Patents

Literature

75results about How to "Unified position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

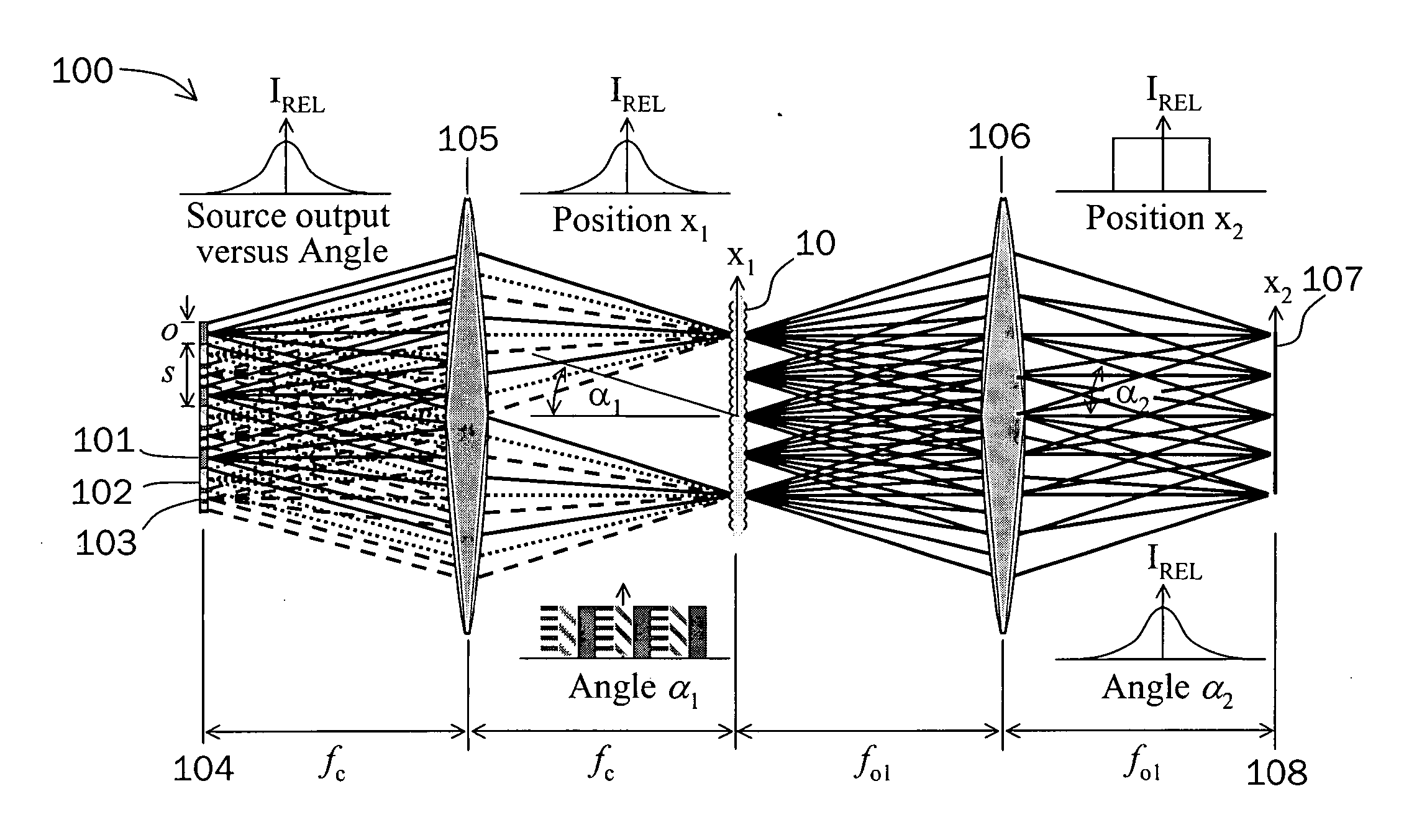

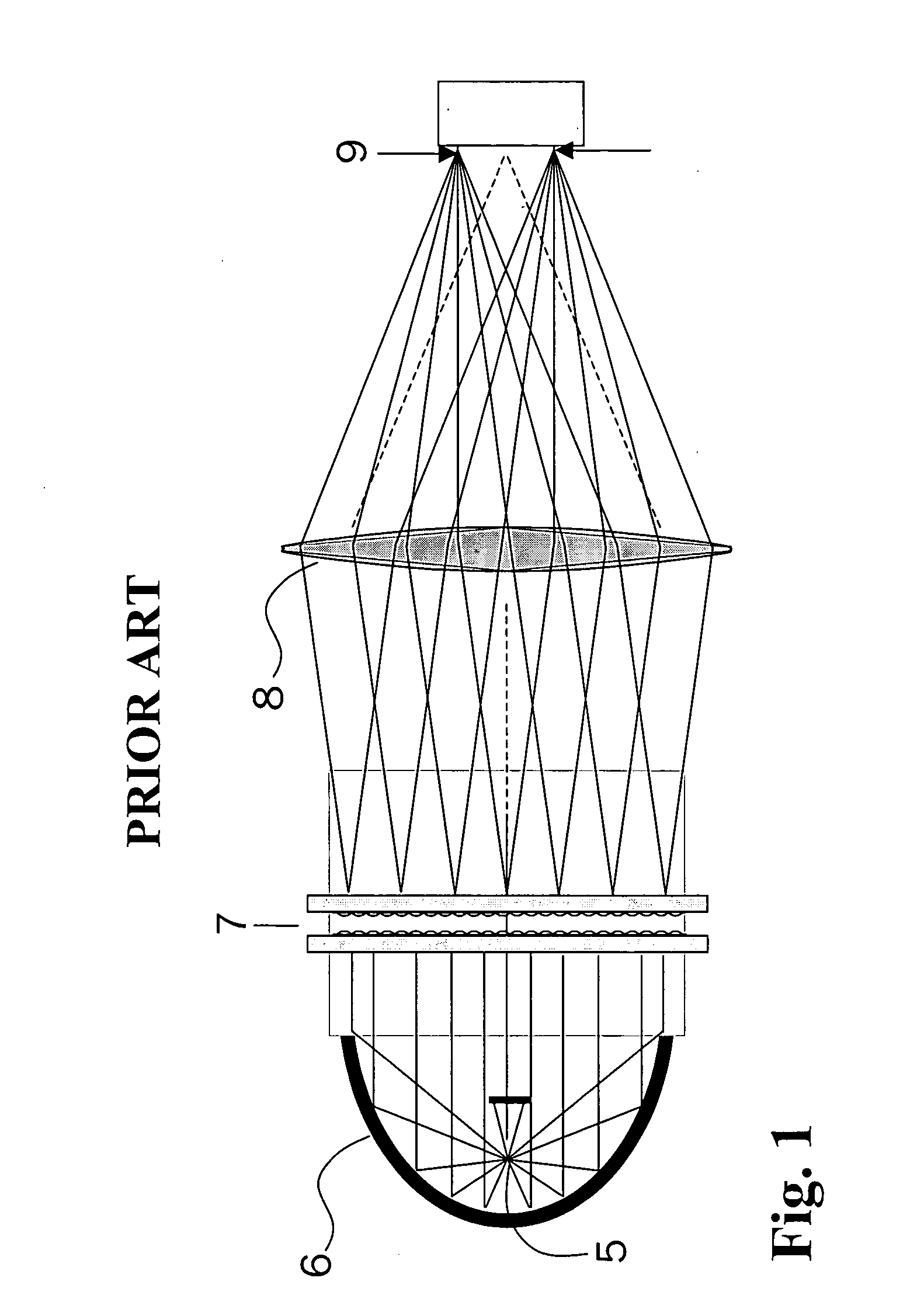

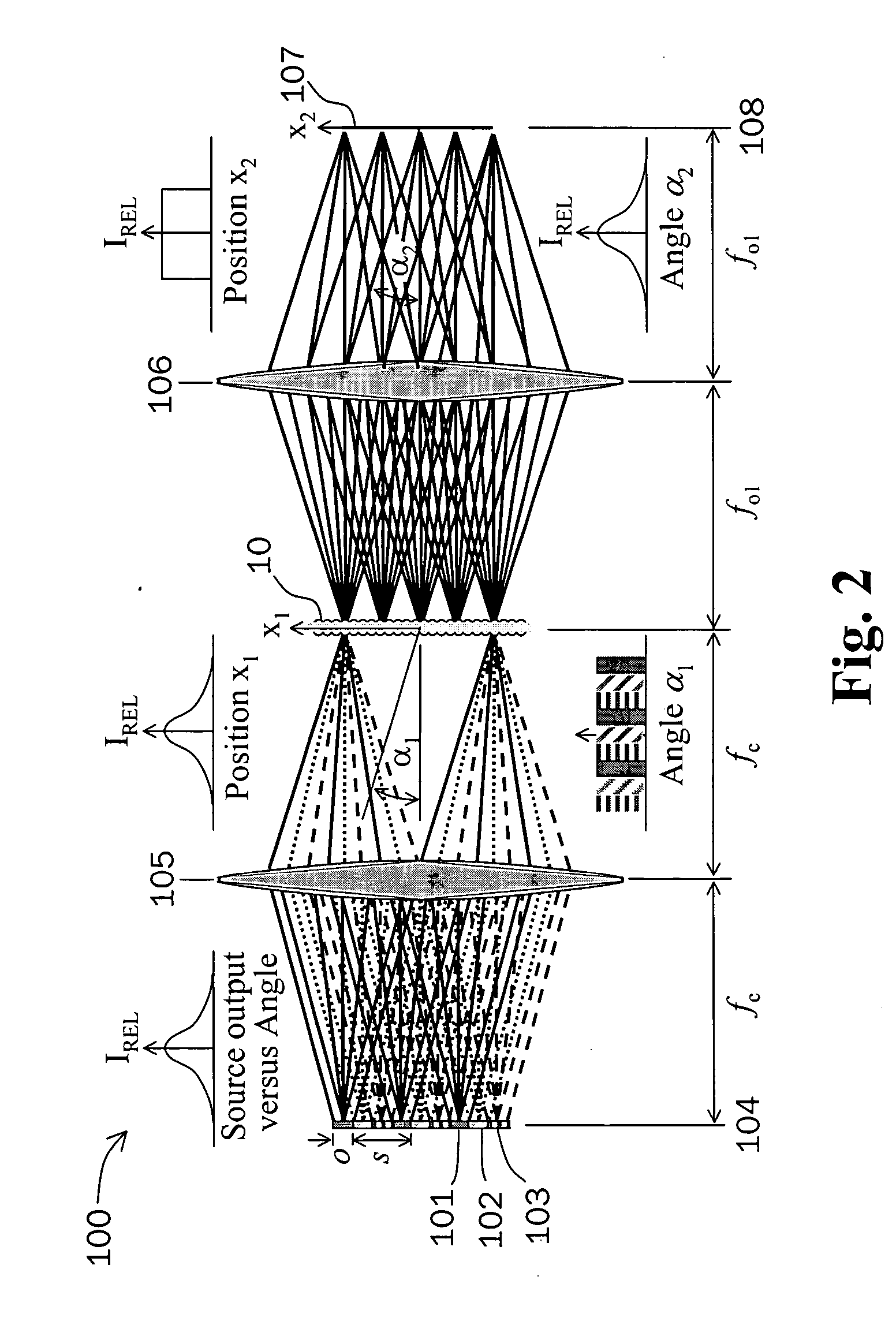

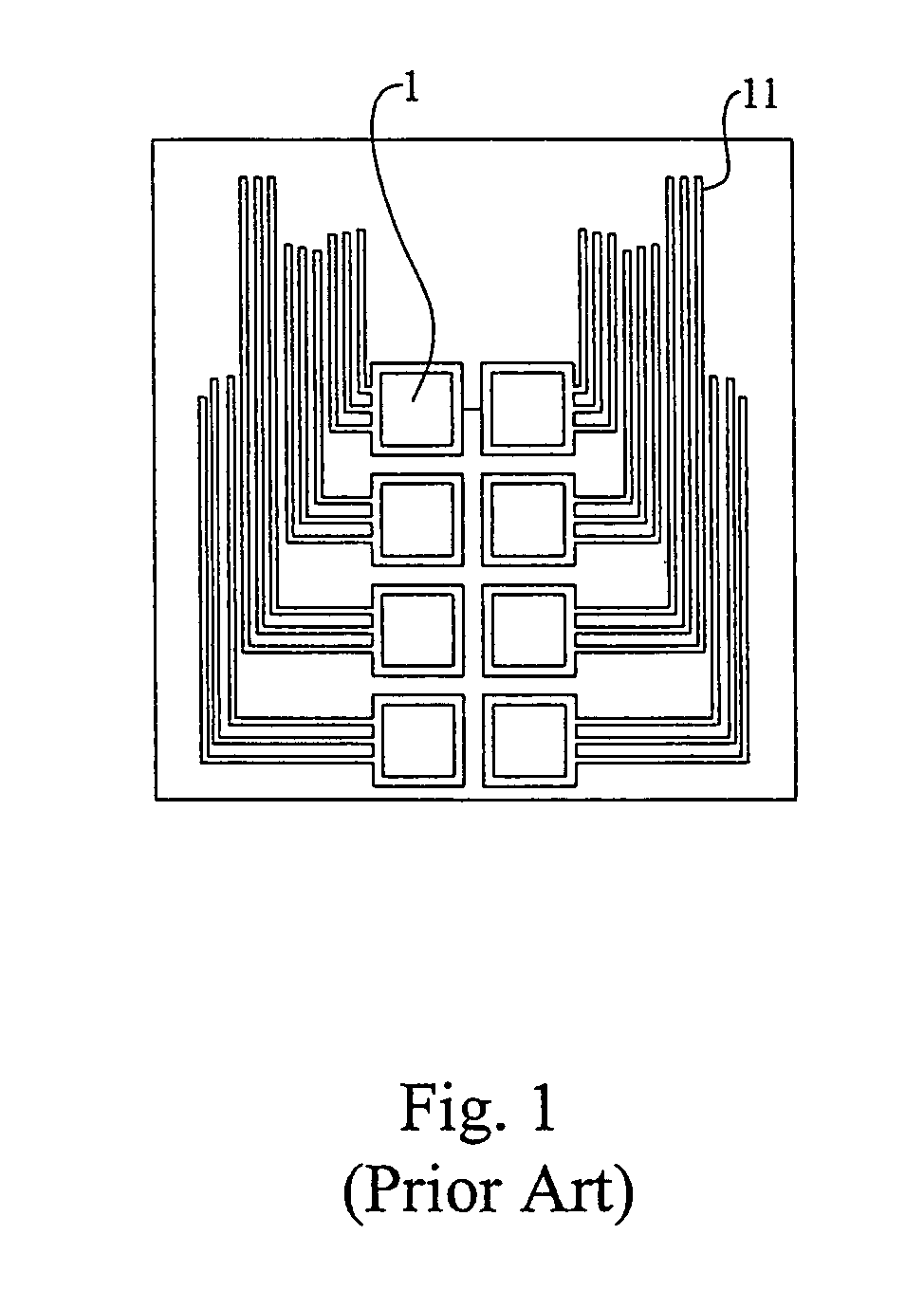

Homogenizing optical sheet, method of manufacture, and illumination system

An optical sheet that accepts light transmitted at or within a specific entrance cone angle that then redirects and transmits the light within an exit cone that is substantially normal to the sheet's plane. The intensity of the light within the exit cone is substantially uniform for any light source entering the sheet within the sheet's acceptance angle. The optical sheet is made of transparent material with microlens arrays formed on its opposite front and back surfaces. The thickness of the optical sheet is sufficient so that the microlens on the opposite surfaces are separated a distance equal to the microlens focal length, with each microlens on the front and back surfaces having substantially similar size and shape, with centers transversely aligned. When used with one or more light sources located on one surface, the transmitted light through the optical sheet is uniform in intensity across a second surface. When used with a second optical sheet, aligned parallel to the first optical sheet, the transmitted light is uniform across and throughout angles within the exit cone at a second surface. An economical method of manufacturing the optical sheet is also provided.

Owner:POWELL KARLTON DAVID +1

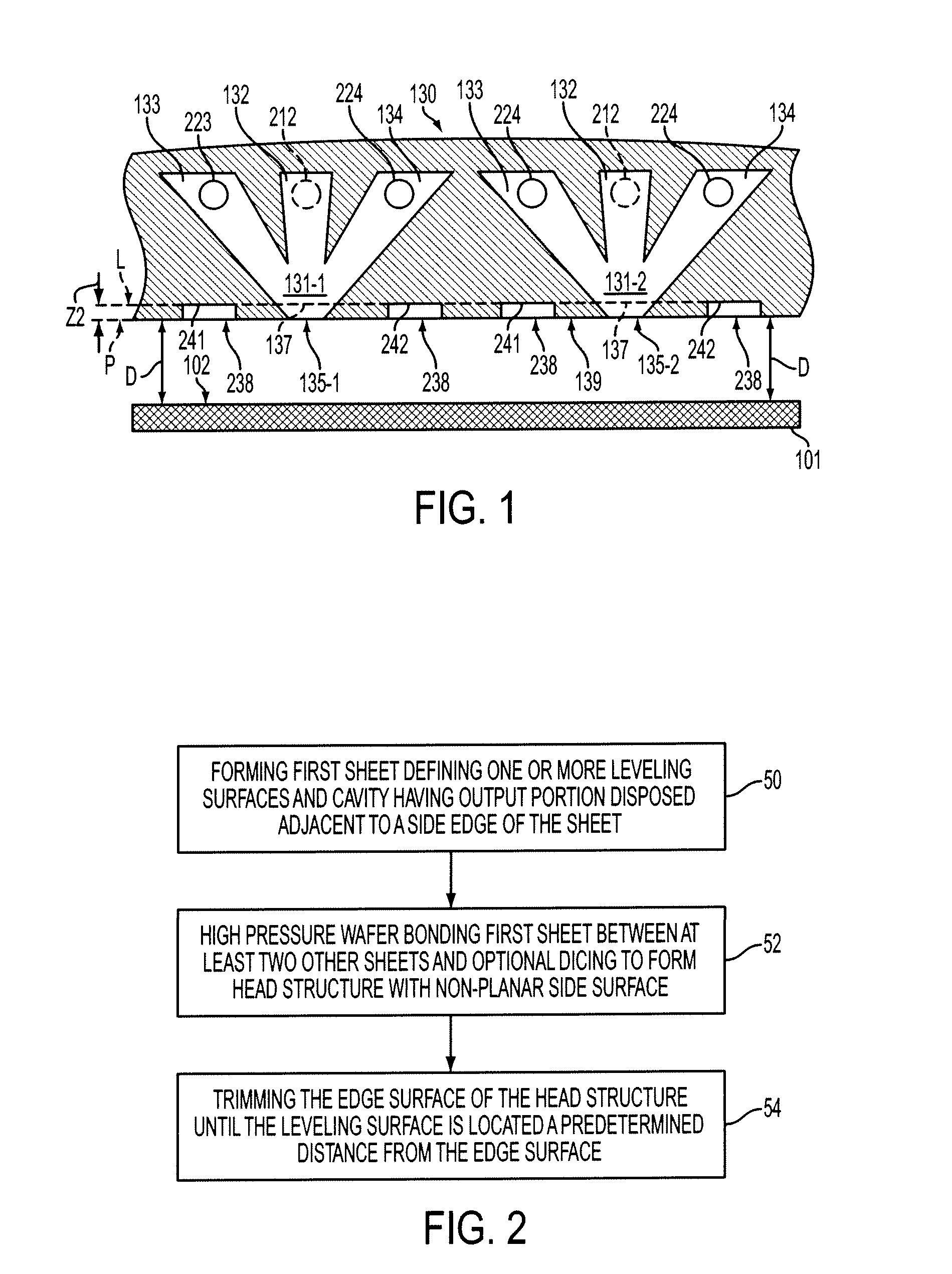

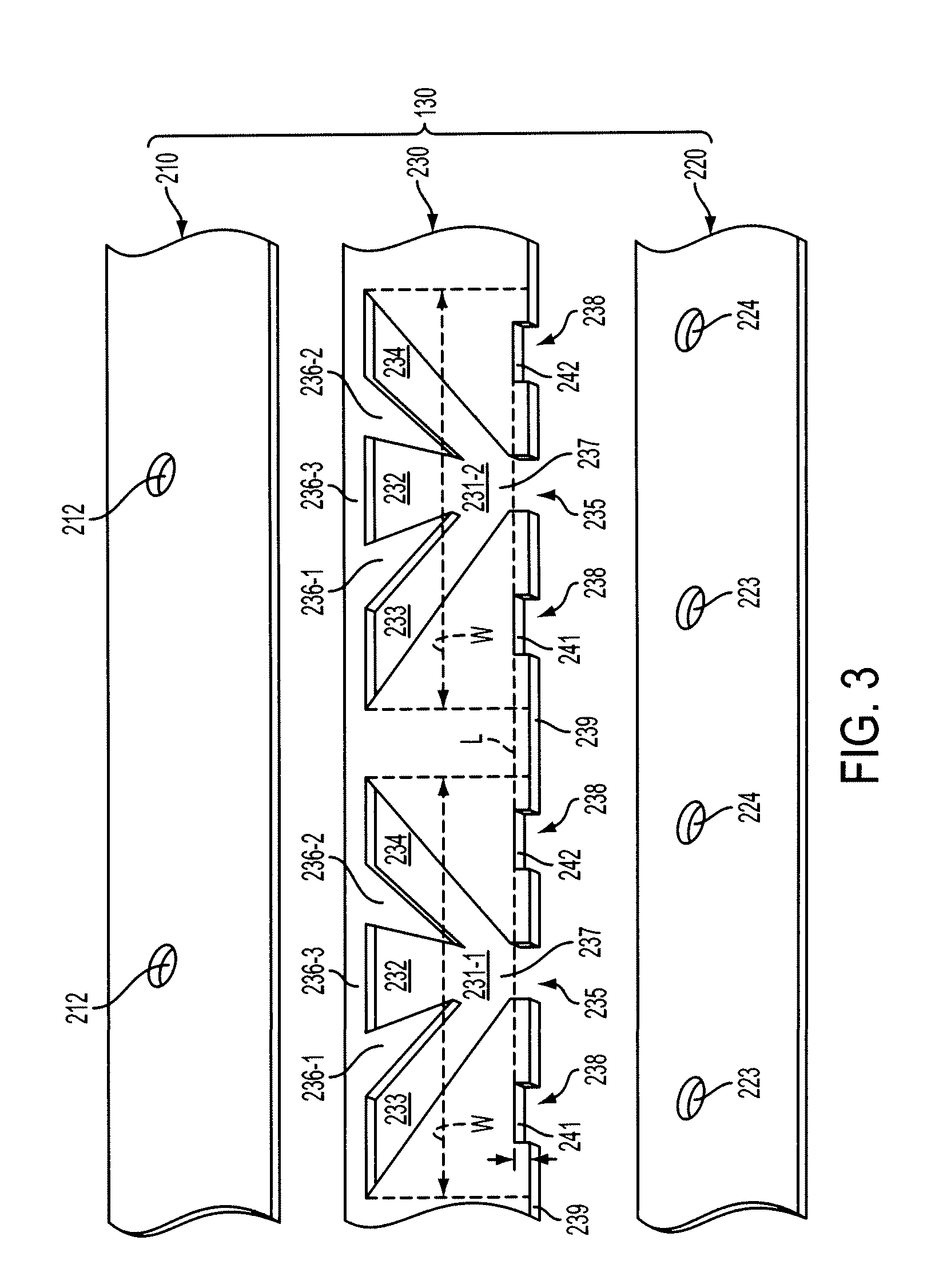

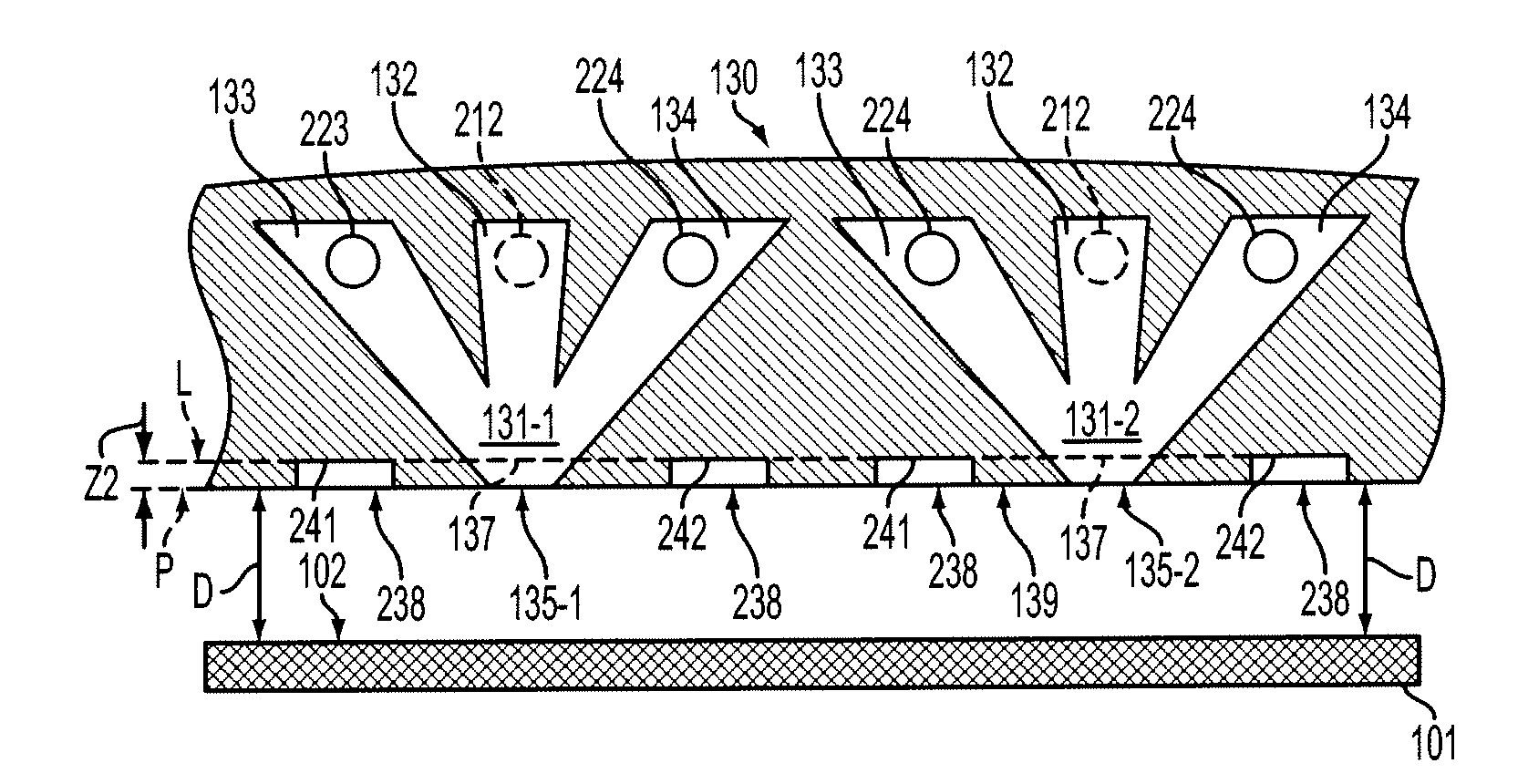

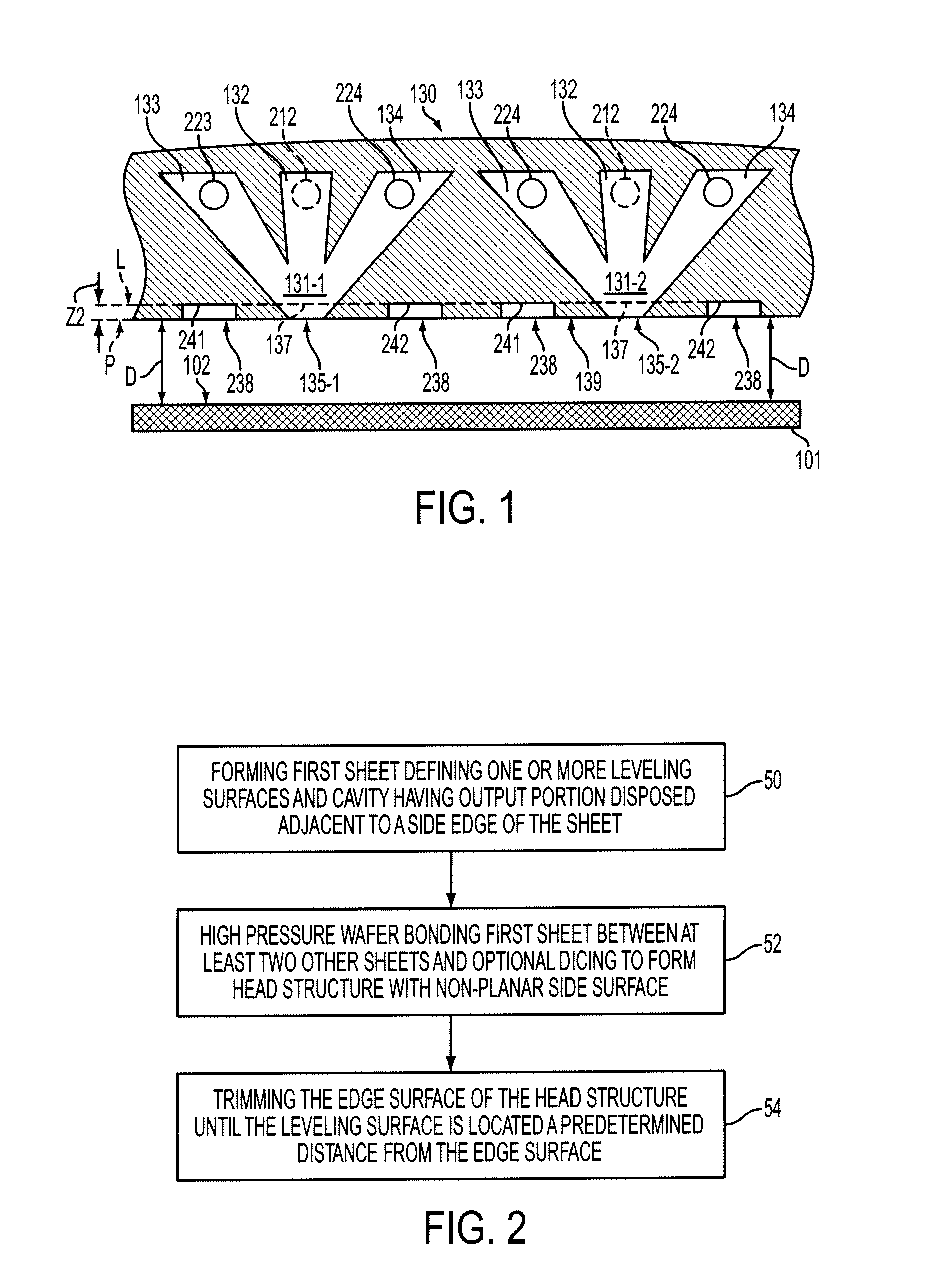

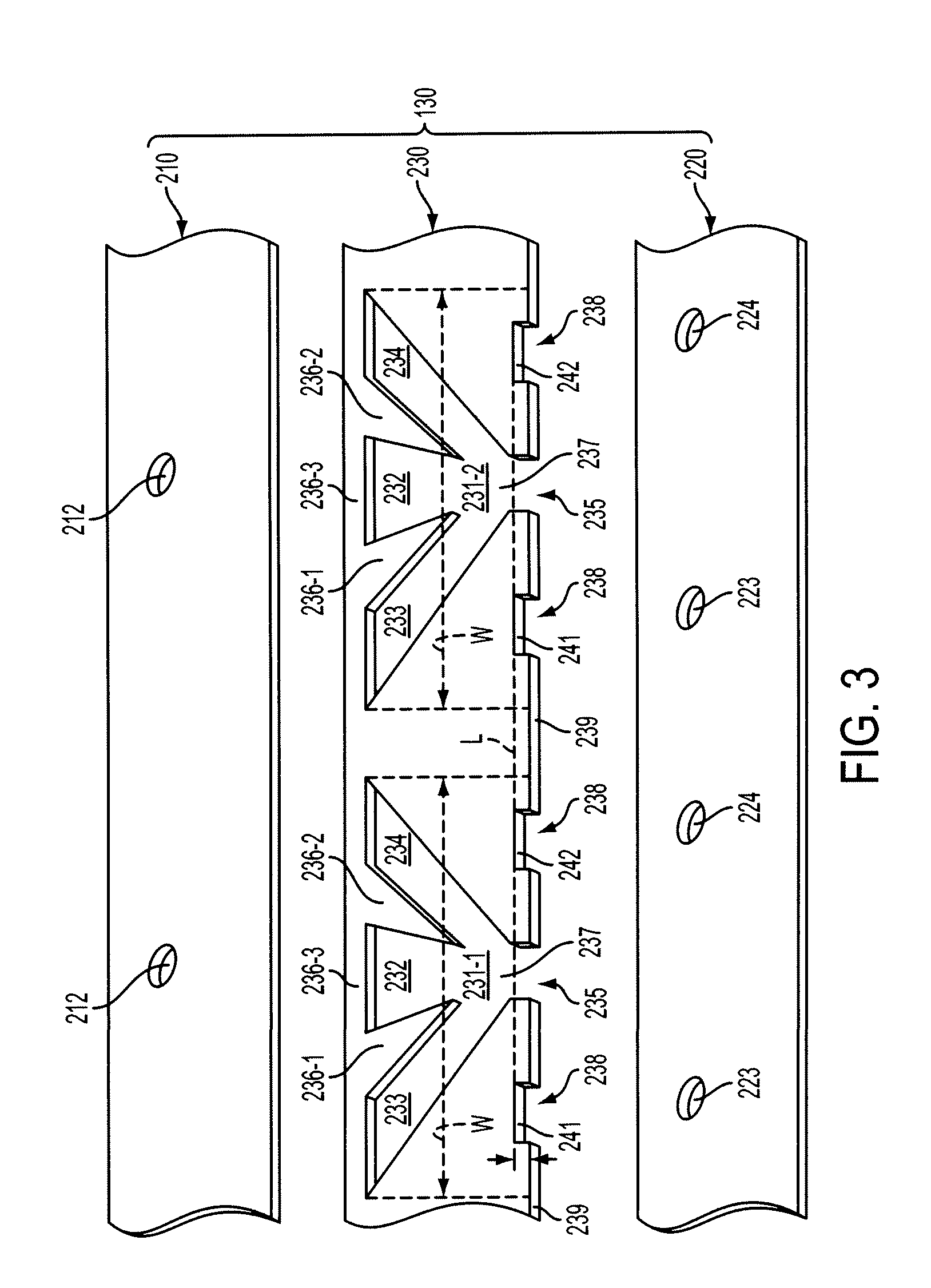

Extrusion head with planarized edge surface

InactiveUS7780812B2Easy to trimUnified positionConfectioneryCeramic shaping apparatusEdge surfaceHigh pressure

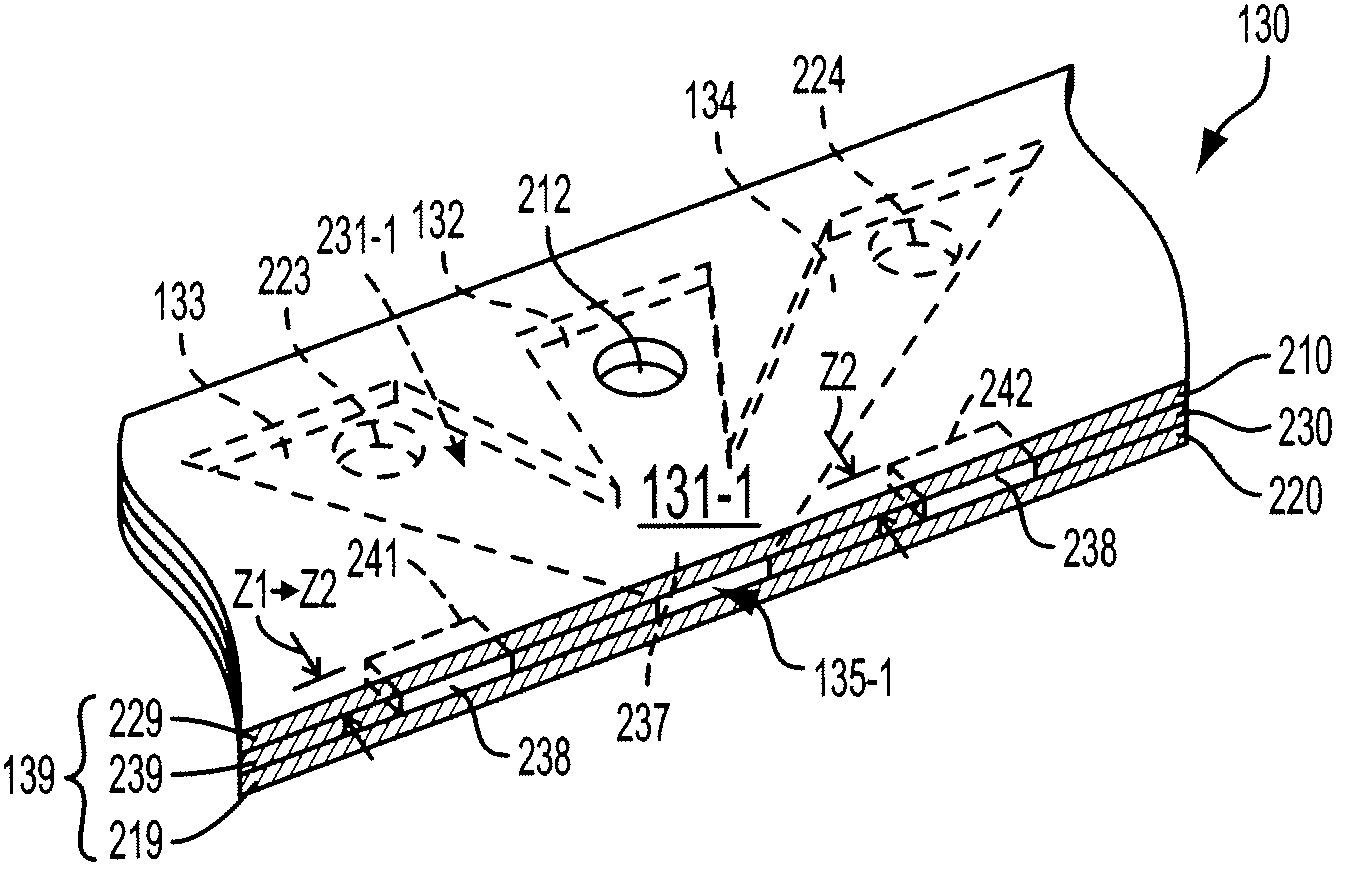

A co-extrusion head for forming high-aspect ratio gridline structures in a micro extrusion apparatus includes multiple sheets (e.g., metal plates) that are machined and assembled to define three-part fluidic channels having associated outlet orifice disposed along an edge surface of the head. Reference surfaces are also etched in the sheets and are aligned in a straight line that intersects output junctions of the three-channel cavities. After assembly (e.g., using high pressure bonding techniques), each reference surface is located inside a notch defined in the edge surface. The edge surface of the co-extrusion head is then trimmed (e.g., machined by wire EDM) using the reference surfaces as a precise guide, thereby producing uniform length outlet orifices with uniform flow impedance.

Owner:SOLARWORLD INNOVATIONS

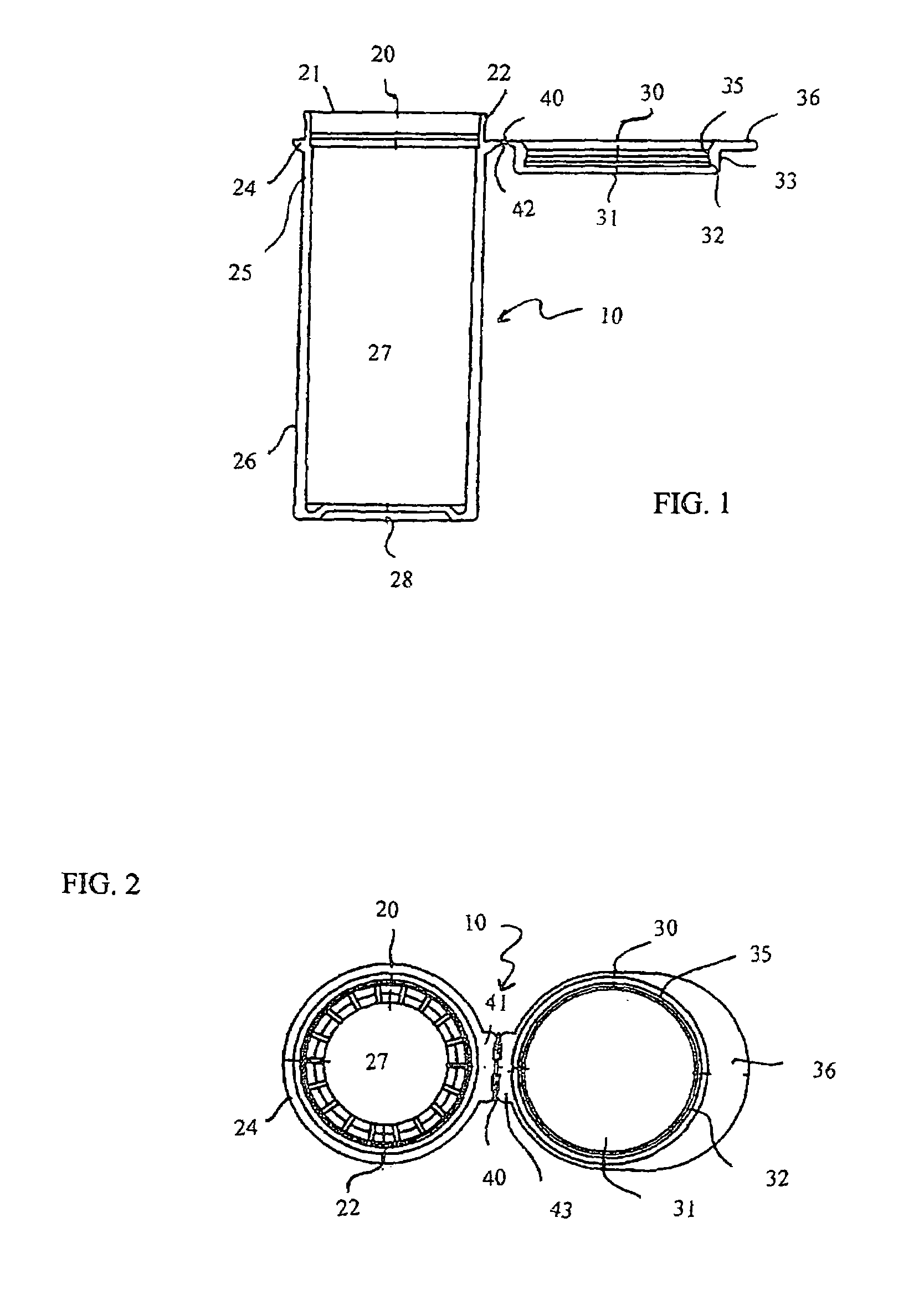

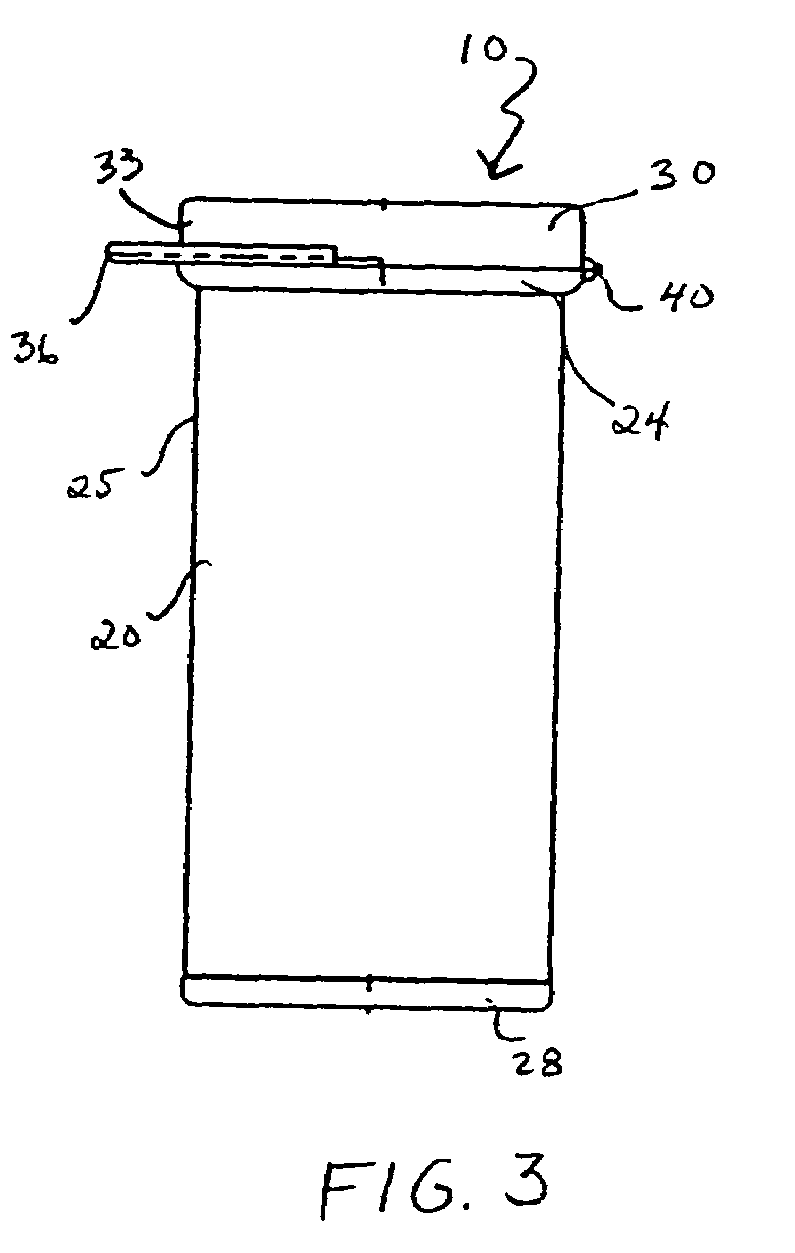

Leakproof, resealable container and cap assembly

InactiveUS7198161B2Prevent openingUnified positionCapsClosure using stoppersEngineeringMechanical engineering

A leakproof, resealable container and cap assembly, consisting essentially of: a container having a rim at its upper portion and a cap having a circular base with an outer periphery, a cylindrical tubular skirt having an inner wall with at least one recess, a thumb tab for facilitating the opening and closing of the container, and a hinge connecting the cap to the container, and in a closed portion, the skirt of the cap overlies the container and the rim of the container is situated within the recess of the inner wall of the skirt of the cap.

Owner:CSP TECH INC

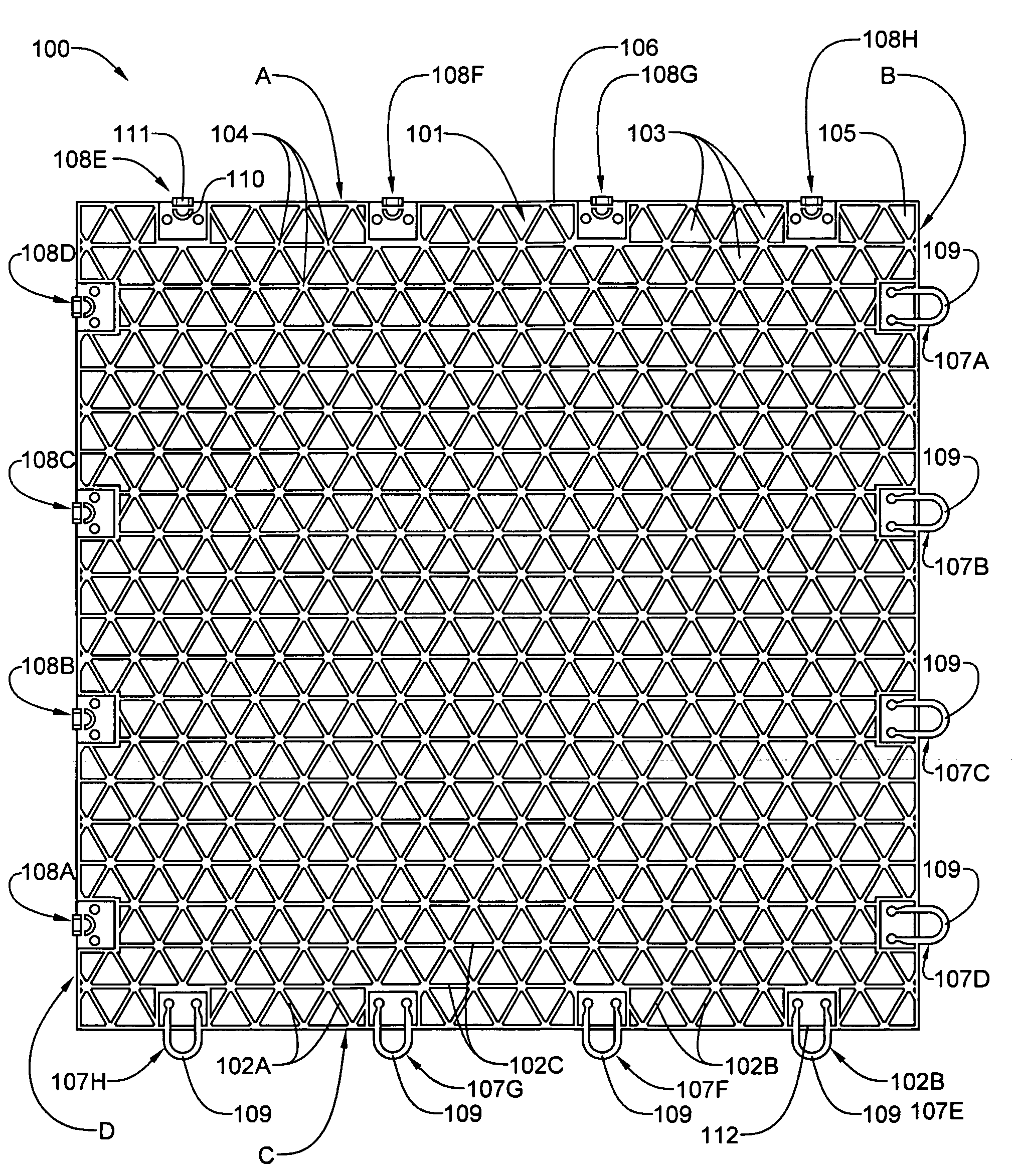

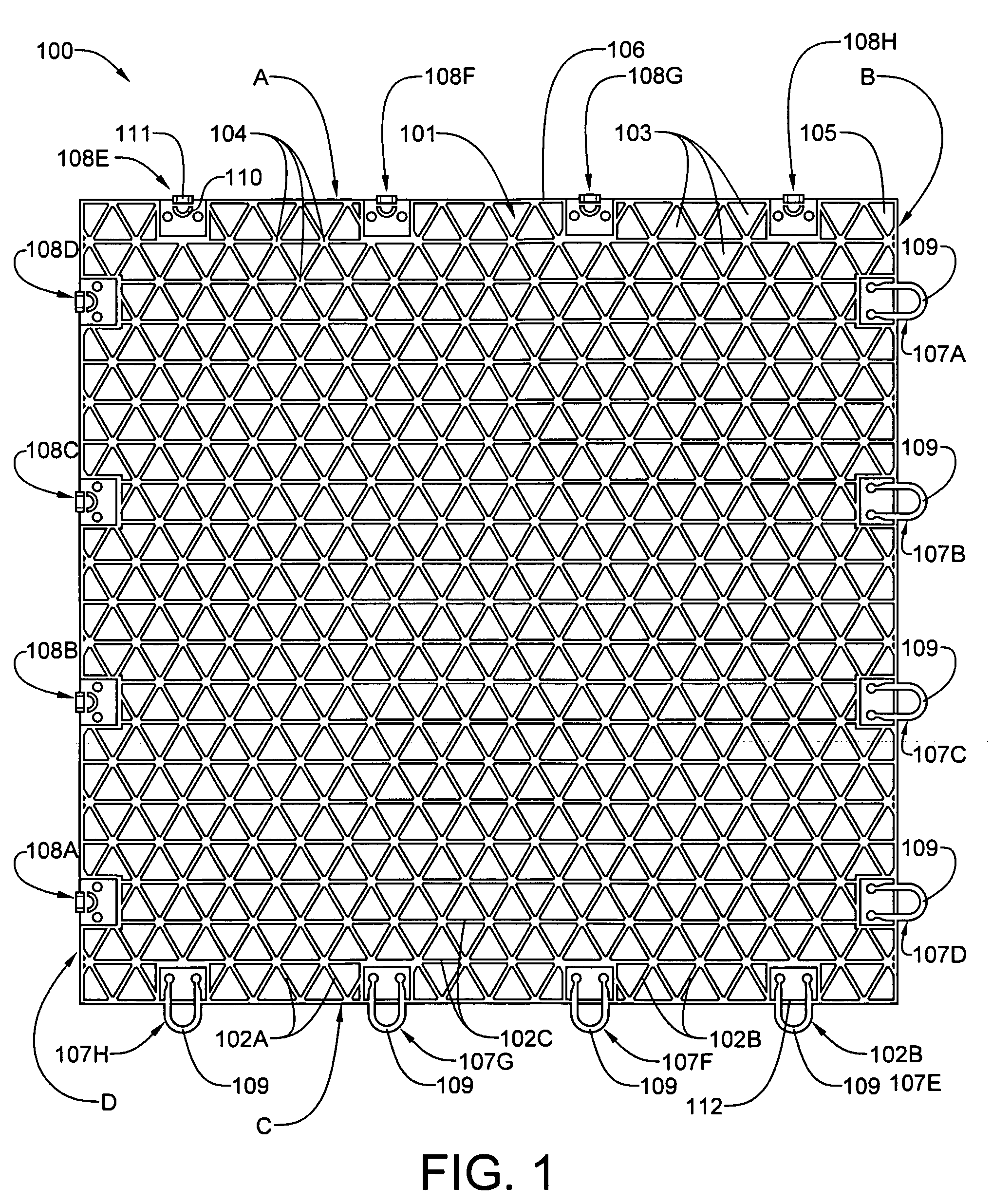

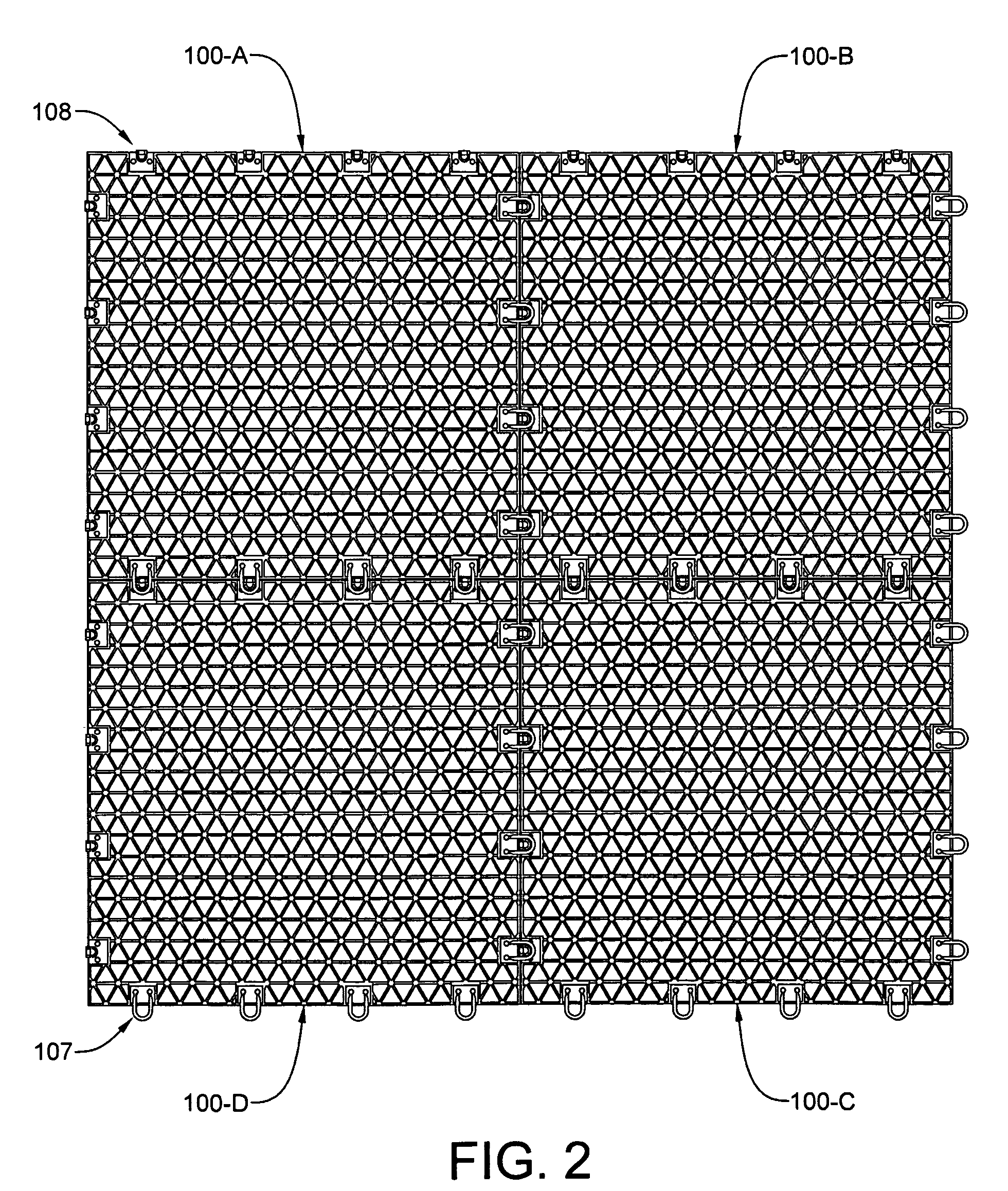

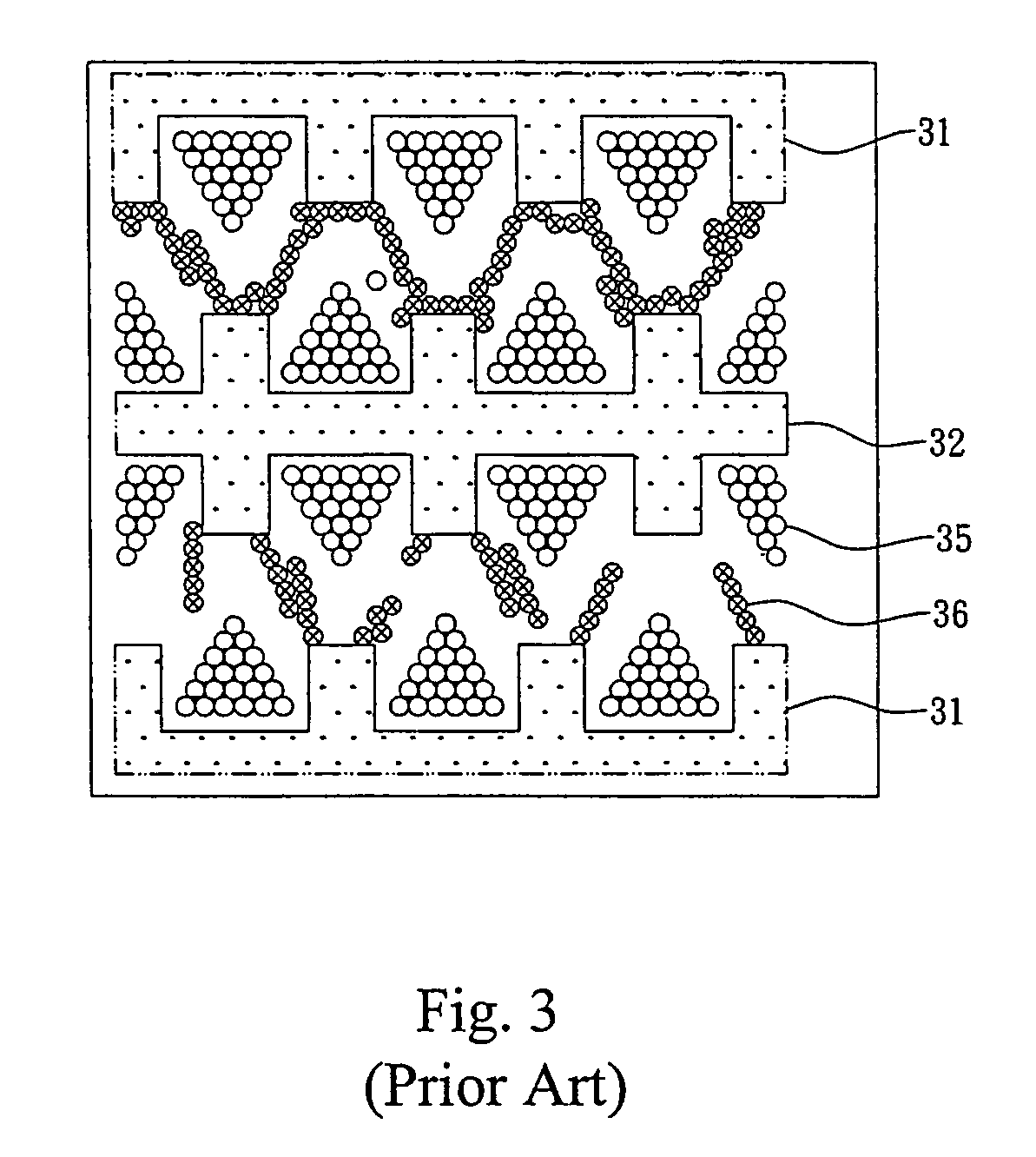

Floating floor assembled from an array of interconnected subunits, each of which includes a stone, ceramic, or porcelain tile bonded to an injection molded polyolefin substrate

A floating floor assembled from an array of interconnected subunits, each of which includes a stone, ceramic or porcelain tile and a one-piece polymeric plastic substrate to which the stone, ceramic, or porcelain tile is bonded. Each substrate is injection molded from certain polyolefin polymers and incorporates the interlock structure and certain other features of the modular sports tiles of U.S. Pat. No. 4,930,286. The substrates of the present invention, however, differ in that the plastic support grid is formed by three sets of mutually intersecting walls, with each set being angularly offset from the other two by 120 degrees, and each substrate is sized to precisely fit a stone, ceramic or porcelain tile, which is accurately positioned by tile locator tabs on a pair of intersecting sides of the substrate.

Owner:HILL DAVID TILGHMAN

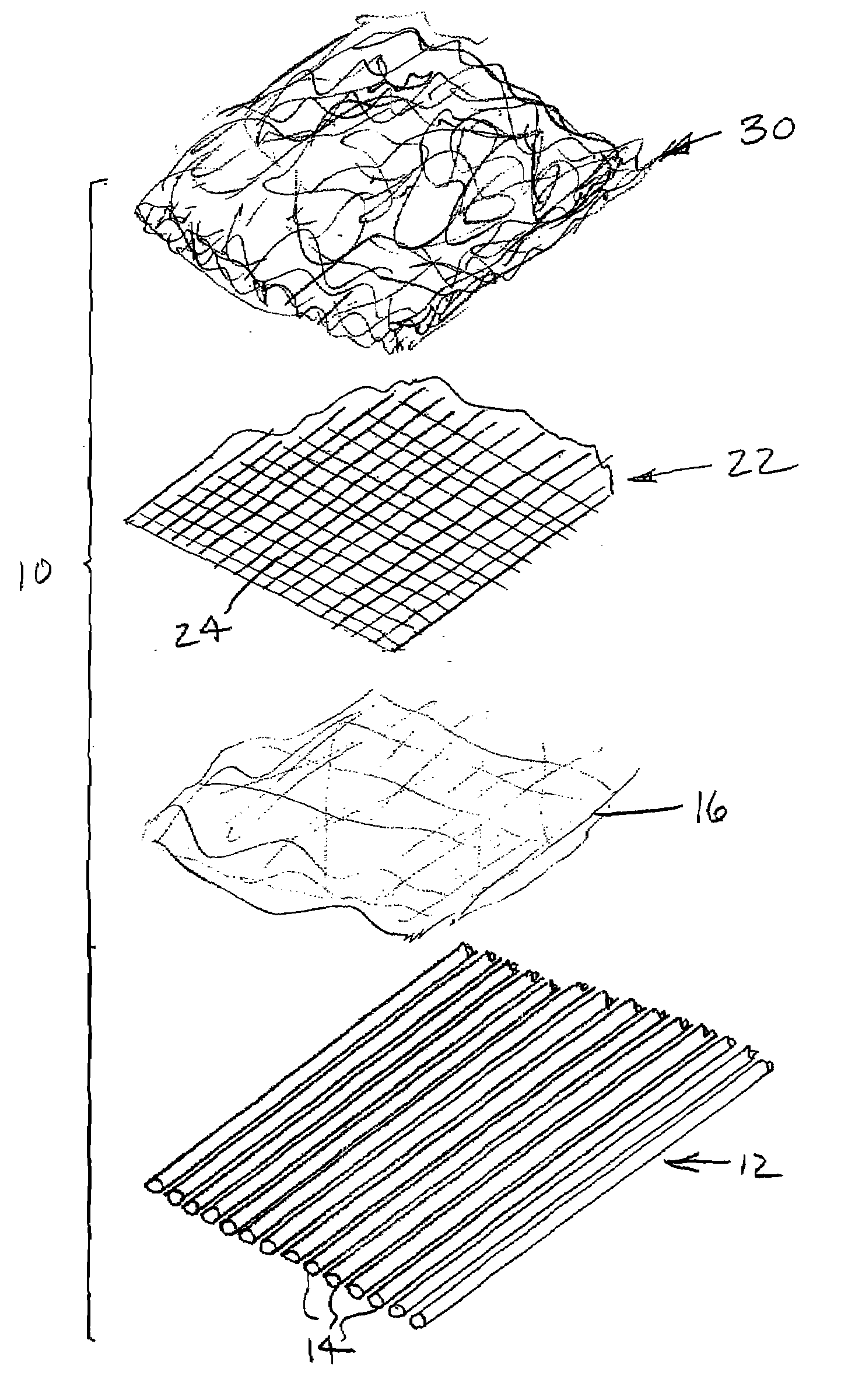

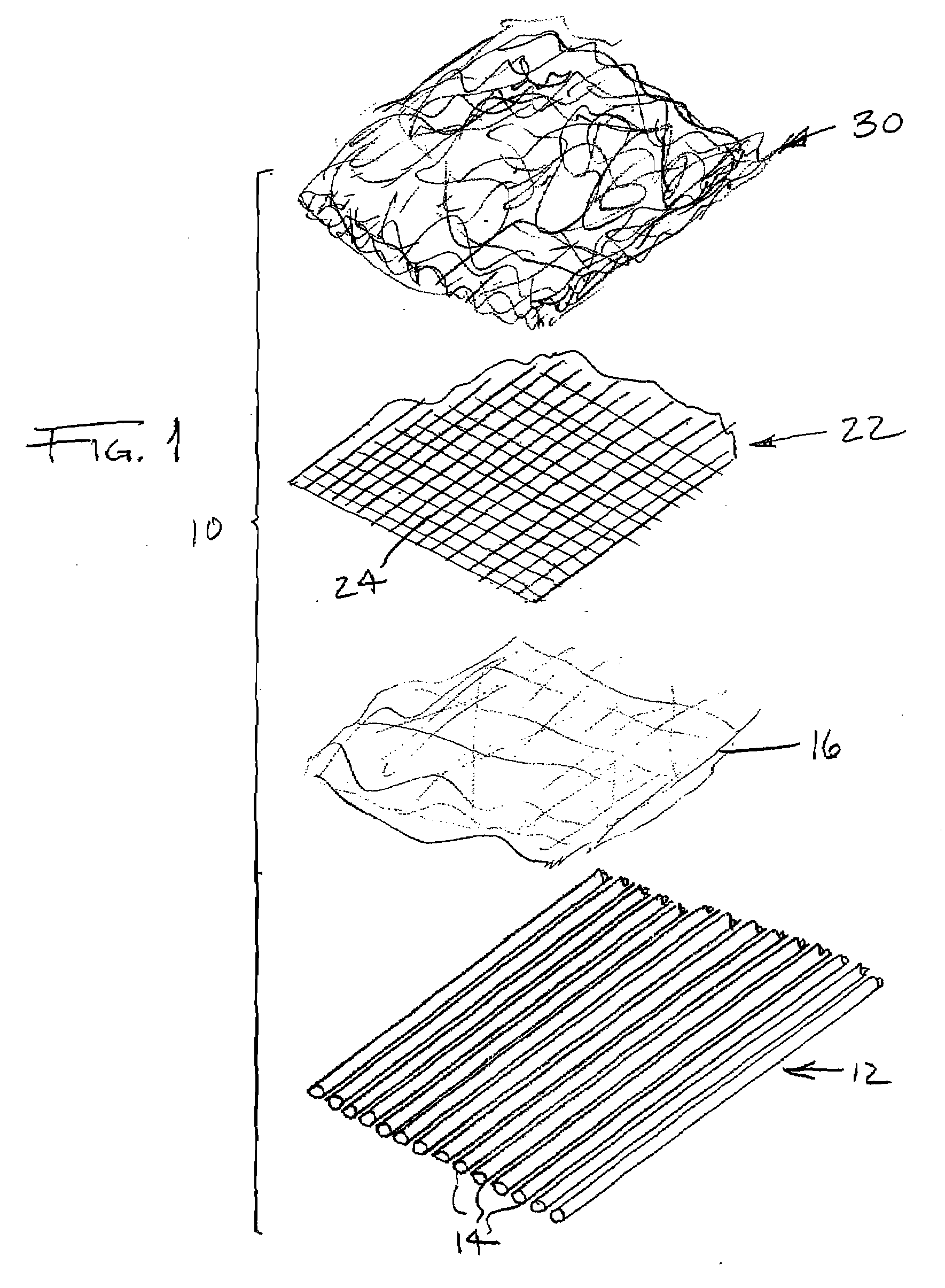

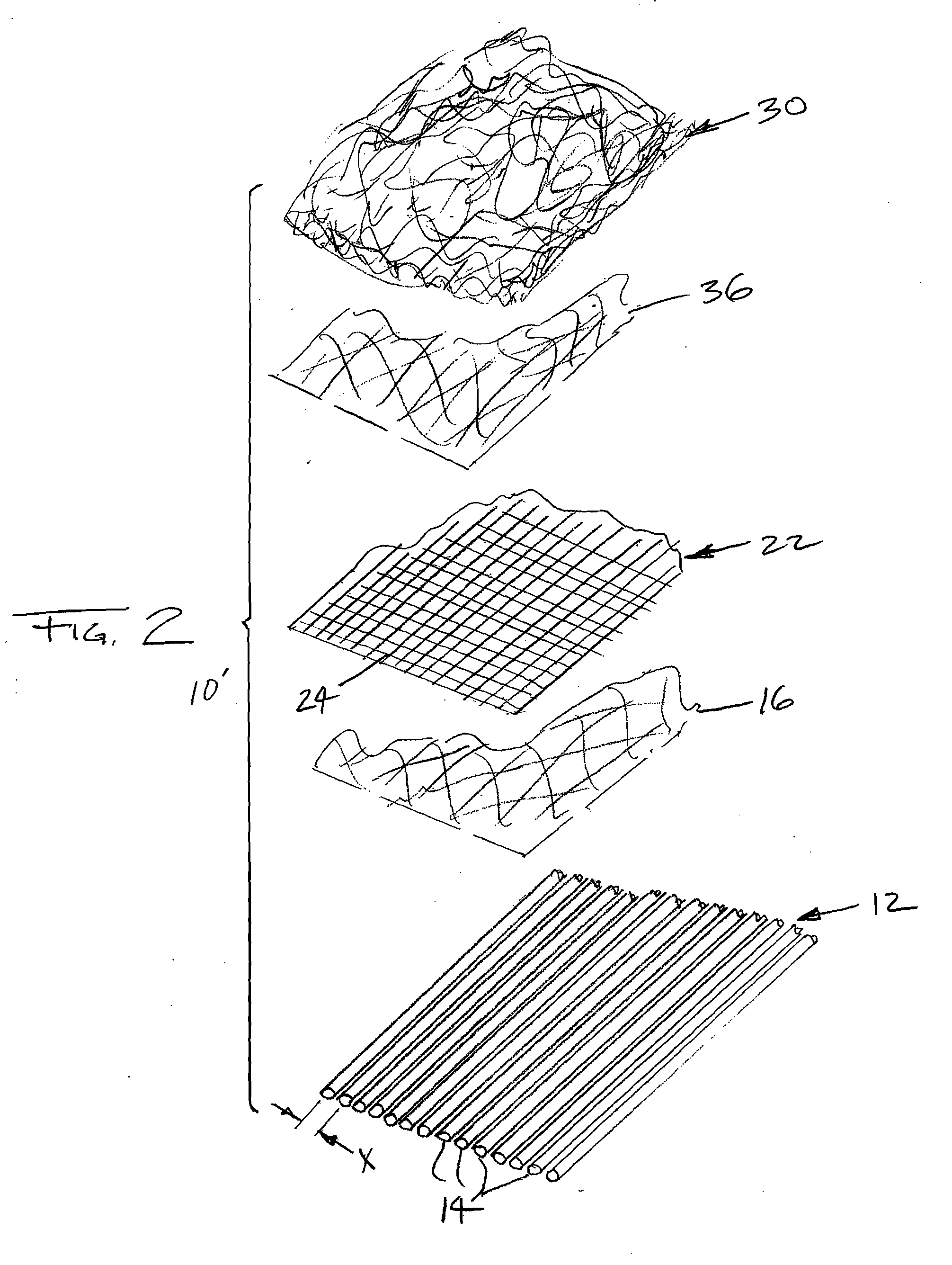

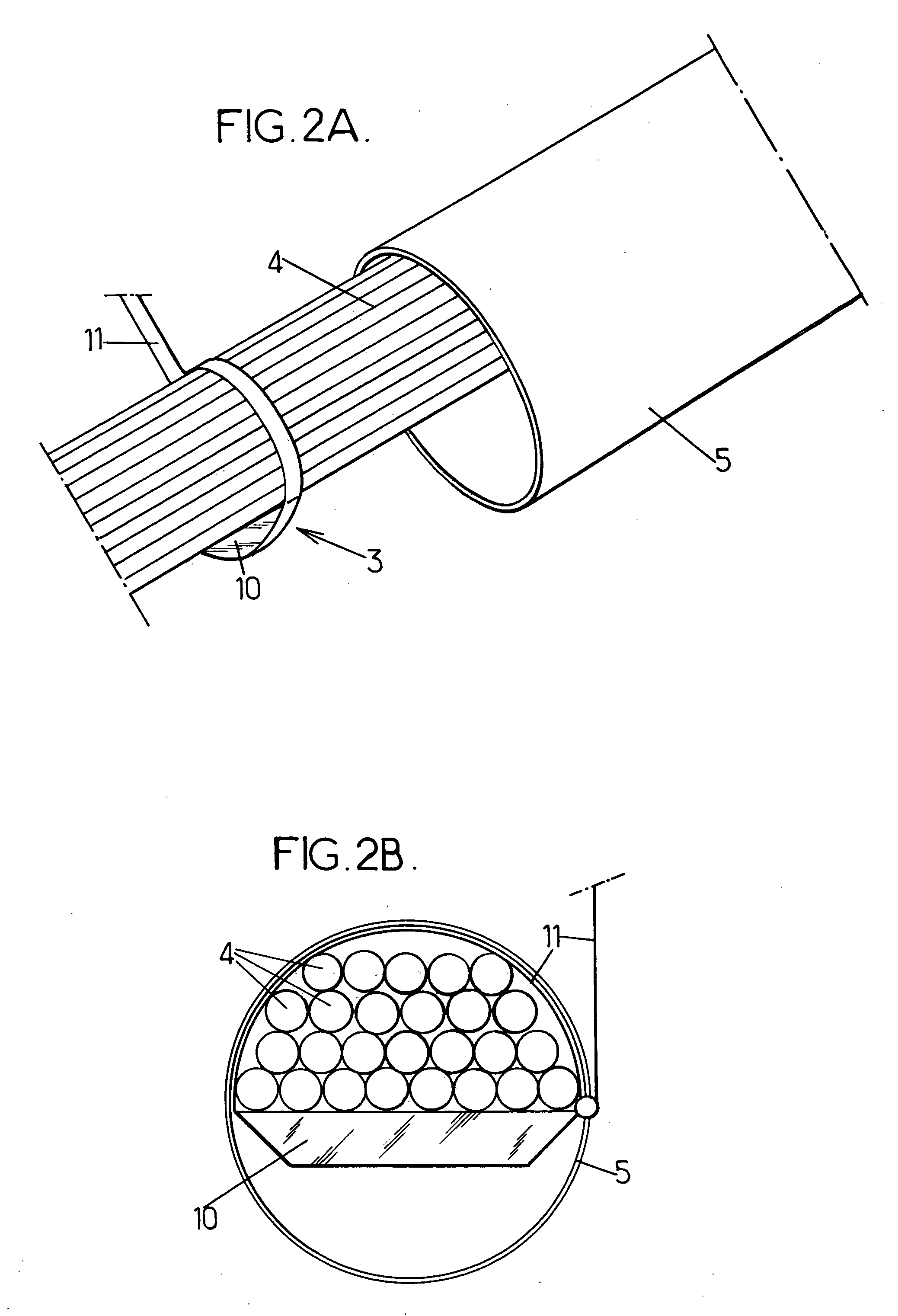

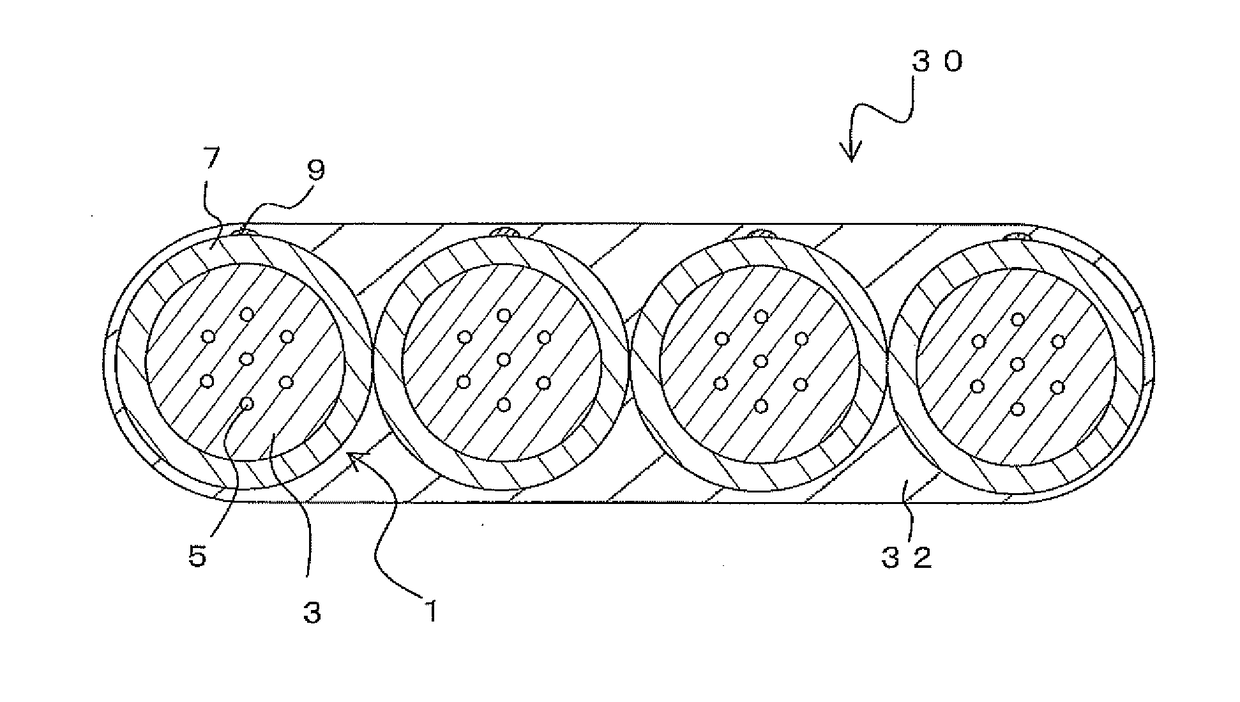

Nonwoven textile assembly, method of manufacture, and spirally wound press felt comprised of same

InactiveUS20070254546A1Little if any markingResist compressive loadingLaminationLamination apparatusYarnEngineering

A nonwoven textile assembly, a method for its manufacture, and a spirally wound press felt made from the assembly are disclosed. The nonwoven textile assembly is manufactured by providing a uniform array of parallel yarns having constant height and spacing as a first textile component and which are oriented in a first direction. An adhesive material is applied to a first side of the first component. A second textile component, such as a second array of parallel yarns oriented at an angle of from 2° to 90° to the first, or a nonwoven mesh, or a nonwoven scrim comprising a regenerated cellulosic is then laid over the adhesive material. A lightweight batt layer optionally including a second adhesive preferably located on the side of the batt facing the second side of the second textile component, is overlaid the second textile component. The assembled first textile component, adhesive component (if applicable), second textile component, adhesive component (if applicable) and batt, is then passed through a pressure zone which is preferably heated so as to activate the adhesives and securely hold the first and second textile components in place along with the batt material. Optionally, the batt material may contain bi-component fibers of which one of the two components is a heat activated adhesive. The resulting nonwoven textile assembly may then be needled in a needling unit downstream of the heated nip, or otherwise processed. A spirally wound press felt comprised of at least one helically wound, abutting strip of the nonwoven textile assembly is provided.

Owner:ASTENJOHNSON

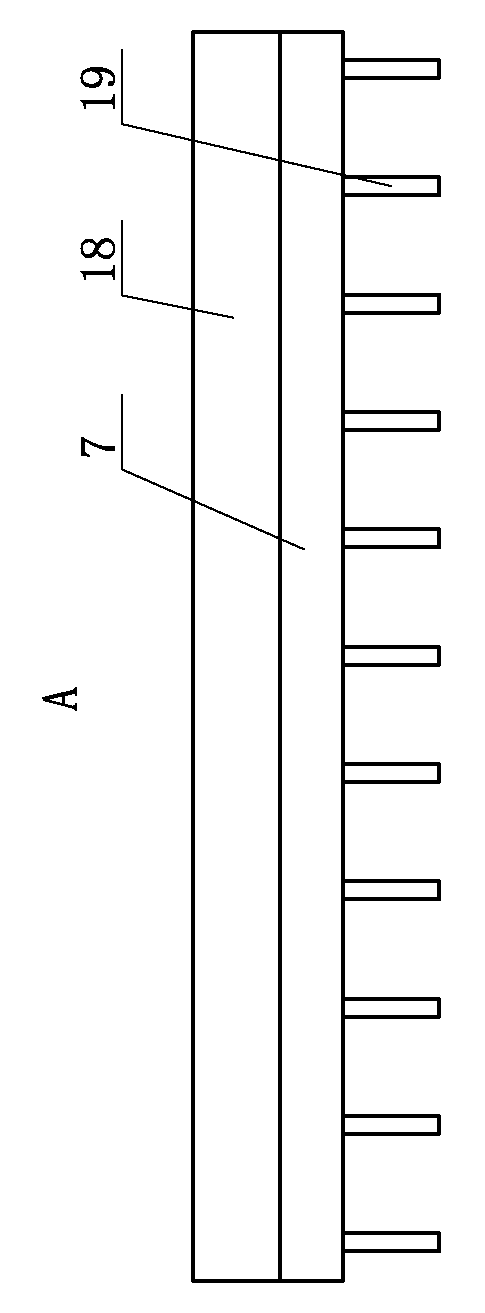

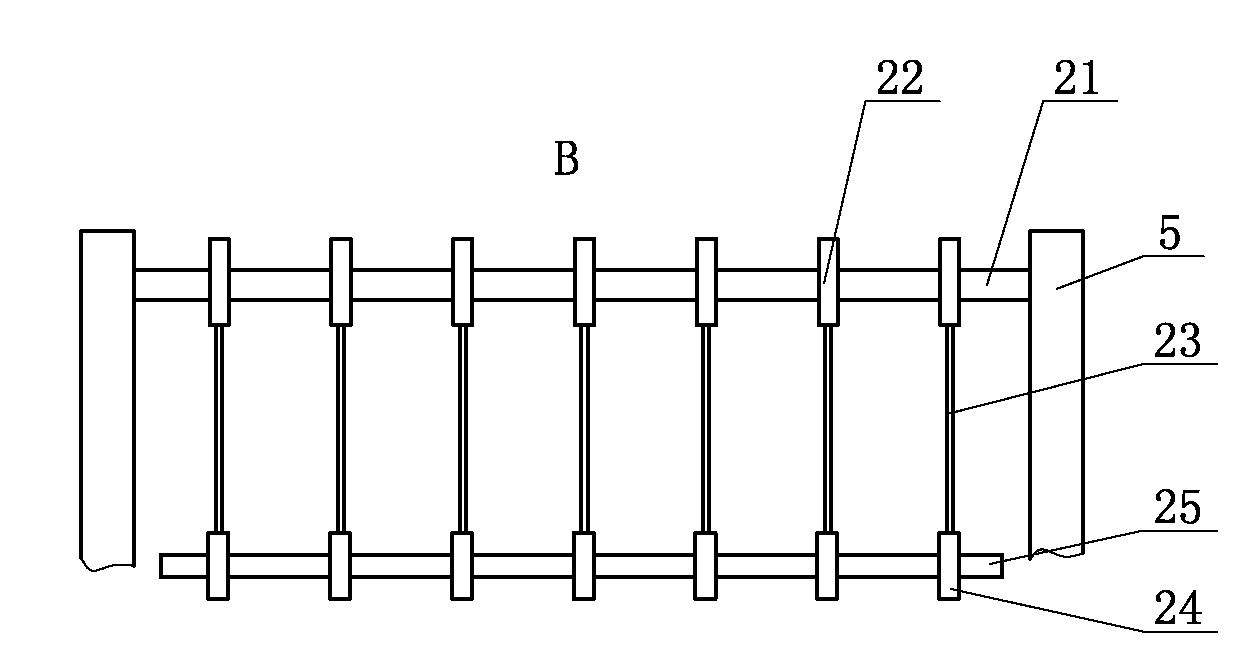

Extrusion Head With Planarized Edge Surface

A co-extrusion head for forming high-aspect ratio gridline structures in a micro extrusion apparatus includes multiple sheets (e.g., metal plates) that are machined and assembled to define three-part fluidic channels having associated outlet orifice disposed along an edge surface of the head. Reference surfaces are also etched in the sheets and are aligned in a straight line that intersects output junctions of the three-channel cavities. After assembly (e.g., using high pressure bonding techniques), each reference surface is located inside a notch defined in the edge surface. The edge surface of the co-extrusion head is then trimmed (e.g., machined by wire EDM) using the reference surfaces as a precise guide, thereby producing uniform length outlet orifices with uniform flow impedance.

Owner:SOLARWORLD INNOVATIONS

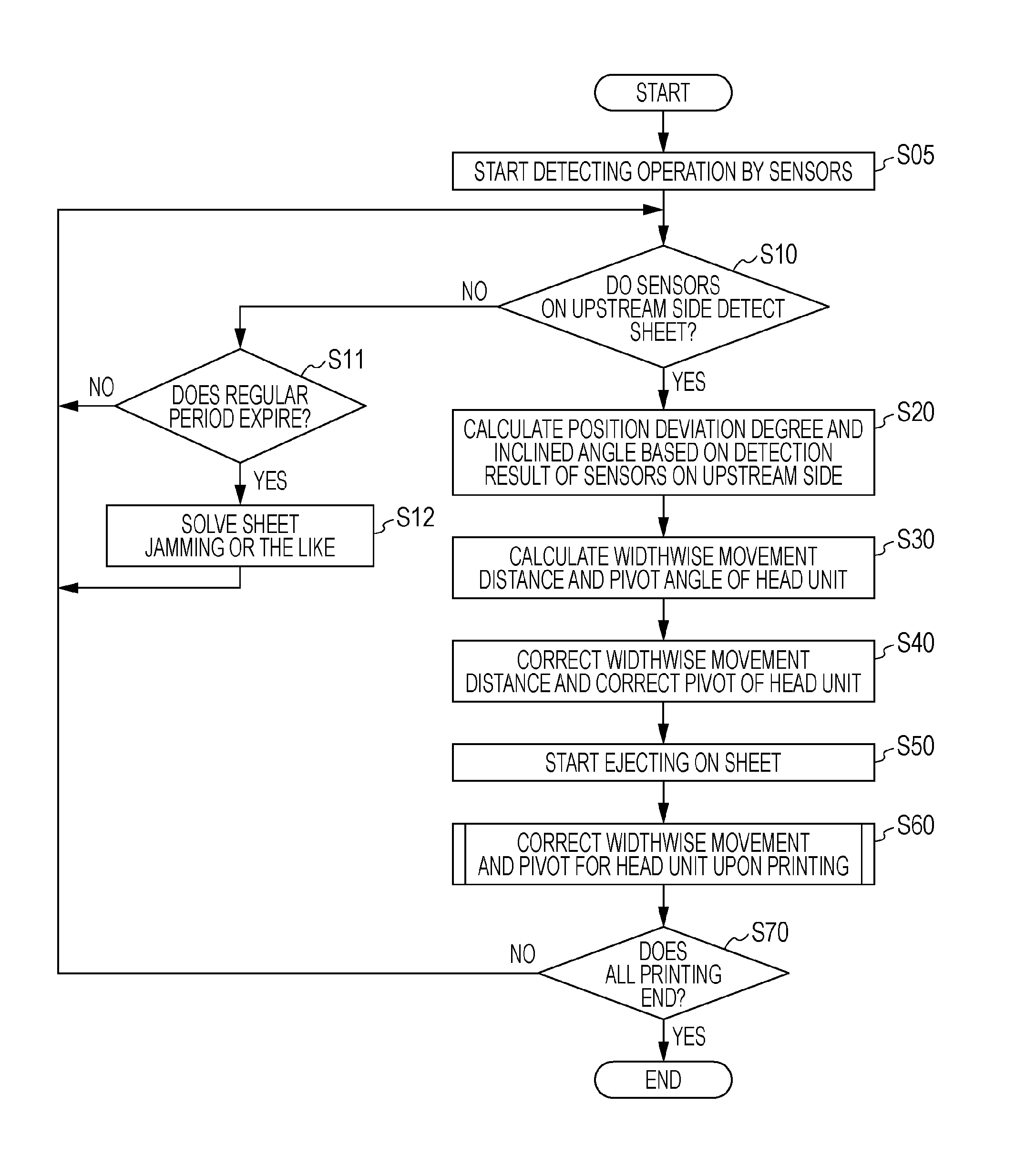

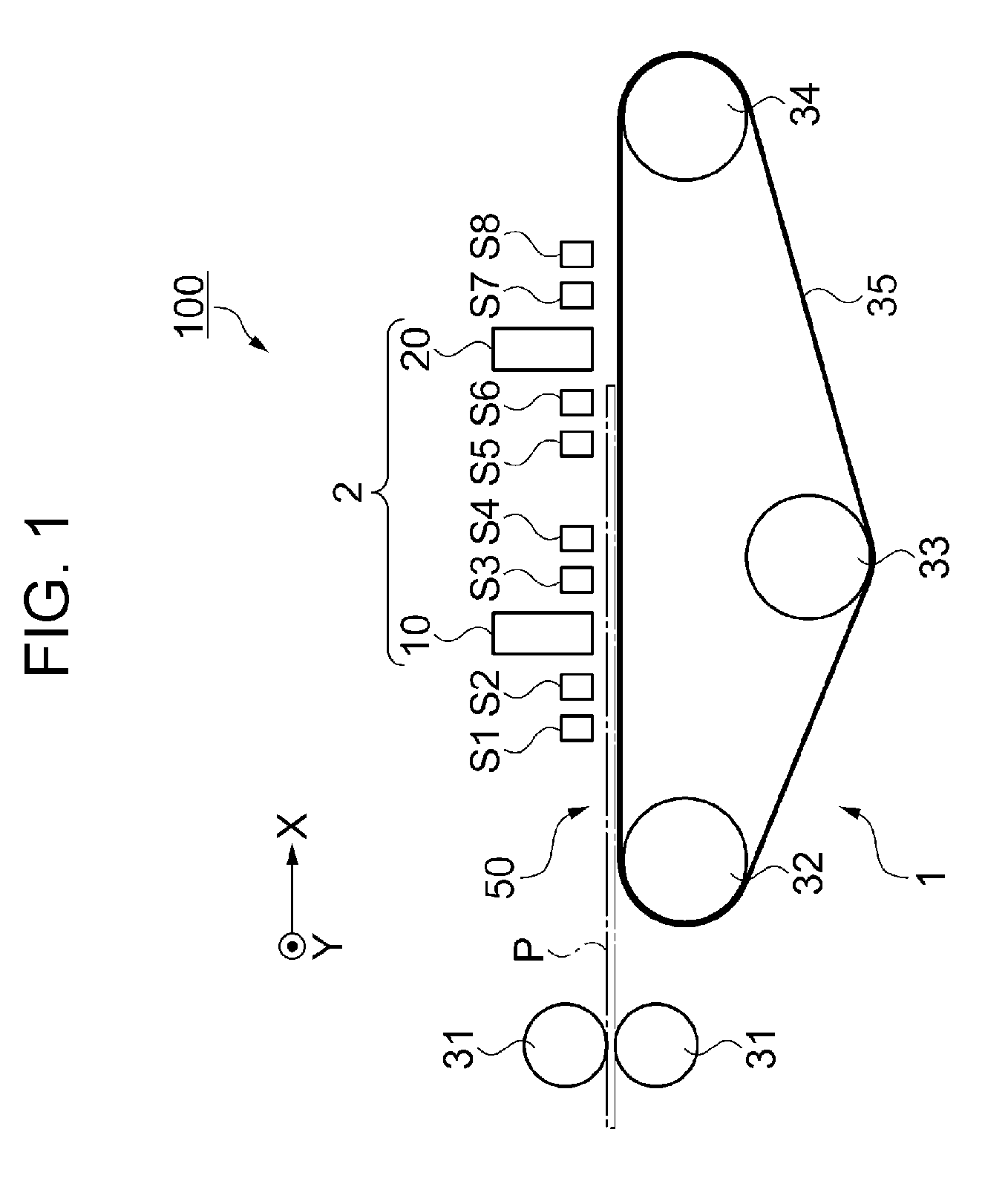

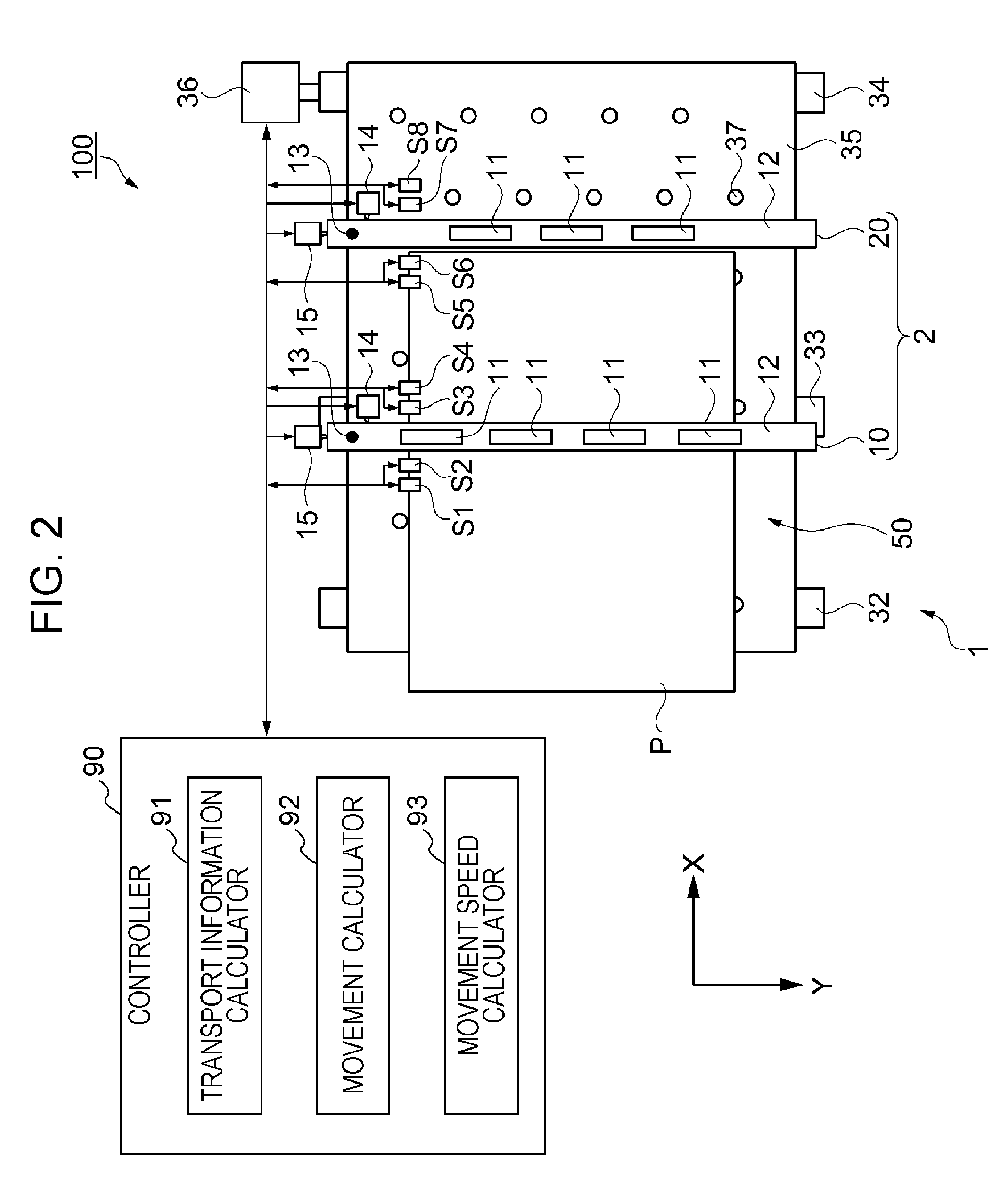

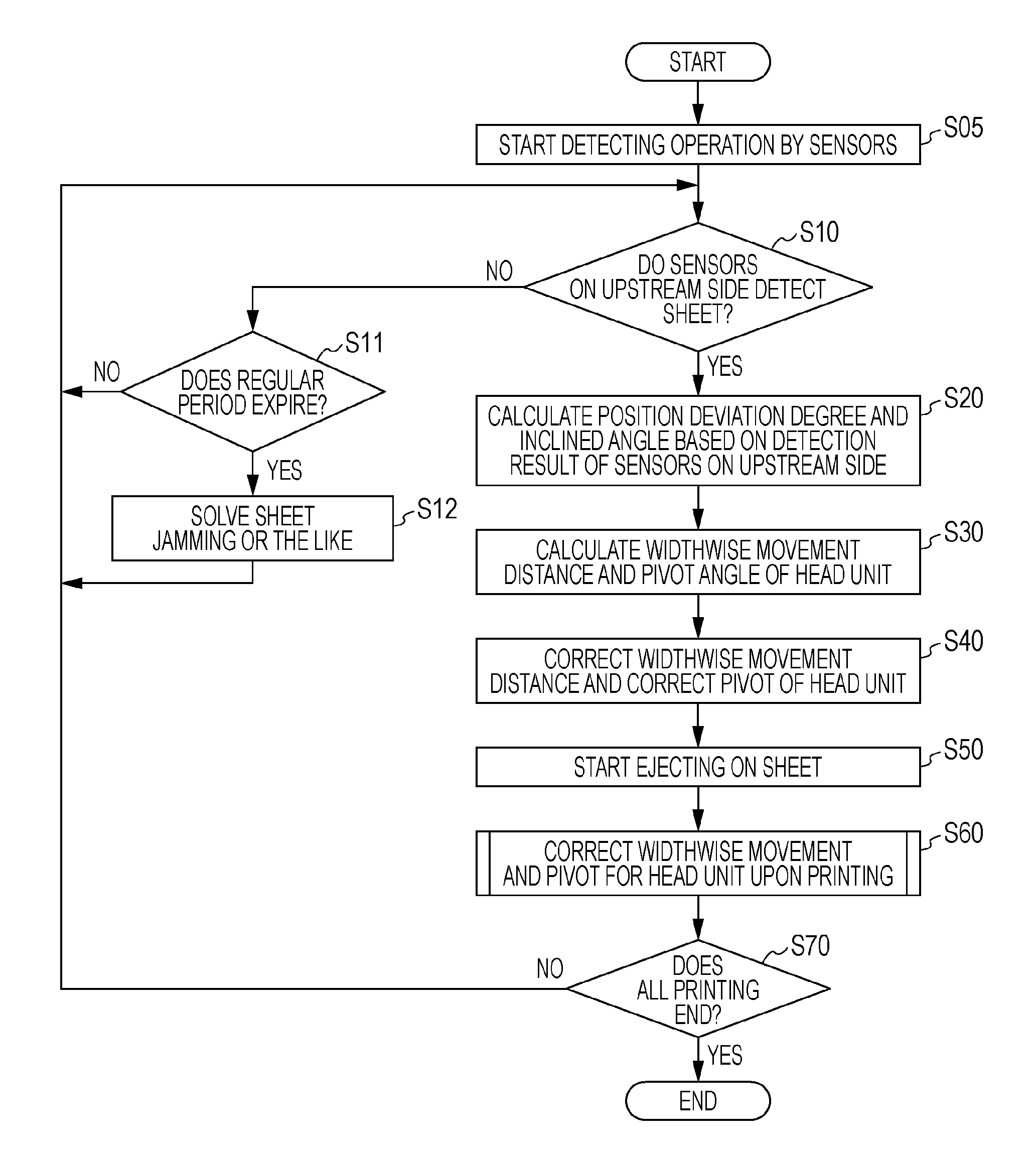

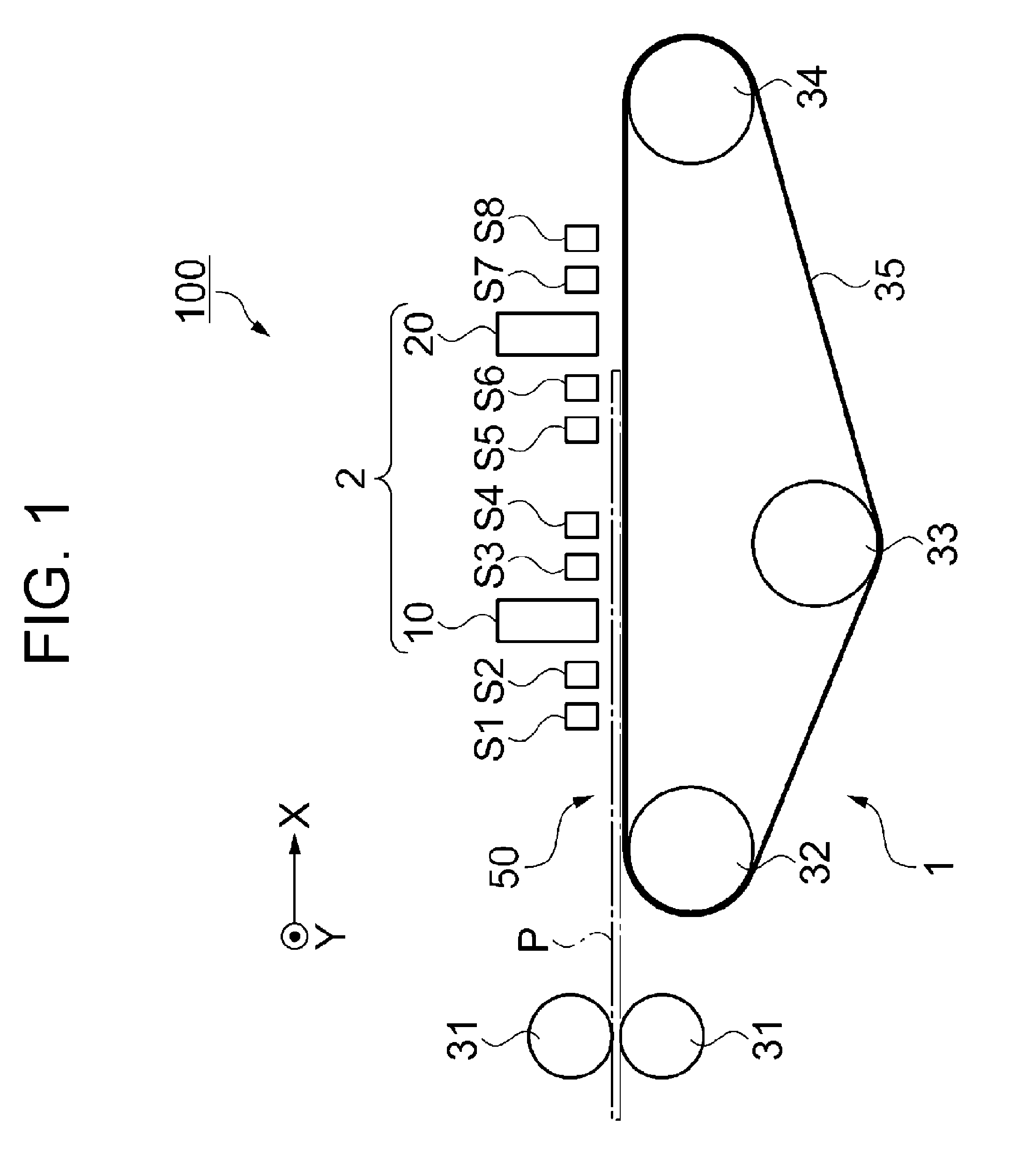

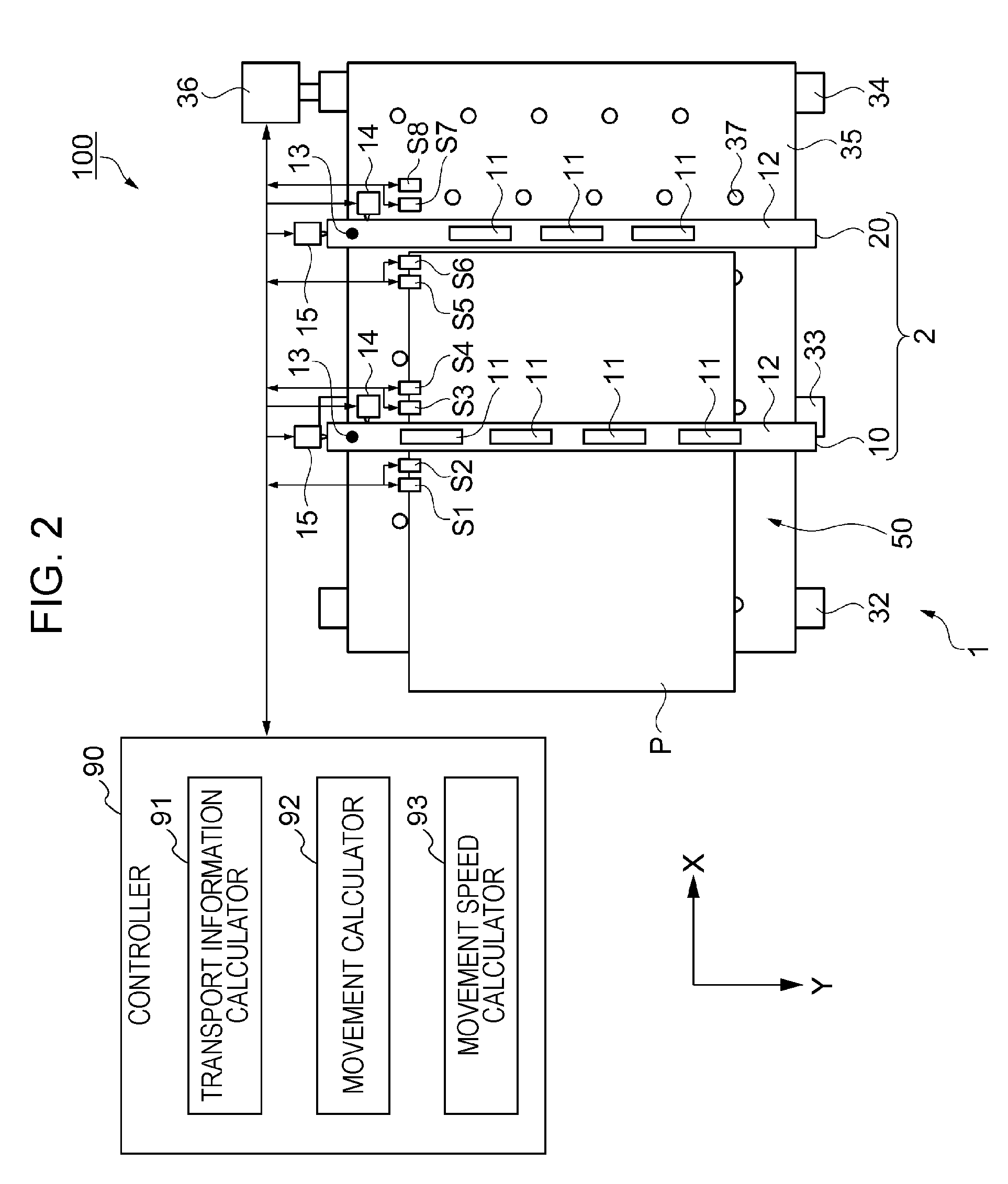

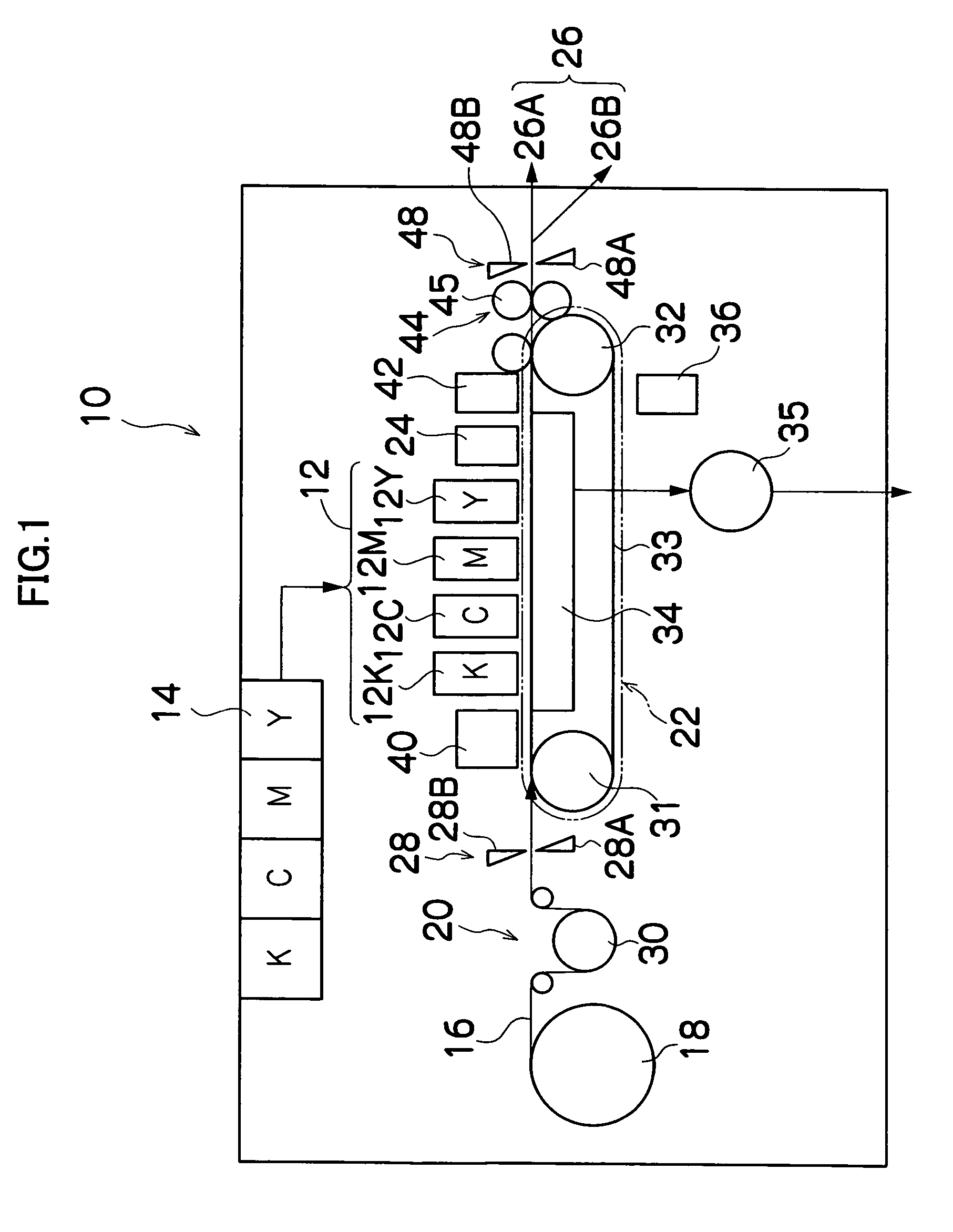

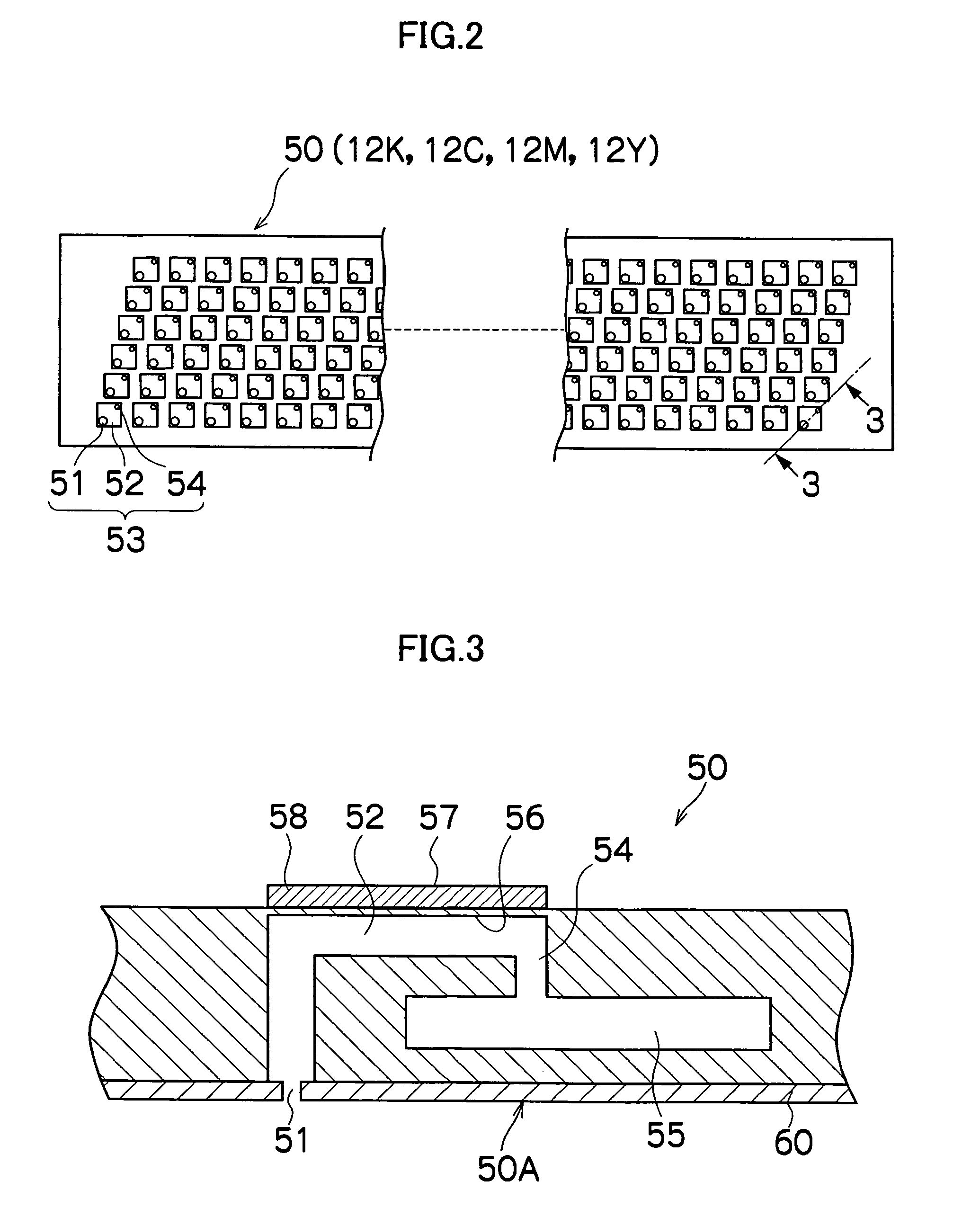

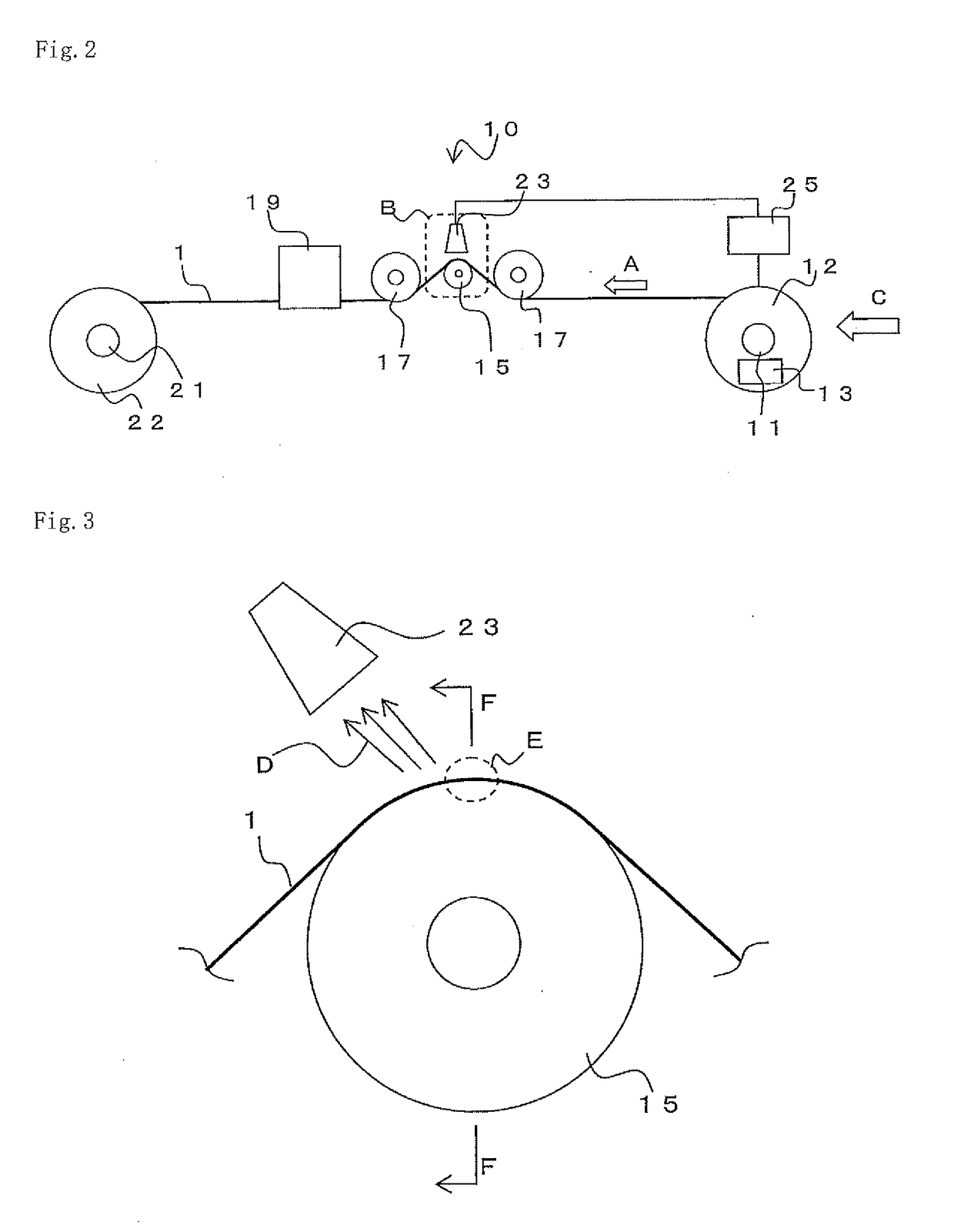

Print position correcting device, method of controlling print position correcting device, and printing apparatus

ActiveUS20100149248A1Smooth movementUnified positionSpacing mechanismsTypewritersComputer scienceCalculator

A print position correcting device includes: a head unit which ejects a liquid onto a print medium being transported on a transport surface; detectors which detect a position of the print medium being transported; a transport information calculator which calculates transport information regarding a transport status of the print medium based on the position of the detected print medium; a movement speed calculator which calculates a movement speed used to move the head unit based on the transport information; and a controller which moves the head unit in a direction parallel to the transport surface based on the transport information and the movement speed.

Owner:SEIKO EPSON CORP

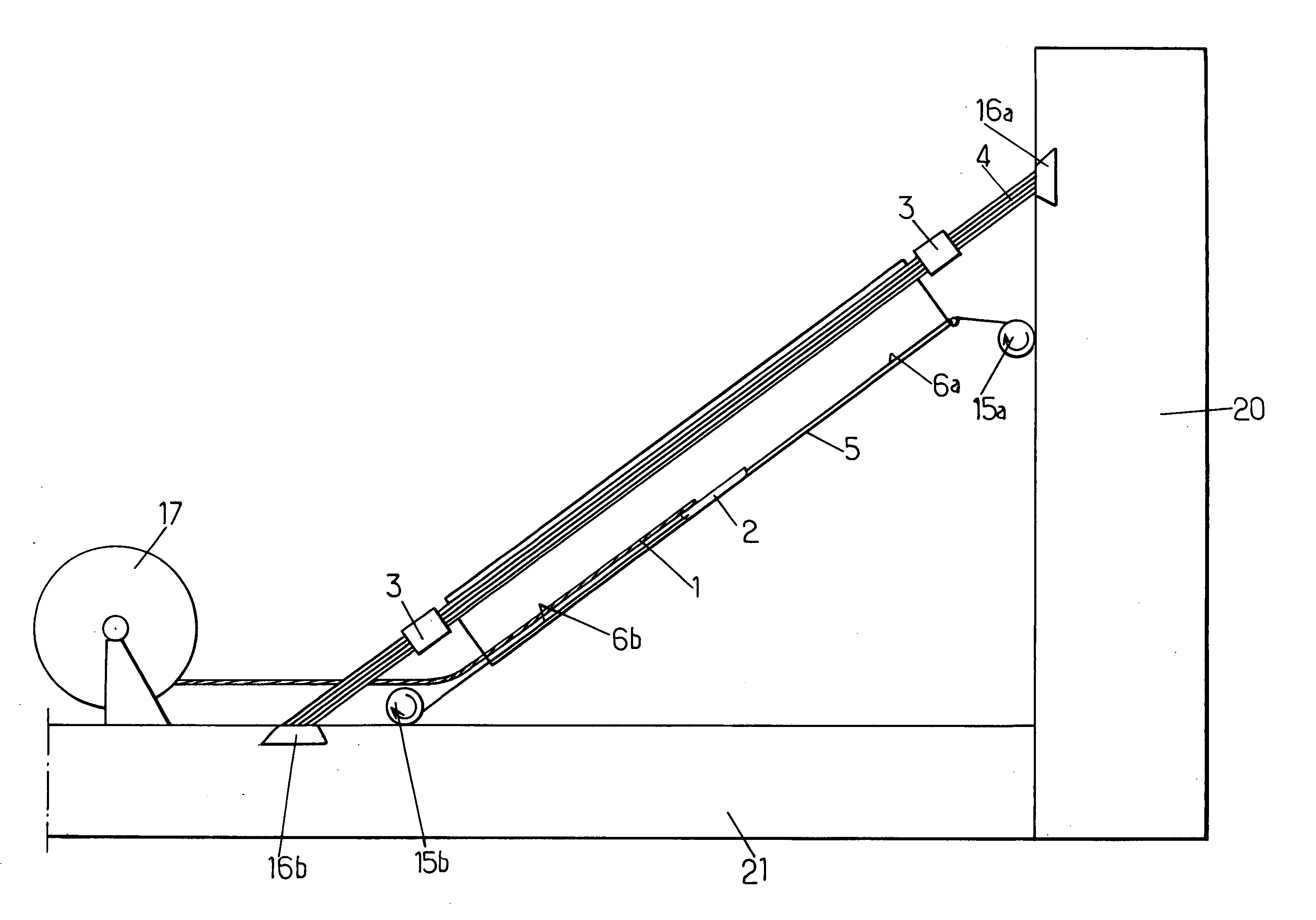

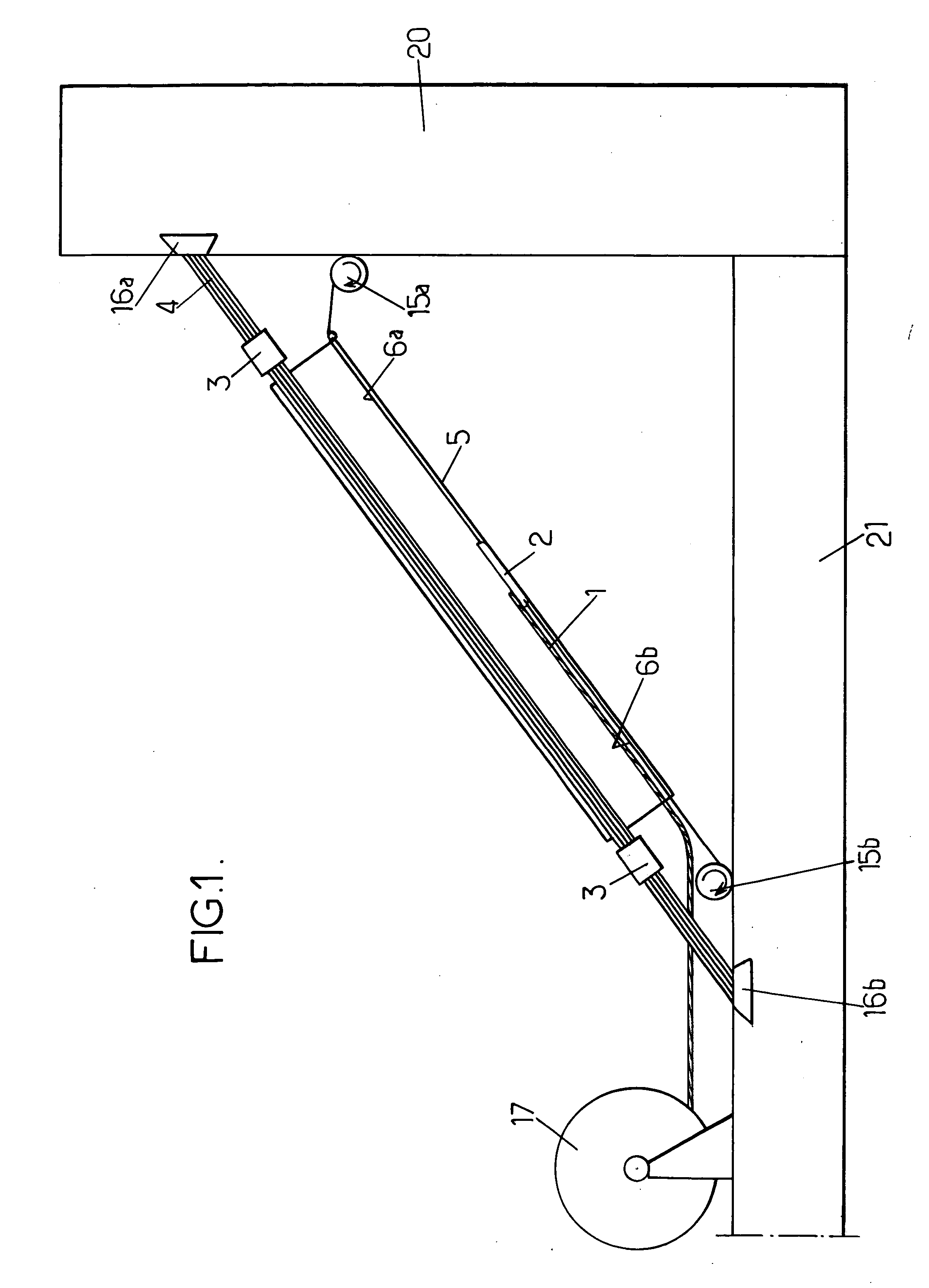

Method for erecting a stay

ActiveUS20060185318A1Avoid frictional damageIncrease the sectionCable-stayed bridgeBuilding repairsEngineeringArchitectural engineering

Owner:FREYSSINET INT STUP

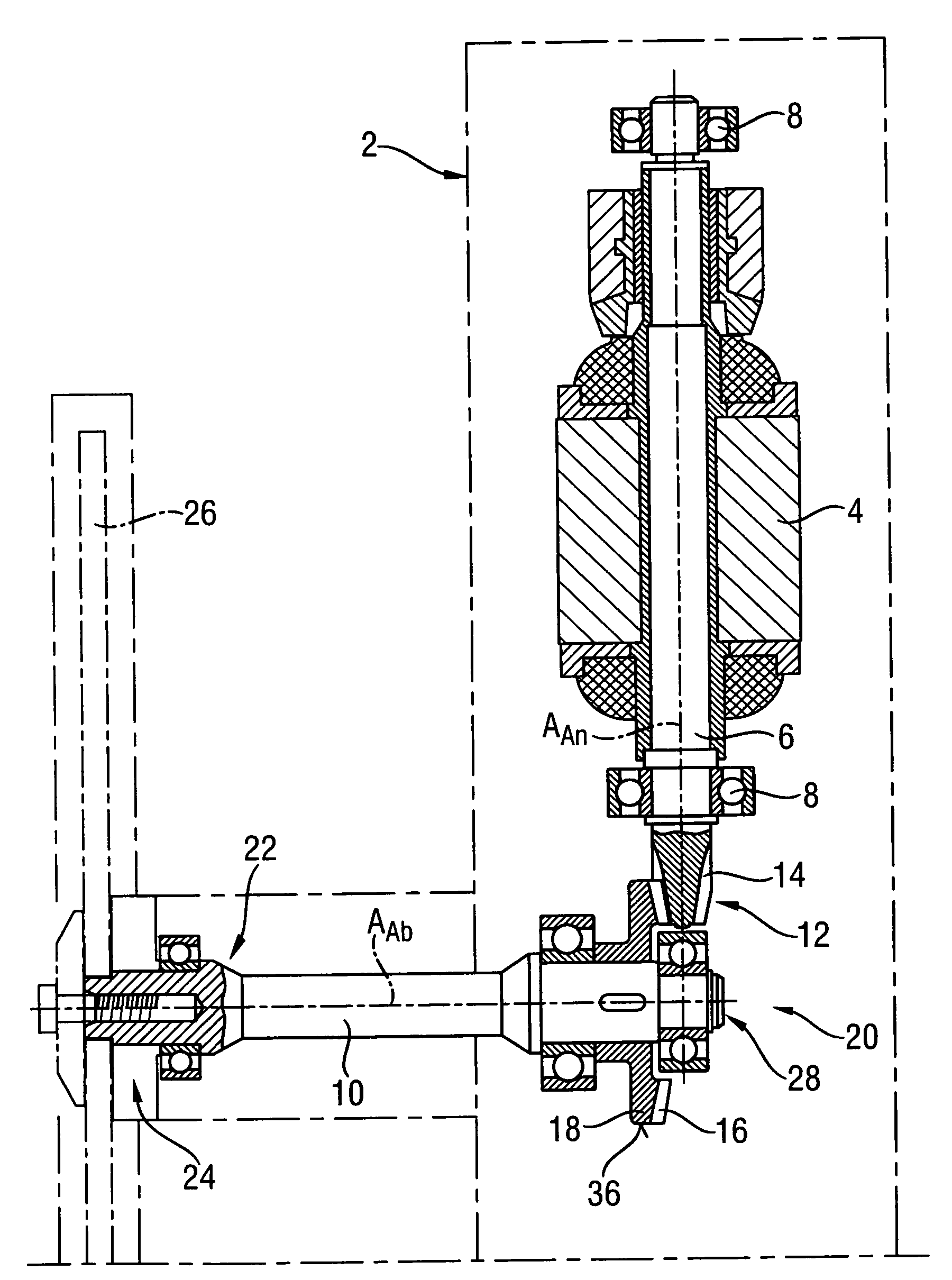

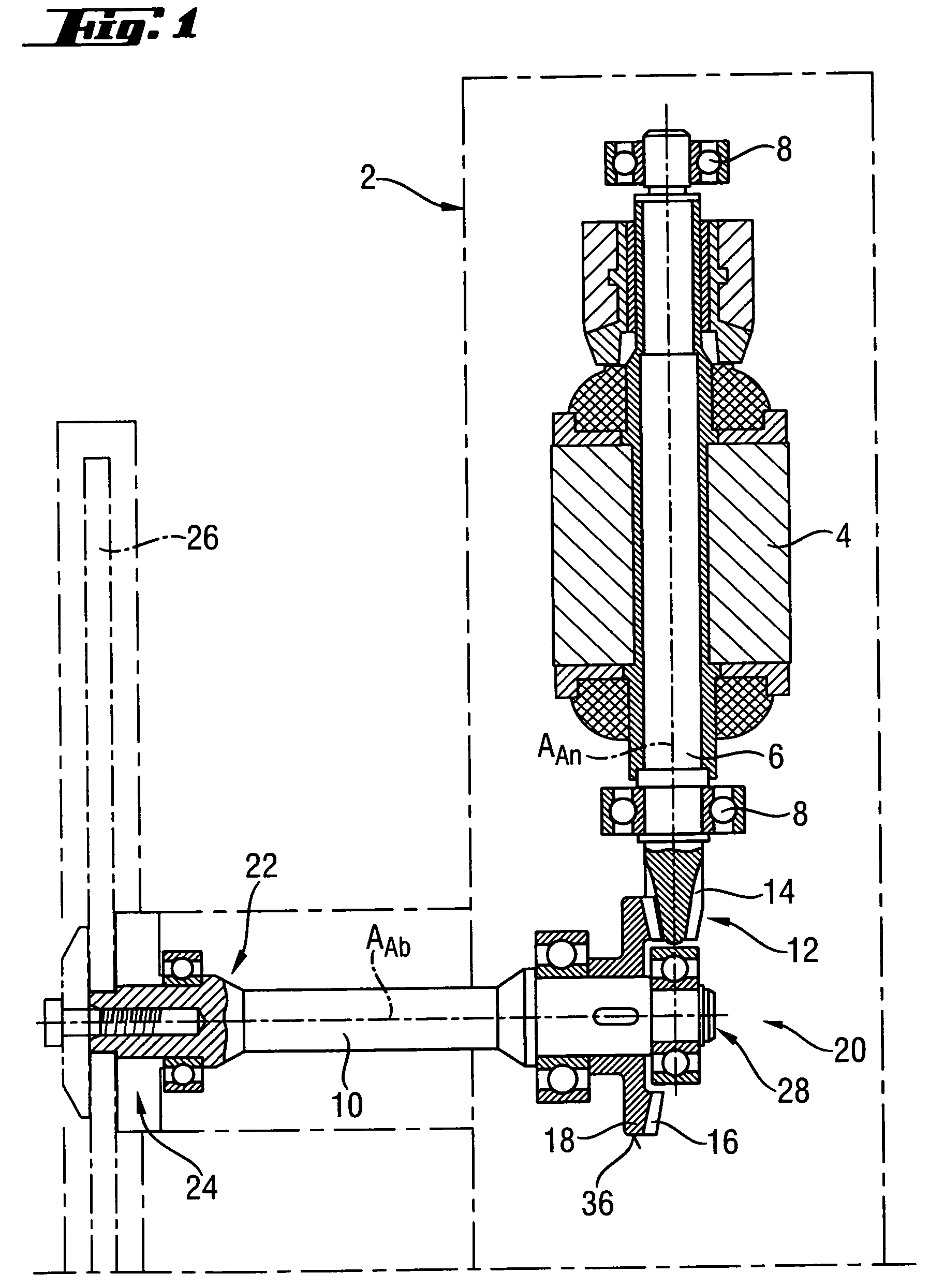

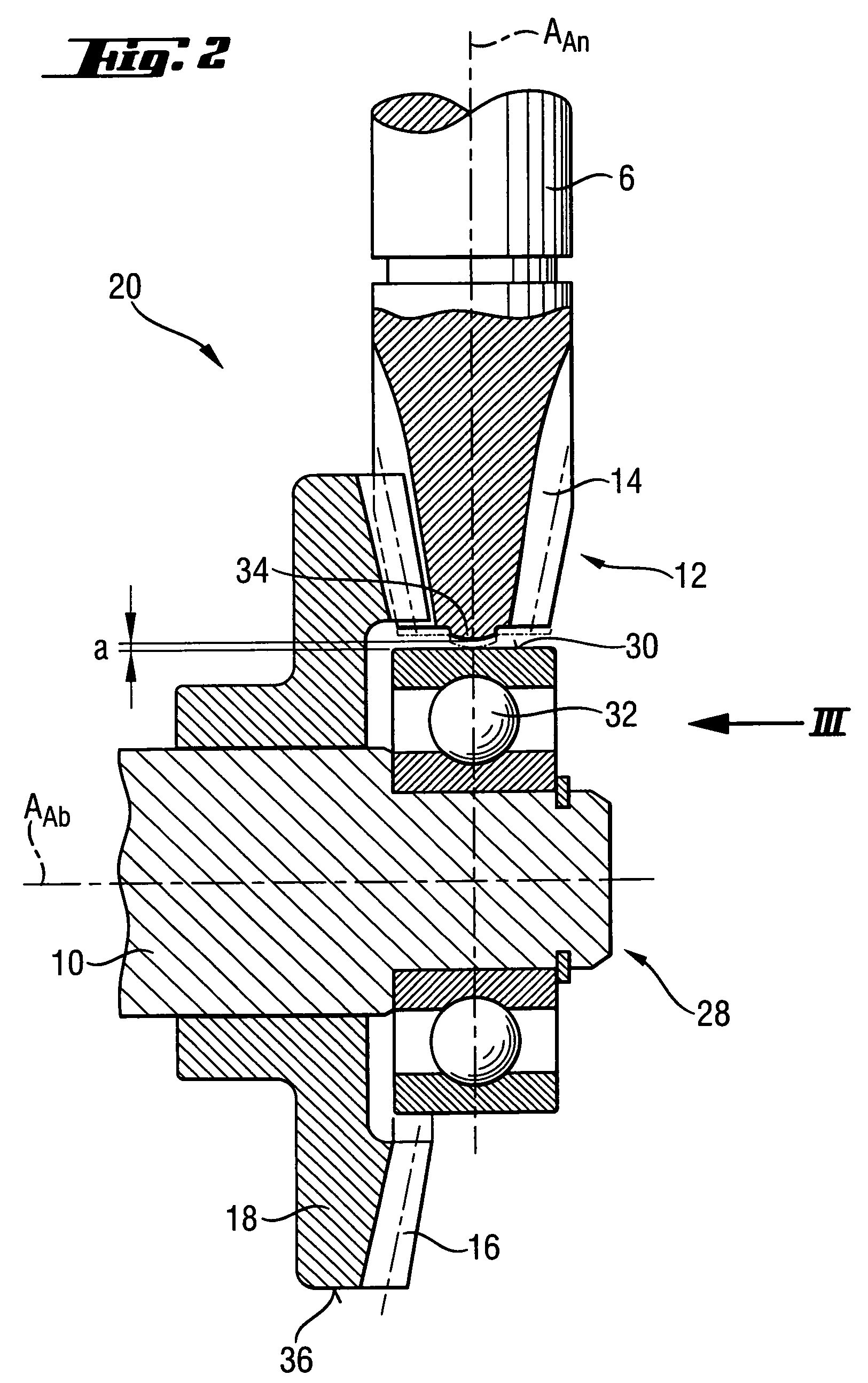

Hand-held power tool with angle drive

InactiveUS7346992B2No increased wearIncreased resistance torqueMetal sawing devicesToothed gearingsAxial displacementMotor drive

Owner:HILTI AG

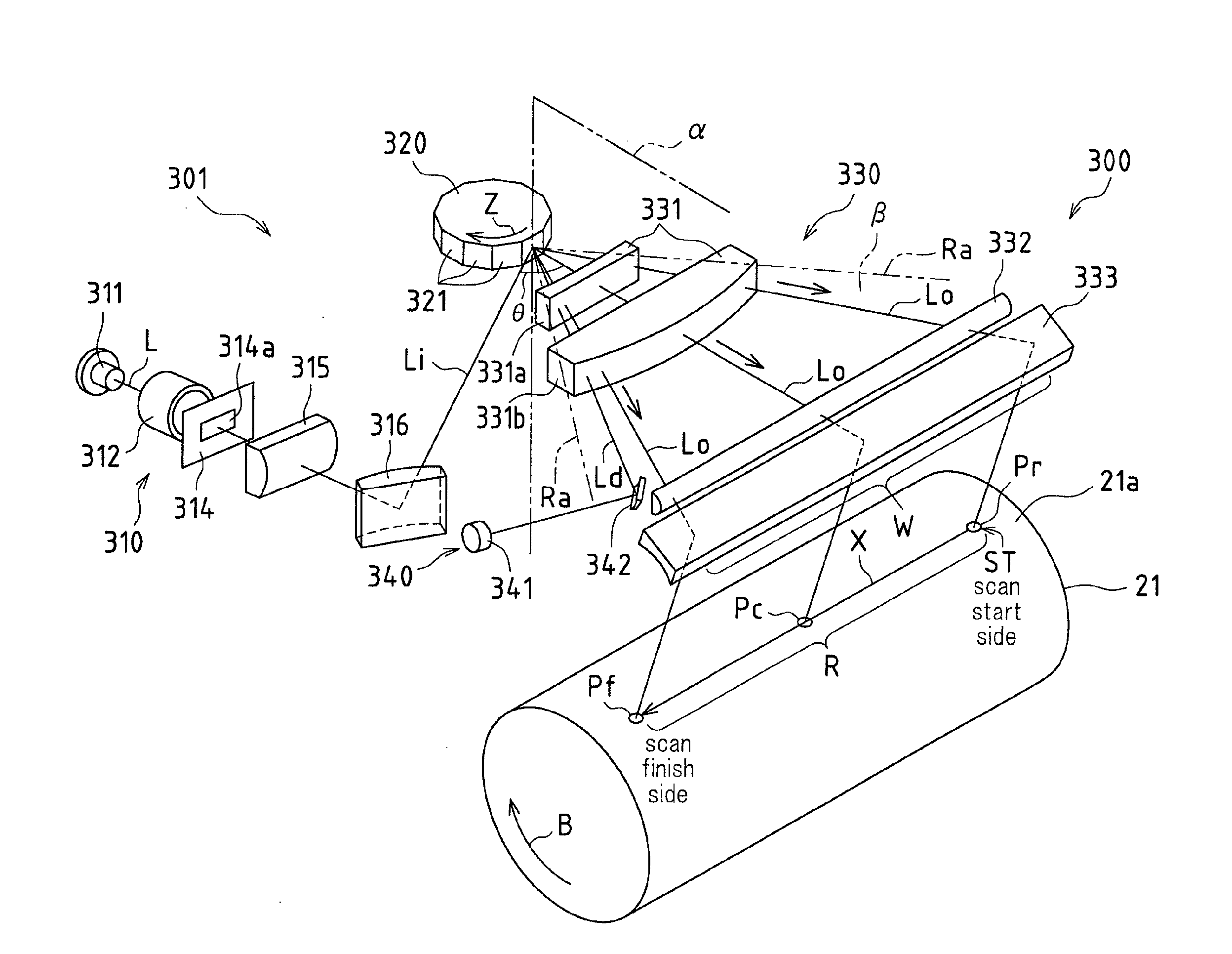

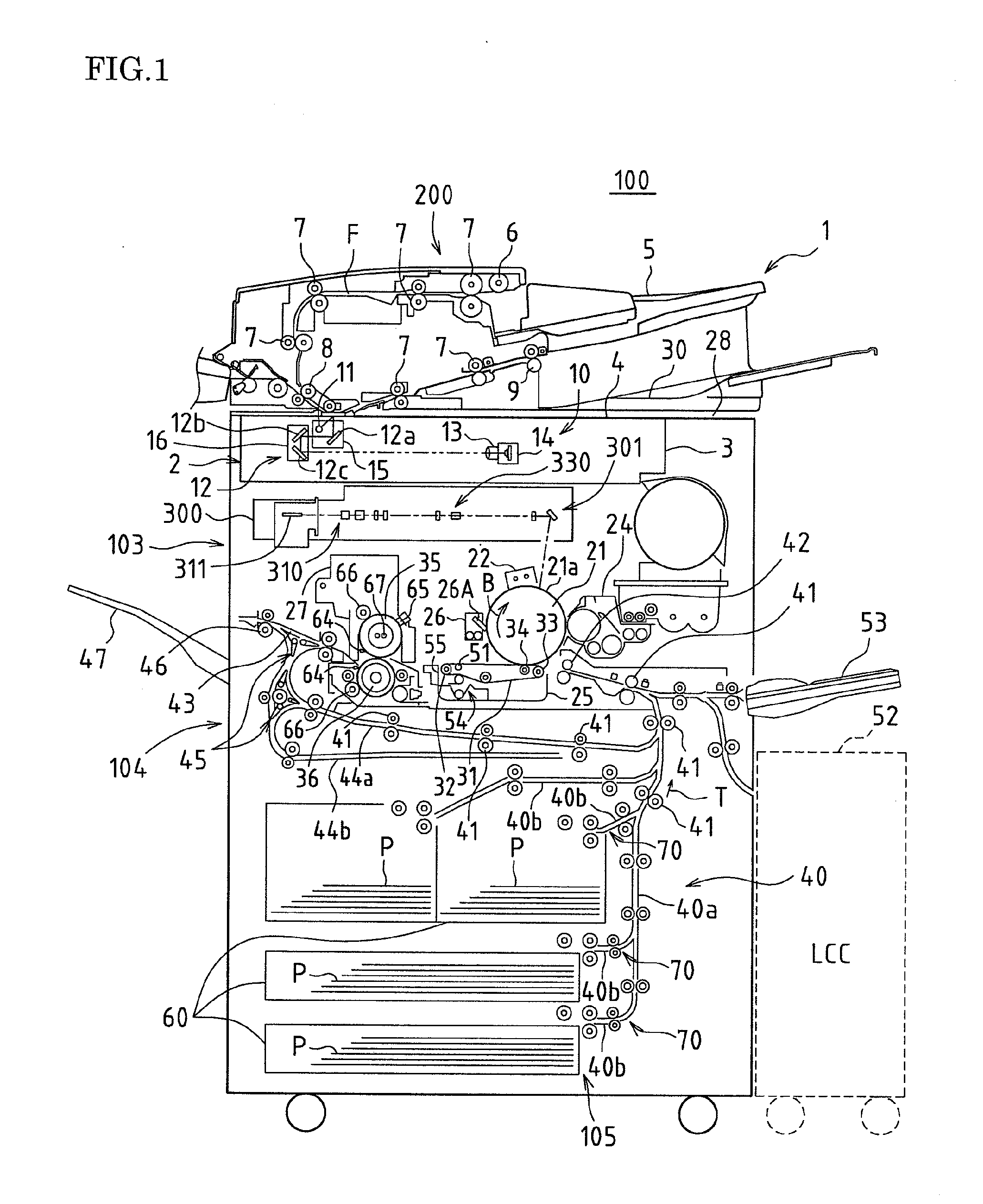

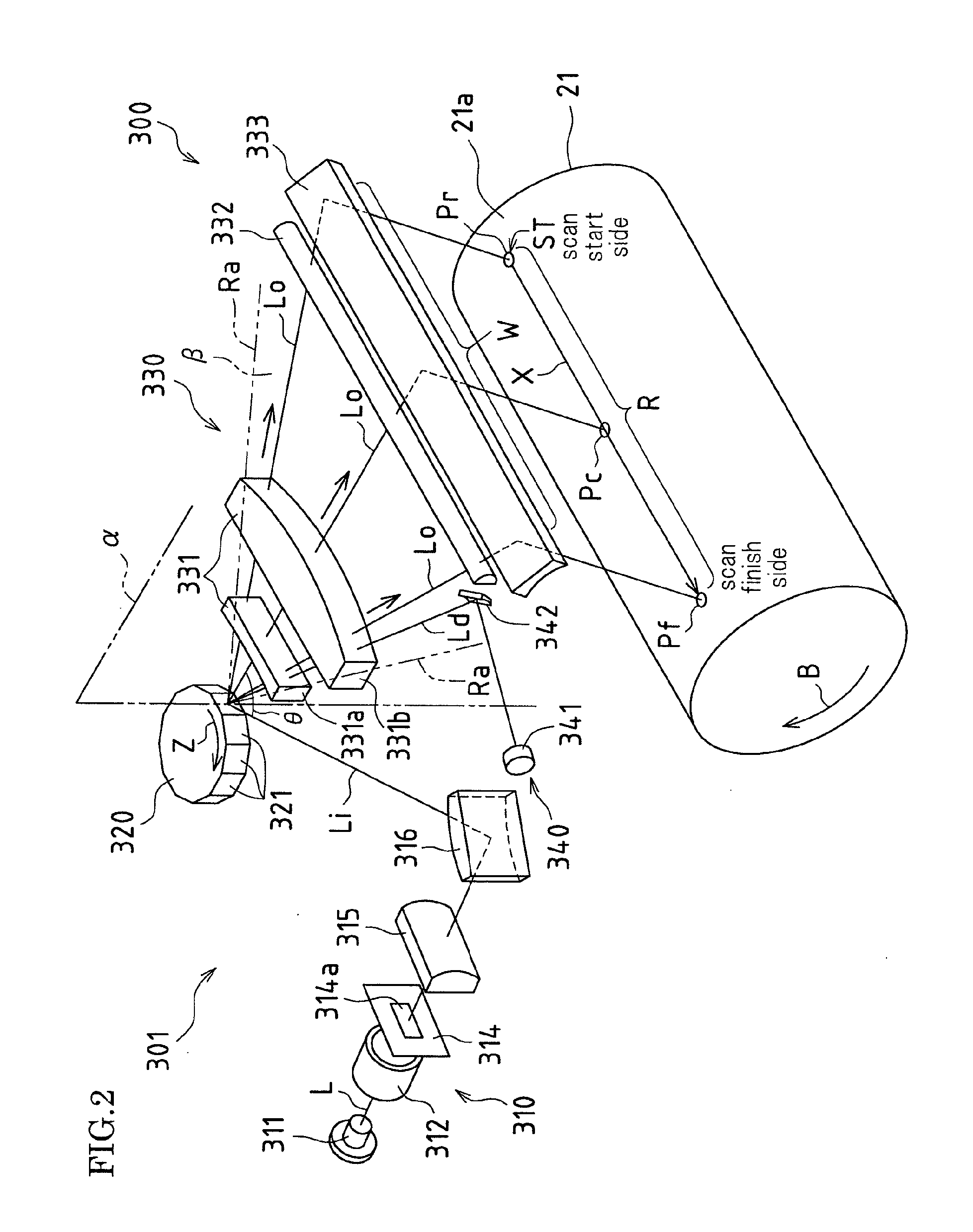

Optical scanning device and image forming apparatus including the same

ActiveUS20110134501A1Simple designEasy to processElectrographic process apparatusPictoral communicationLight beamImage formation

One embodiment of an optical scanning device according to the present invention is directed to an optical scanning device comprising an overfilled optical system in which an incoming beam of a light beam from a light source formed wider than a width in a rotation direction of a reflective surface of a rotating multifaceted mirror is caused to be incident on the reflective surface, and a scanning surface of a scanning object is scanned by an outgoing beam reflected by the reflective surface, wherein the incoming beam is caused to be incident on the reflective surface of the rotating multifaceted mirror in a state having an angle with respect to a virtual vertical surface that is vertical to the scanning surface and vertical to a scanning direction of the outgoing beam, and a light amount distribution for positions on the scanning surface in the scanning direction is corrected based on a slope of a straight line that expresses a ratio of change of light amounts for positions on the scanning surface in the scanning direction when scanning the scanning surface using the outgoing beam.

Owner:SHARP KK

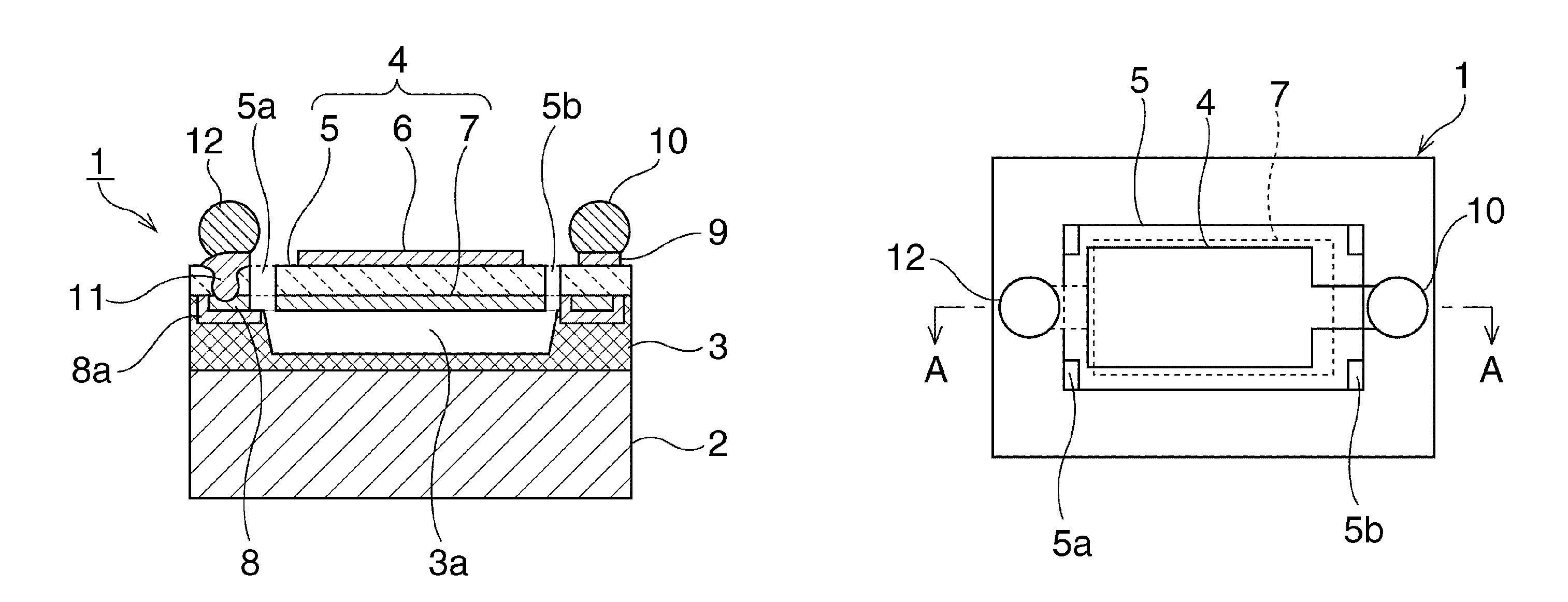

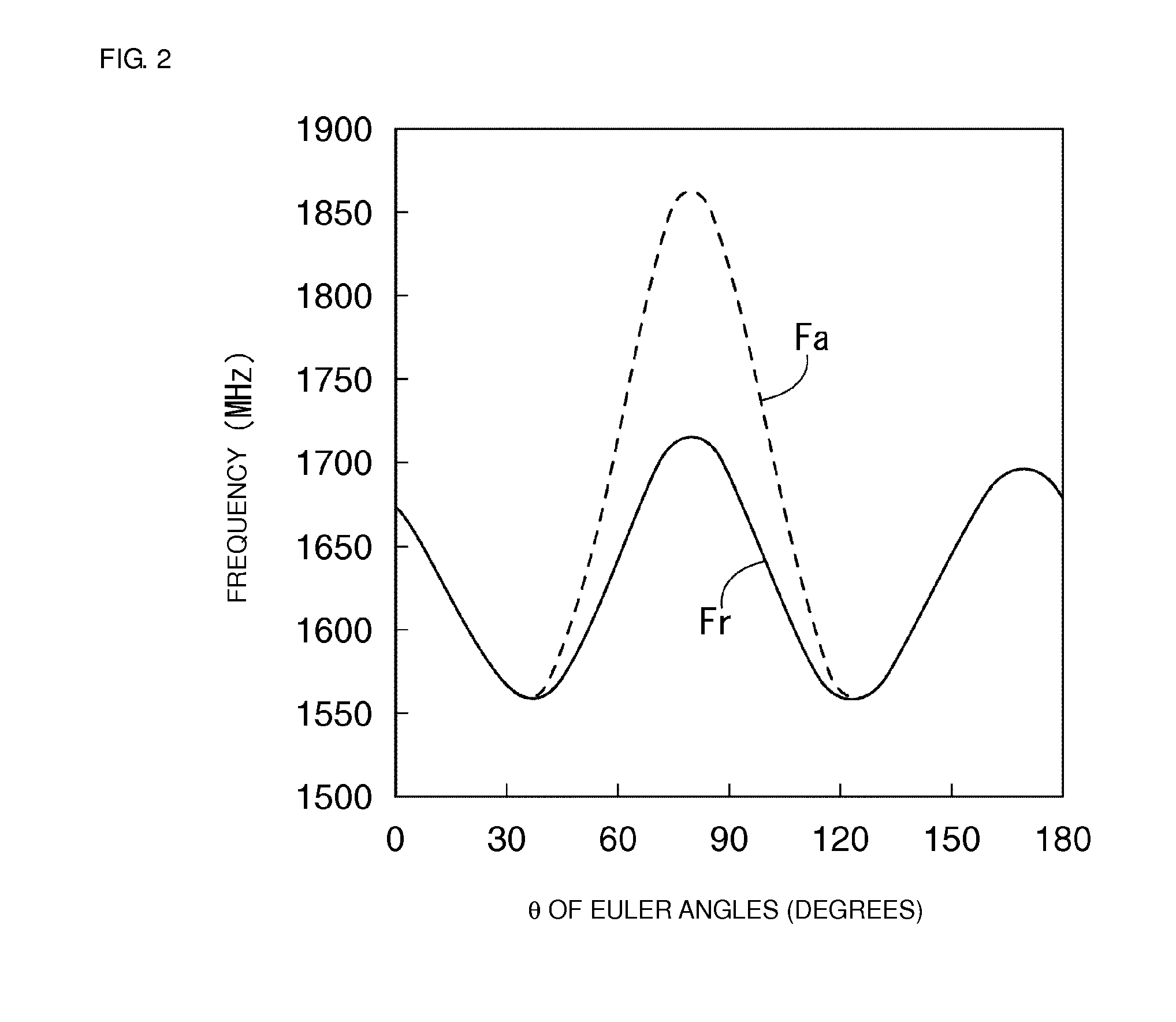

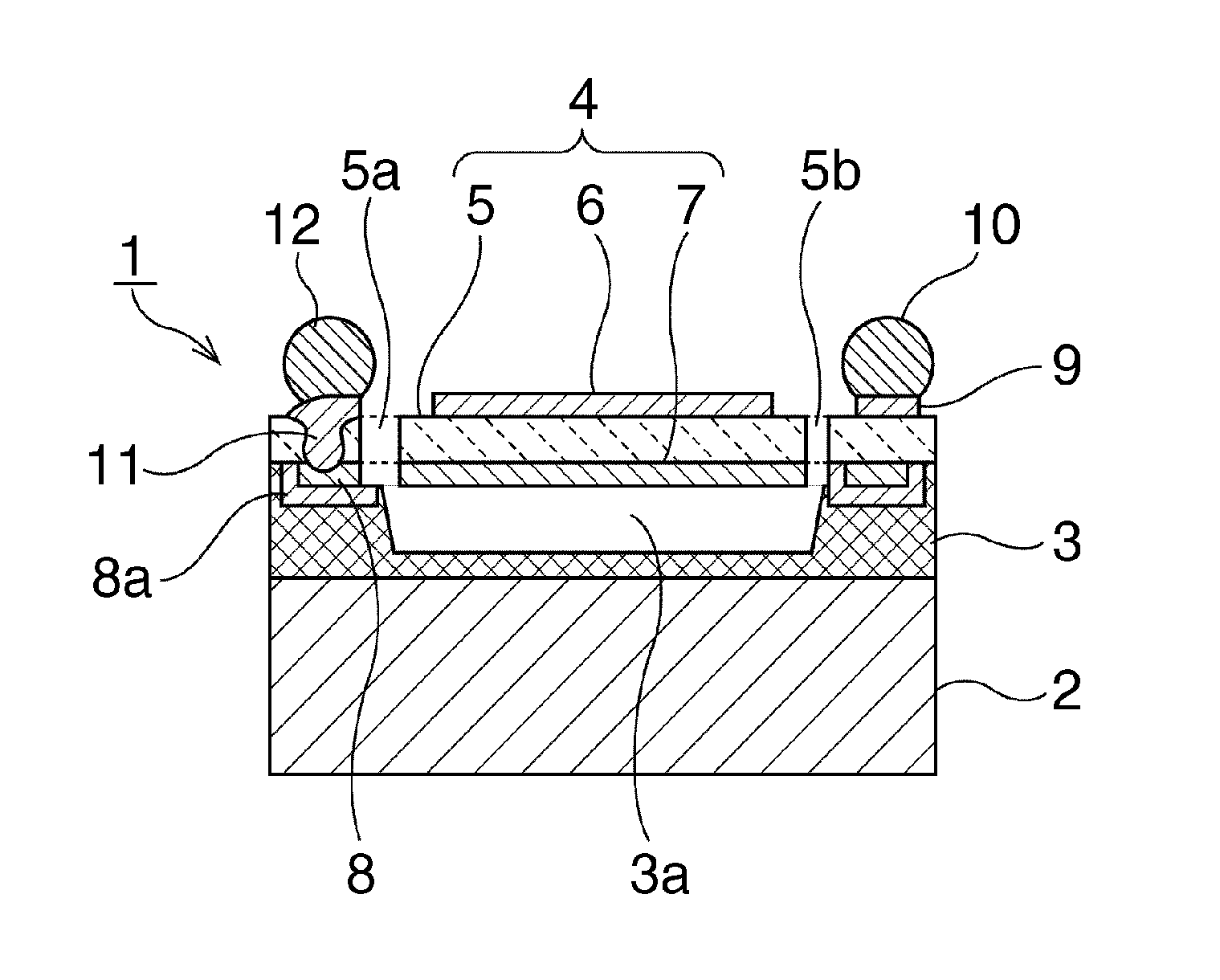

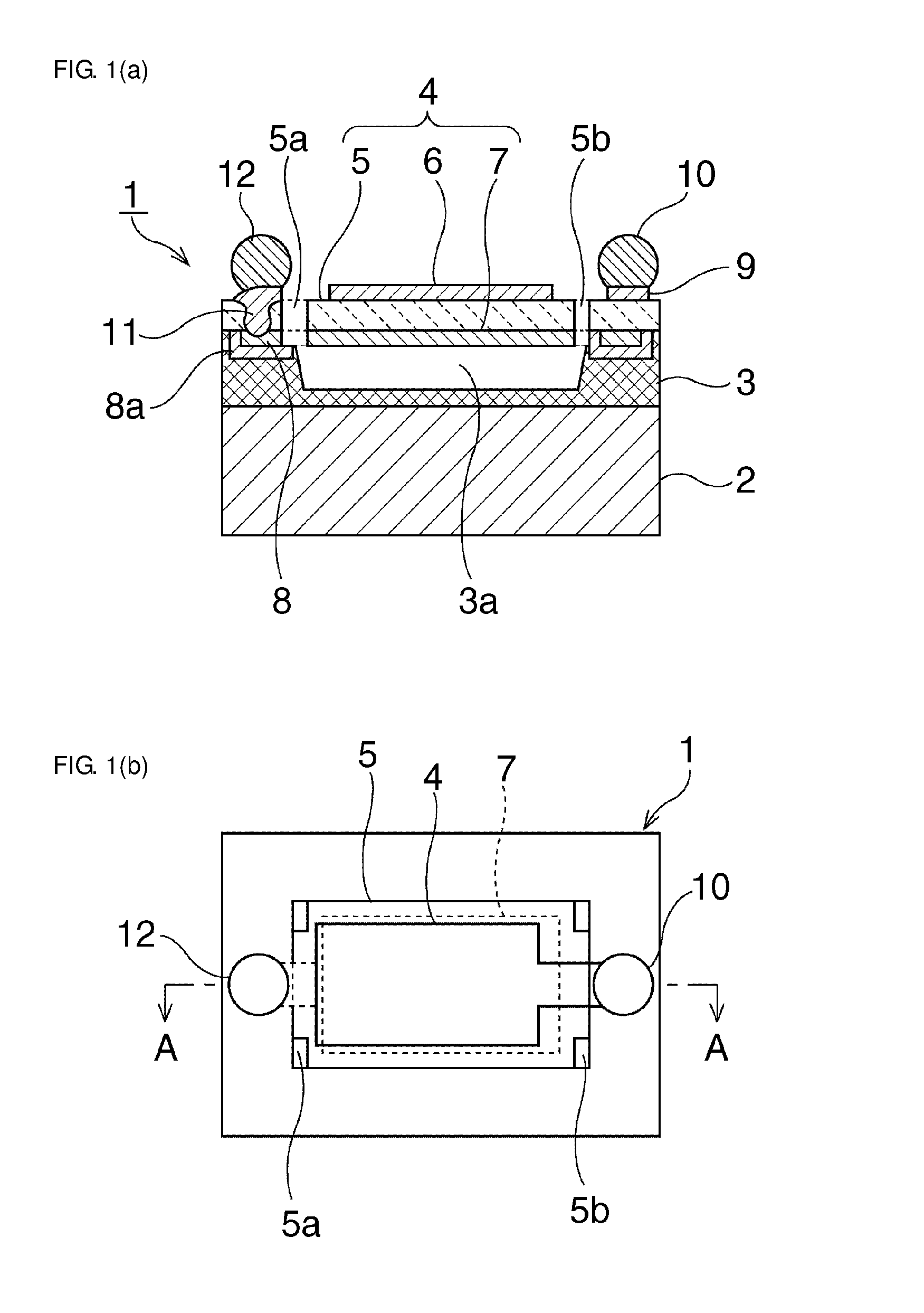

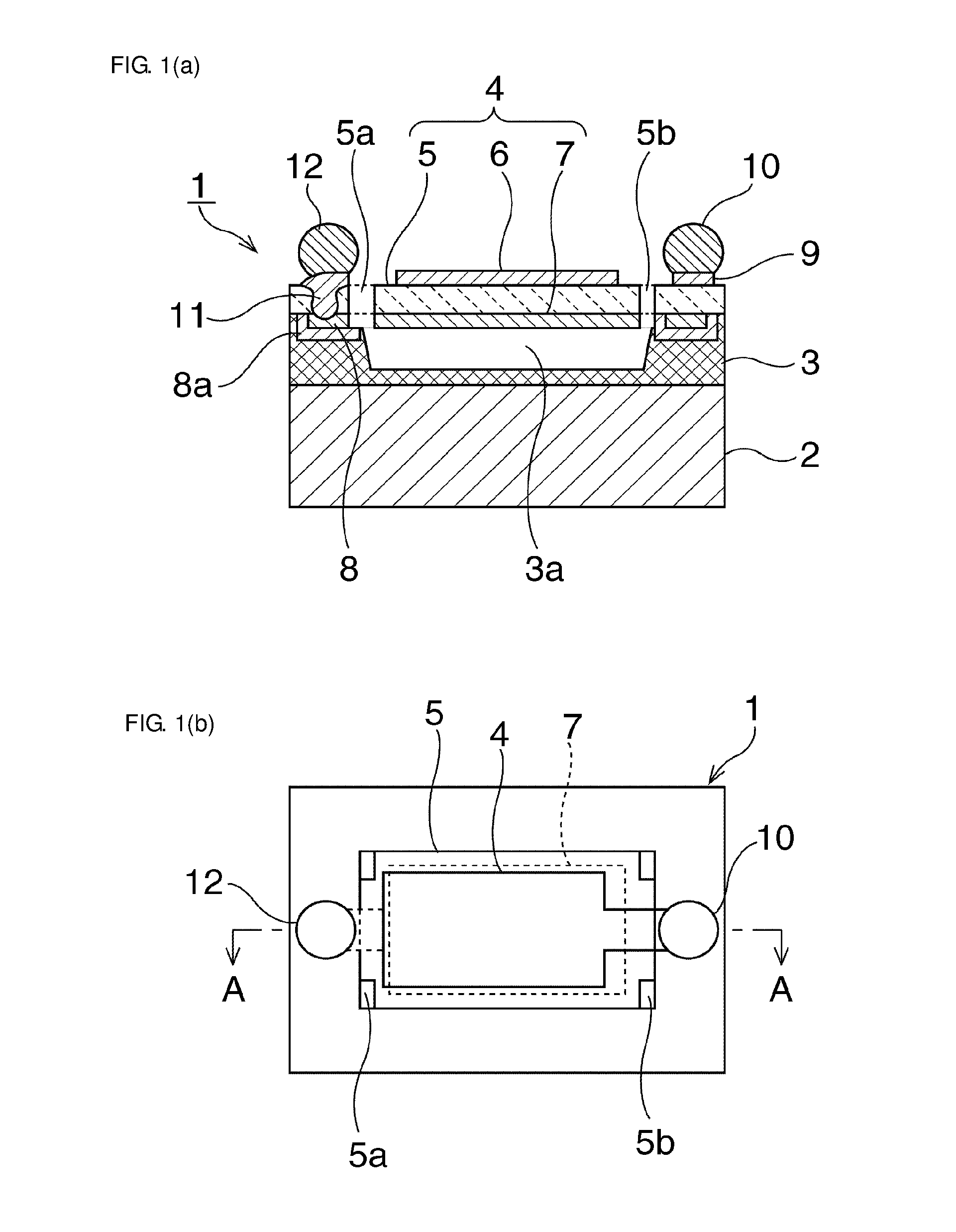

Piezoelectric bulk wave device, and method of manufacturing the piezoelectric bulk wave device

ActiveUS20140167566A1Wider band widthWide range of adjustmentPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEuler anglesAcoustics

A piezoelectric bulk wave device that includes a piezoelectric thin plate that is made of LiTaO3, and first and second electrodes that are provided in contact with the piezoelectric thin plate. The piezoelectric bulk wave device utilizes the thickness shear mode of the piezoelectric thin plate made of LiTaO3, and of the Euler Angles (φ, θ, φ) of LiTaO3, φ is 0°, and θ is in the range of not less than 54° and not more than 107°.

Owner:MURATA MFG CO LTD

Print position correcting device, method of controlling print position correcting device, and printing apparatus

ActiveUS8172357B2Smooth movementUnified positionSpacing mechanismsTypewritersComputer scienceCalculator

A print position correcting device includes: a head unit which ejects a liquid onto a print medium being transported on a transport surface; detectors which detect a position of the print medium being transported; a transport information calculator which calculates transport information regarding a transport status of the print medium based on the position of the detected print medium; a movement speed calculator which calculates a movement speed used to move the head unit based on the transport information; and a controller which moves the head unit in a direction parallel to the transport surface based on the transport information and the movement speed.

Owner:SEIKO EPSON CORP

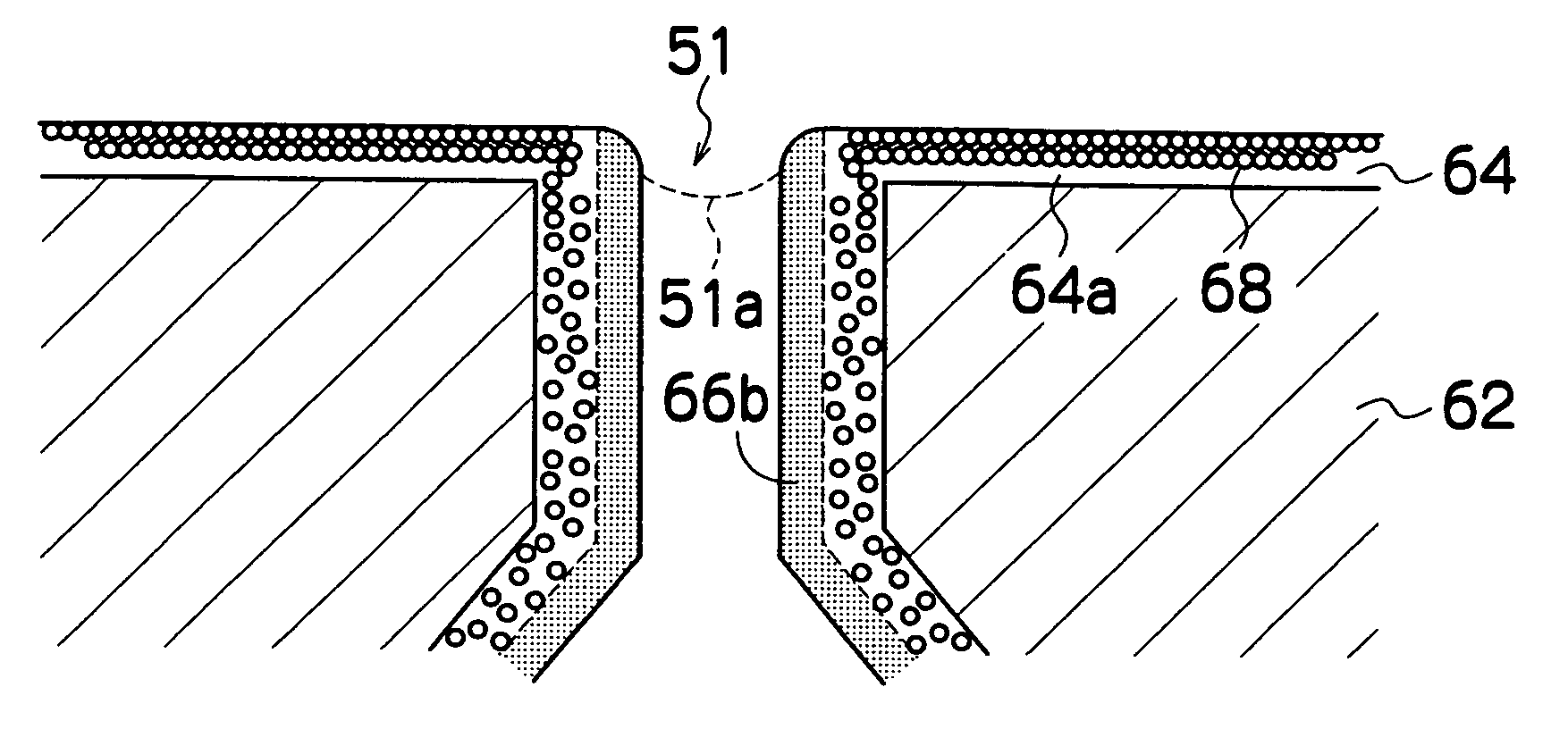

Method of manufacturing nozzle plate, nozzle plate, liquid ejection head and image forming apparatus

The method manufactures a nozzle plate. The method comprises: a liquid-repelling film forming step of forming a liquid-repelling film on an entire surface of a nozzle plate forming substrate having been formed with nozzles for ejecting liquid droplets; a liquid-repelling film solidification step of solidifying the liquid-repelling film formed in the liquid-repelling film forming step on a liquid droplet ejection surface of the nozzle plate forming substrate; a liquid-philic film forming step of forming a liquid-philic film on the liquid-repelling film formed on the entire surface of the nozzle plate forming substrate, after the liquid-repelling film solidification step; a liquid-philic film solidification step of solidifying the liquid-philic film formed in the liquid-philic film forming step; and a liquid-philic film removal step of removing the liquid-philic film formed on the liquid-repelling film on the liquid droplet ejection surface of the nozzle plate forming substrate, after the liquid-philic film solidification step.

Owner:FUJIFILM CORP

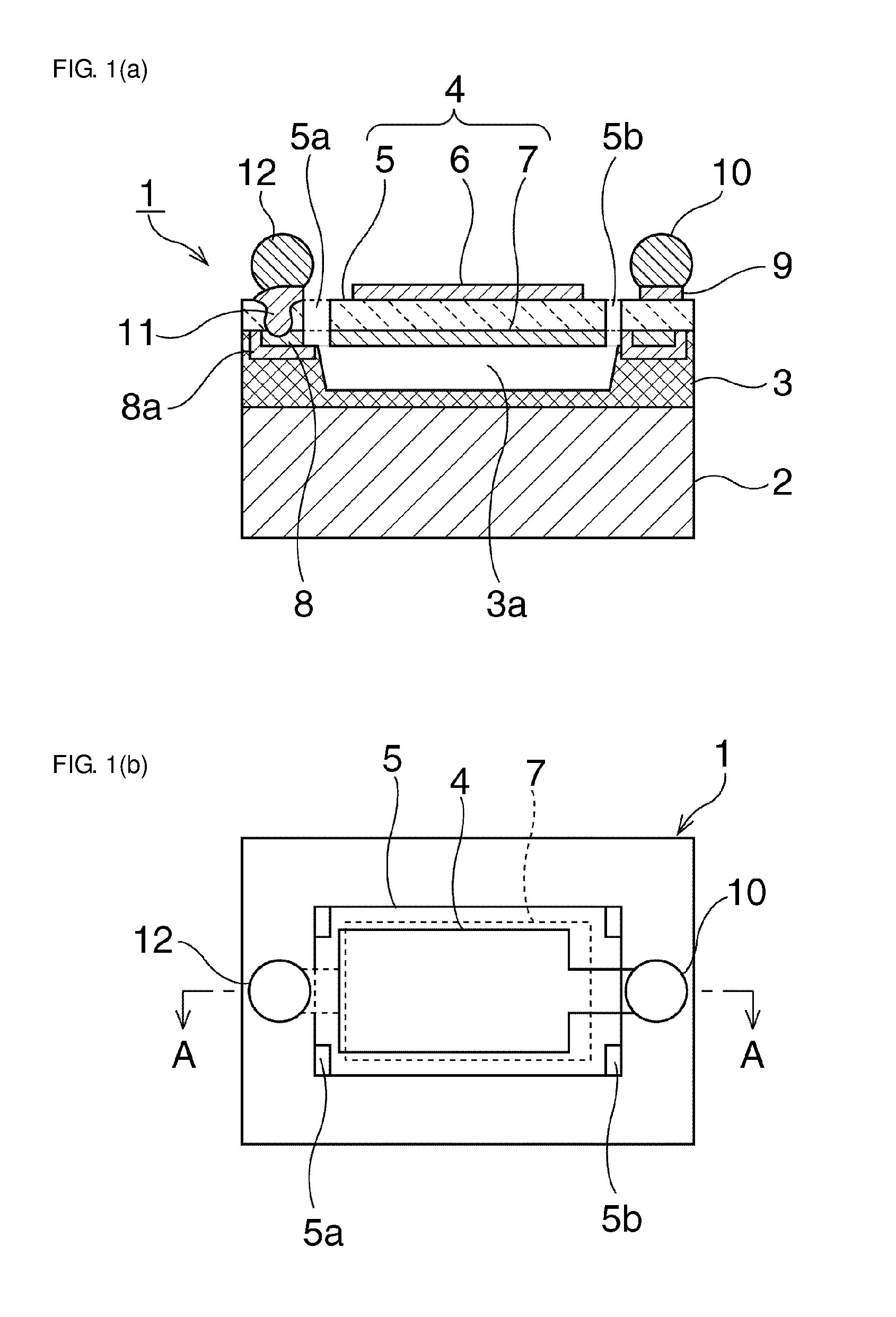

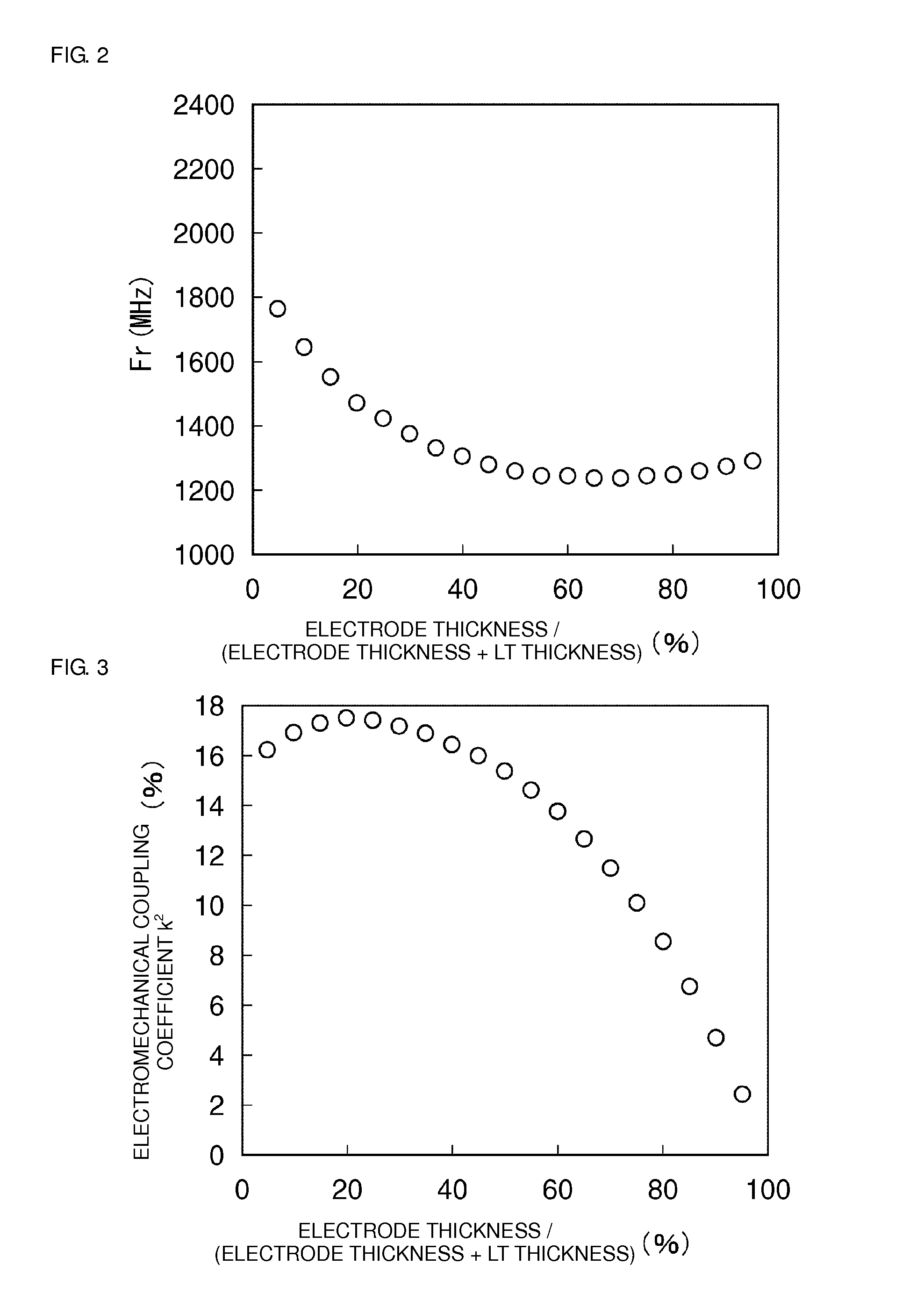

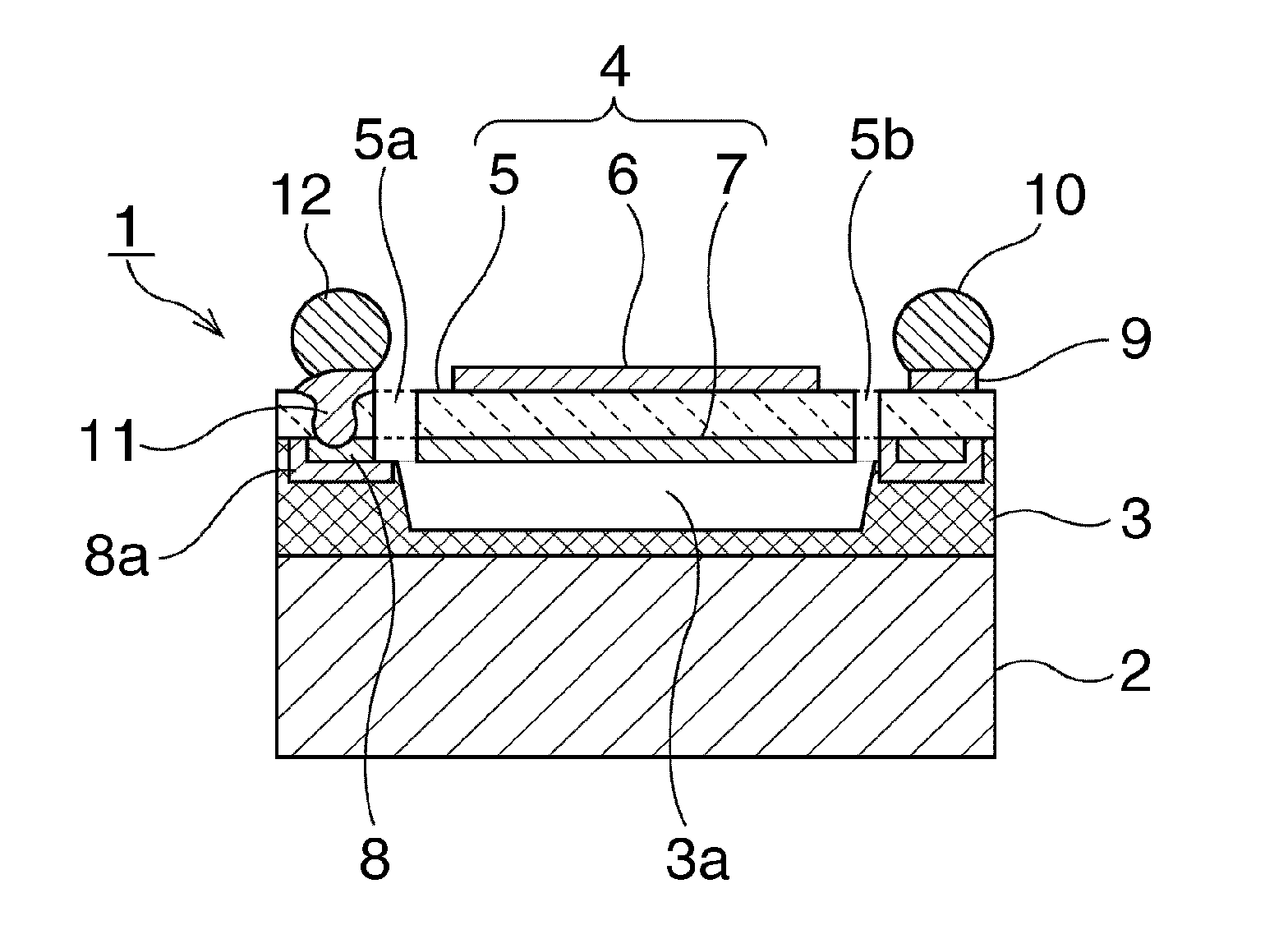

Piezoelectric bulk wave device, and method of manufacturing the piezoelectric bulk wave device

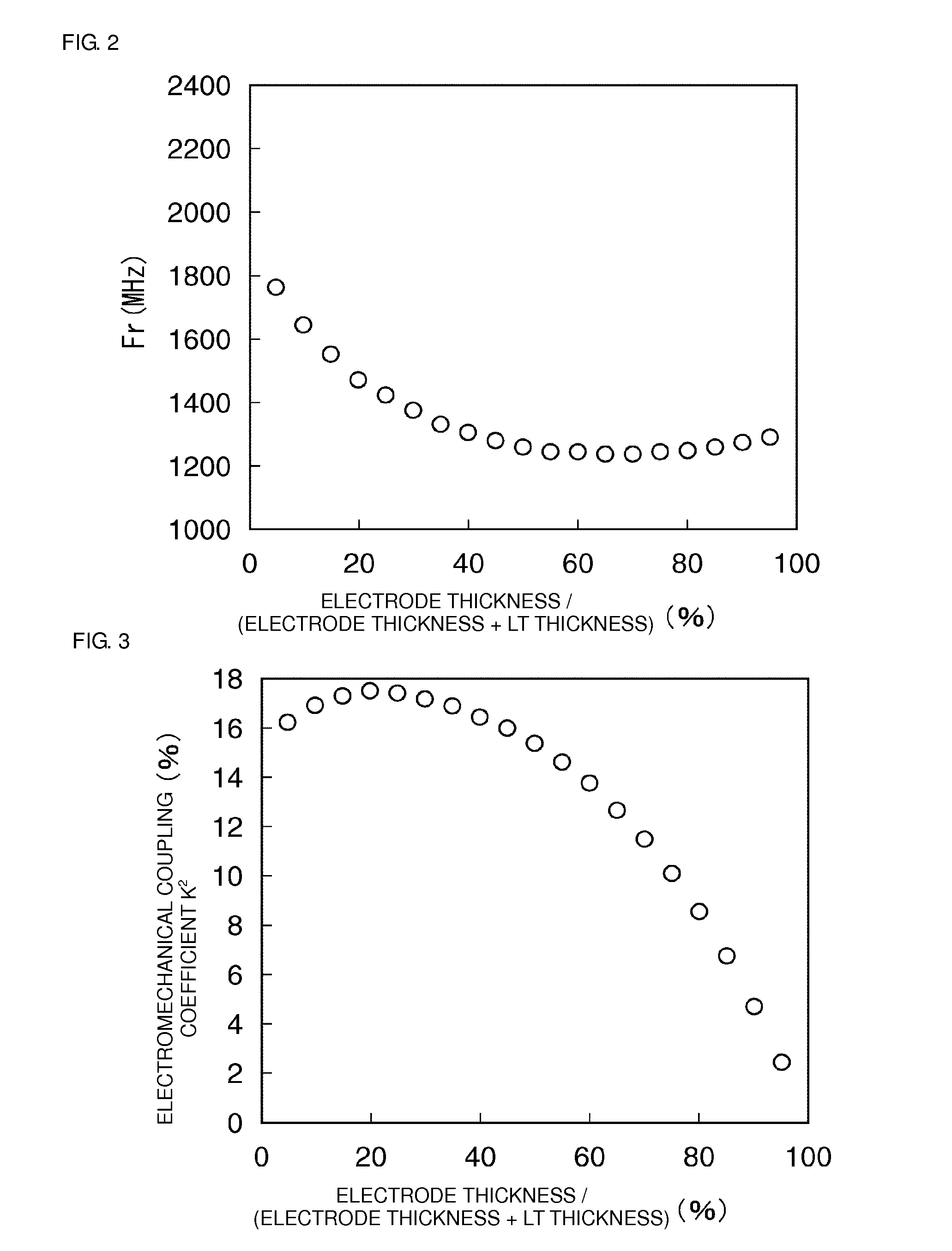

ActiveUS20140175945A1Little changeEasy to controlPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustics

A piezoelectric bulk wave device that includes a piezoelectric thin plate that is made of LiTaO3, and first and second electrodes that are provided in contact with the piezoelectric thin plate. The piezoelectric bulk wave device utilizes the thickness shear mode of the piezoelectric thin plate made of LiTaO3. The first and second electrodes are each formed by a conductor having a specific acoustic impedance higher than the specific acoustic impedance of a transversal wave that propagates in LiTaO3. When the sum of the film thicknesses of the first and second electrodes is defined as an electrode thickness, and the thickness of the piezoelectric thin plate made of LiTaO3 is defined as an LT thickness, the electrode thickness / (electrode thickness+LT thickness) is not less than 5% and not more than 40%.

Owner:MURATA MFG CO LTD

Piezoelectric bulk wave device, and method of manufacturing the piezoelectric bulk wave device

ActiveUS20140175949A1Small fluctuationLittle changePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustics

A piezoelectric bulk wave device that includes a piezoelectric thin plate that is made of LiTaO3, and first and second electrodes that are provided in contact with the piezoelectric thin plate. The piezoelectric bulk wave device utilizes the thickness shear mode of the piezoelectric thin plate made of LiTaO3. The first and second electrodes are each formed by a conductor having a specific acoustic impedance higher than the specific acoustic impedance of a transversal wave that propagates in LiTaO3. When the sum of the film thicknesses of the first and second electrodes is defined as an electrode thickness, and the thickness of the piezoelectric thin plate made of LiTaO3 is defined as an LT thickness, the electrode thickness / (electrode thickness+LT thickness) is in the range of not less than 40% and not more than 95%.

Owner:MURATA MFG CO LTD

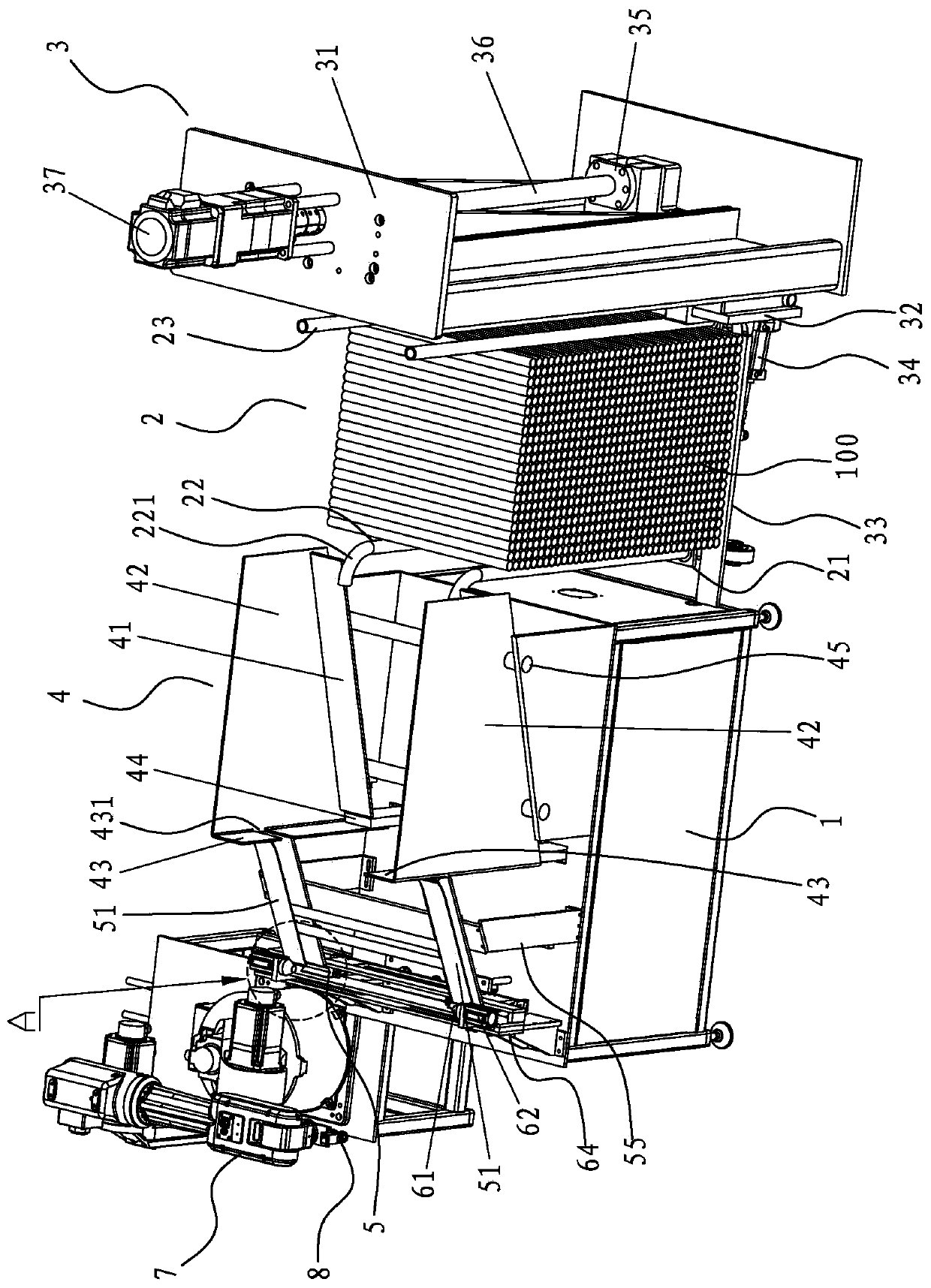

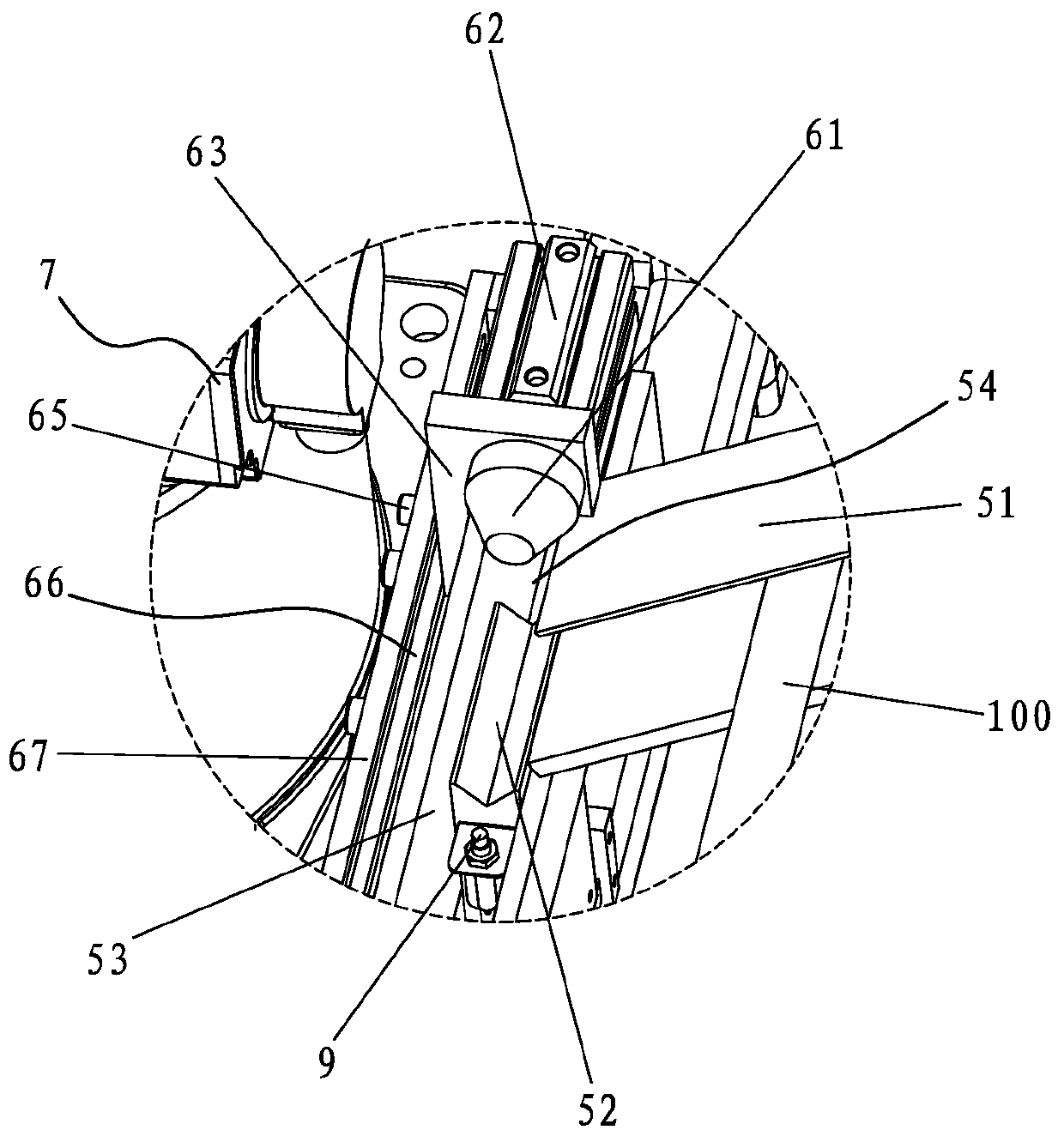

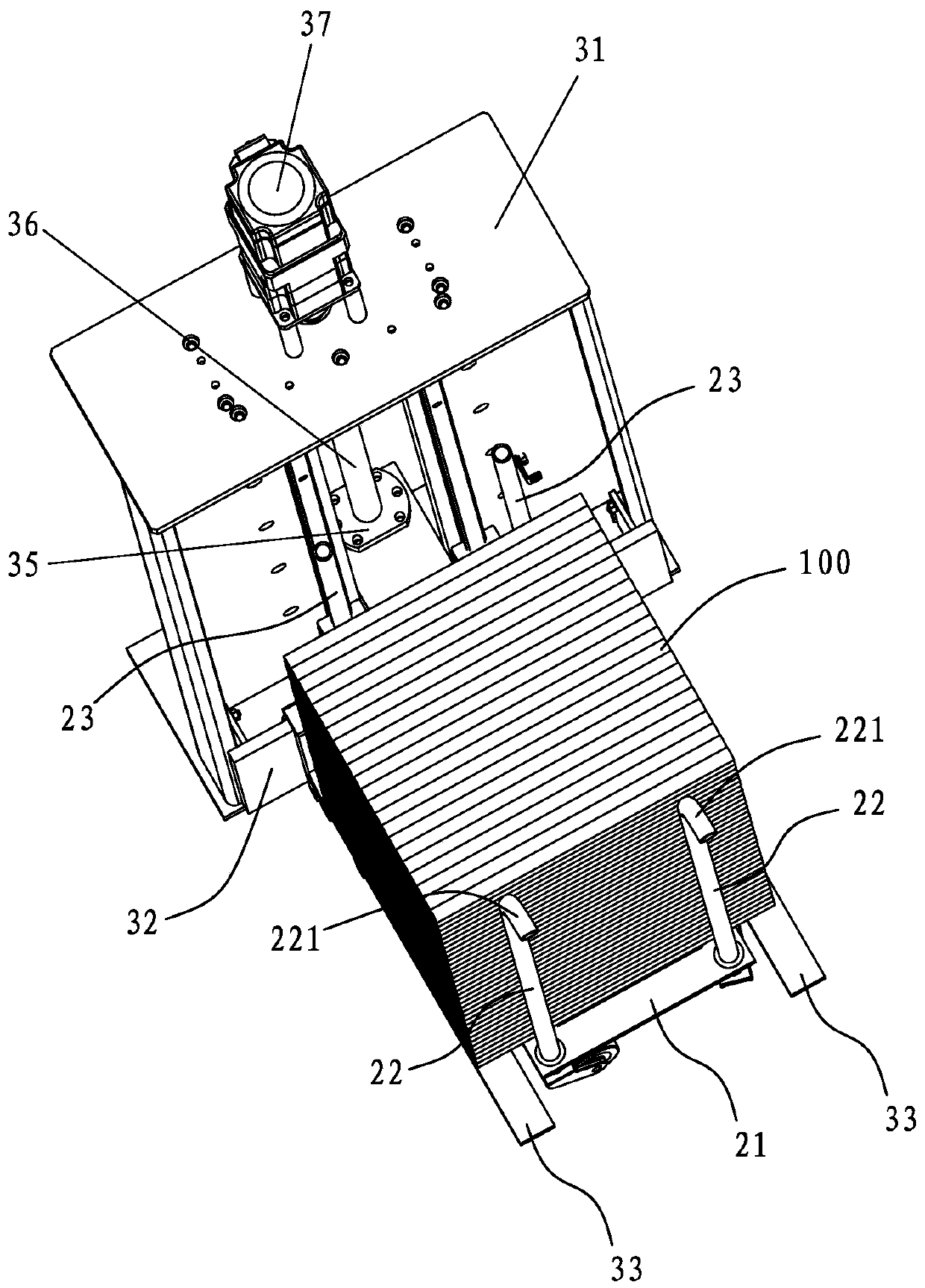

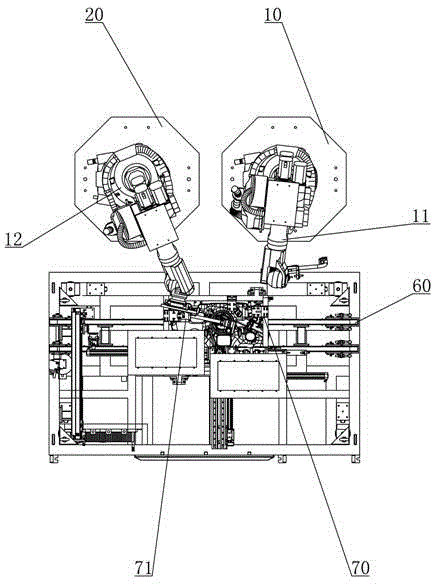

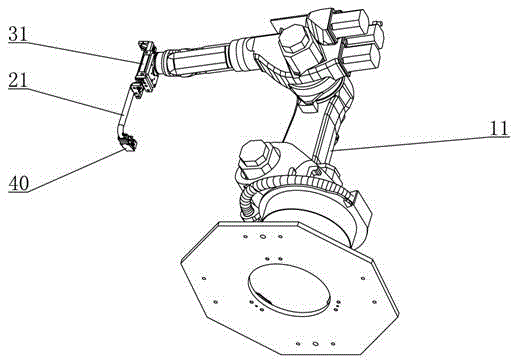

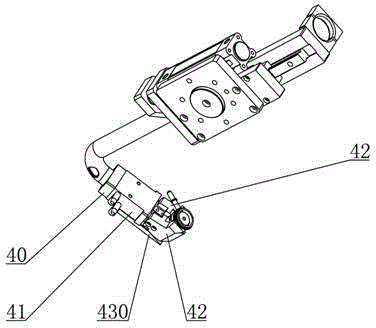

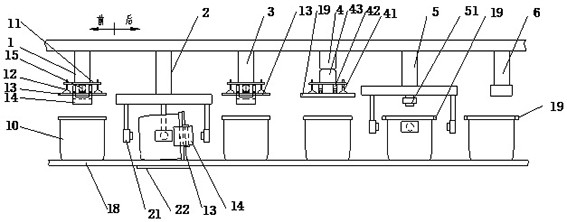

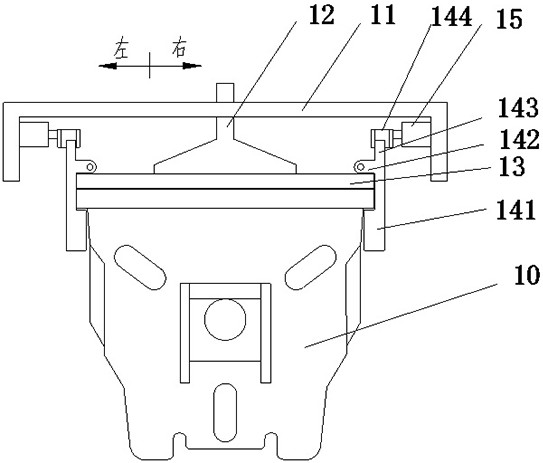

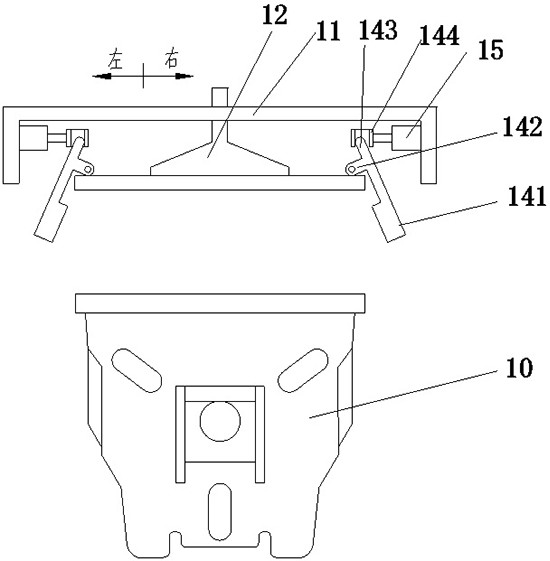

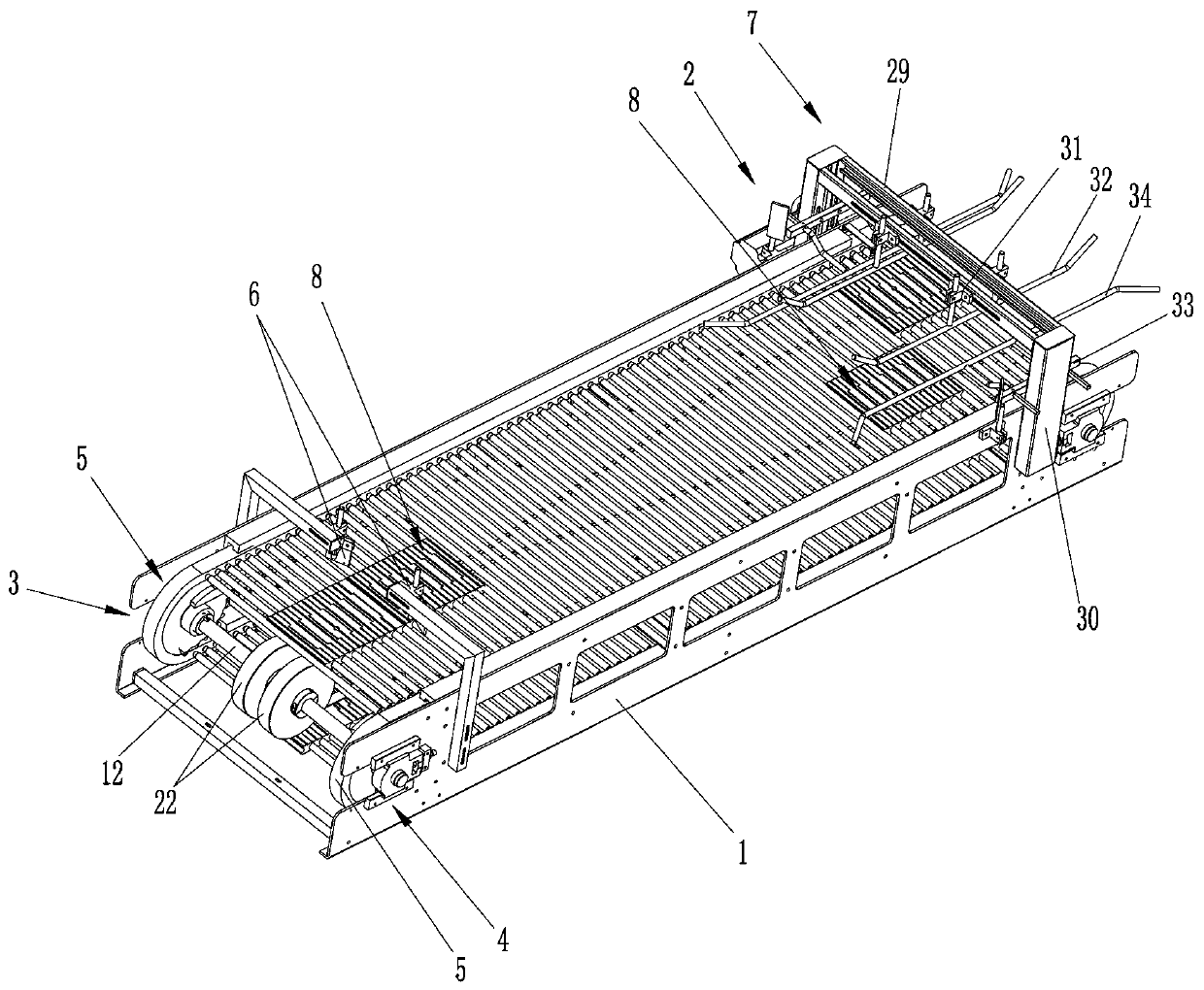

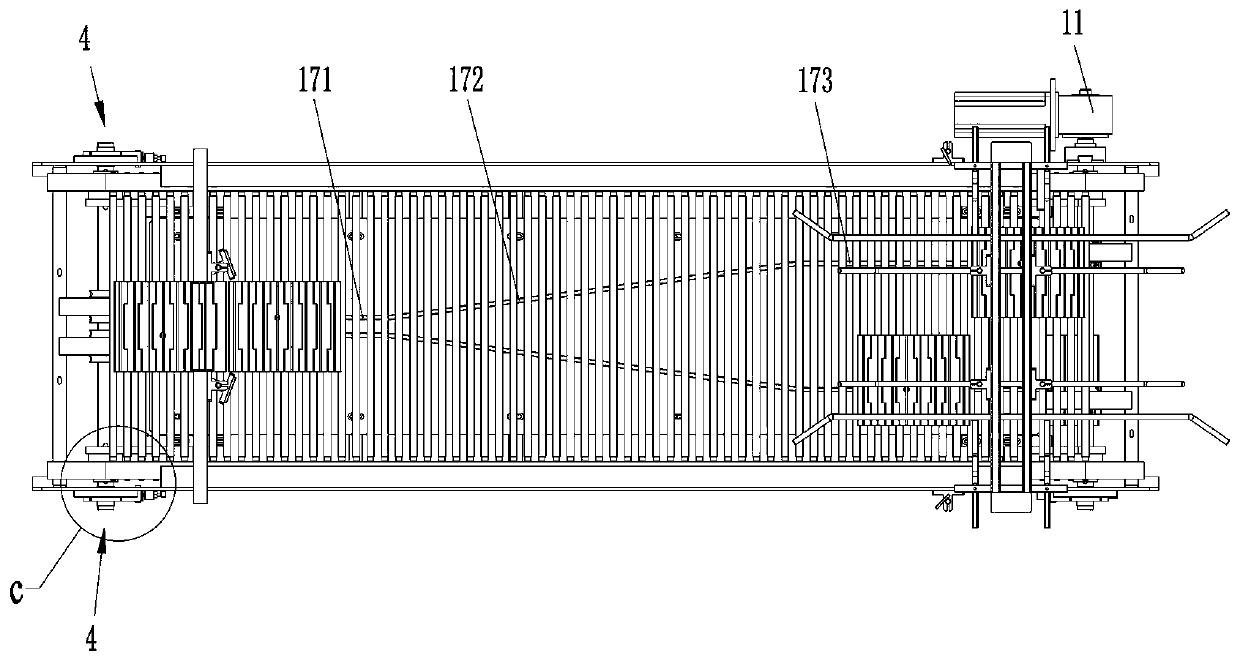

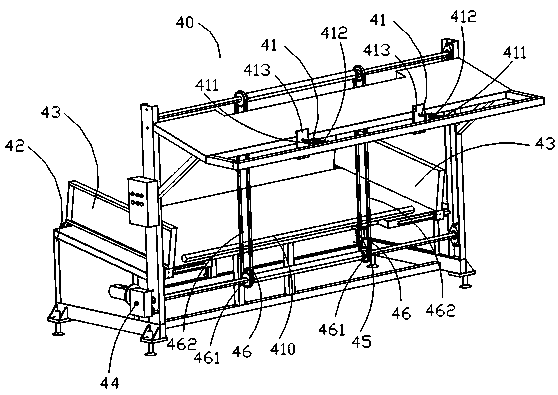

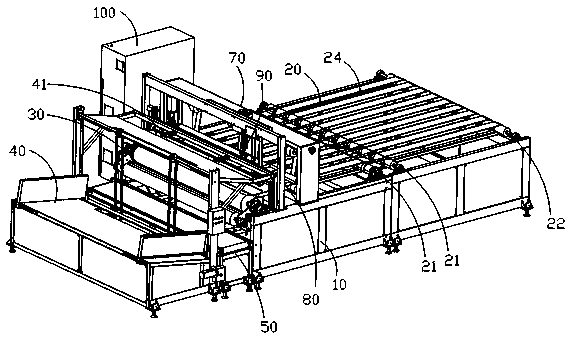

Full-automatic bending pipe production feeding line and bending pipe production method thereof

PendingCN110217565AReduce area occupationOrderly and efficient workControl devices for conveyorsProduction lineManipulator

The invention discloses a full-automatic bending pipe production feeding line. The full-automatic bending pipe production feeding line comprises a conveying platform, a cart, a forking mechanism and astorage hopper, wherein the cart comprises a cart base, a left handrail and a right handrail; the right handrail is higher than the left handrail; the cart is used for stacking a large number of straight pipes and conveying the straight pipes; the forking mechanism is used for lifting the straight pipes in the cart and then automatically unloading the straight pipes in a storage hopper; the storage hopper is used for storing a large amount of straight pipes; a jacking plate is used for jacking the straight pipes in the storage hopper, feeding the straight pipes into a guide slot from a rolling outlet for single-row discharging, and discharging the straight pipes orderly one by one; the straight pipes are pushed up one by one through a delivery mechanism; the straight pipes are located bypiercing plugs and then are grabbed to the processing station of a pipe-bending machine by mechanical arms; and the full-automatic feeding of the straight pipes is realized. The invention also discloses a full-automatic bending pipe production method. The feeding line and the pipe-bending machine form a bending pipe production line, so that the automatic straight pipe feeding and bending pipe processing are realized; and the full-automatic bending pipe production feeding line has the characteristics of manpower saving, high production efficiency and safe and stable production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

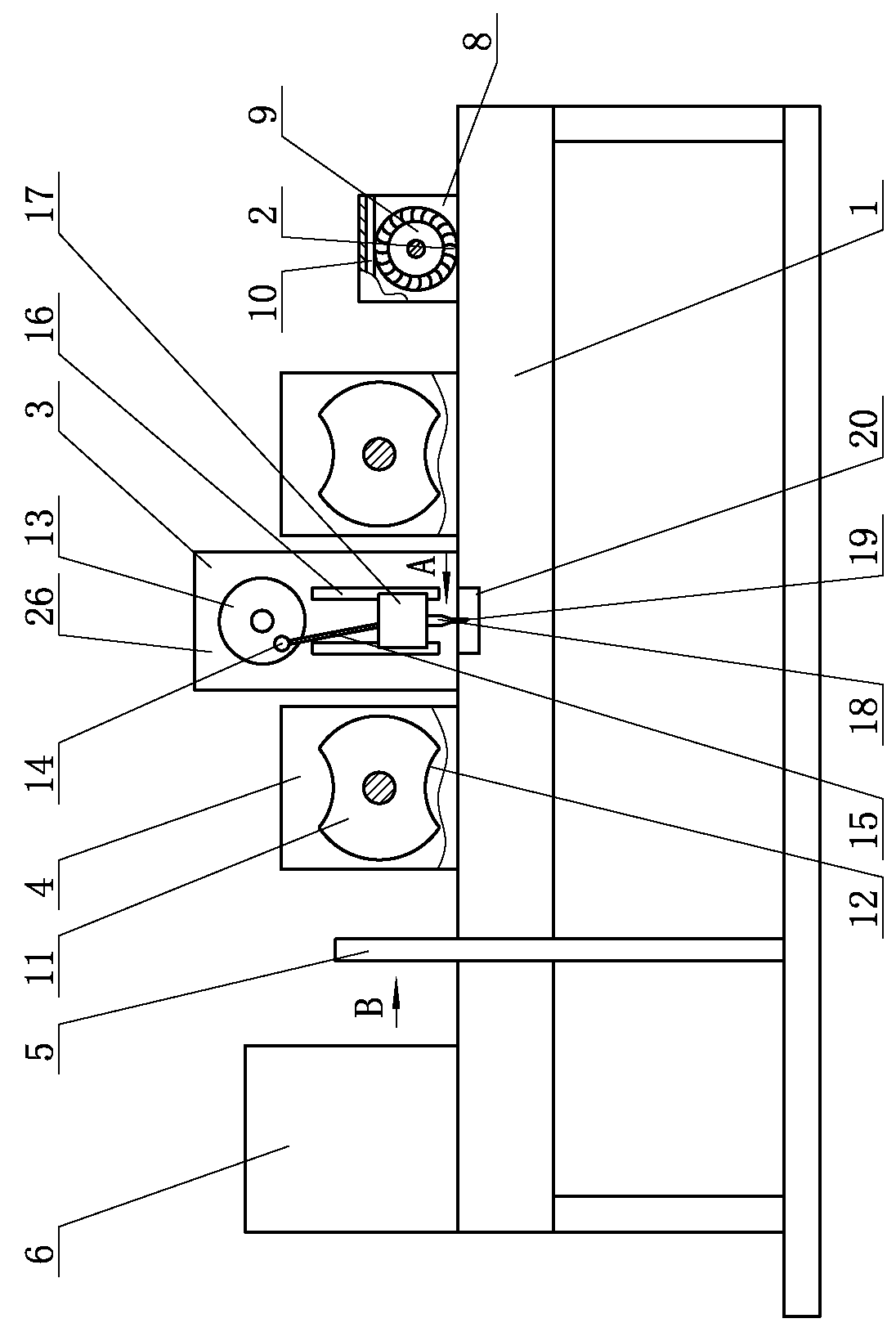

Automatic welding equipment of plastic case

The invention discloses automatic welding equipment of a plastic case. The automatic welding equipment comprises a control system, a welding device and a conveyer device and a fixation device which are arranged below the welding device. The welding device, the conveyer device and the fixation device are all electrically connected with the control system. The welding device comprises a weldment clamping mechanism and a hot mould mechanism. The weldment clamping mechanism contains a first six-axis manipulator and an L-shaped first linking arm connected with the first six-axis manipulator. The other end of the first linking arm is connected with a clamping jaw. The hot mould mechanism contains a second six-axis manipulator and an L-shaped second linking arm connected with the second six-axis manipulator. The other end of the second linking arm is connected with a heating module. By the welding equipment, weldments can efficiently be welded from an inner side of an enclosed case towards an inner wall of the enclosed case, and welding quality is raised greatly.

Owner:深圳市远望工业自动化设备有限公司

Code punching device for anti-fake printing

A code punching device for anti-fake printing comprises a workbench. The workbench is provided with a code punching machine, a pressing device and a transmission device. The transmission device is composed of a supporting frame and a conveying roller with a motor. An arc-shaped groove is formed in the roller face of the conveying roller. The motor is arranged on the supporting frame. A rotary disc is installed on an output shaft of the motor. The edge of the rotary disc is hinged to one end of a connecting rod and the other end of the connecting rod is hinged to the upper portion of a sliding block. The sliding block is matched with a sliding rail. The sliding rail is vertically installed on the supporting frame. A connecting board is arranged on the lower portion of the sliding block. A pressing sheet is arranged on the lower portion of the connecting board. A groove is formed in the workbench and located on the lower portion of a punching nail. According to the code punching device for anti-fake printing, marking and code punching can be completed at one time, work steps are reduced, and work time is saved; ticket paper is fed at intervals, the feeding distance of each time is fixed, so that the code punching positions of tickets of the same batch are unified, and the anti-fake effect is achieved; each time of code punching can be completed in a static state, so that the deflection of patterns or characters printed on the tickets is avoided, and the definition of code punching is guaranteed.

Owner:广州东港安全印刷有限公司

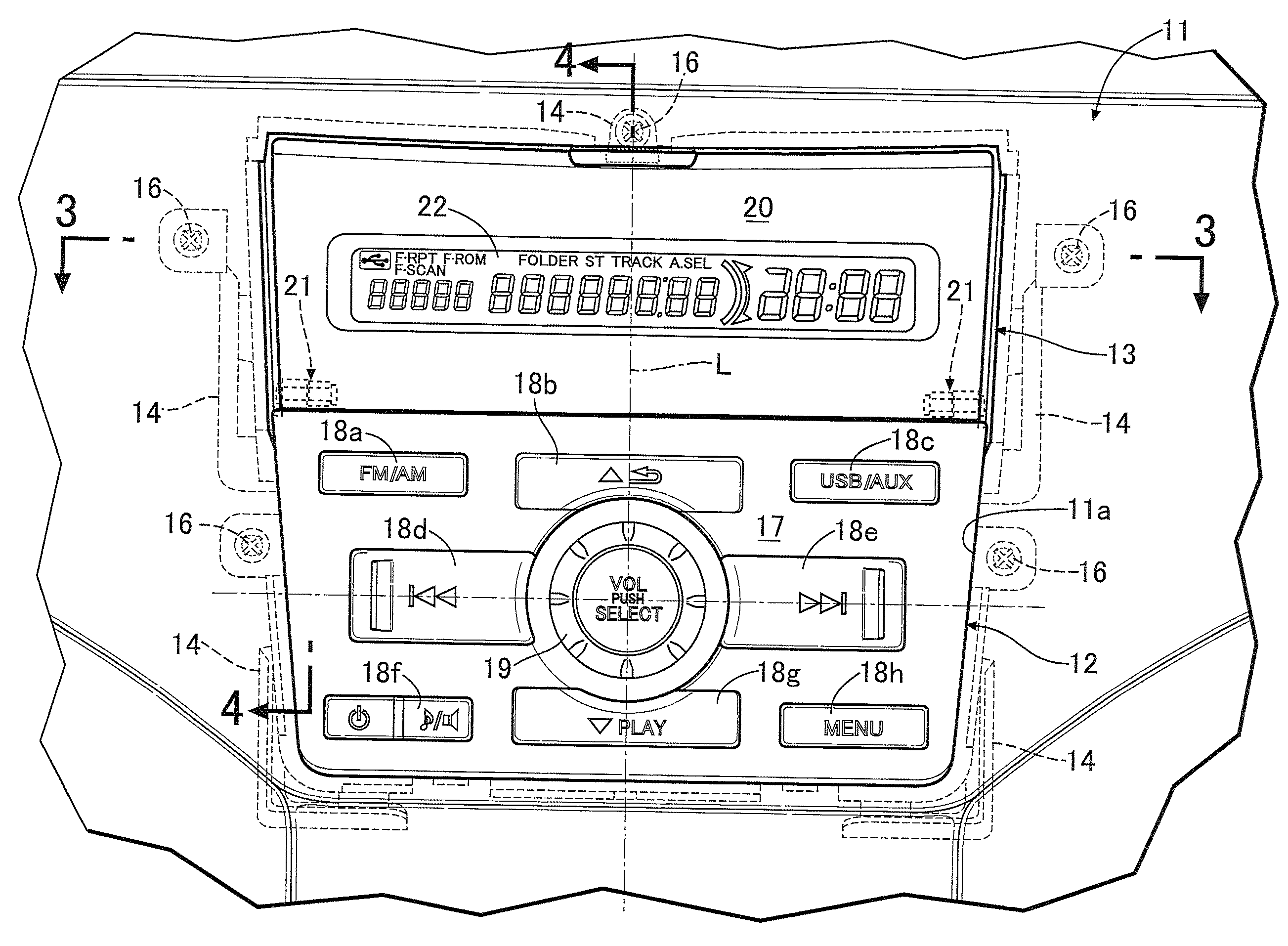

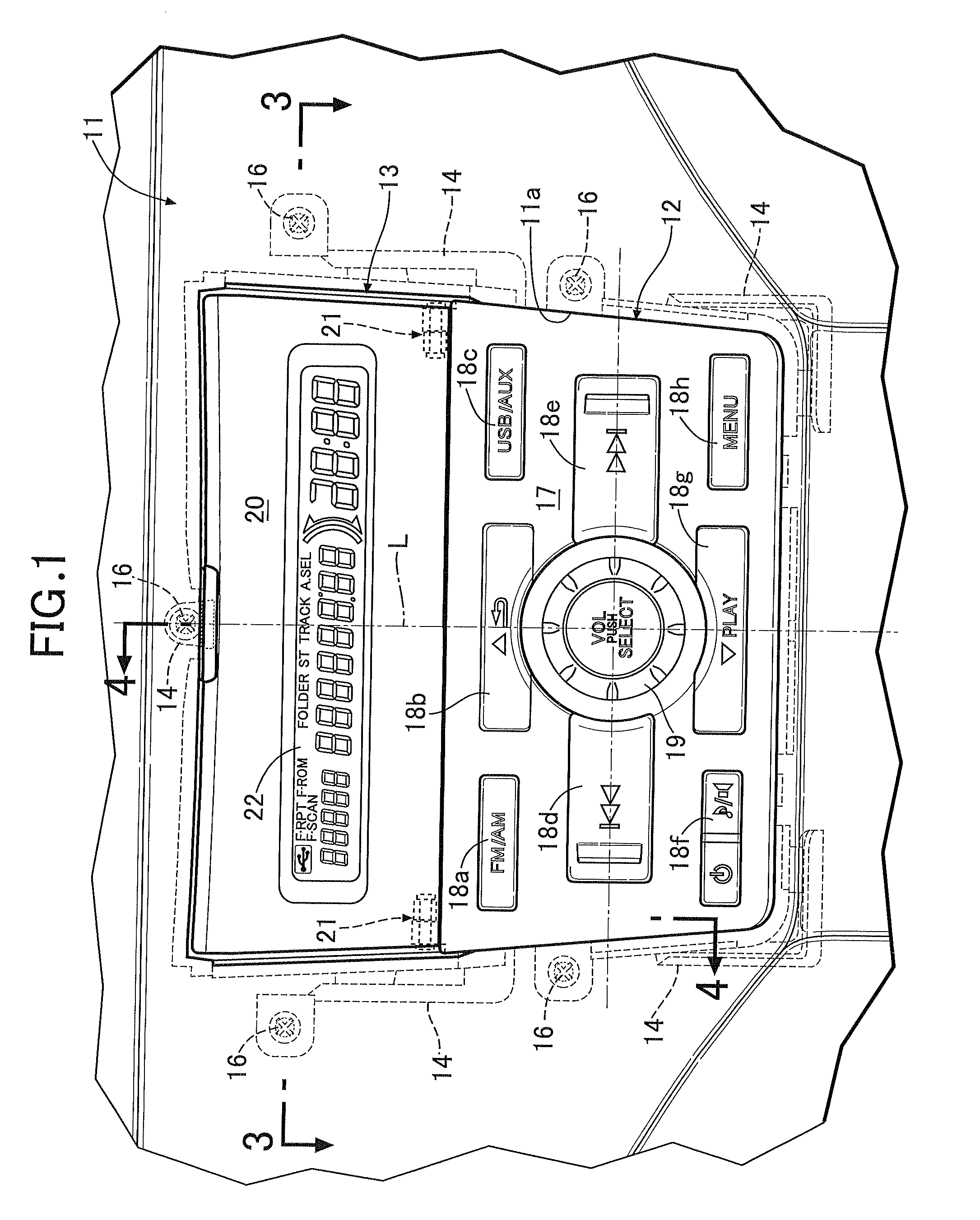

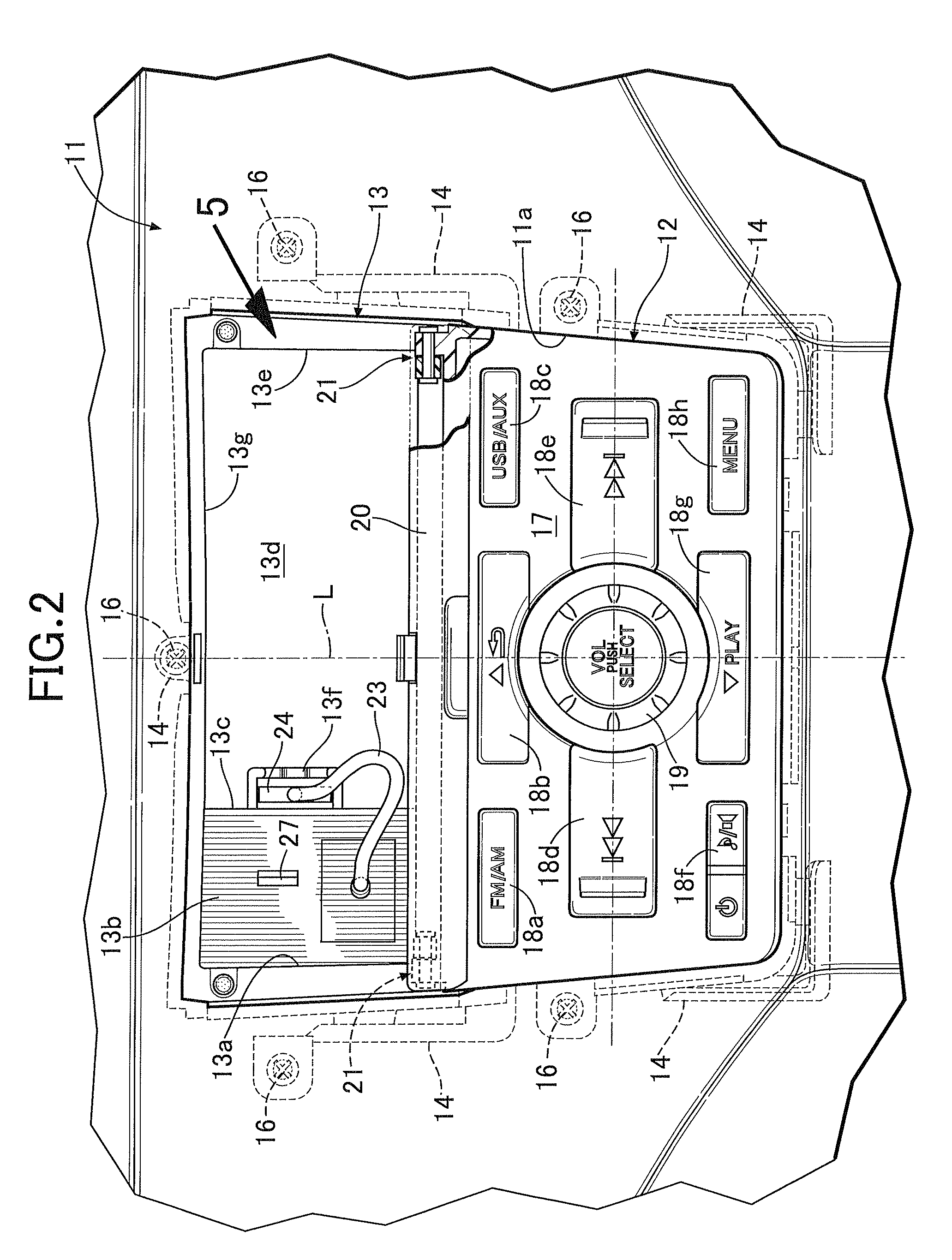

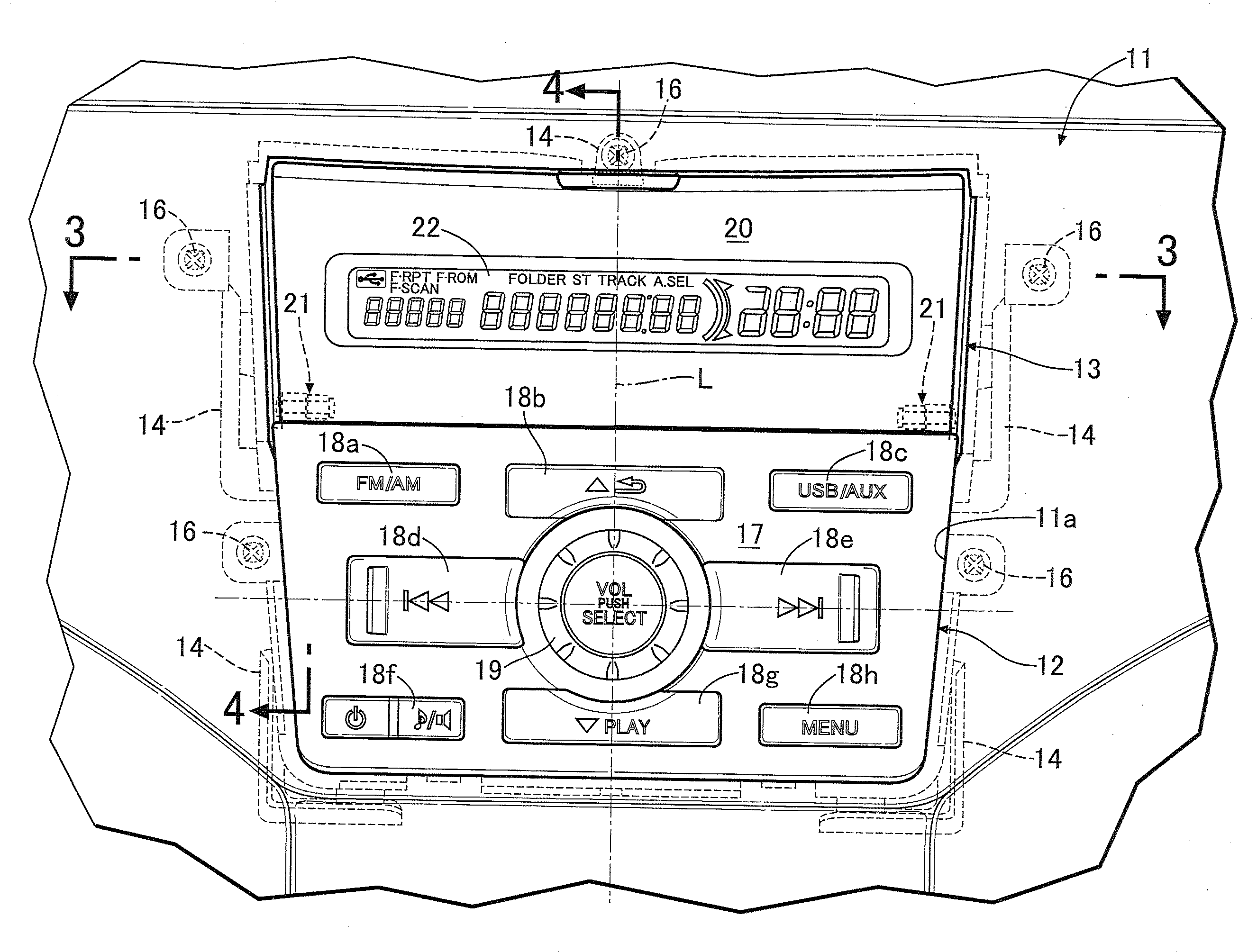

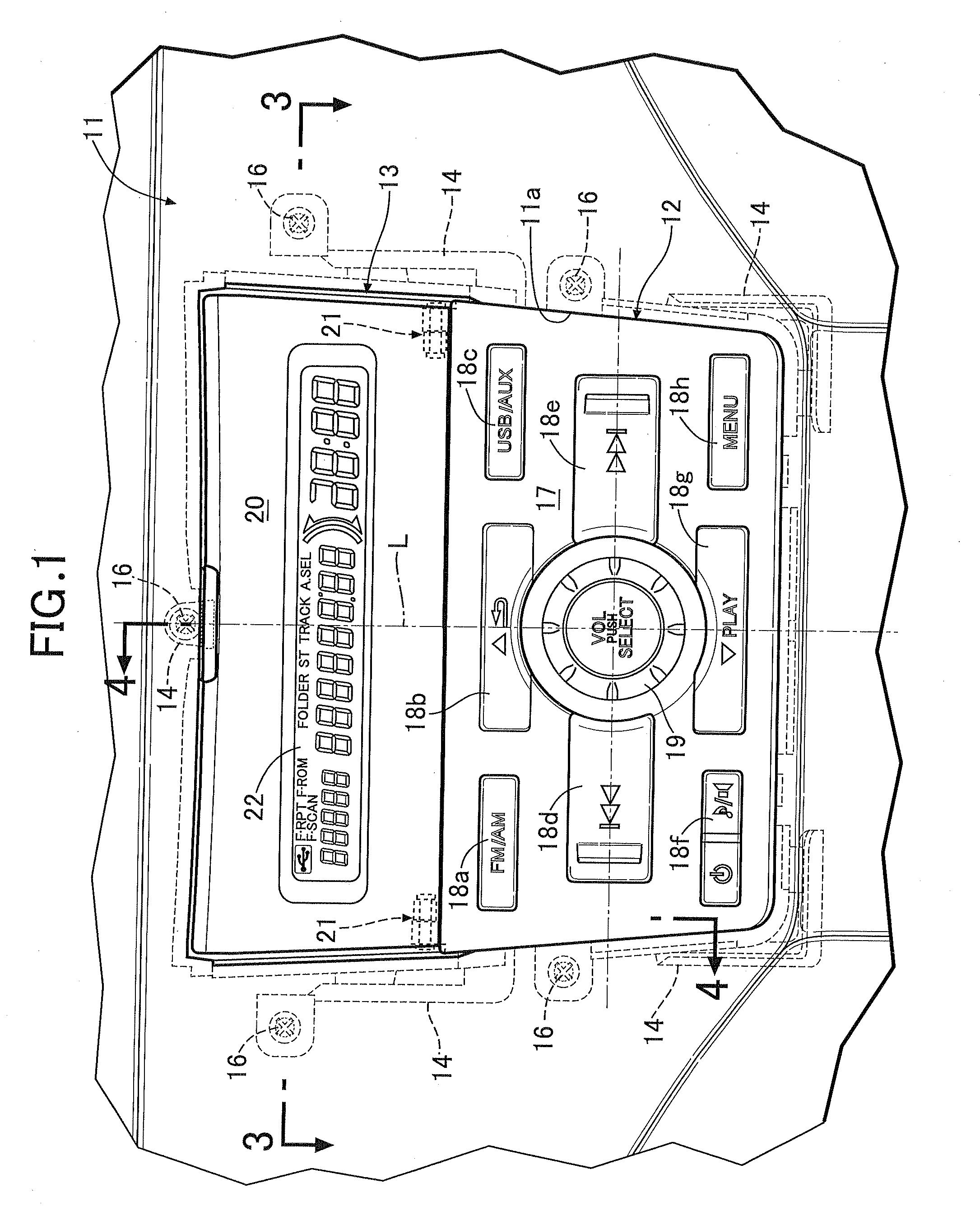

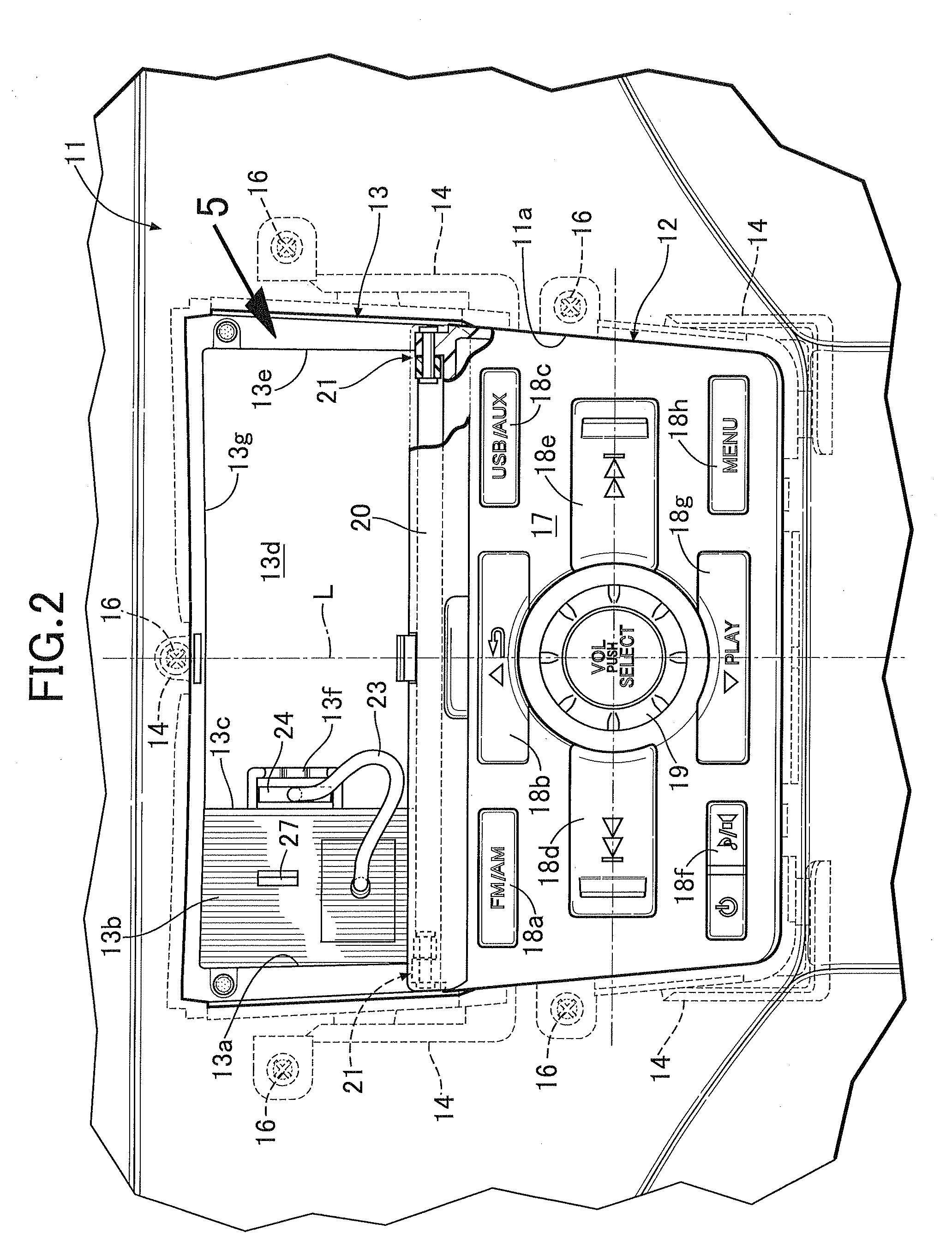

Audio apparatus for vehicle

ActiveUS8562056B2Good lookingGood size controlPassenger spaceRecord information storageEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

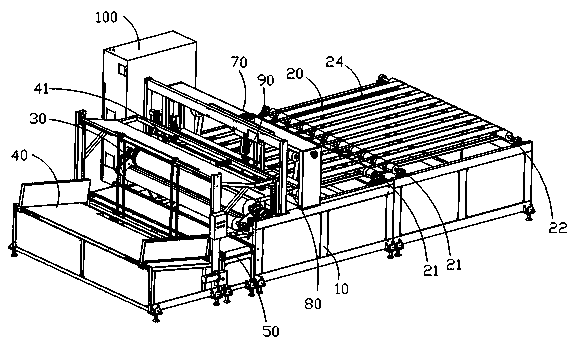

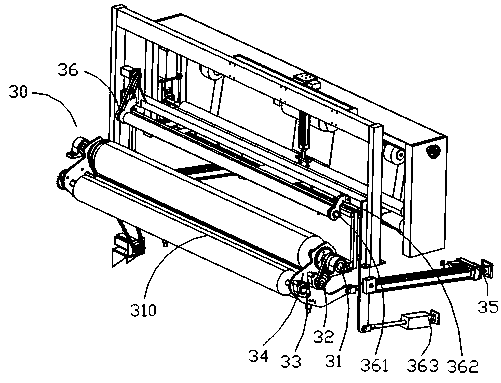

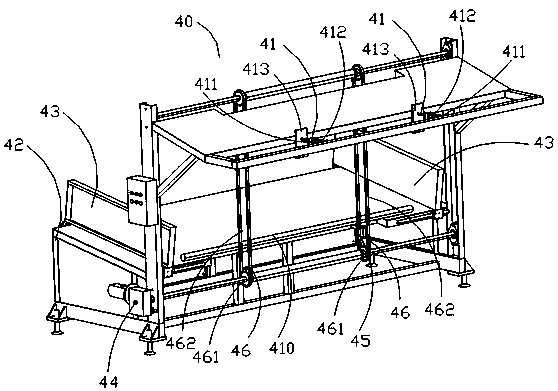

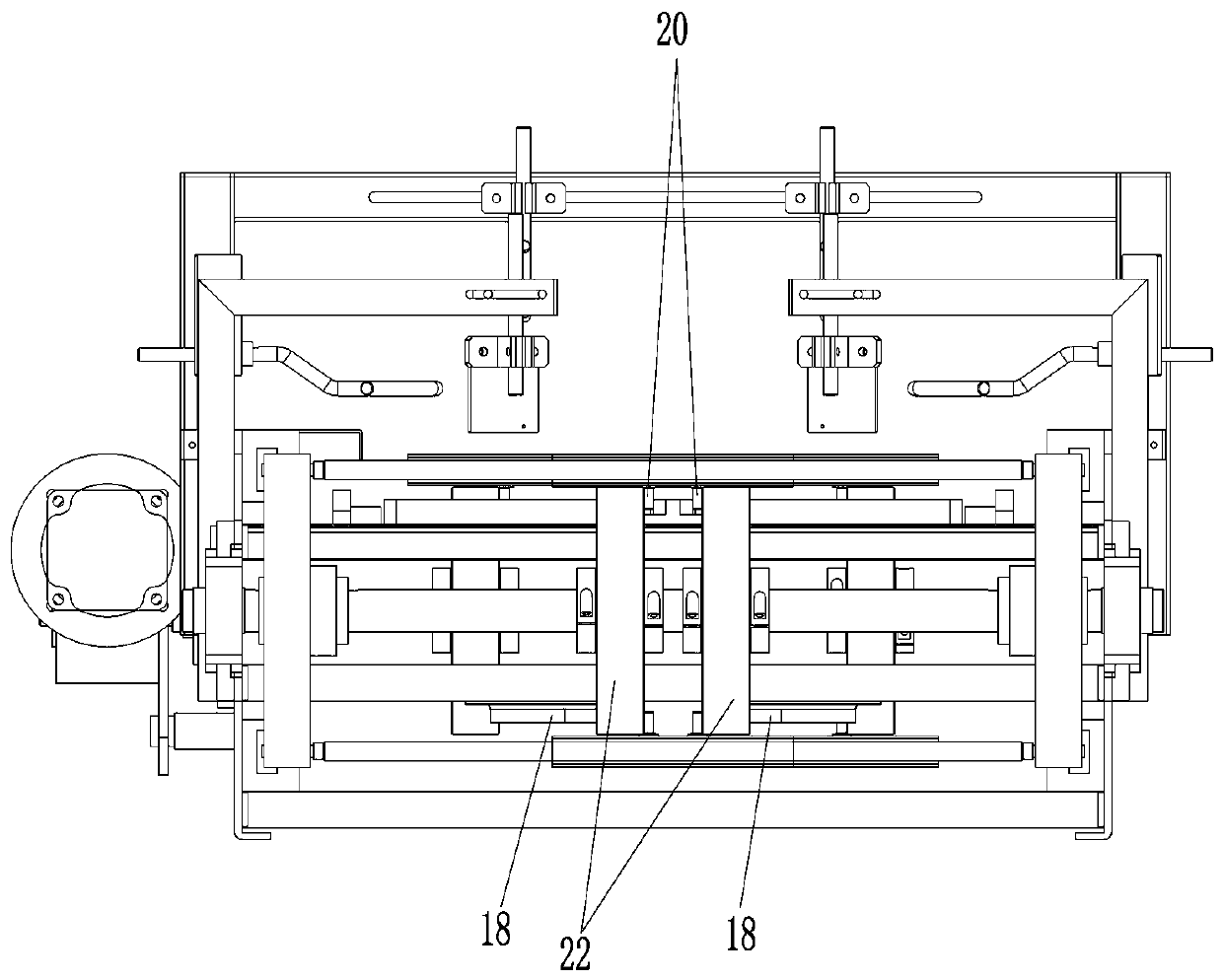

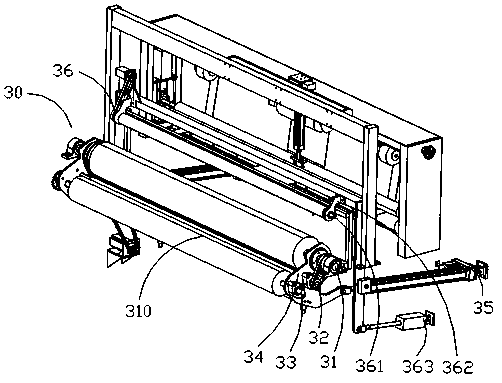

Automatic winding device

PendingCN110723577AAutomatic winding goodRealize autonomous cuttingPaper article packagingAffixing tagsMechanical engineeringElectrical and Electronics engineering

The invention provides an automatic winding device. The automatic winding device comprises a rack, a conveying mechanism, a multi-shaft linkage winding mechanism and automatic tubular material feedingconveying equipment, wherein the conveying mechanism, the multi-shaft linkage winding mechanism and the automatic tubular material feeding conveying equipment are arranged on the rack; the automatictubular material feeding conveying equipment comprises a discharging push rod mechanism; the discharging push rod mechanism can move so as to release tubular materials to the preset position of the multi-shaft linkage winding mechanism; and the conveying mechanism is used for conveying the tubular materials to the multi-shaft linkage winding mechanism. According to the scheme, the wound materialsare automatically cut, automatically fed and automatically fed to paper tubes on the automatic winding device, through the structural design of the multi-shaft linkage winding mechanism, the wound materials can be well and automatically wound, packaging paper or packaging films are automatically discharged, and the packaging paper or the packaging films are automatically cut according to the product specification; manual pre-winding is not needed, the production efficiency is improved, and the manufacturing cost is reduced; and through the structural design, the performance is stable, and theprecision is high.

Owner:TAICANG KELITE METAL COMPONENTS TECH CO LTD

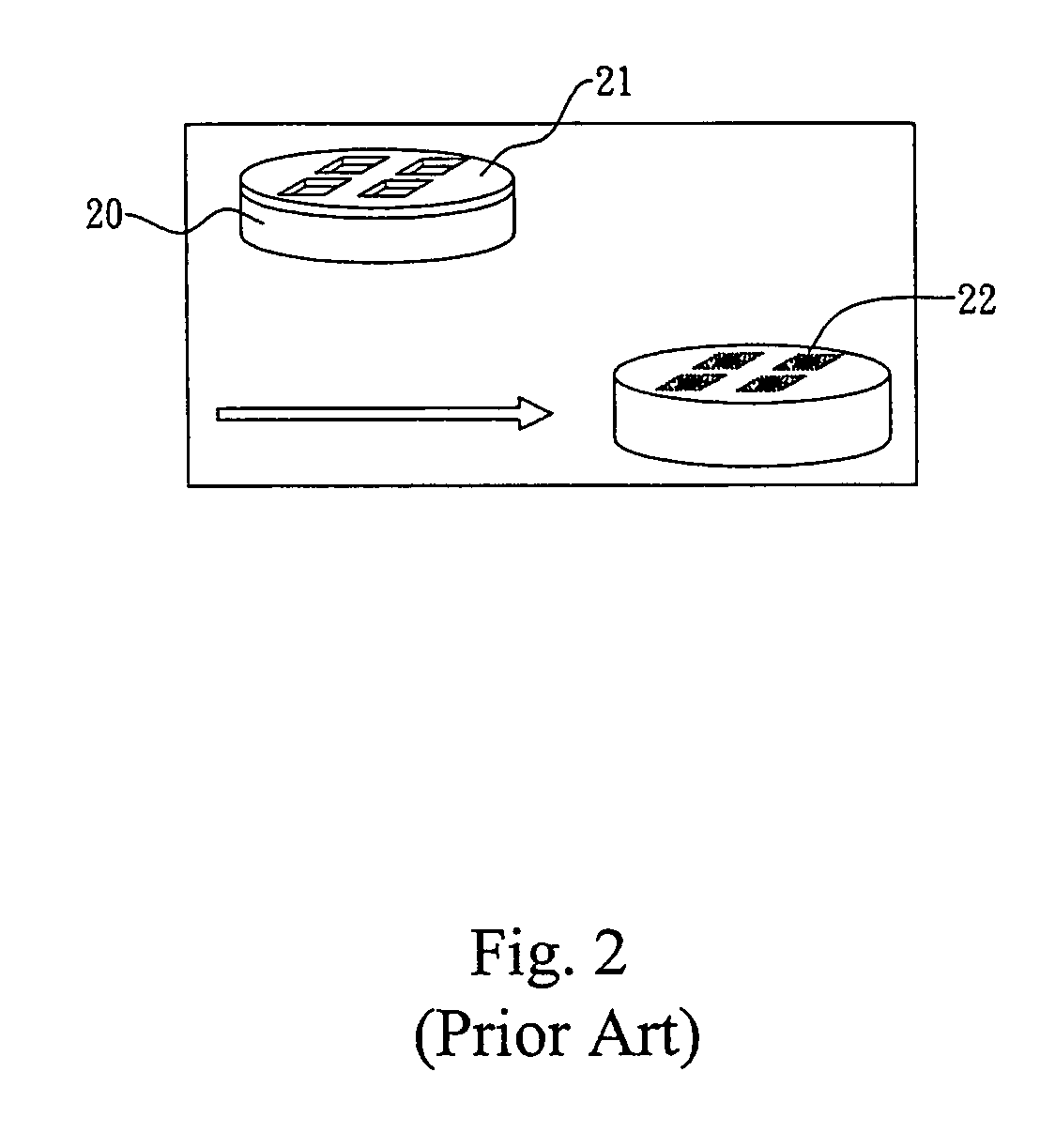

Microelectronic positioning for bioparticles

InactiveUS7682827B2Advantageous for collection and redistributionUnified positionTissue cultureElectrical/wave energy microorganism treatmentPresent methodElectrical control

The present invention provides a method for microelectronic positioning bioparticles, which utilizes dielectric and non-contact electrical force of cell themselves associated with multi-phase electrical signals to attain uniformity of distribution of the bioparticles and positioning thereof within micro-areas in a cell culture system. The obstacle of system geometrical structure is eliminated so as to simplify the system layout and programmably change cells' positions. The present method is suitable for treating cell array in a large quantity. The present method utilizes electrical control for the cells. The clamping of the cells can be removed at any time. It is very advantageous for collection and redistribution of cell products.

Owner:IND TECH RES INST

Device for detecting position of wafer in wafer boat box

ActiveCN114379830AAvoid enteringReduce labor intensityPackaging automatic controlUsing optical meansWaferEngineering

The invention relates to a wafer position detection device in a wafer boat box, which comprises a processing unit and a conveying belt, a cover closing position and a rear photographing position are sequentially arranged on the conveying belt, a cover closing mechanical arm is arranged above the conveying belt corresponding to the cover closing position, and a rear photographing mechanical arm is arranged above the conveying belt corresponding to the rear photographing position; the rear photographing mechanical arm comprises a fifth telescopic frame capable of stretching and retracting up and down and a rear photographing unit arranged on the fifth telescopic frame, and the rear photographing unit comprises five cameras for photographing the wafer box reaching the rear photographing position from the front, the rear, the left, the right and the upper part respectively; the box body covered with the box cover is photographed through the rear photographing unit, whether the box cover of the wafer box is well covered or not and whether the position of the wafer in the wafer box is correct or not are distinguished, and if the position is wrong, an alarm is given to remind a worker to intervene in processing, so that the problems of wafer breakage and the like in the subsequent transportation process caused by position dislocation of the wafer are prevented.

Owner:南京伟测半导体科技有限公司

Audio apparatus for vehicle

ActiveUS20100070985A1Good lookingGood size controlPassenger spaceRecord information storageMechanical engineeringAudio equipment

Owner:HONDA MOTOR CO LTD

One-into-two conveying device for packages

ActiveCN109573541ASimple structureLow costConveyorsControl devices for conveyorsMechanical engineering

The invention discloses a one-into-two conveying device for packages. The conveying device comprises a machine frame, a driving mechanism arranged at one end of the machine frame, a tensioning mechanism arranged at the other end of the machine frame, a conveying chain assembly wound around the driving mechanism and the tensioning mechanism, and a carrying mechanism which is arranged on the conveying chain assembly and can transversely move along the conveying chain assembly, wherein the driving mechanism and the tensioning mechanism divide the conveying chain assembly into an upper conveying chain assembly and a lower conveying chain assembly, the conveying device further comprises a guide mechanism, the guide mechanism comprises two symmetrically-formed guide grooves which are formed below the upper conveying chain assembly, the two ends of the guide grooves extend to the input end and the output end of the conveying chain assembly correspondingly, the guide grooves comprise first inclined section which is inclined outwards in the moving direction of the upper conveying chain assembly, the carrying mechanism comprises at least two carrying plates, guide rollers are fixed at the bottoms of the carrying plates, and each guide groove is provided with at least one guide roller. According to the one-into-two conveying device for the packages, the carrying plates are guided by the two independent guide grooves, and an additional branching device does not need to be arranged at a one-into-two branching position, so that the structure is simple, the cost is low, and the operationis stable and reliable.

Owner:广州市万世德智能装备科技有限公司 +1

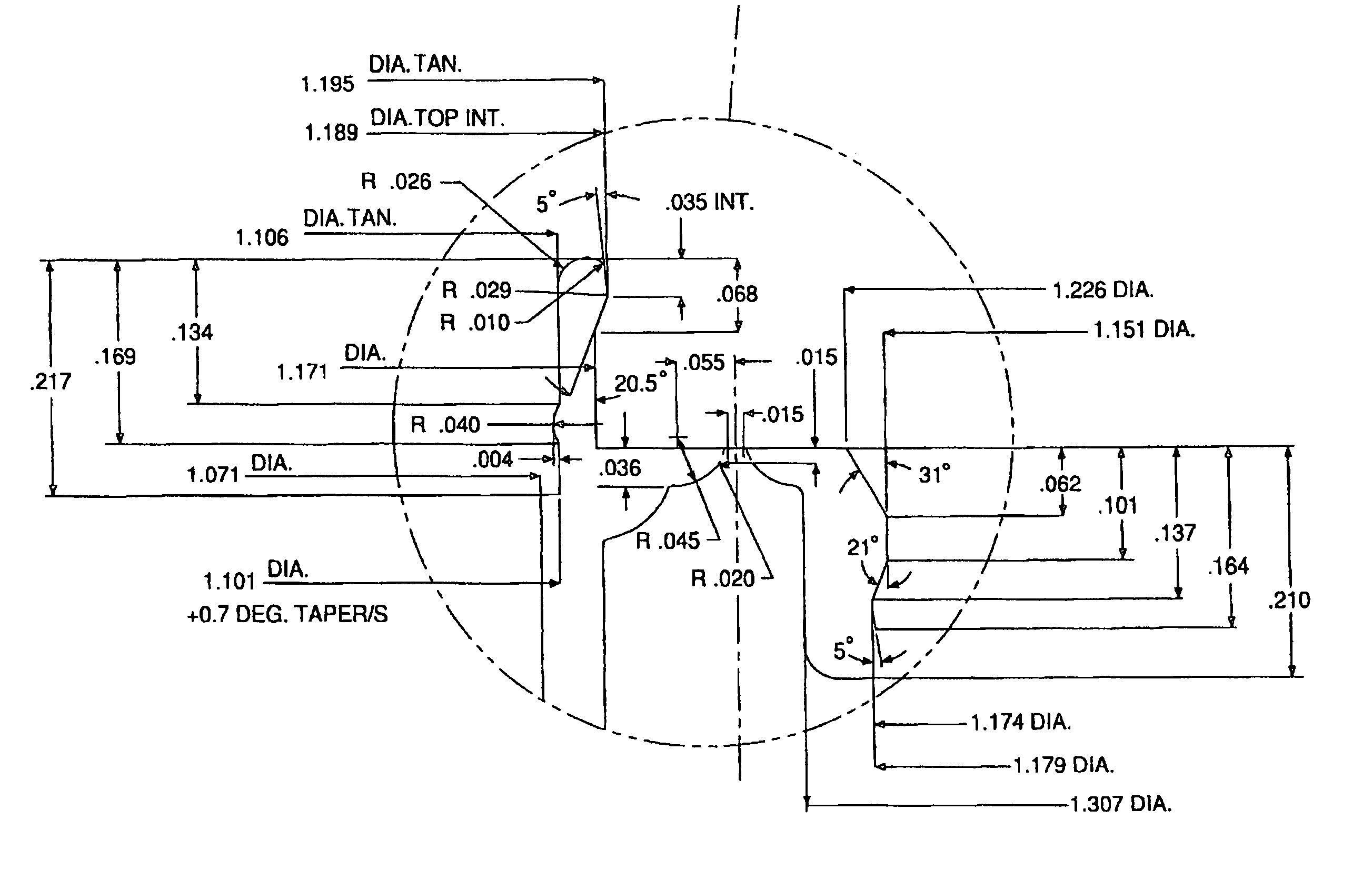

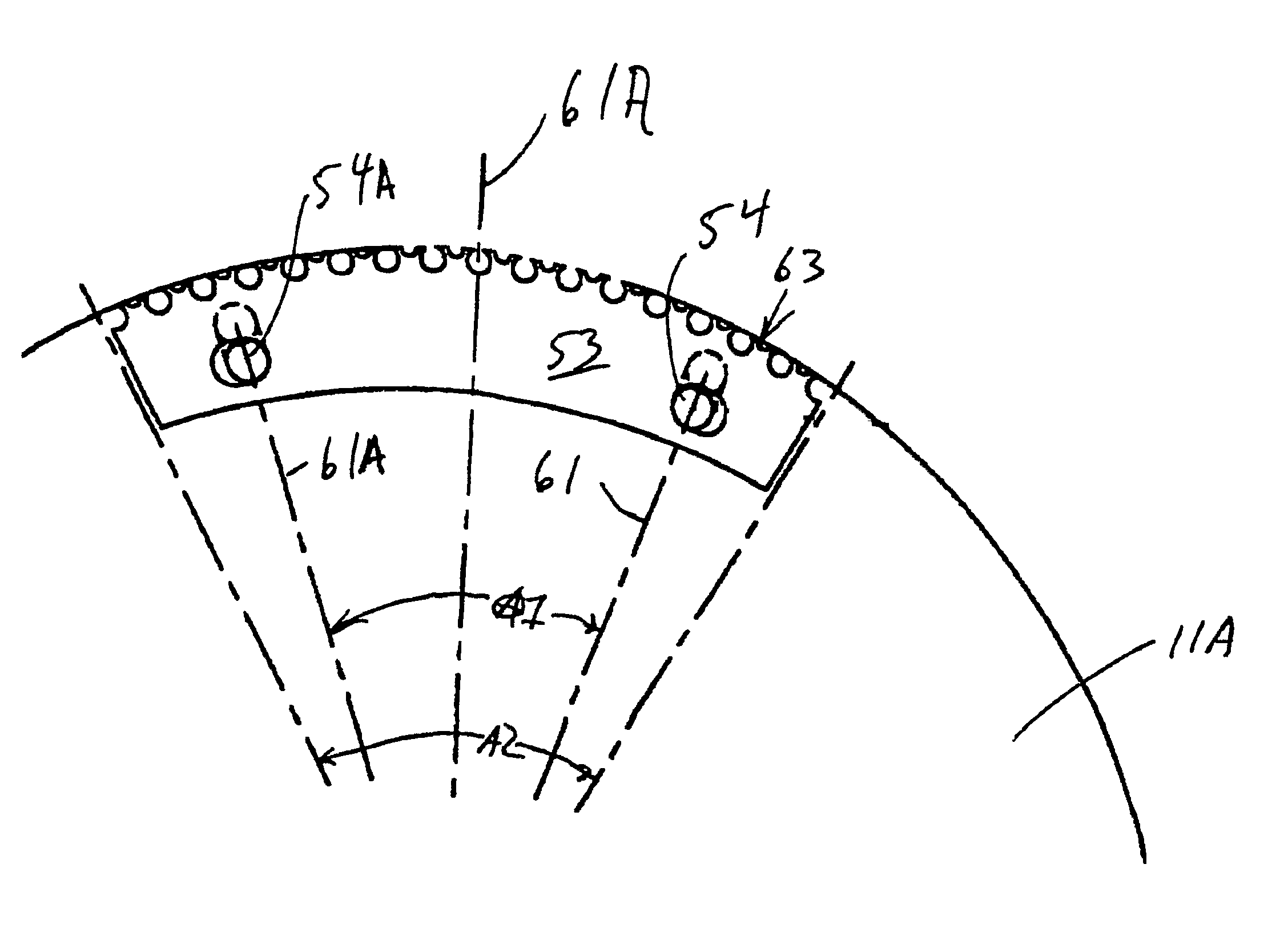

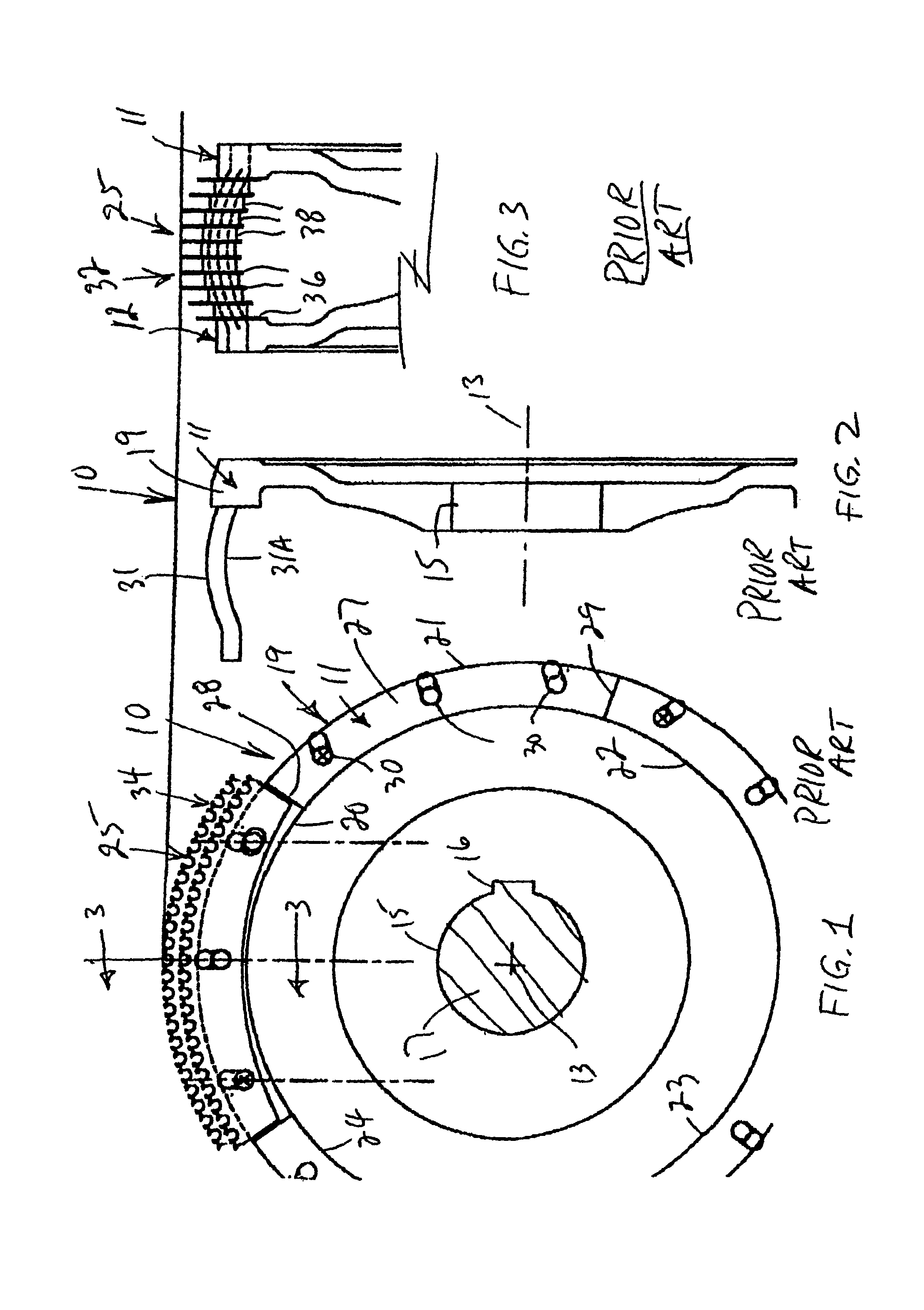

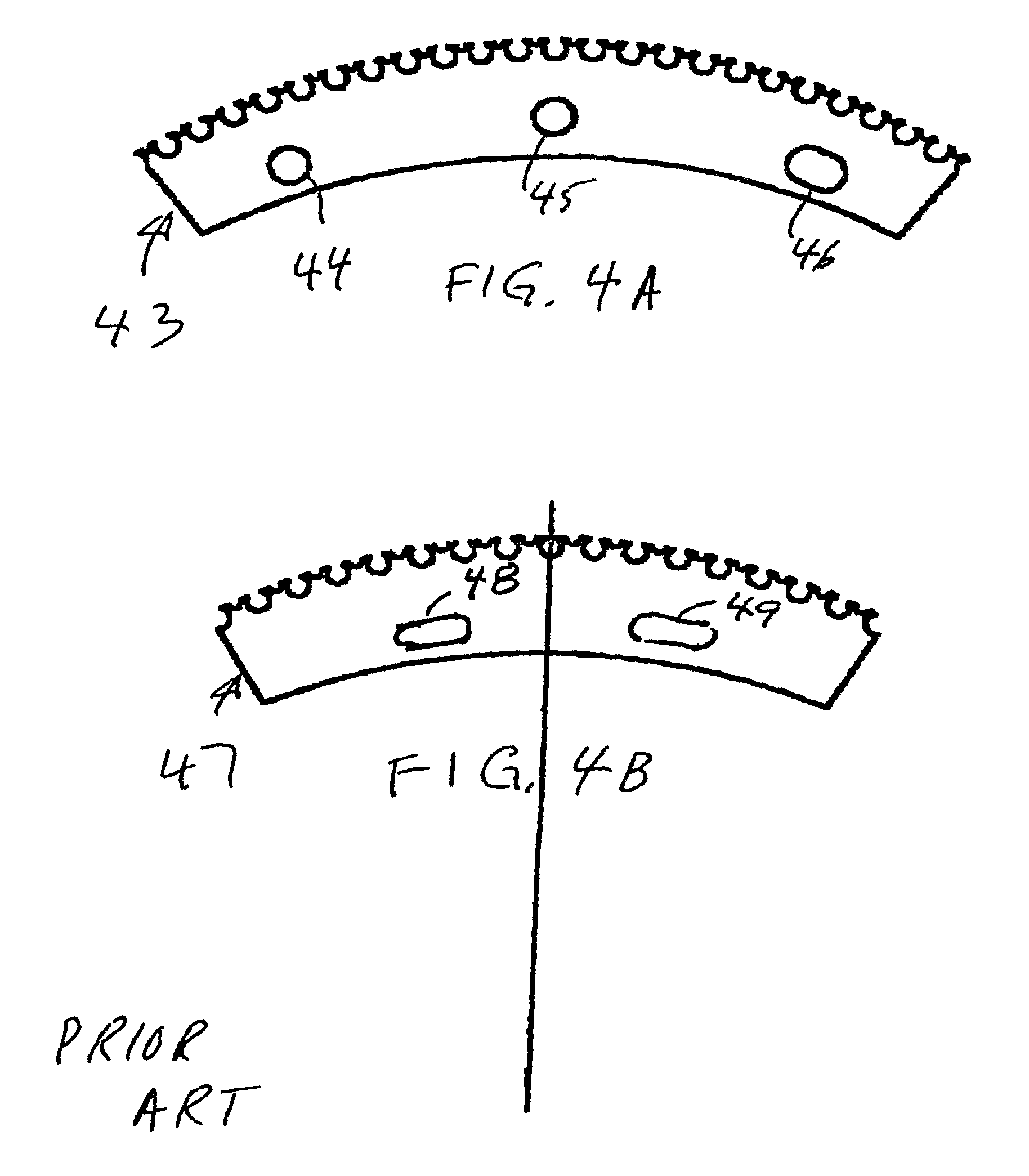

Rasp hub for tire retreading machine

InactiveUS7891915B2High concentricityImprove consistencyPlastic recyclingTyresRaspAerospace engineering

A rasp hub for use in tire retreading machines includes two side plates with mounting pins extending between the plates. Rasp blades arranged in stacks are mounted on the mounting pins. The stacks extend end-to-end circumferentially about the hub. The center portion of the mounting pins is curved so that the cut profile of the blades is convex. The blades are inclined relative to a plane perpendicular to the axis of rotation to define a cut angle. The center planes of the mounting pins intersect, preferably close to the axis of rotation of the hub, to reduce deviation of the blades from the concentricity.

Owner:B&J ROCKET AMERICA INC

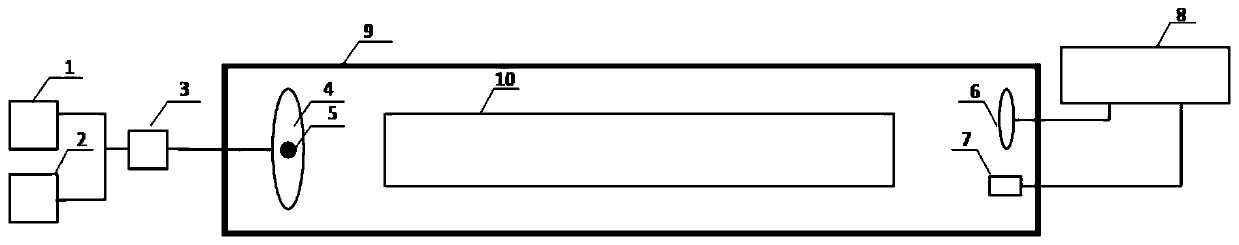

GIS ultrahigh frequency-optical signal consistency test equipment, device and method

PendingCN110082658AFrequency controllableUnified positionTesting using optic methodsConsistency testPhotomultiplier

The invention relates to GIS ultrahigh frequency-optical signal consistency test equipment, device and method. The equipment comprises a pulse generator, a light source controller, a switch, a test chamber, an ultrahigh-frequency transmitting sensor, a light source, an ultrahigh-frequency receiving sensor, a photomultiplier tube and an oscilloscope. The input end of the switch is connected with the pulse generator and the light source controller; the output end of the switch is connected with the ultrahigh-frequency transmitting sensor and the light source; the ultrahigh-frequency receiving sensor and the photomultiplier tube are connected with the oscilloscope; the ultrahigh-frequency transmitting sensor and the light source are arranged at one end of the test chamber; the ultrahigh-frequency receiving sensor and the photomultiplier tube are arranged at the other end of the test chamber; the test chamber is internally provided with an accommodation groove for holding an obstacle; andthe accommodation groove is arranged between the light source and the photomultiplier tube, and between the ultrahigh-frequency transmitting sensor and the ultrahigh-frequency receiving sensor. Compared with the prior art, the GIS ultrahigh frequency-optical signal consistency test equipment, device and method can test influence laws of various obstacles on the consistency of light and ultrahigh-frequency signals generated through discharge.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

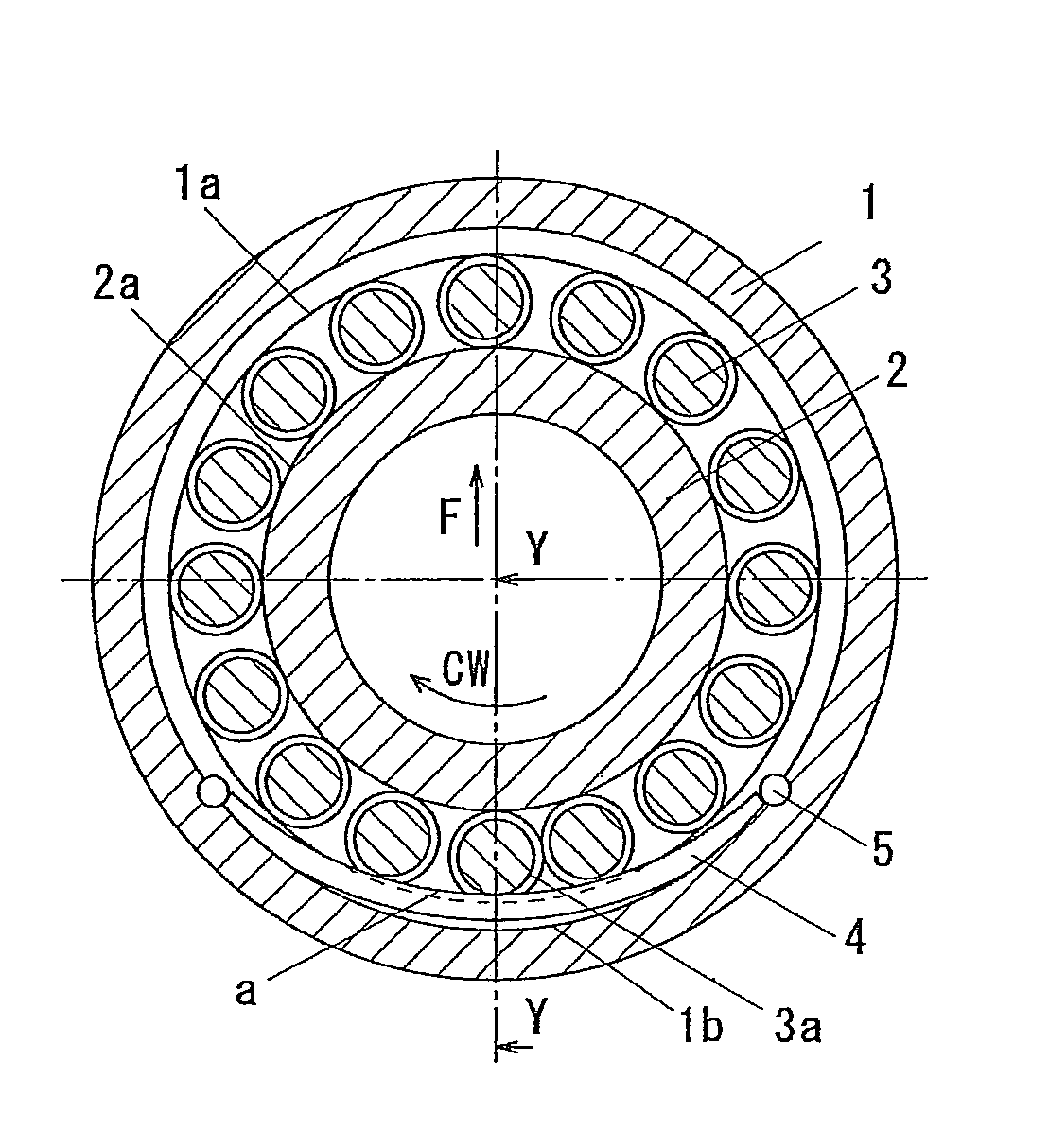

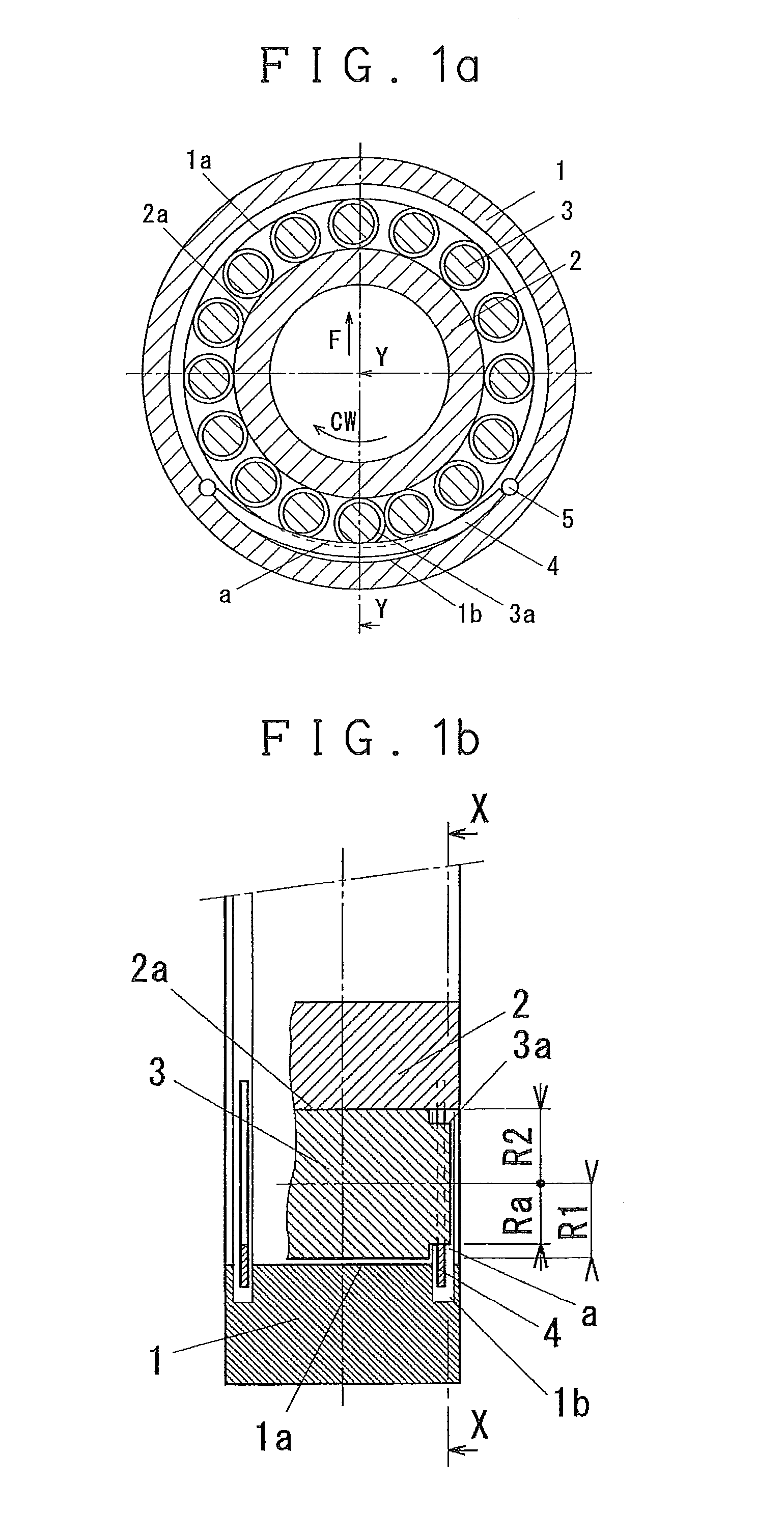

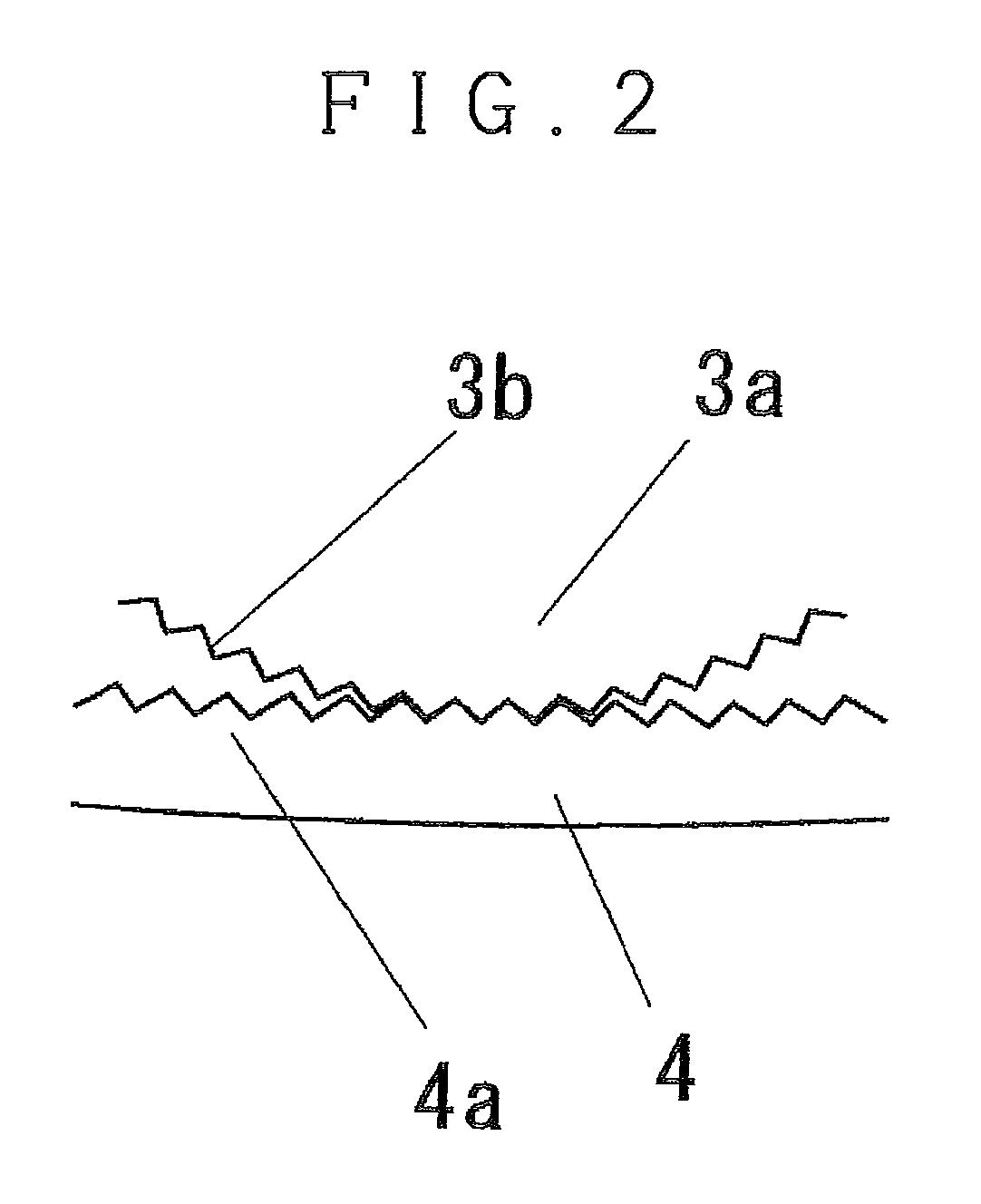

Rolling device and using method thereof

ActiveUS8783958B2Increase in rotary torqueReduced dimensionRoller bearingsLinear bearingsPoint changeMechanical engineering

Intervals are provided between rolling elements in a load area to avoid jostling of rolling elements in a rolling device. A portion of a transfer groove has such a sectional shape as to form a contact point changing path for coming in contact with smaller diameter portions of the rolling elements than outer diameters of the rolling elements to thereby reduce revolution quantities of the rolling elements to bring rolling elements in contact with or close to each other at this portion. Then, when the rolling elements come out of the contact point changing path, the outer diameter portions of the rolling elements come in contact with the transfer groove to thereby increase the revolution quantities of the rolling elements to create intervals between the rolling elements entering the load area.

Owner:COO SPACE CO LTD

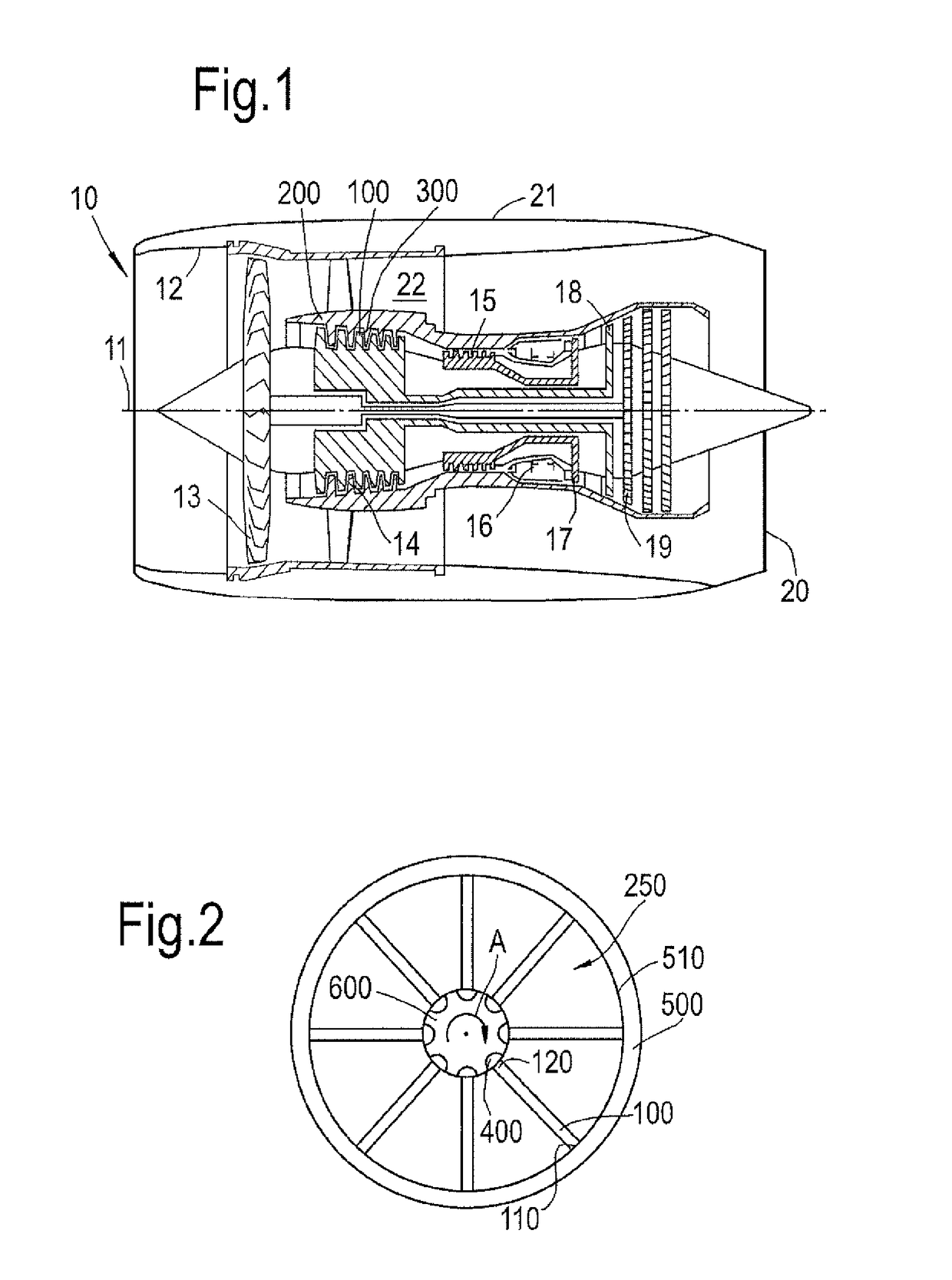

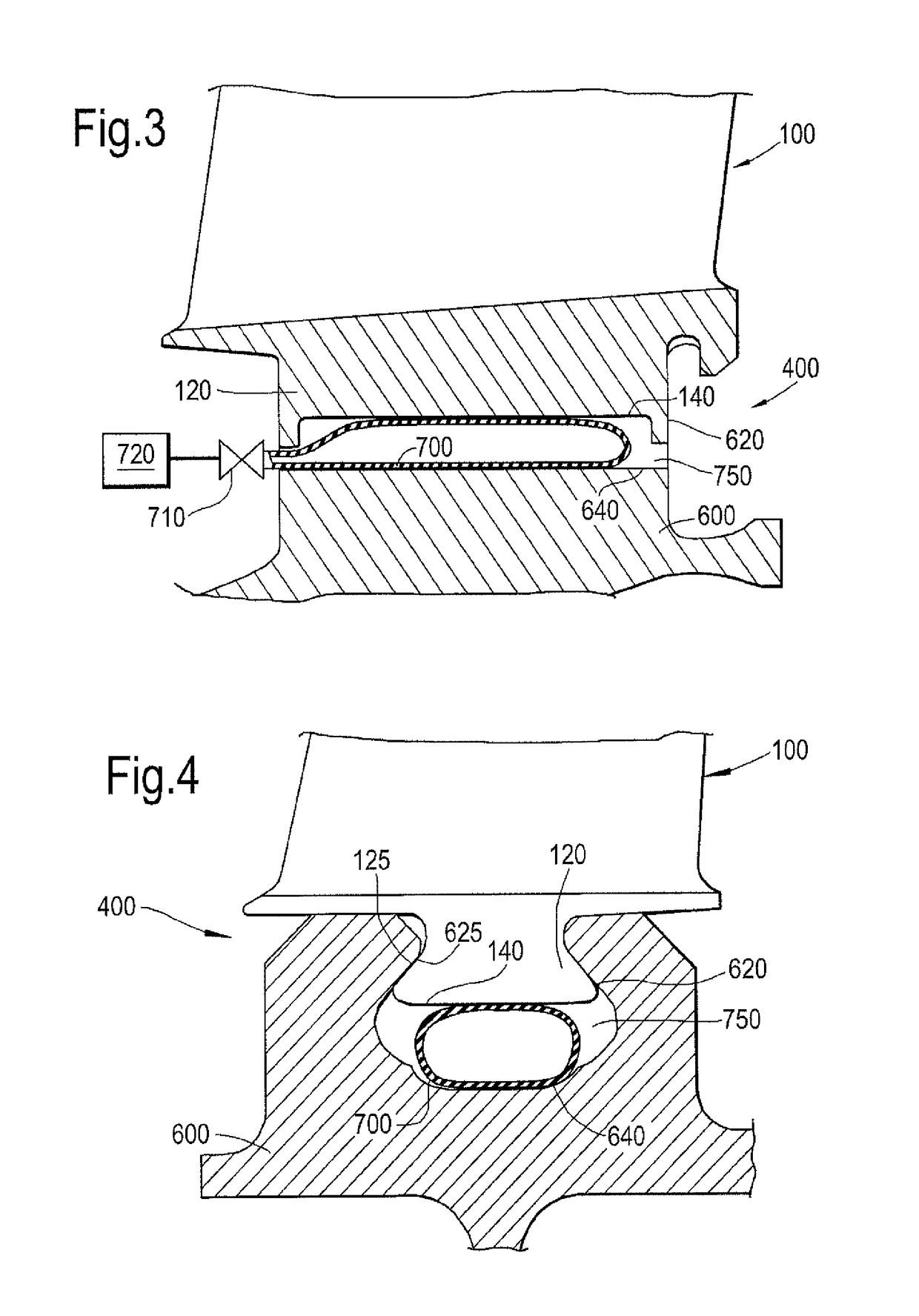

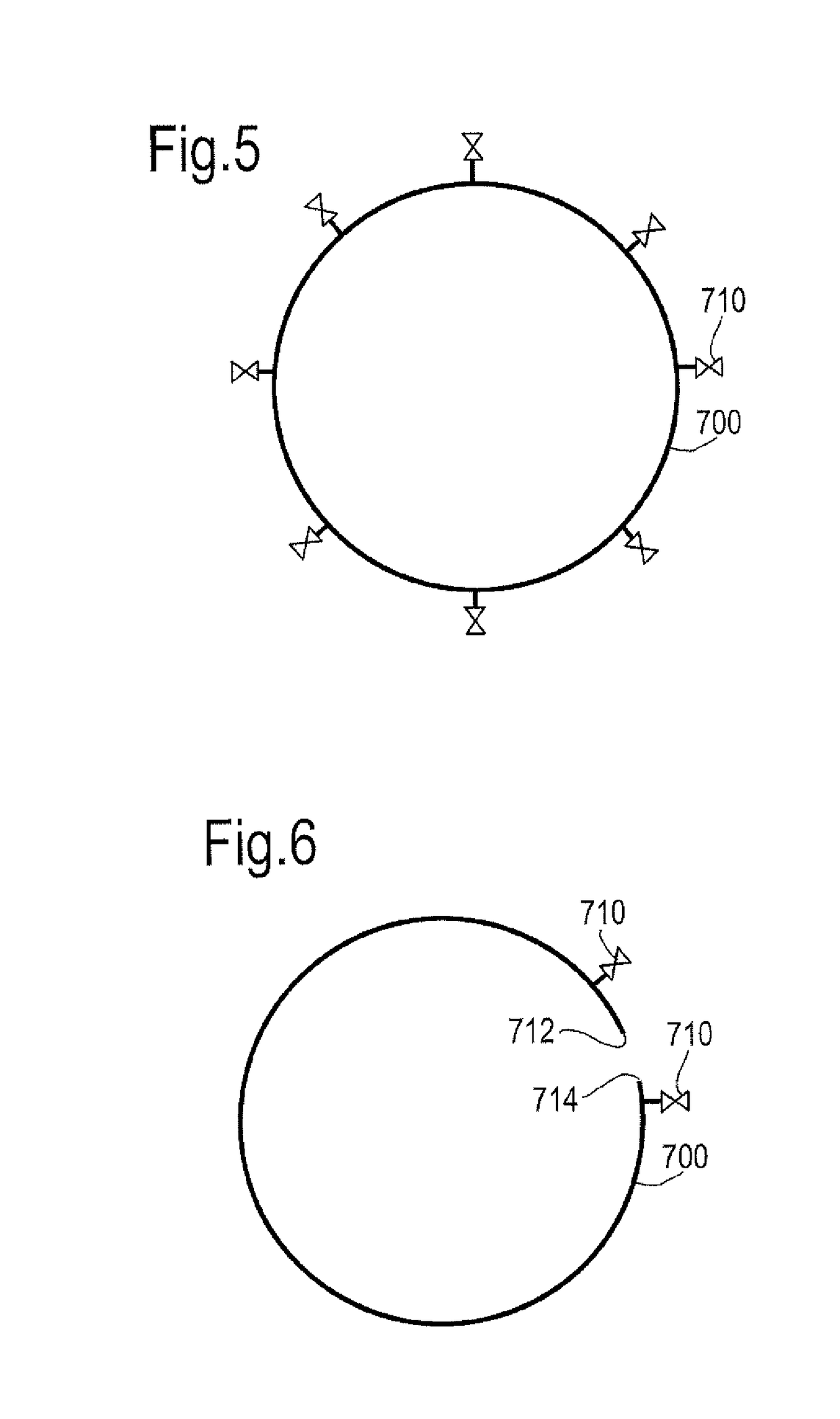

Blade positioning

ActiveUS10160086B2Reduce leakageImprove engine efficiencyPump componentsBlade accessoriesEngineeringTurbine

A method of, and apparatus for, urging blades of a gas turbine engine radially outwardly is disclosed. The method may be used to grind blade tips of blades of a rotor stage of a gas turbine engine. The method comprises locating a fluid-tight bag which is in a radial gap formed between a radially inner surface of a respective blade root and a slot in a disc which the blade root cooperates. The method comprises inflating the fluid-tight bag and rotating the rotor stage relative to a grinding surface so as to grind any blade tips that contact the grinding surface during rotation. This results in more accurate positioning of the blades during the grinding process and / or during operation.

Owner:ROLLS ROYCE PLC

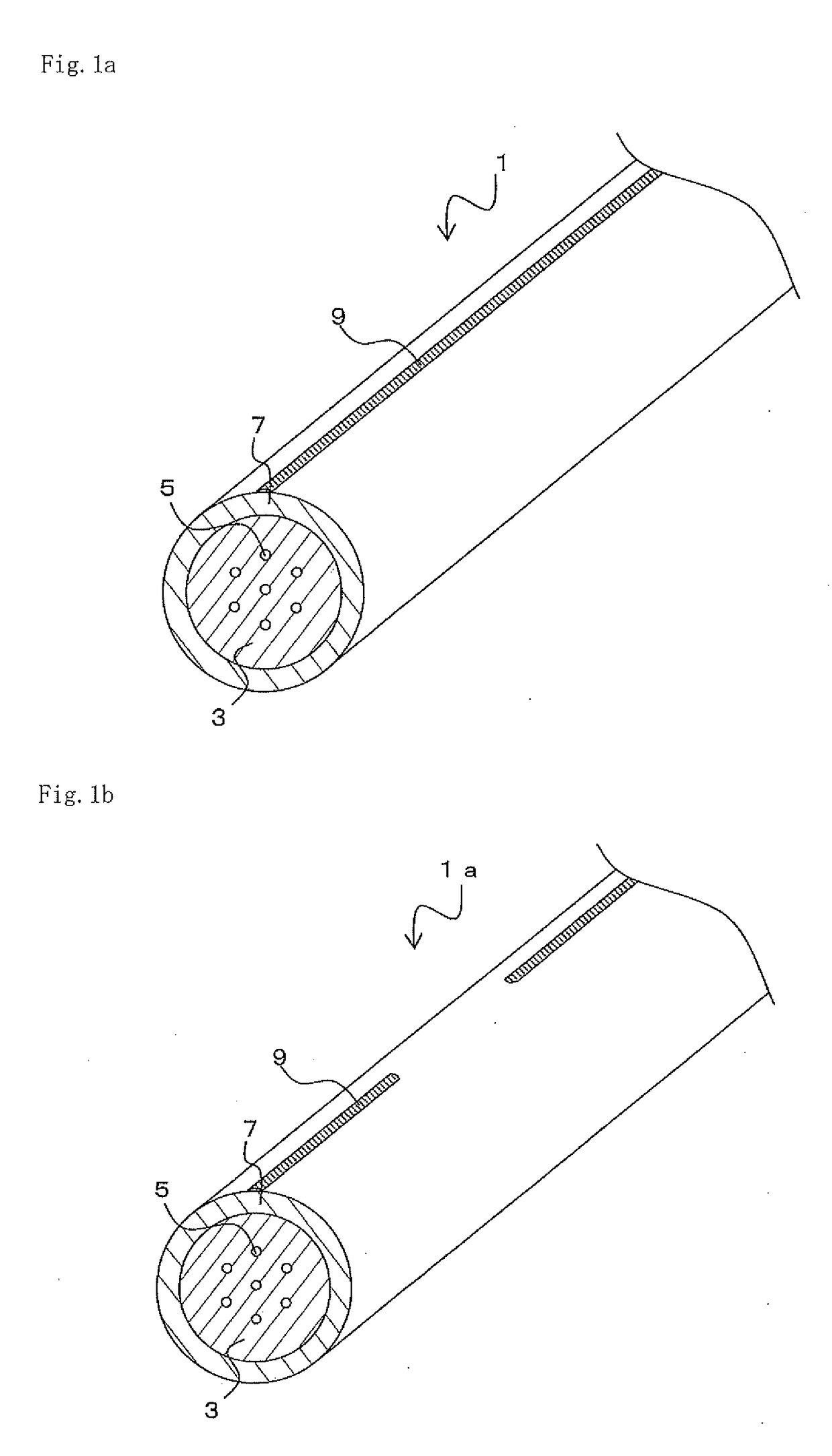

Optical Fiber, and Optical-Fiber Production Method

ActiveUS20170285258A1Easy to identifyEasy optical alignmentGlass optical fibreOptical fibre with polarisationRefractive indexEngineering

In this multi-core fiber, a plurality of cores are arranged at a prescribed interval, and the peripheries thereof are covered by a cladding having a lower refractive index than the plurality of cores. A resin coating is formed on the outer periphery of the cladding. A colored section is formed on a section of the outer surface of the resin coating in the peripheral direction. The colored section is formed continuously along the length direction of the multi-core fiber. In a multi-core fiber cross section orthogonal to the length direction, the position of a specific core and the peripheral position where the colored section is formed are substantially constant along the length direction of the multi-core fiber. In other words, in the multi-core fiber cross section orthogonal to the length direction, the position of the specific core and the position where the colored section is formed are substantially constant along the length direction of the multi-core fiber.

Owner:FURUKAWA ELECTRIC CO LTD

Automatic tubular material feeding conveying equipment

PendingCN110723578AGood self-windingNo manual pre-rolling requiredWebs handlingManufacturing lineIndustrial engineering

The invention provides automatic tubular material feeding conveying equipment. The automatic tubular material feeding conveying equipment comprises a tubular material feeding lathe bed, baffles arranged on the two sides of the tubular material feeding lathe bed, a tubular material feeding drive device, a grabbing tool, a tubular material feeding transmission mechanism and a discharging push rod mechanism. The tubular material feeding drive device is configured to drive the grabbing tool to grab tubular materials, drive the tubular material feeding transmission mechanism to convey the tubular materials to the discharging push rod mechanism and drive the discharging push rod mechanism to move in order to release the tubular materials to preset positions. According to the scheme, by means ofthe automatic tubular material feeding conveying equipment, automatic paper tube feeding is achieved, manual pre-rolling is not needed, the production efficiency is improved, and the manufacturing cost is reduced. Packaged finished products are automatically discharged and sent out of a production line; and by means of the structural design, the automatic tubular material feeding conveying equipment is stable in performance and high in precision.

Owner:TAICANG KELITE METAL COMPONENTS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com