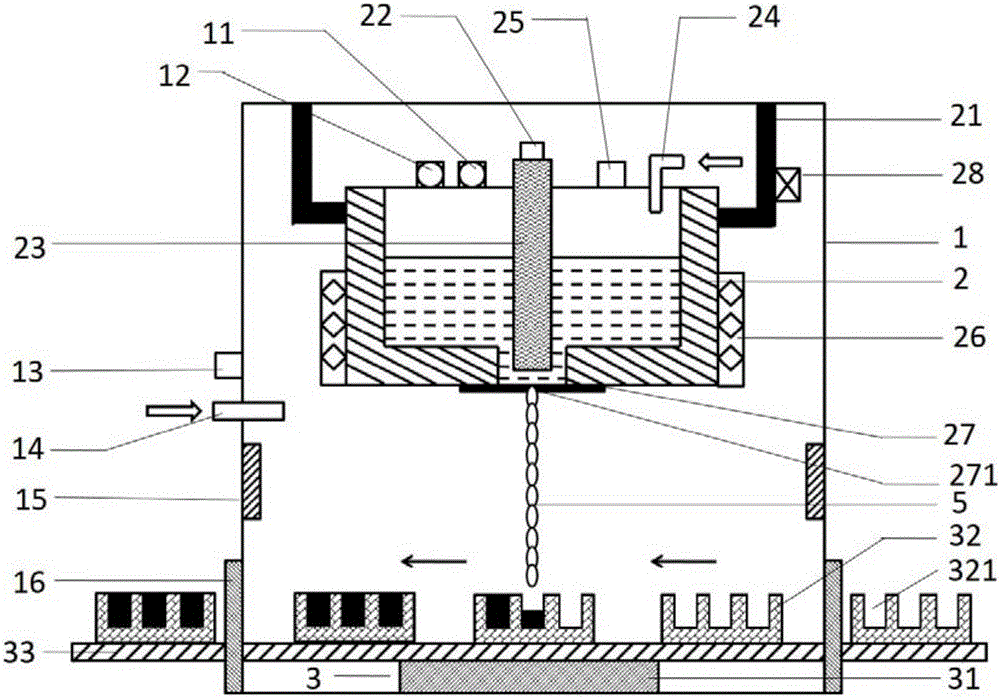

[0036] Such as figure 1 As shown, a device for filling vertical through holes includes a molten metal spraying device and a filling work area 3, the molten metal spraying device is placed on the upper part of the cavity 1, and the molten metal spraying device includes a droplet spraying device Crucible 2, a piezoelectric ceramic 22 arranged on the top of the crucible 2, a transmission rod 23 connected to the piezoelectric ceramic 22 and deep into the inside of the crucible 2 and the melt therein, the bottom of the crucible 2 is provided with a center hole, the bottom of the crucible 2 is also connected with a sheet 27 communicating with the central hole, the sheet 27 is provided with a spray hole 271, the outside of the crucible 2 is provided with a heating belt 26, and the top of the crucible 2 is provided with a crucible Air inlet 24 and crucible exhaust outlet 25, described cavity 1 side has cavity inlet 14 and cavity exhaust outlet 13, mechanical pump 11 and diffusion pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com