Transverse defect verification method in eddy current testing and pipe cutting device with vernier adjustment knob

An eddy current flaw detection and lateral defect technology, applied in the direction of material magnetic variables, etc., can solve the problems affecting the accuracy of eddy current monitor sensitivity calibration, lack of flexibility, inconvenient calibration, etc., to achieve controllable verification frequency, increase smoothness, use Flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

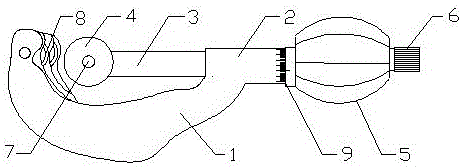

Image

Examples

Embodiment 1

[0032] The method for verifying lateral defects of eddy current flaw detection specifically includes the following steps:

[0033] (1) The eddy current inspection line includes pay-off machine, straightener, shot blasting machine, eddy current inspection equipment, automatic painting equipment and drawing equipment along the direction of steel wire advance; the steel wire in production is pulled by the drawing equipment Travel along the direction from the pay-off machine to the drawing equipment; the eddy current flaw detection equipment includes a pass-through flaw detection module and a rotary flaw detection module, the pass-through flaw detection module is provided with a detection coil; the eddy current flaw detection equipment detects transverse defects on the steel wire passing through the detection coil detection;

[0034] (2) Select the steel wire surface at the front end of the eddy current flaw detection equipment and 1-2m away from the detection coil for transverse sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com