Automatic tubular material feeding conveying equipment

A technology for conveying equipment and materials, which is applied in the field of automatic upper tubular material conveying equipment, can solve the problems of low packaging efficiency of single parts, increased labor intensity, and prolonged packaging time, so as to save labor costs, improve production efficiency, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

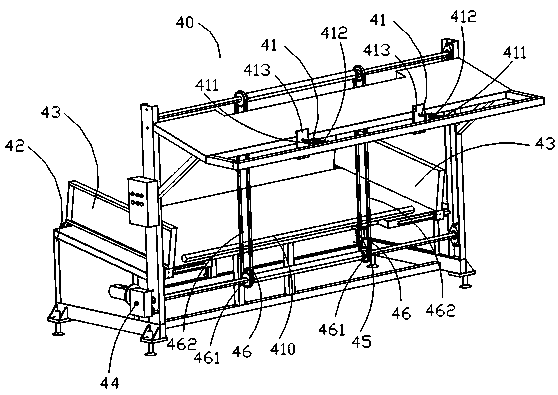

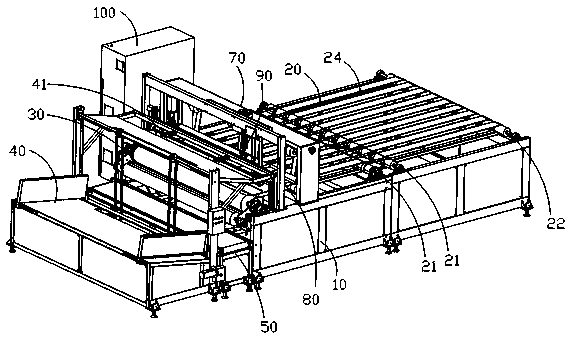

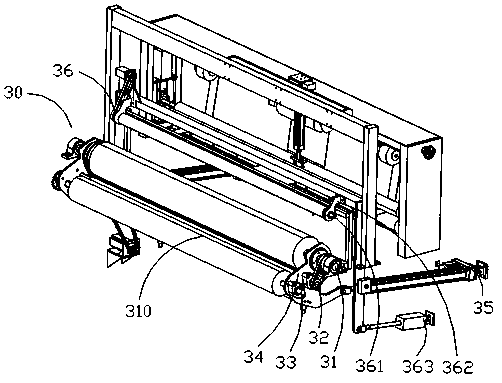

[0026] Such as Figure 1-2 As shown, an embodiment of the present invention discloses an automatic winding device, comprising: a frame 10, a conveying mechanism 20 arranged on the frame 10, a multi-axis linkage winding mechanism 30, and an automatic upper tubular material conveying device 40, wherein, the automatic upper tubular material conveying equipment 40 includes a discharge push rod mechanism 41, and the discharge push rod mechanism 41 can move to release the tubular material 410 to the preset position of the multi-axis linkage winding mechanism 30, the The conveying mechanism 20 is used to convey the tubular material 410 to the multi-axis linkage winding mechanism 30 . Preferably, the frame 10 is cut and welded from a 40x80mm, 50x100mm, 60*120mm square tube or a 1-20mm plate. The above-mentioned automatic loading tubular material conveying device 40 can work alone or in combination with the above-mentioned automatic winding device, and can also be applied to other occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com