Gas spark gap switch for nanosecond pulse generator

A gas spark gap and nanosecond pulse technology, which is applied to spark gaps, spark gaps, electrical components, etc. And other problems, to achieve the effect of wide range of breakdown voltage, small switch coupling capacitance, and controllable frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

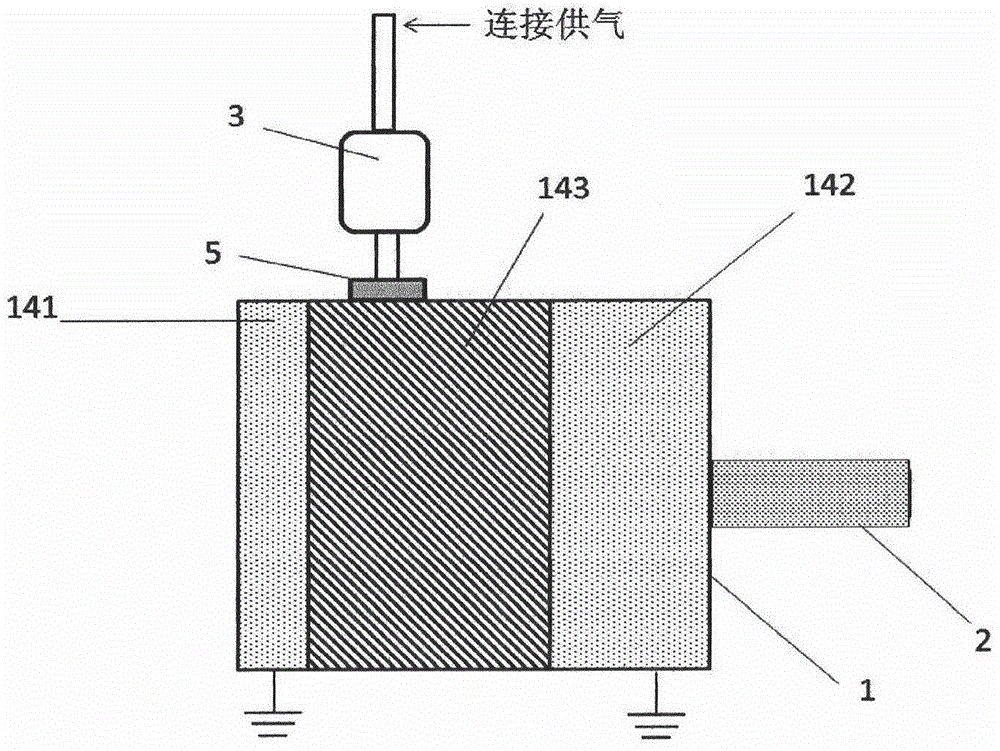

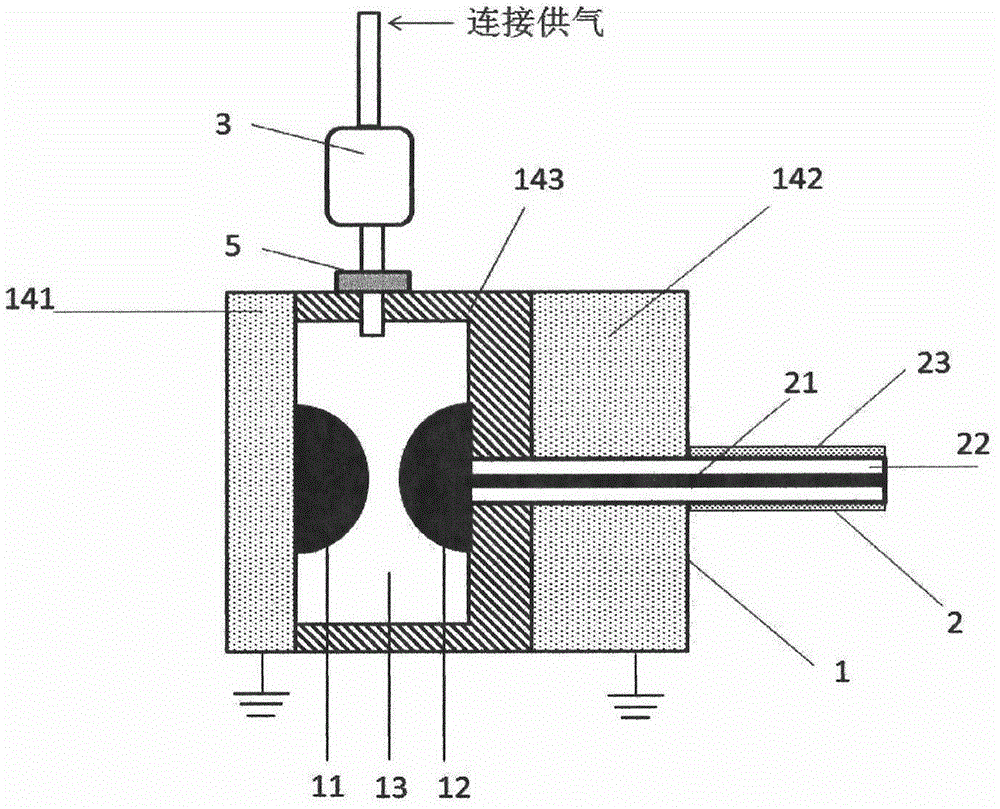

[0026] figure 1 A schematic diagram of the external structure of a gas spark gap switch is shown, figure 2 For its profile, such as figure 2 As shown, a gas chamber 13, a coaxial cable 2, an electronic air pressure controller 3, an air charging interface 5 connecting the electronic air pressure controller 3 and the gas chamber 13, a high voltage spark discharge electrode 12 and a grounding spark discharge electrode 11 ; Wherein, the coaxial cable includes from the inside to the outside: an inner conductor 21, a dielectric insulating layer 22 and an outer conductor 23, the coaxial cable 2 is arranged on one side of the gas chamber 13, and the high-voltage spark discharge e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com