Code punching device for anti-fake printing

An anti-counterfeiting printing and coding machine technology, which is applied in printing, typewriters, etc., can solve the problems of inconsistency of ticket coding positions, easy deviation of coding positions, low definition of patterns or text, etc., and achieve low manufacturing cost , improve quality, avoid the effect of pattern or text offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

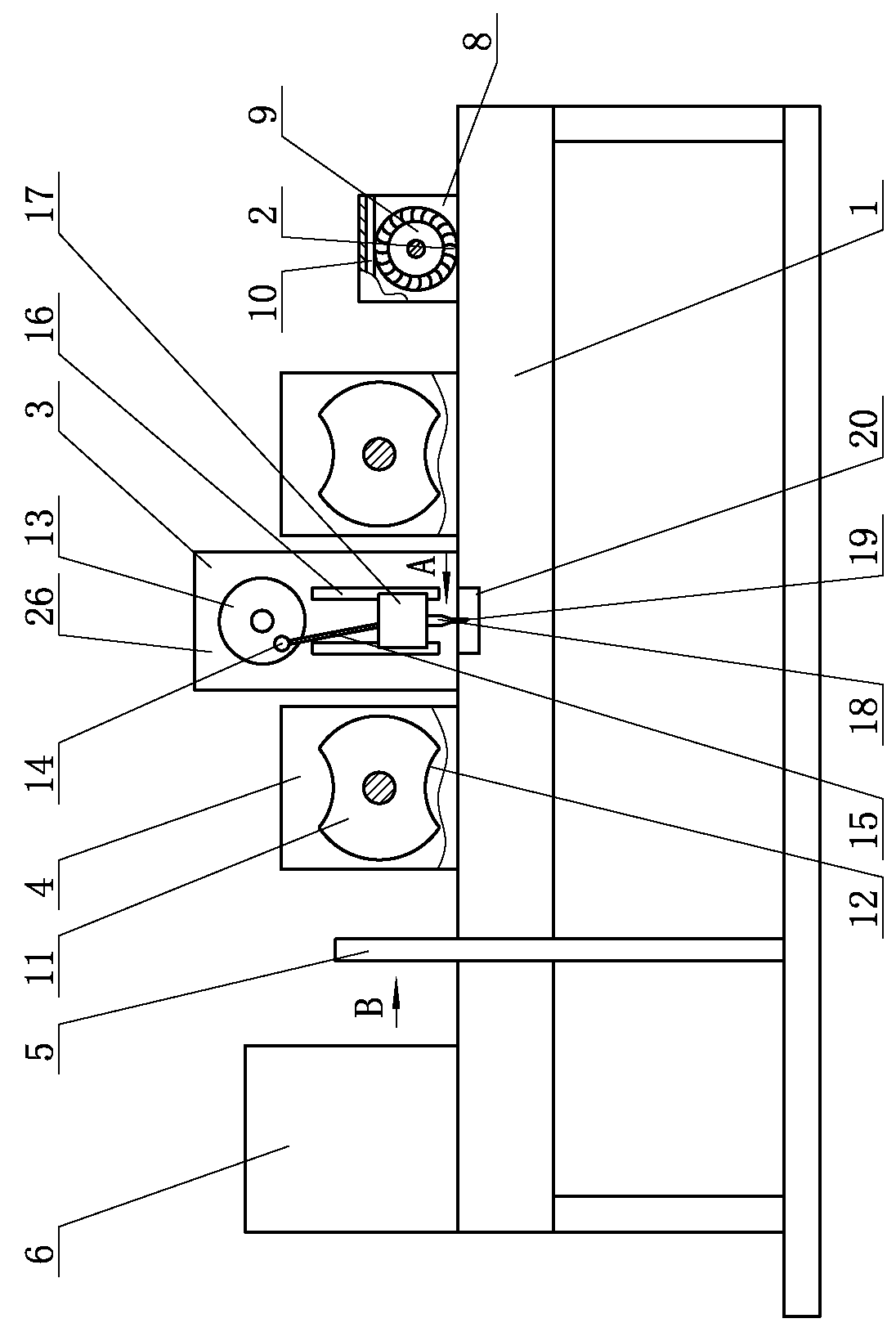

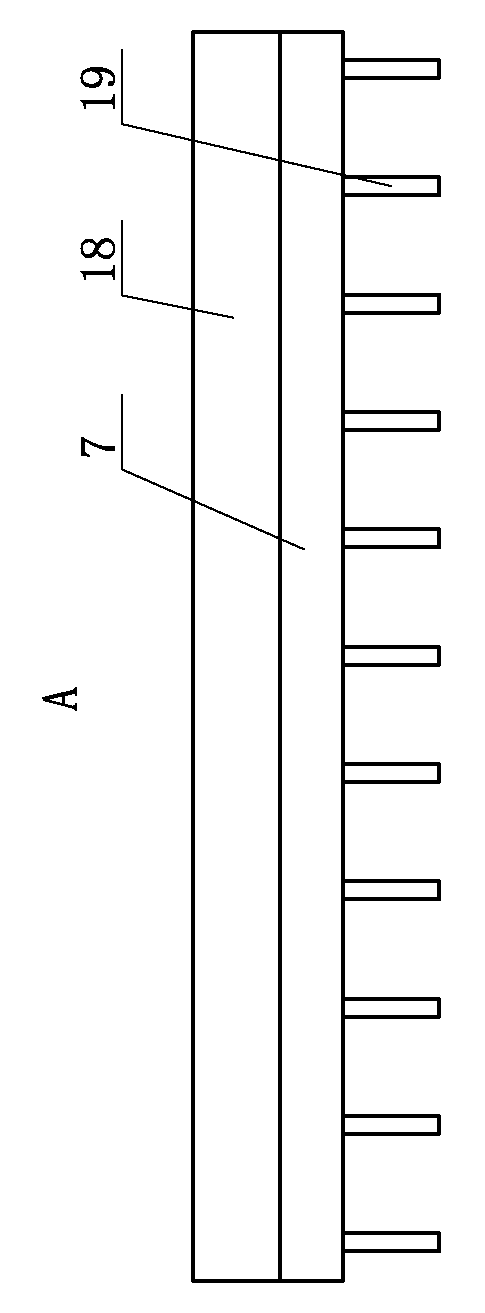

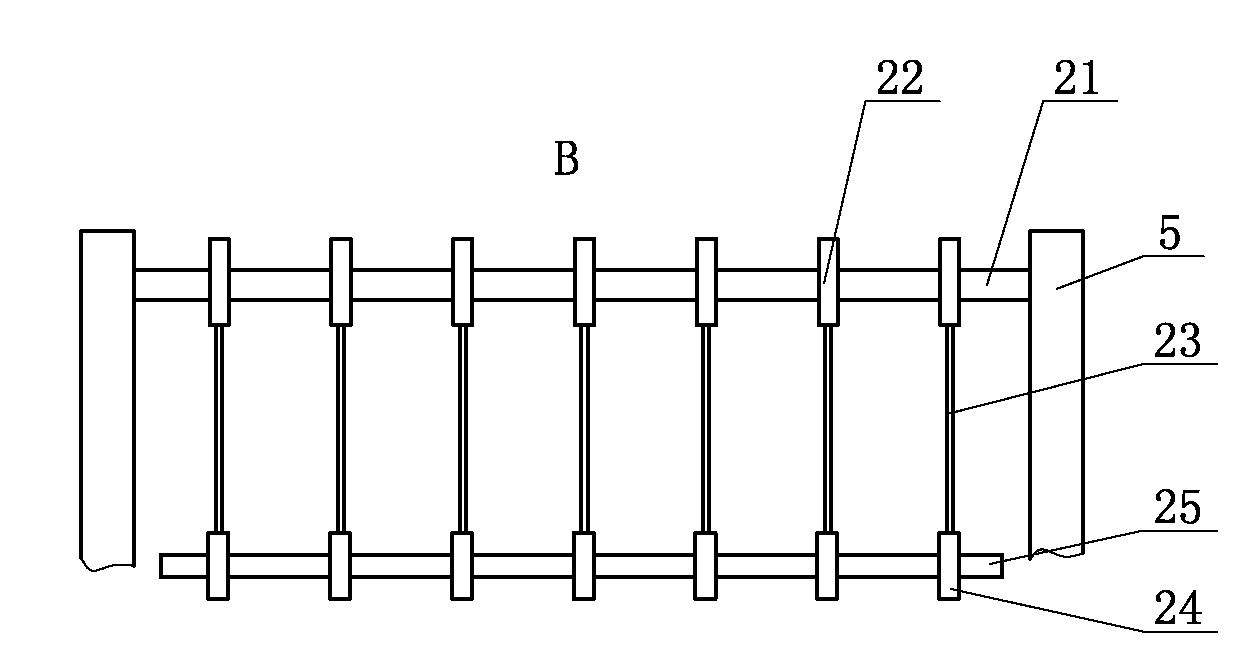

[0009] A special coding device for anti-counterfeiting printing, such as figure 1 As shown, it includes workbench 1, and workbench 1 is provided with coding machine 6, pressing device and two sets of transmission devices, such as figure 1 In the direction shown, the pressing device and the transmission device are on the right side of the paper inlet of the coding machine 6, and two sets of transmission devices are arranged on the left and right sides of the pressing device. Stable, each set of transmission devices is composed of a support frame 4 and a conveying roller 11 with a motor. The roller surface of the conveying roller 11 is provided with an arc-shaped first groove 12. When the roller surface of the conveying roller 11 contacts the ticket paper, it can The ticket paper is moved, and when the first groove 12 is turned to the top of the ticket paper, the conveying roller 11 is separated from the ticket paper, and the ticket paper is in a static state. There are two fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com