Method and device for obtaining high-voltage electricity surface unipolar discharging trace

A discharge trace and surface discharge technology, applied in special decorative structures, decorative art, etc., can solve the problems of short circuit on the surface of products, different discharge trace directions and distribution patterns, and affect the directionality and continuity of discharge trace patterns, etc., to achieve uniform development , Guaranteed pattern continuity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0032] Example 5 provides a counter example to illustrate the effect of the peak voltage higher than 3kV between the positive and negative electrodes when there is no load. The self-excited push-pull boost power supply is used as a control device, and the power structure is a self-excited push-pull ZVS boost with frequency open loop control. The circuit has a working frequency range of 13-42kHz. After rectifying the output of the power supply into a pulsating direct current and connecting it to the positive and negative electrodes, the no-load peak voltage between the electrodes is 10kV. The peak power of the device is 200W, the rectifier circuit is the same as the rectifier circuit in the test device of the present invention, and the test device and the control device use the same electrode group to provide the conditions required for the control test.

[0033] In Examples 1 to 3, the surface discharge starts at the first power supply condition. After the discharge trace covers a...

Embodiment 1

[0036] In this example, conditions 1 to 3 illustrate the feasibility of unipolar discharge, and conditions 4 to 5 are used as a comparison to illustrate the significance of unipolar discharge; condition 6 illustrates the occurrence of another polarity discharge during unipolar surface discharge And development is inhibited or cannot happen. In 9M NiCl 2 Add 2.3wt.% SiO to the aqueous solution 2 , 4.2wt.% PEG-200 is used as the conductive agent used in this embodiment, and the metal ion charge concentration is 18M. The volume of the conductive agent applied to the test range of the modified article is 1.0ml.

Embodiment 1

[0037] Example 1 Condition 1. Using the test device 1, the electrode is loaded with a pulsating direct current of 35 kHz and a duty ratio of 0.3. During surface discharge, the peak voltage is 0.78kV and the power consumption is 25W.

[0038] Example 1 Condition 2. Using the test device 2, the electrode is loaded with a pulsating direct current of 18 kHz and a duty ratio of 0.4. During surface discharge, the peak voltage is 0.91kV and the power consumption is 55W.

[0039] Example 1 Condition 3. Using the test device 3, the electrode is loaded with a pulsating direct current of 120kHz and a duty ratio of 0.5. During the surface discharge process, the peak voltage is 0.98kV and the power consumption is 7.5W.

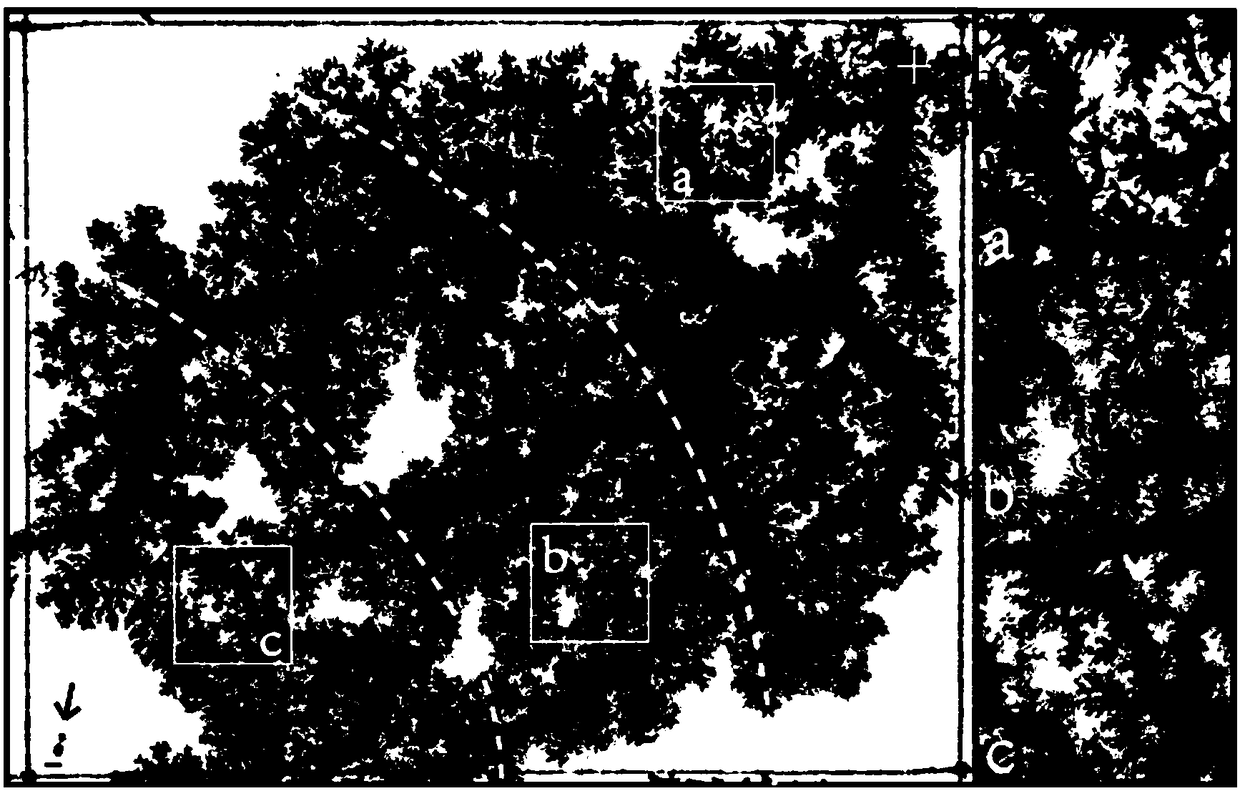

[0040] The implementation results of conditions 1 to 3 of Example 1 are as follows figure 2 . The oblique line in the figure is the dividing line for switching power supply conditions. The implementation results of conditions 1 to 3 are divided from right to left. There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com