Patents

Literature

58results about How to "Increased resistance torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

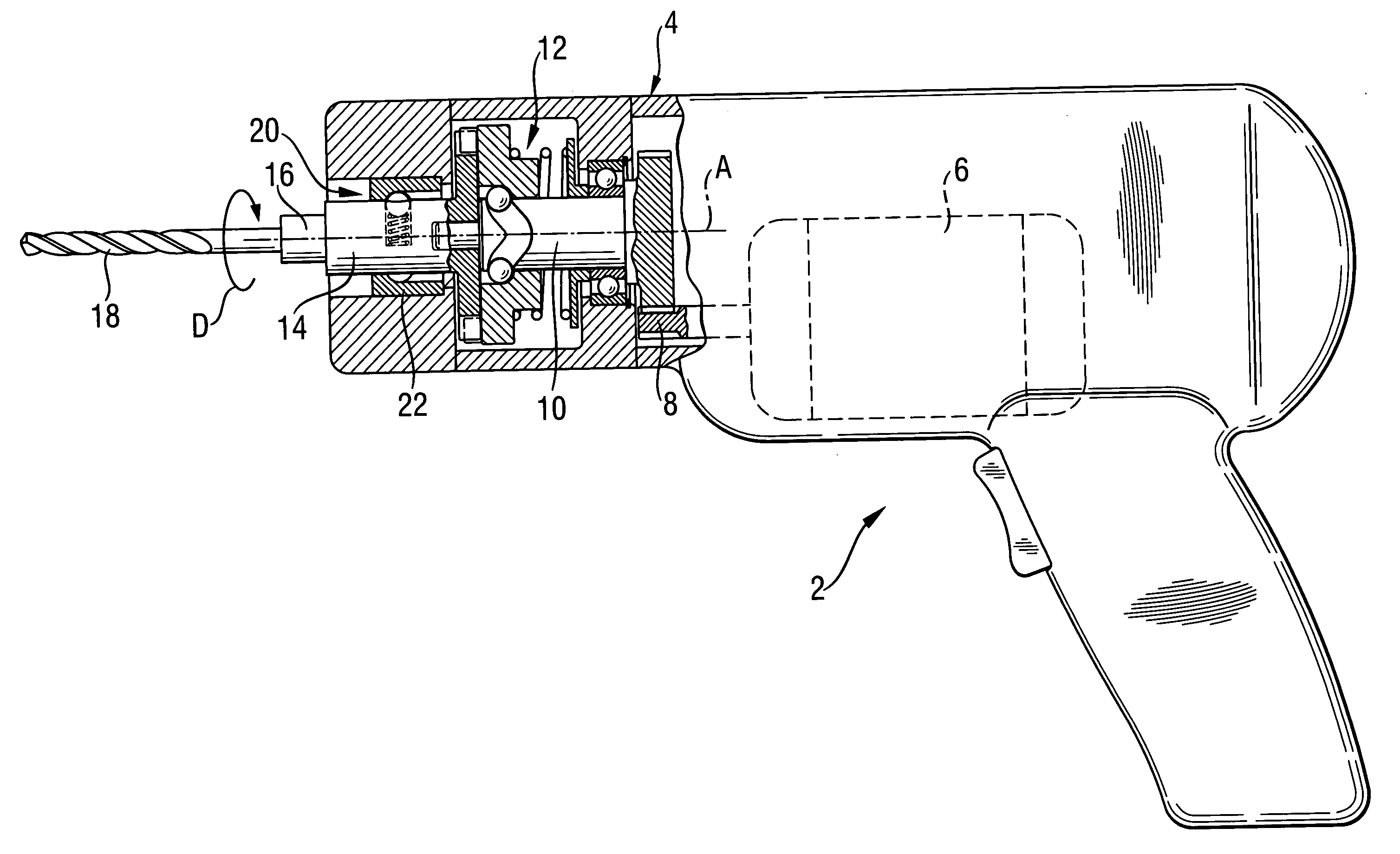

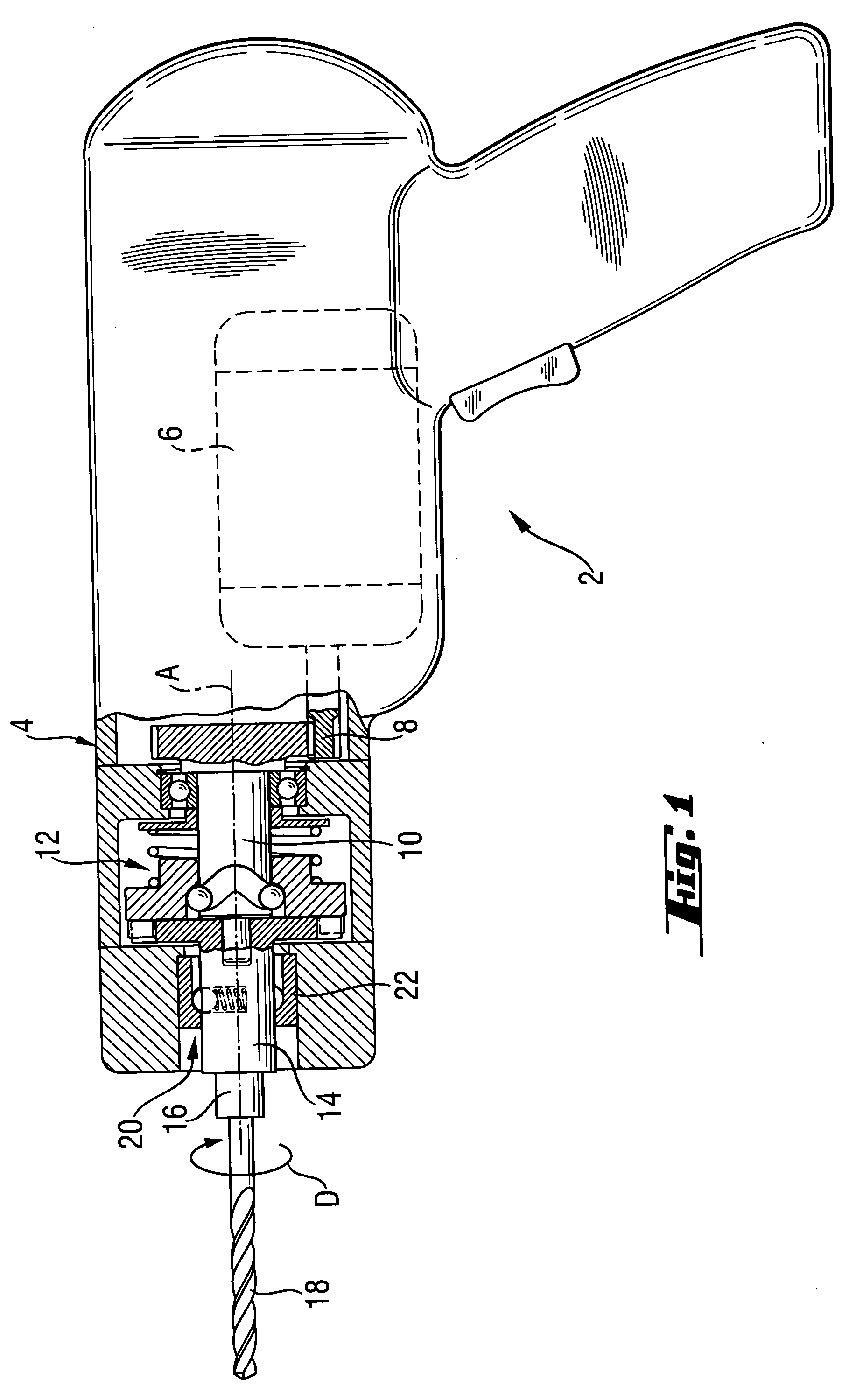

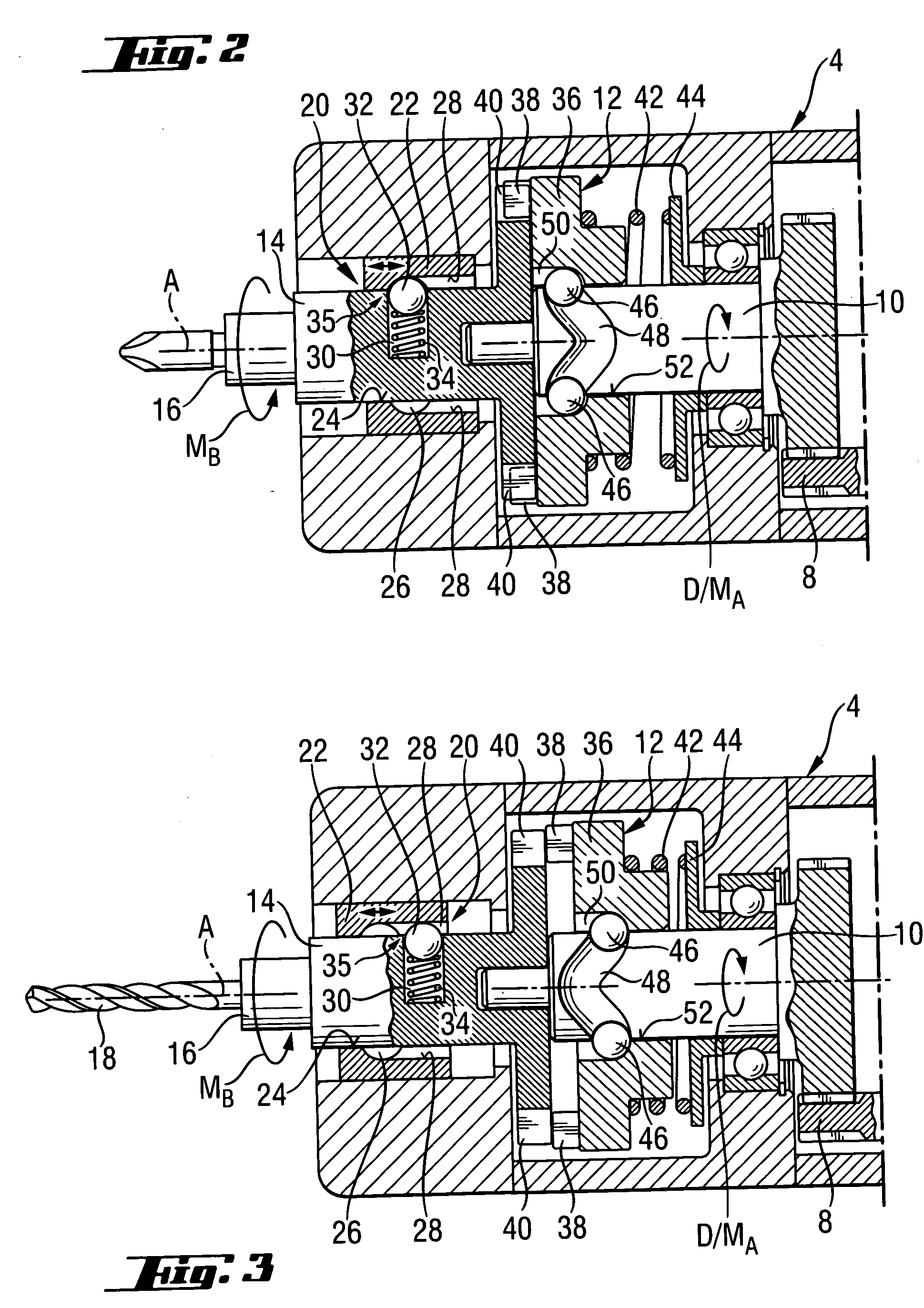

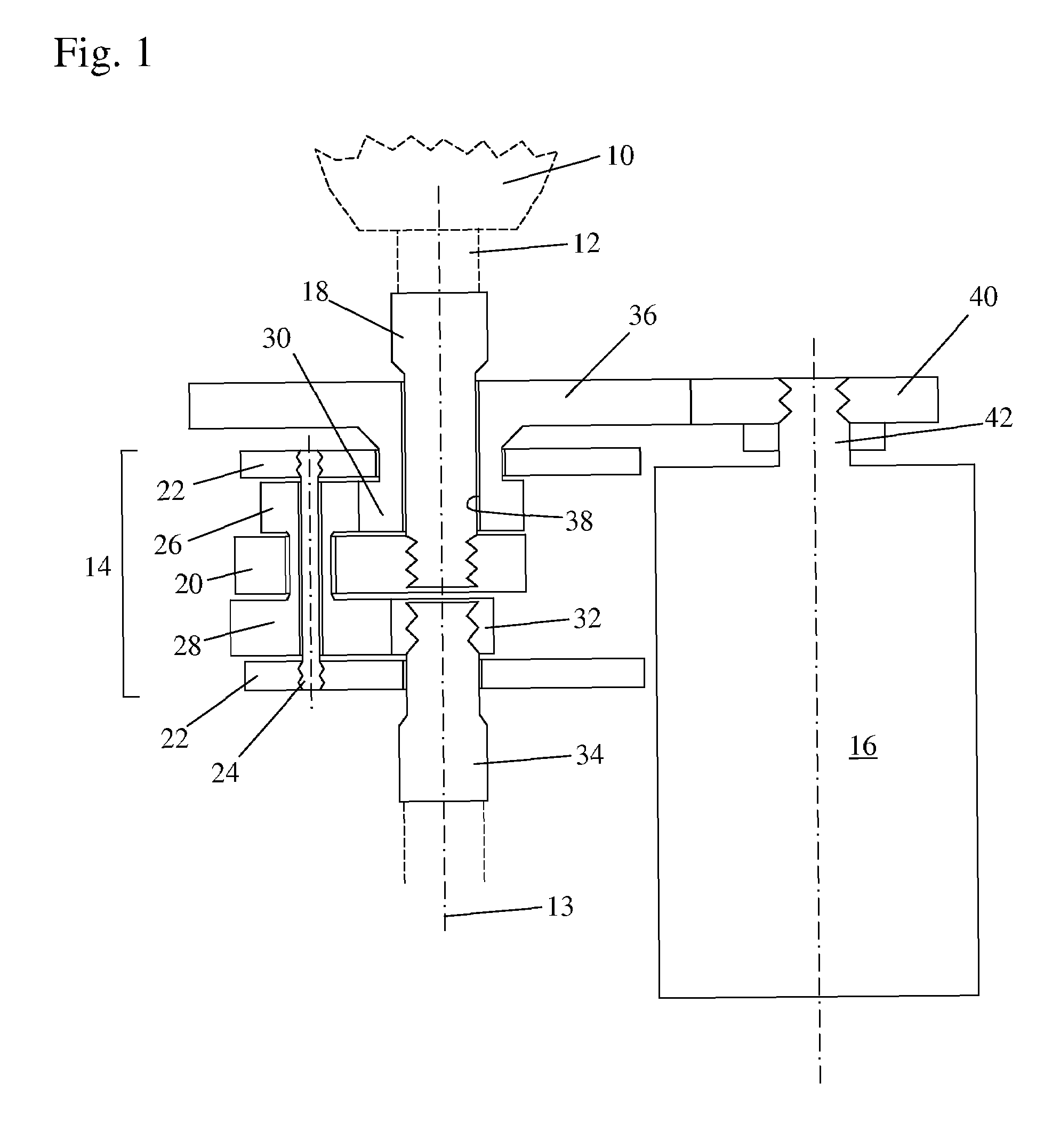

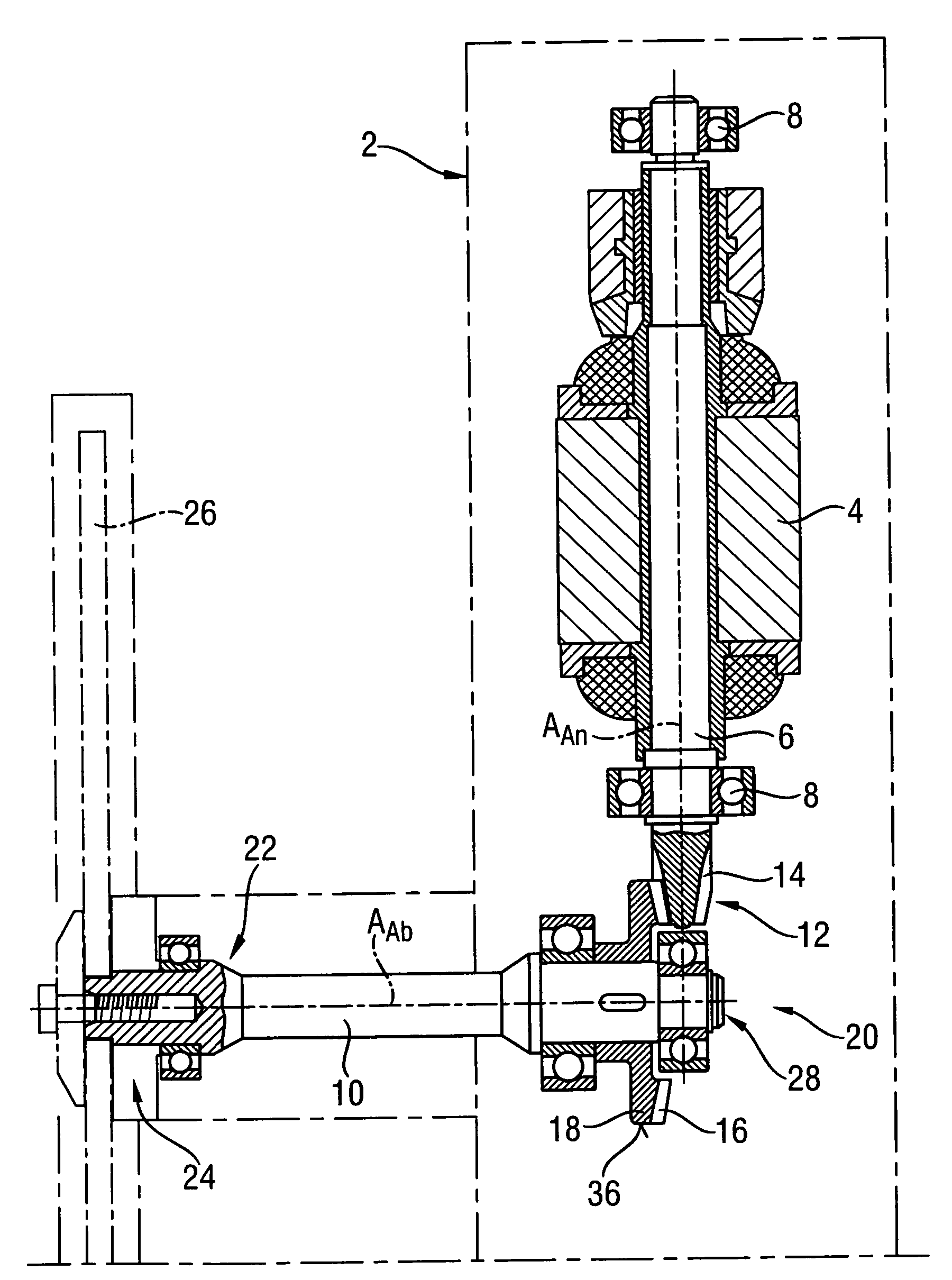

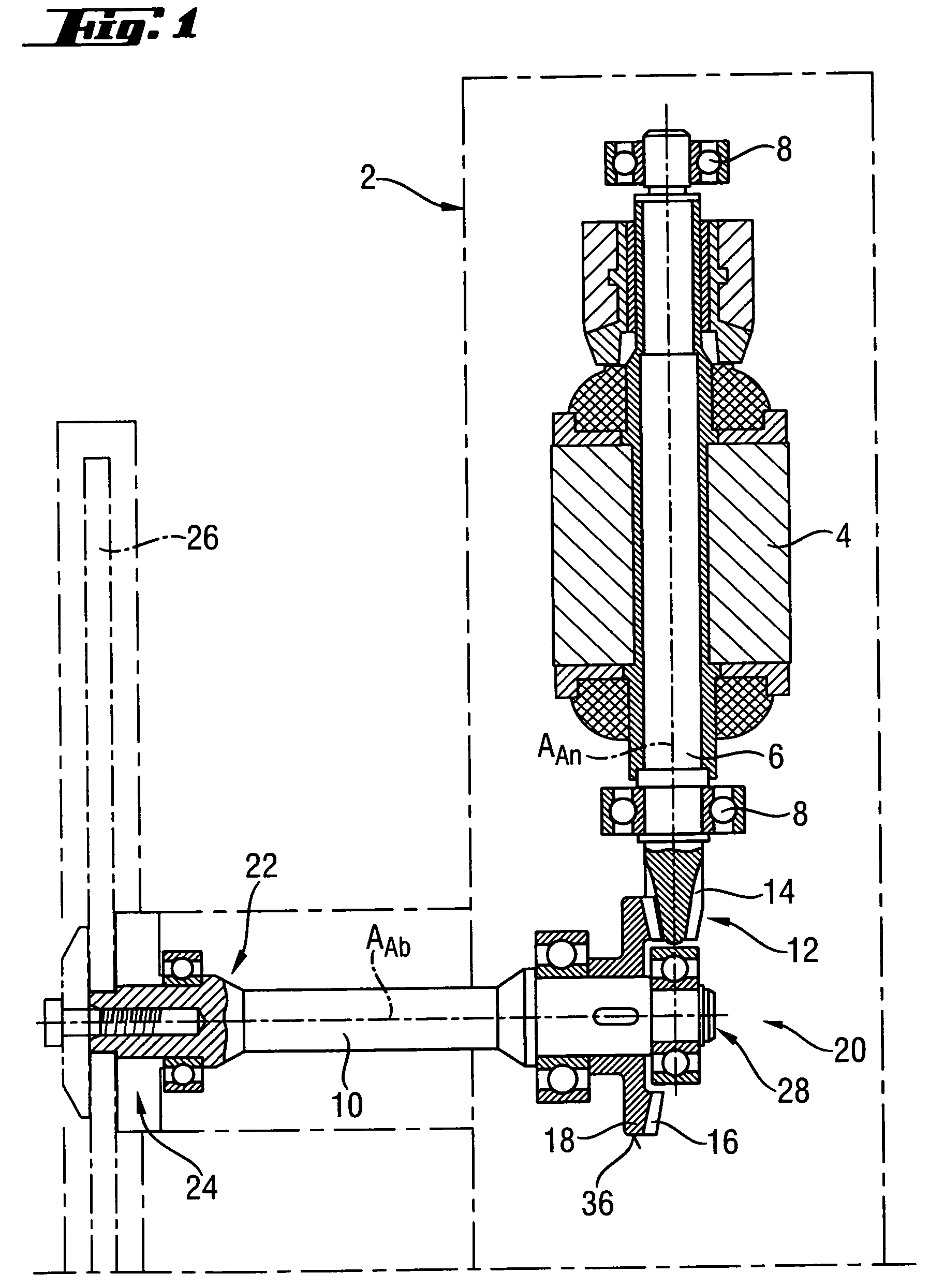

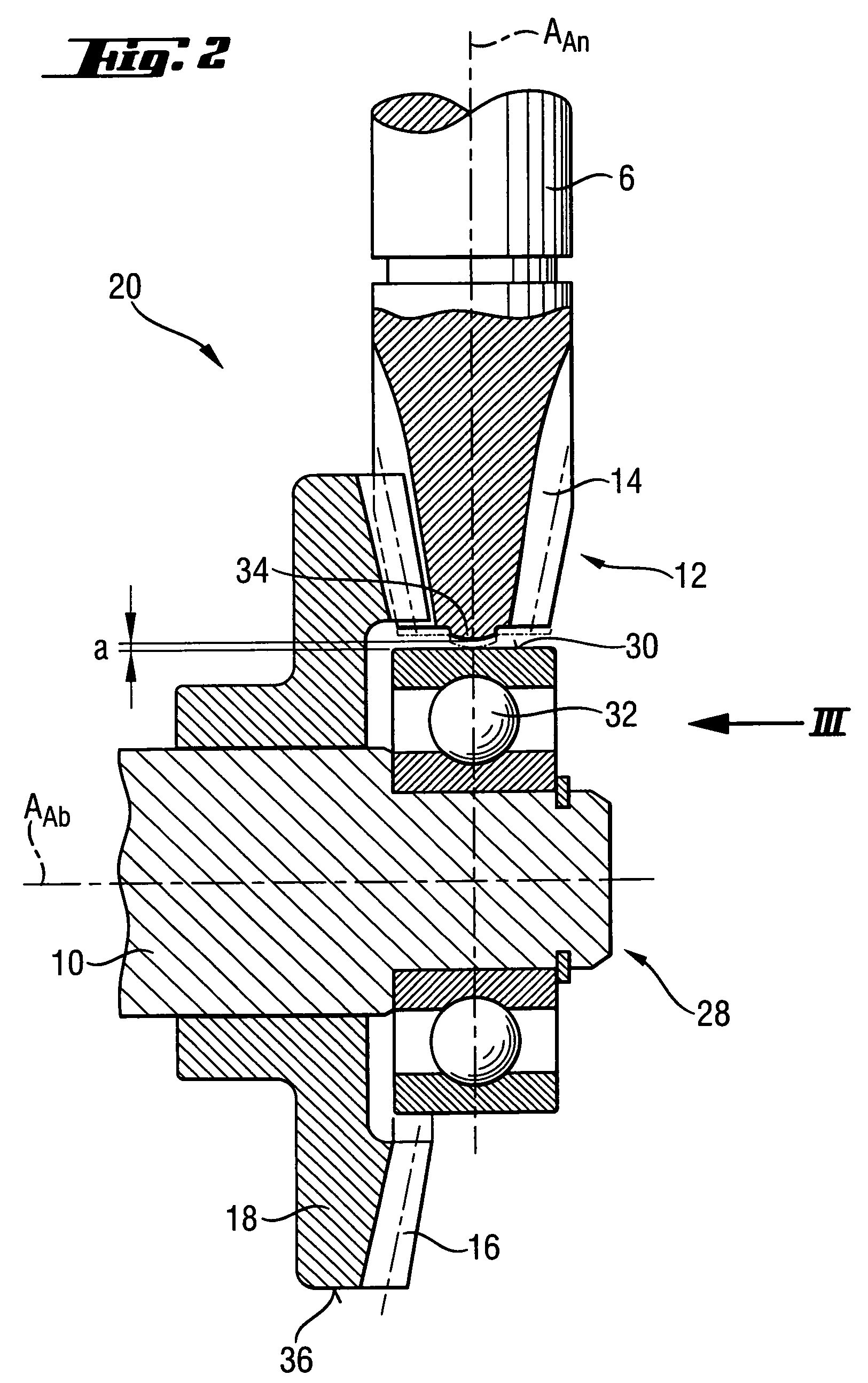

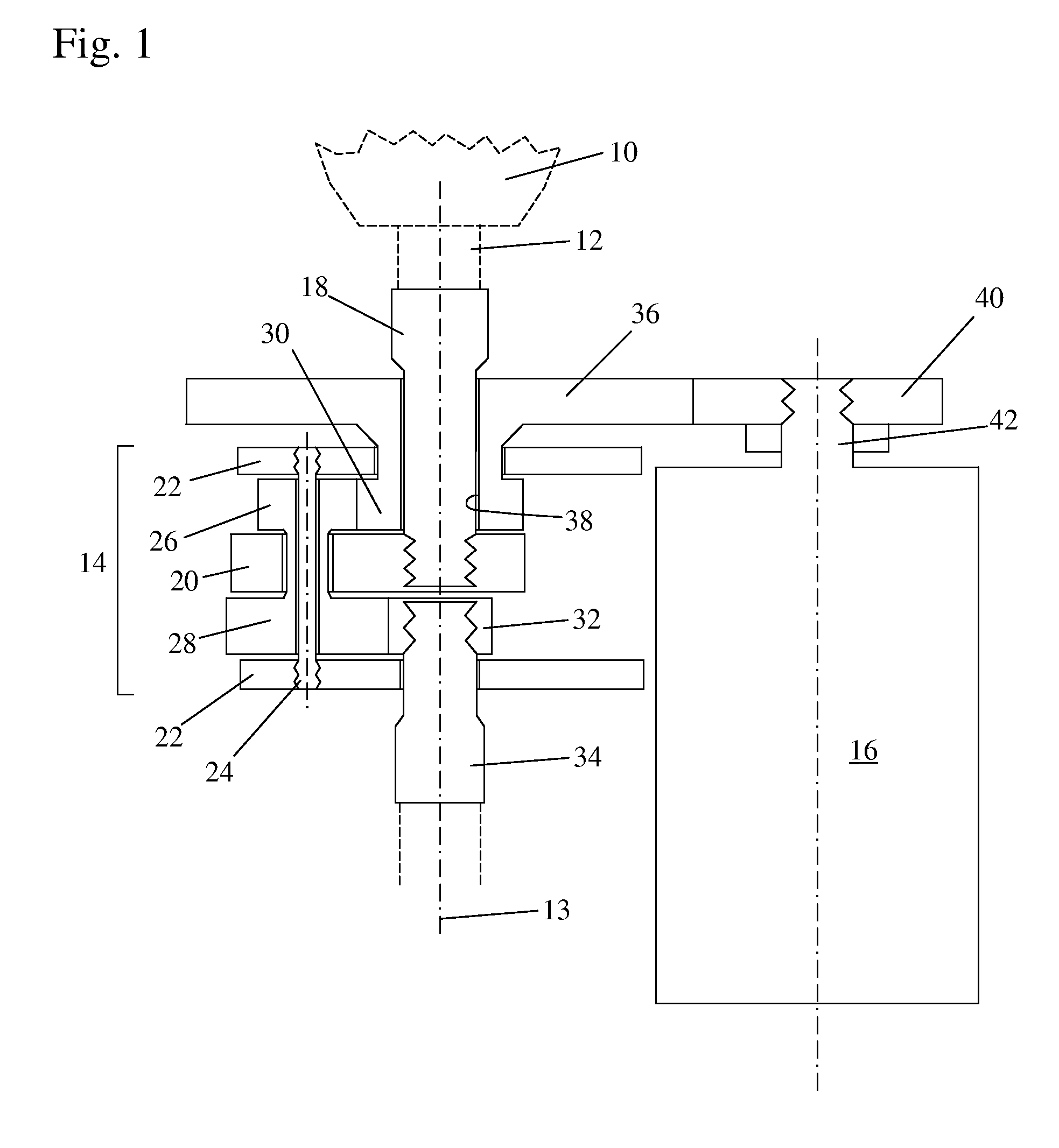

Power tool with an intermittent angular torque pulse

InactiveUS20060024141A1Simple and cost-effective to manufacturePrevent unnecessary noise generationThread cutting machinesPortable percussive toolsHand heldPower tool

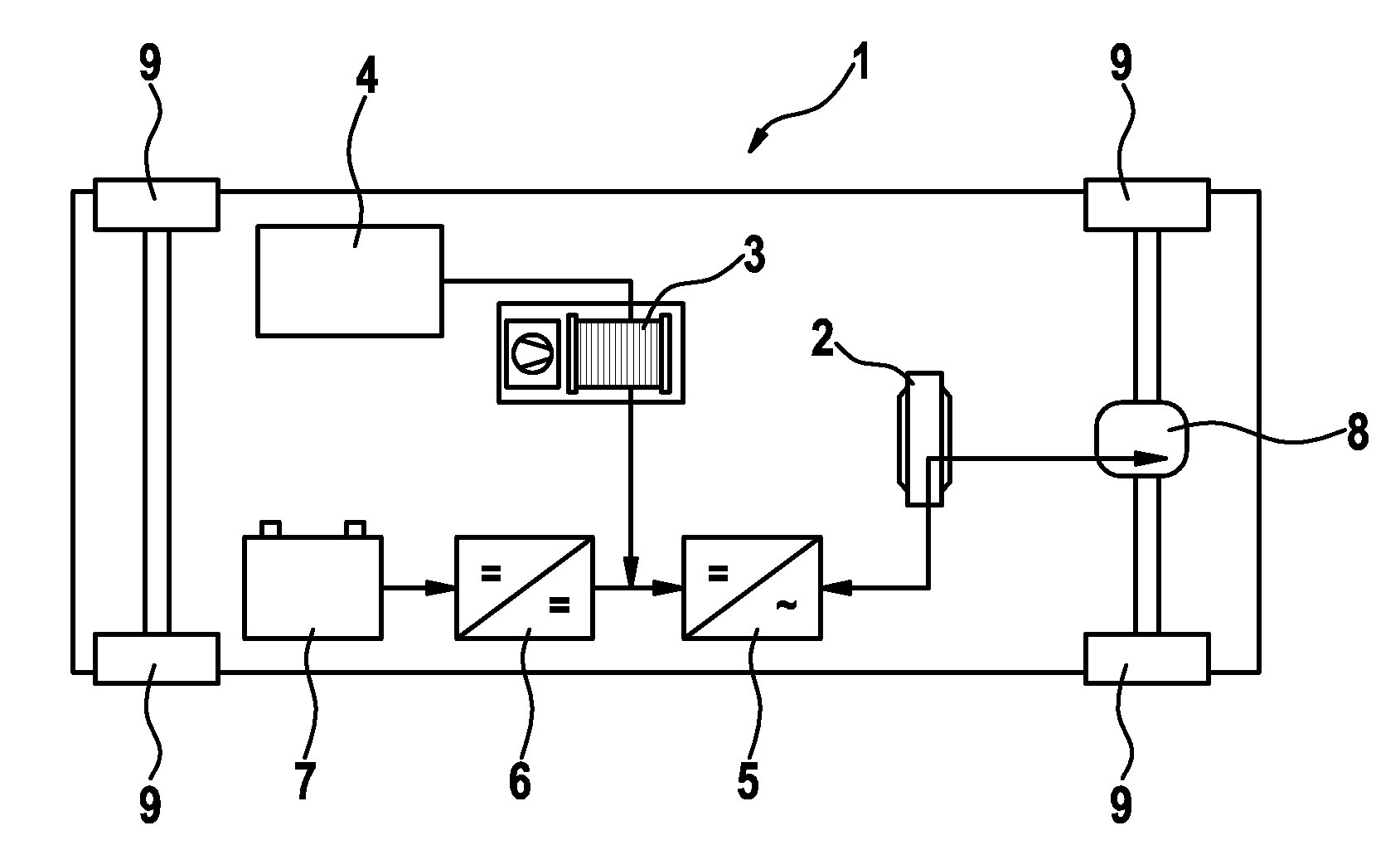

A hand-held power tool includes a motor (6) for applying a drive torque (MA) to the drive spindle (10) of the power tool, a working tool spindle (14) for driving a tool bit (18) in a rotational direction (D) and connectable with the drive spindle (10), an angular torque generator (12) for applying an angular torque pulse to the working tool spindle (14) when a resistance torque (MB) acting on the working tool spindle (10) reaches a predetermined threshold, and a braking force generator (20) arranged on the working tool spindle (14) for applying thereto a braking force in a direction opposite the rotational direction of the working tool spindle.

Owner:HILTI AG

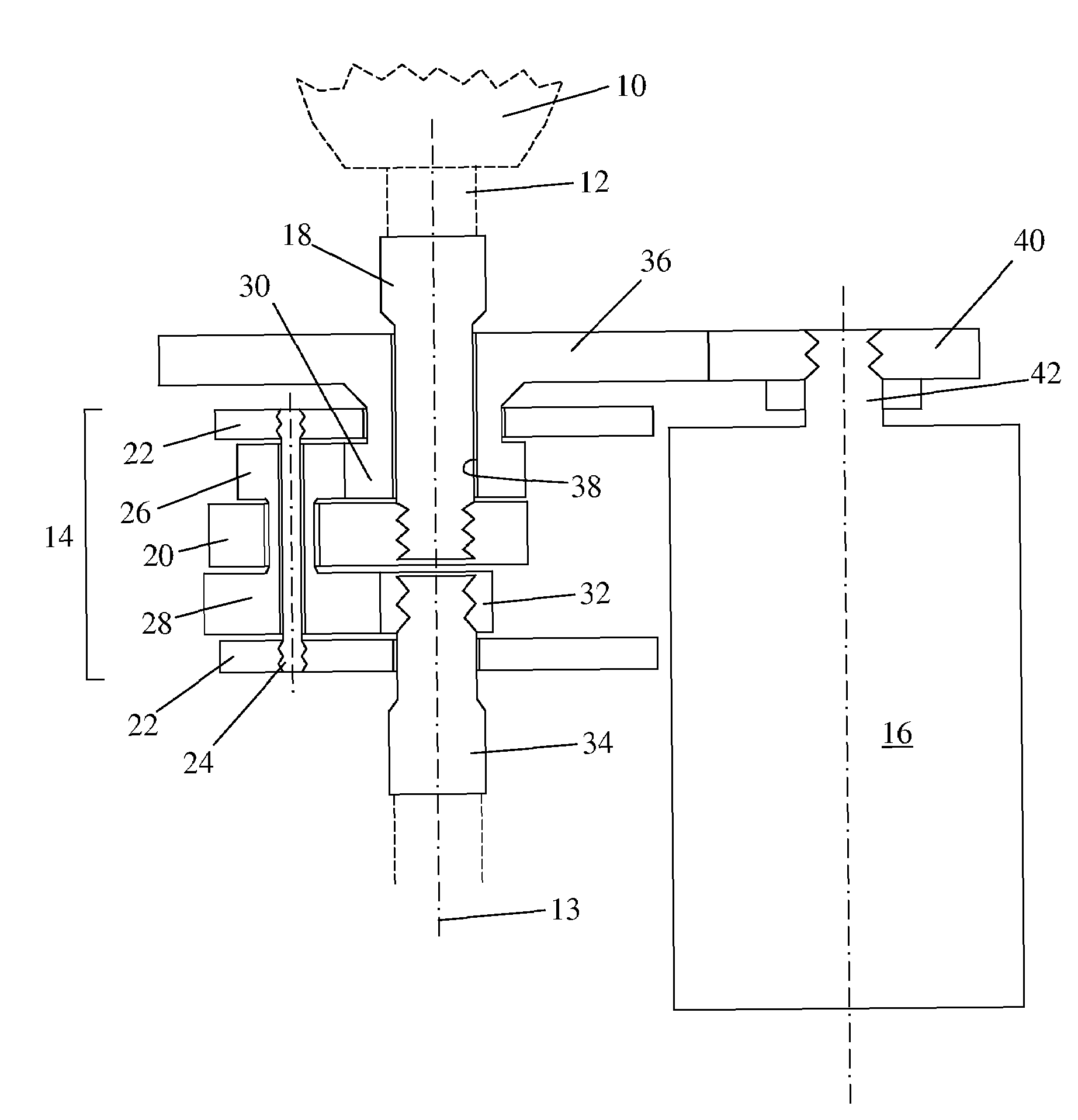

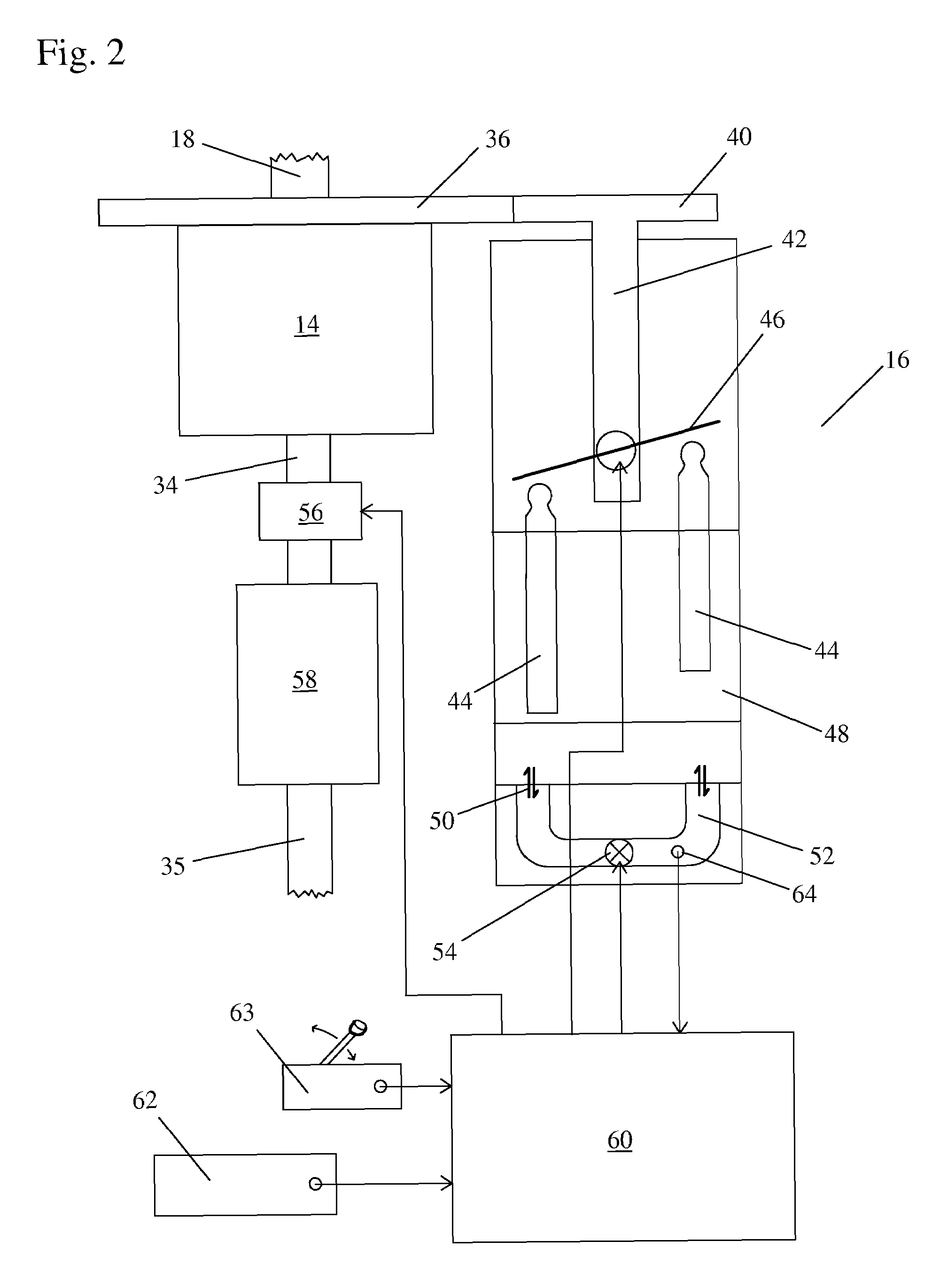

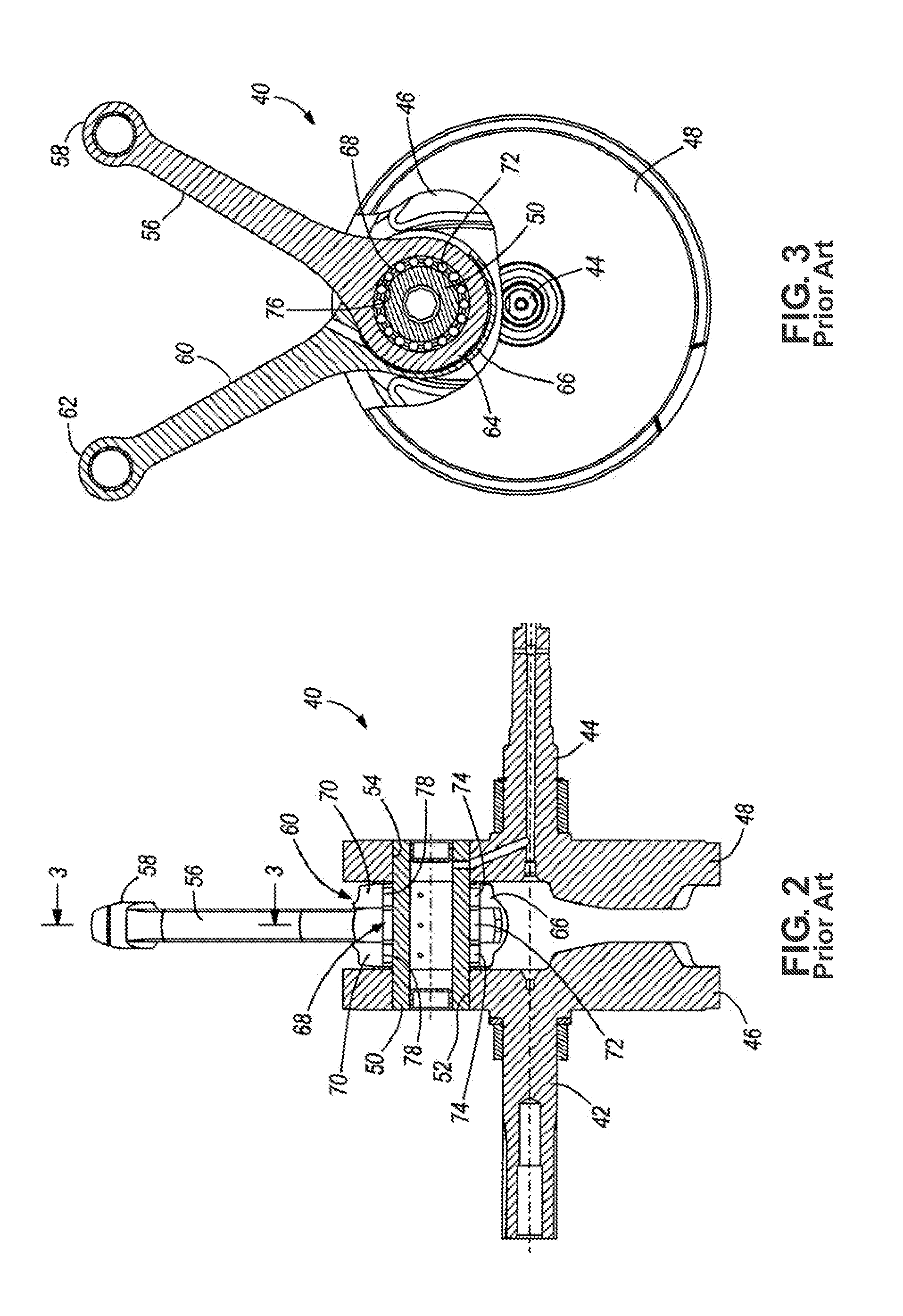

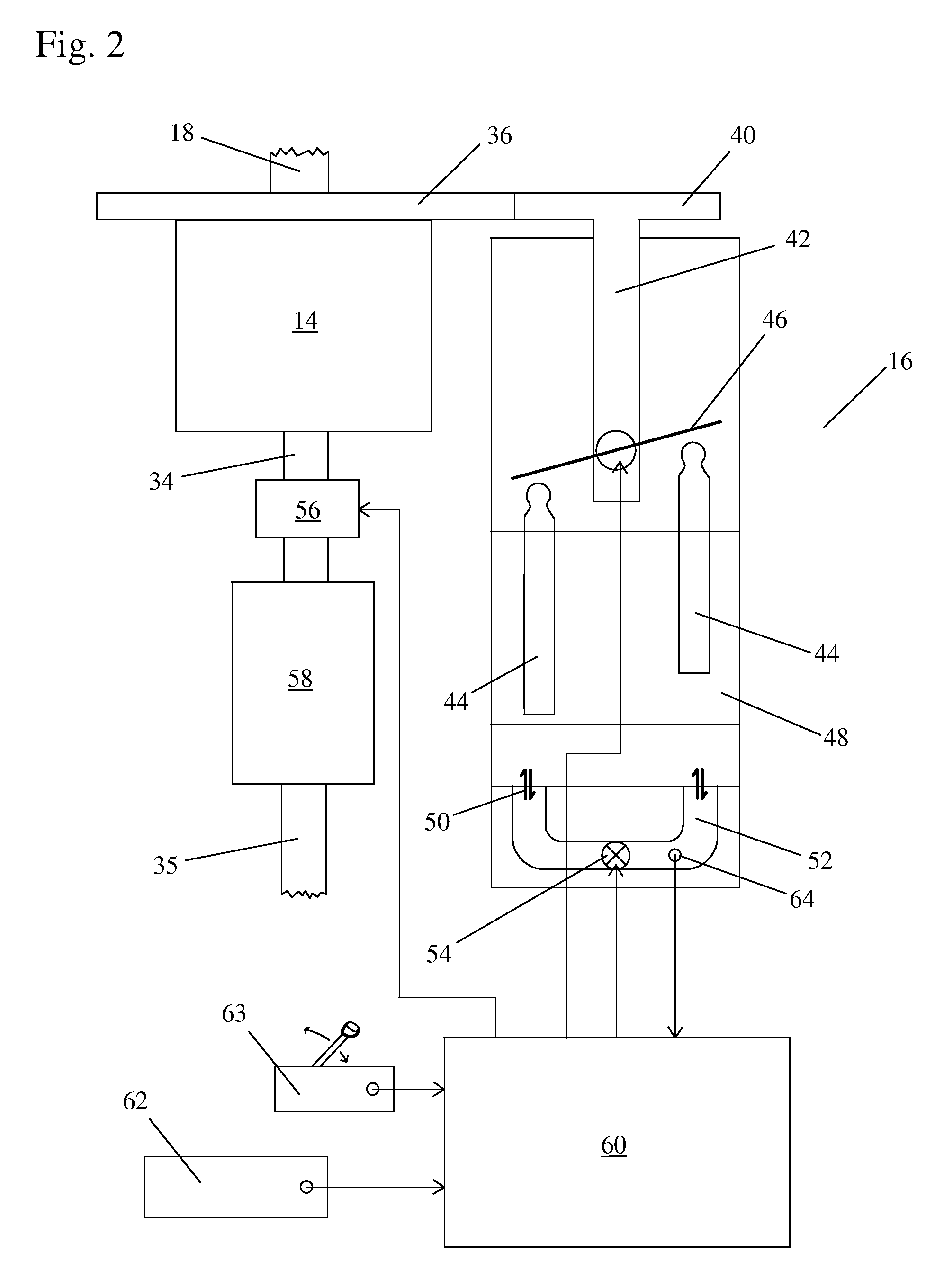

Transmission with resistance torque control

InactiveUS7575534B2Increased resistance torqueImprove engine efficiencyToothed gearingsEngine controllersDrive shaftGear wheel

The transmission includes a minimal-orbiter gear complex and a single infinitely-variable rotary control device. The minimal orbiter includes only a control gear and an output gear interconnected by the different gearing portions of at least one cluster gear supported by an orbiting web responsive to an input drive provided by a primary engine. The rotary control device may be any kind of apparatus that is capable of providing resistance torque that can match the torque of the primary engine to slow and stop the control gear of the orbital complex. In a preferred embodiment disclosed, the rotary control device is a hydraulic jack machine having a drive shaft connected to an adjustable swash plate that provides primary control of the flow of fluid through the machine.

Owner:TORVEC INC

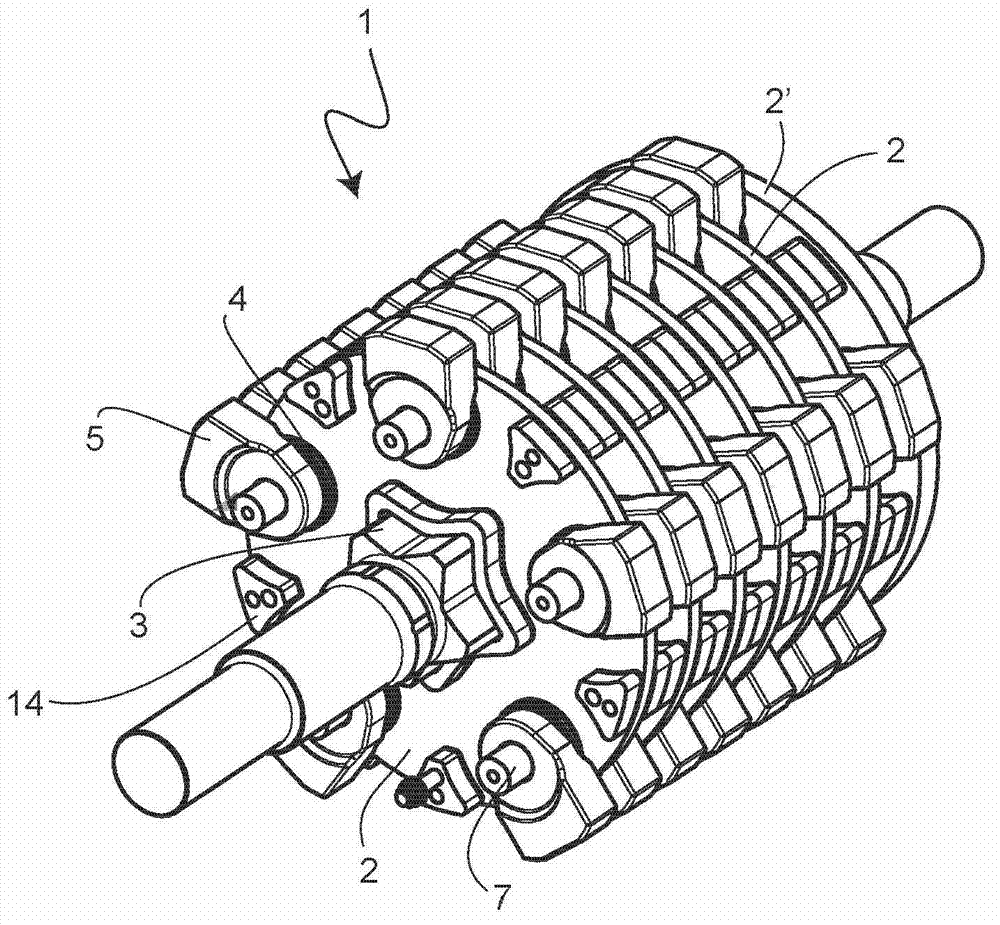

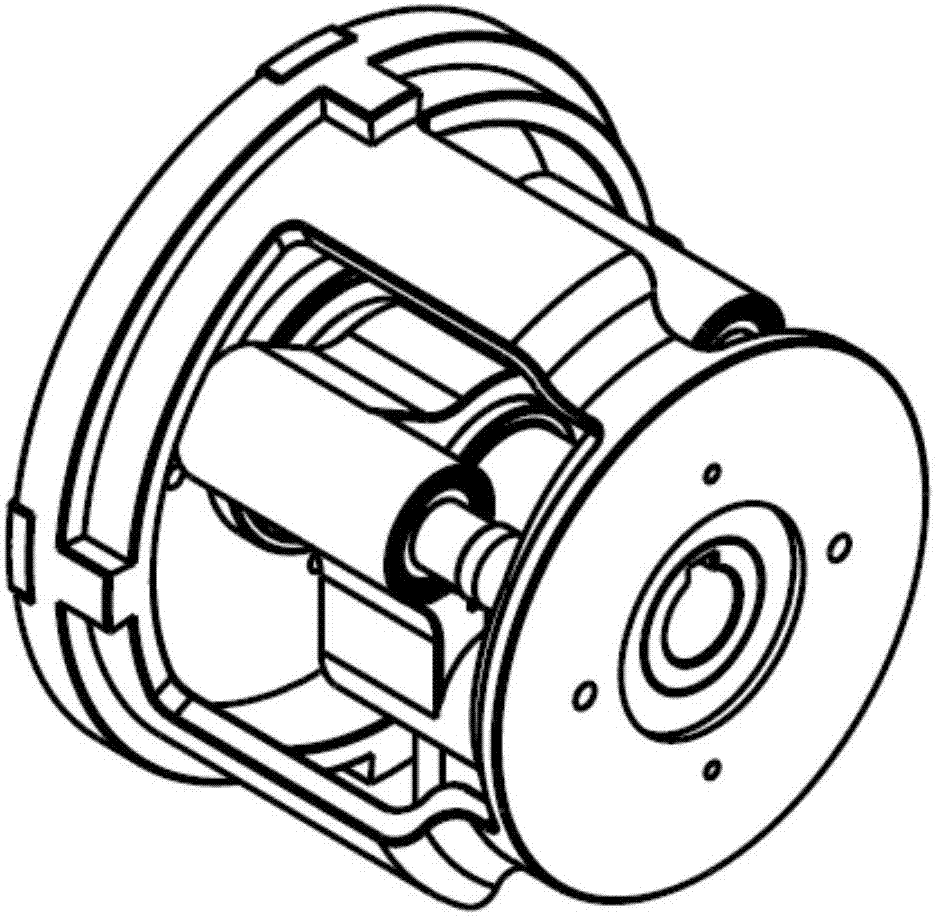

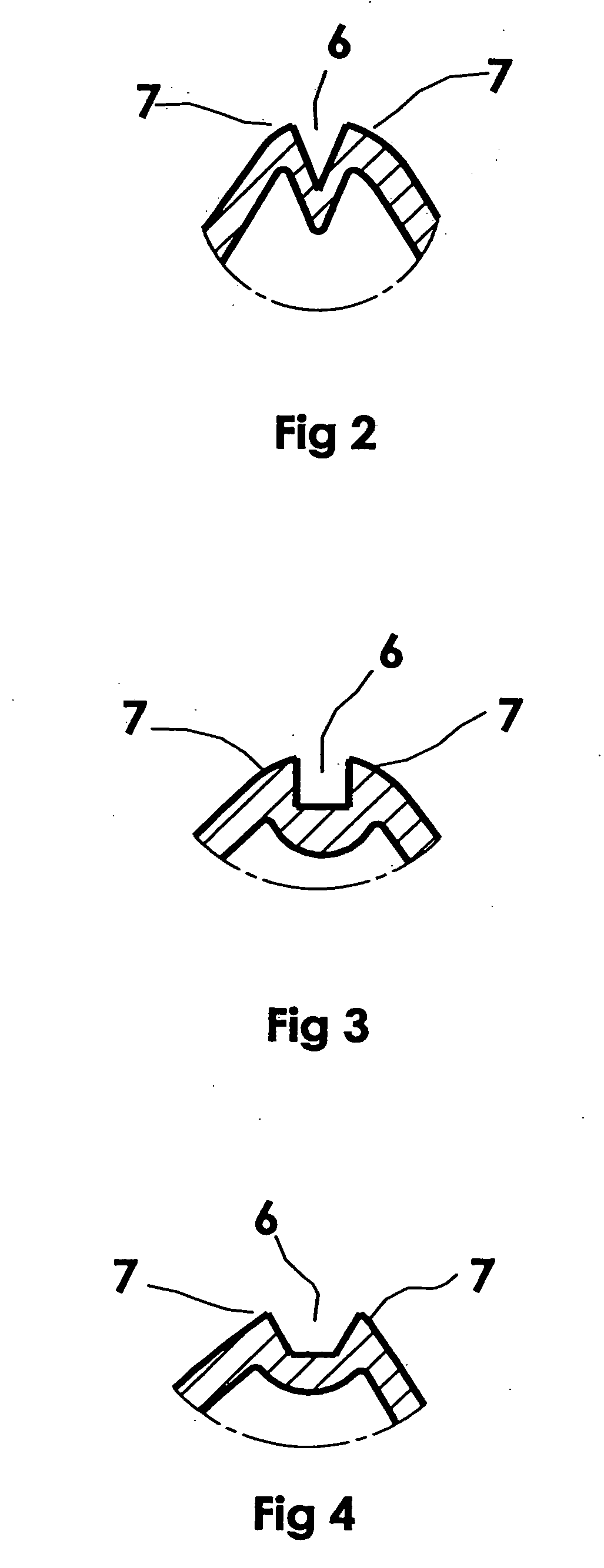

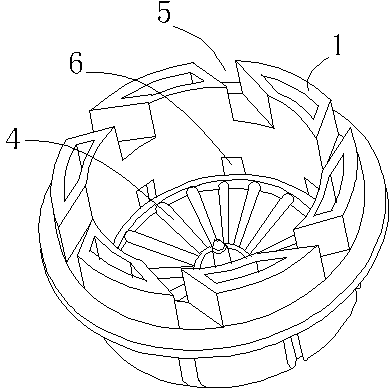

Rotor of a hammer crusher

InactiveCN102886289AIncreased resistance torqueImprove performanceGrain treatmentsTorque transmissionEngineering

Owner:克劳斯里希特

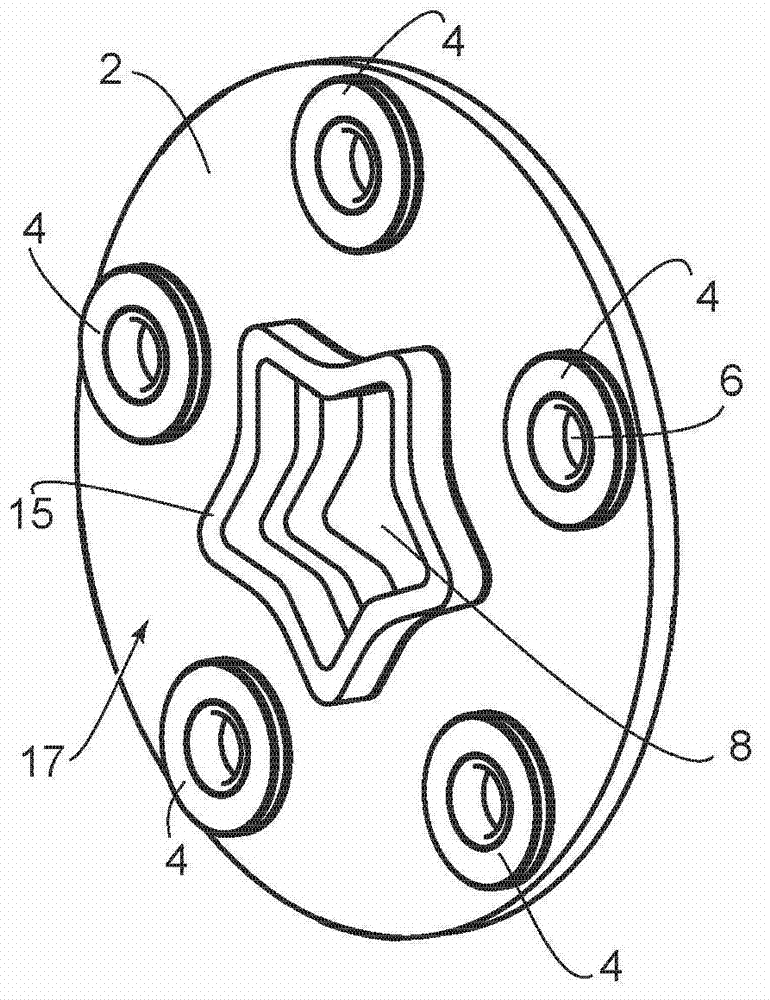

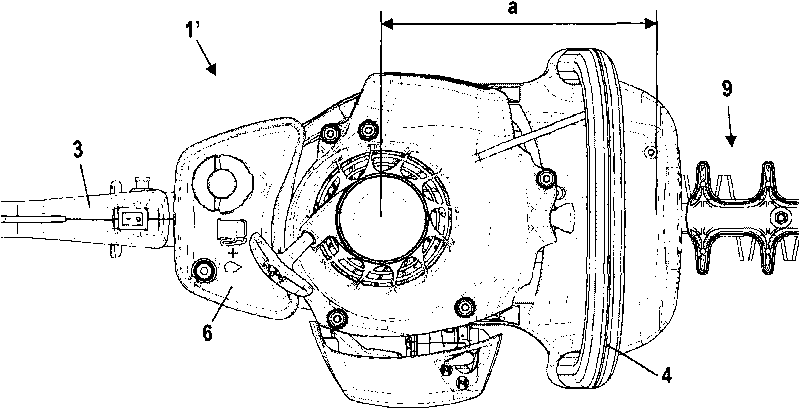

Hand-held power tool with angle drive

InactiveUS7346992B2No increased wearIncreased resistance torqueMetal sawing devicesToothed gearingsAxial displacementMotor drive

Owner:HILTI AG

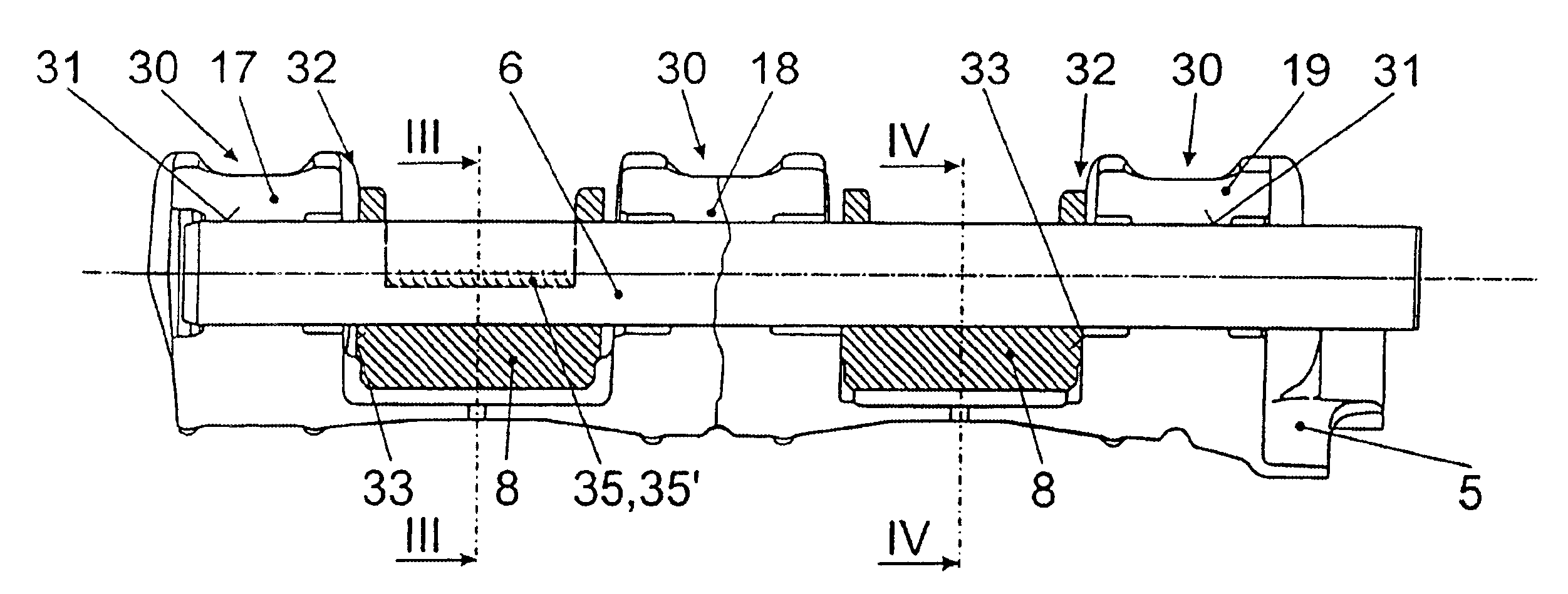

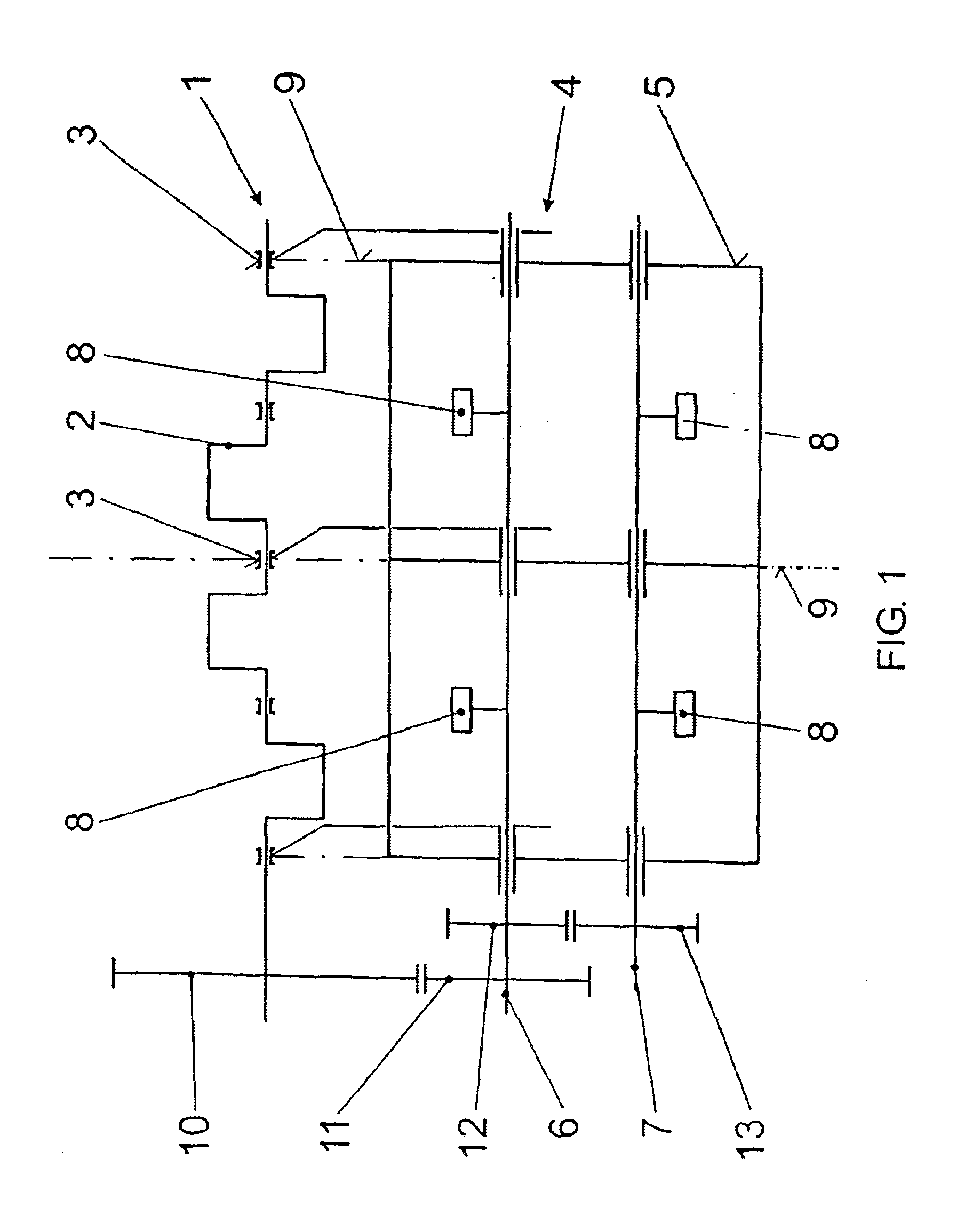

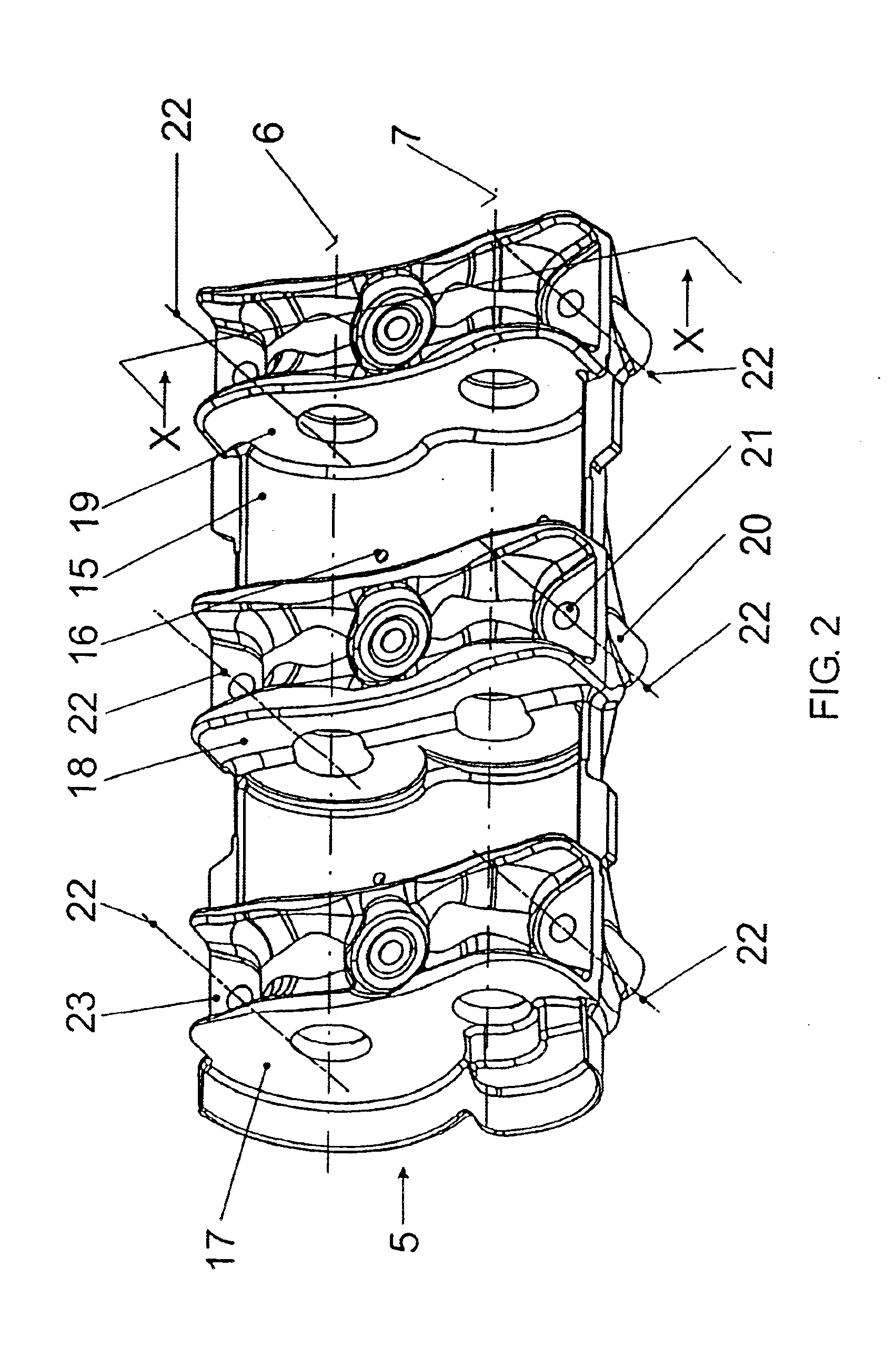

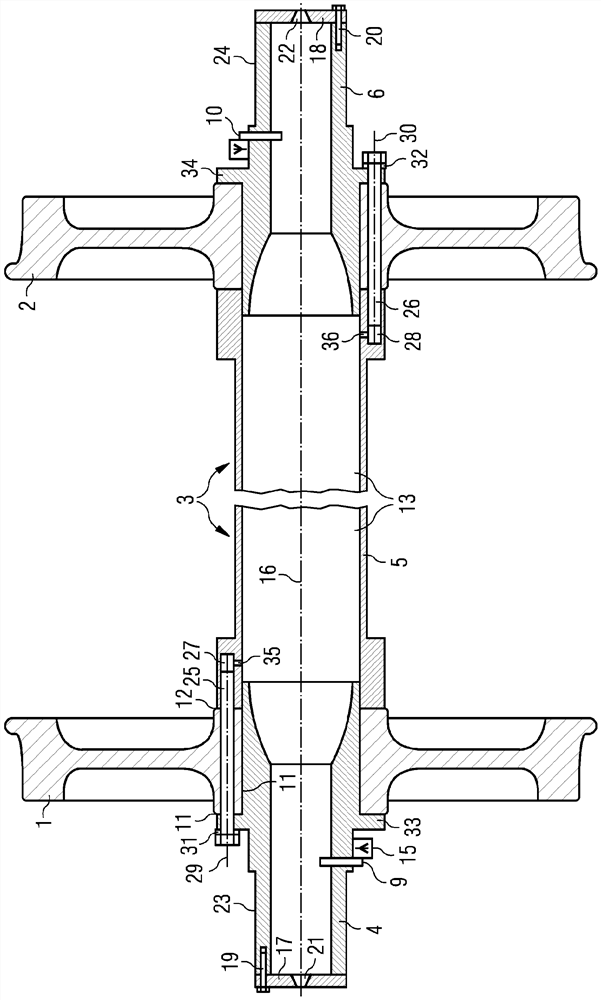

Compensating shaft assembly for piston engines

InactiveUS6854358B1Manufacturing cost to minimumLarge mass eccentricityControlling membersControlled membersCombustionMachined surface

A balance shaft unit for internal combustion engines consists of at least one balance shaft (6, 7) supported in a balance casing (5) and counterweights (8) connected onto it. In order to achieve maximum precision, reliable fastening and minimum external dimensions at minimum manufacturing costs, the counterweight (8) is essentially a cylindrical ring with two end surfaces (61) normal to the axis and with a cutout (55) in the longitudinally central region, so that the counterweight consists of two ring parts (60, 61) abutting the two end surfaces (61) and an intermediate segmental part (62). One of the end surfaces (61) of the counterweight (8) forms, jointly with a machined surface (33) of the balance casing (5), a thrust bearing (32).

Owner:STEYR POWERTRAIN

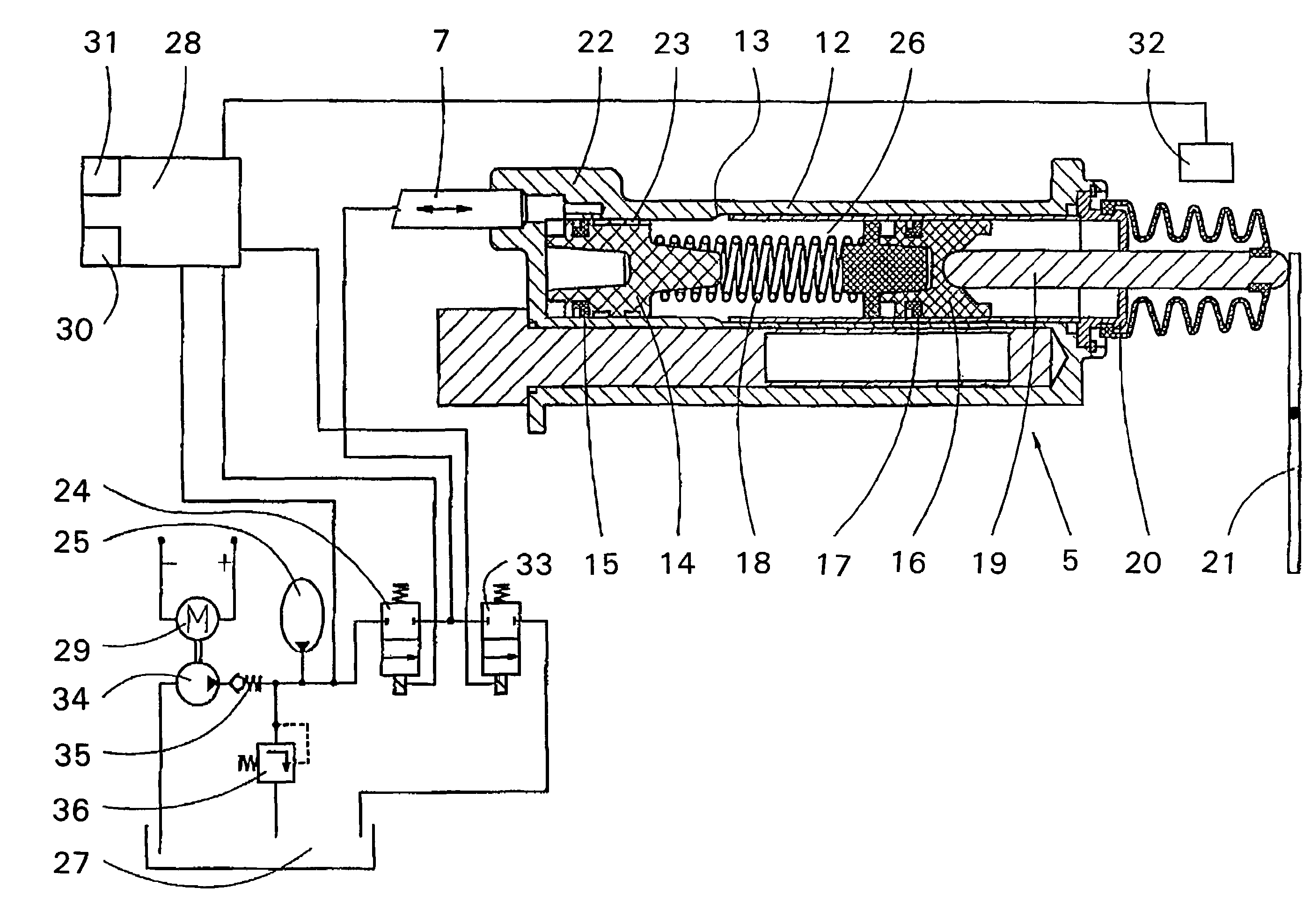

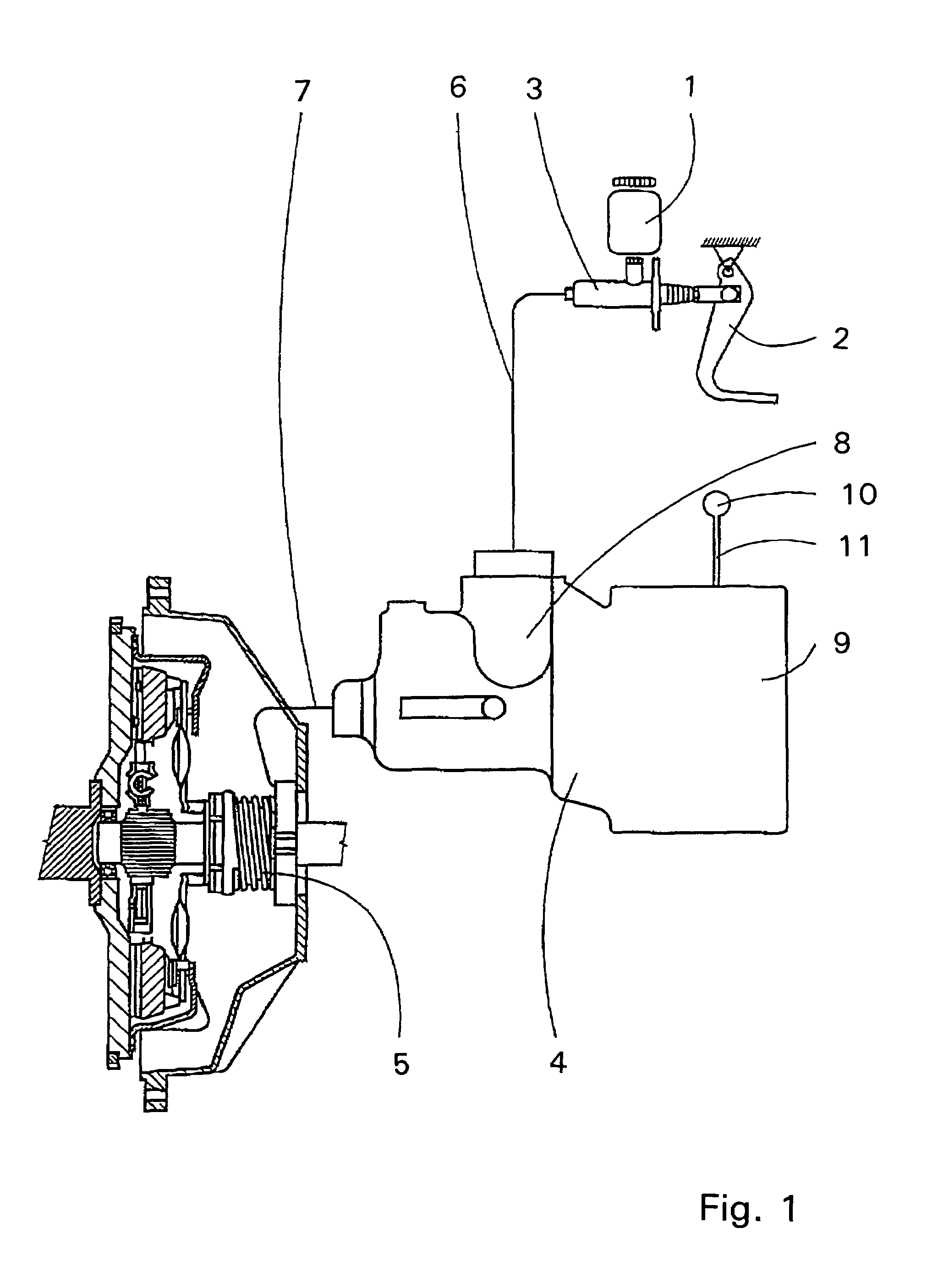

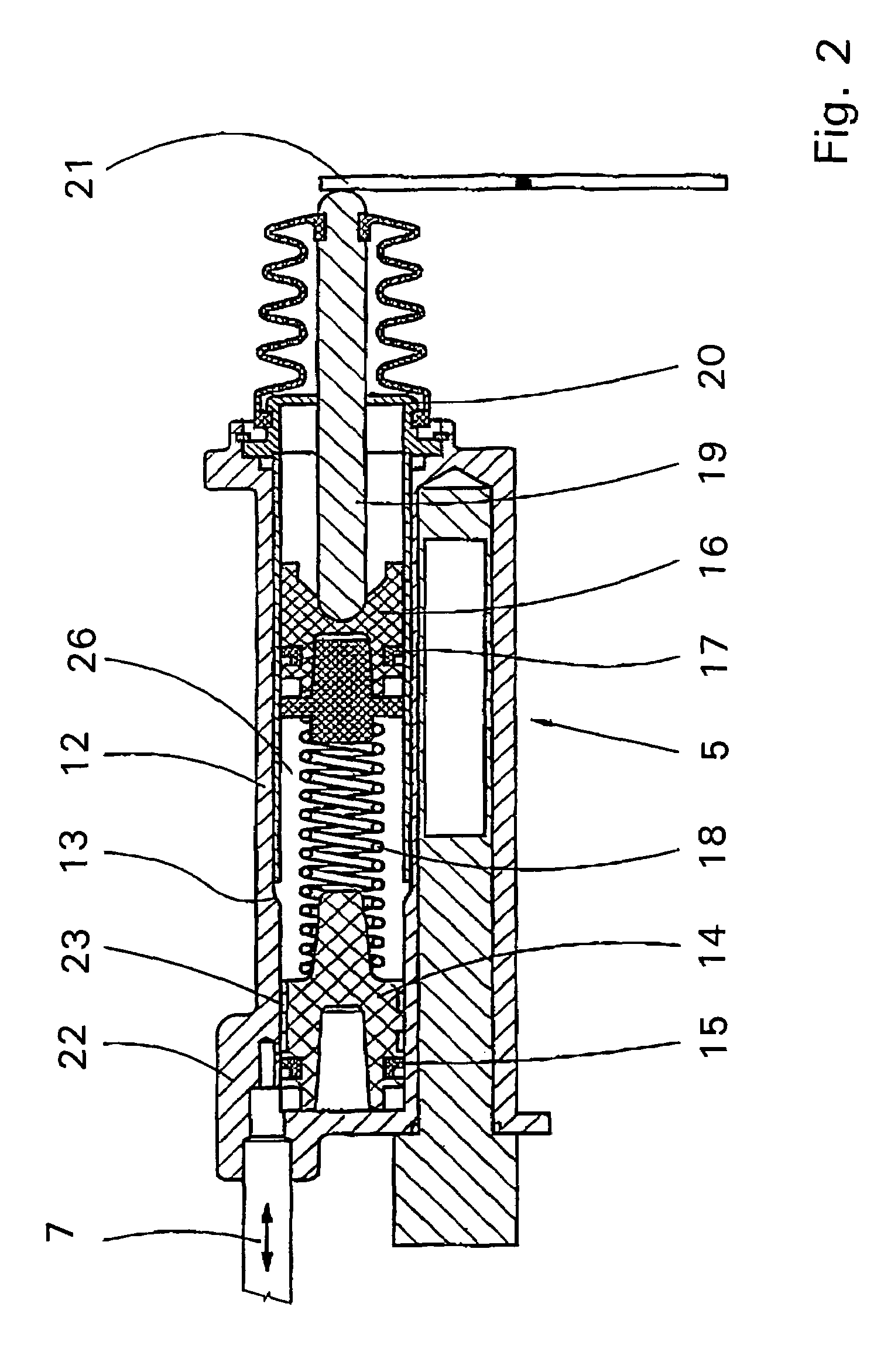

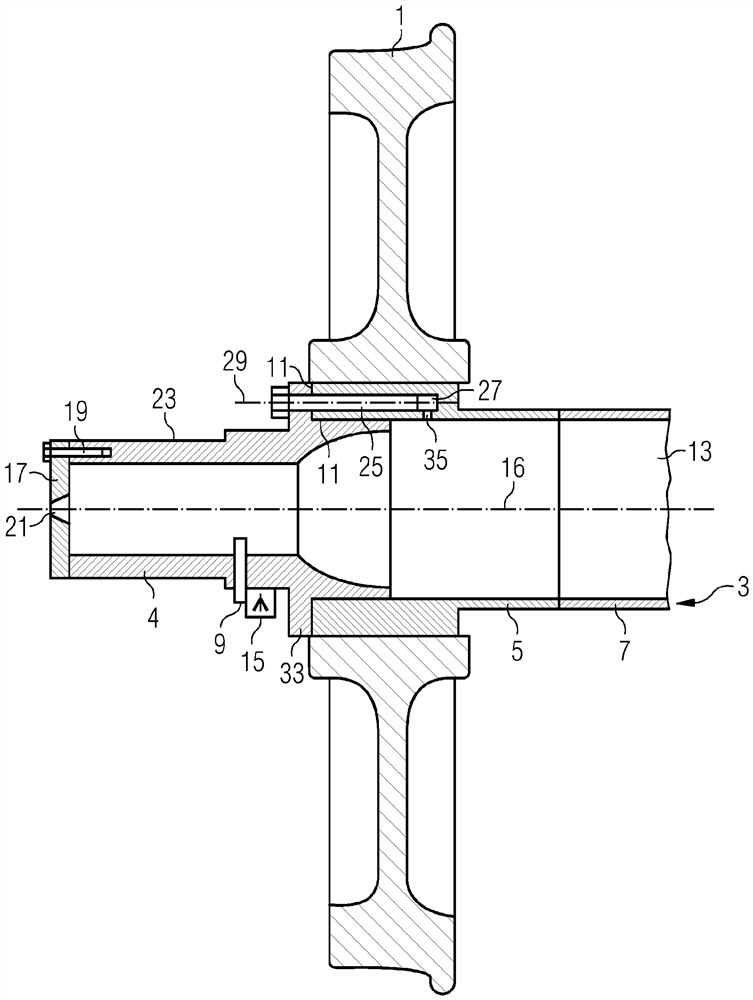

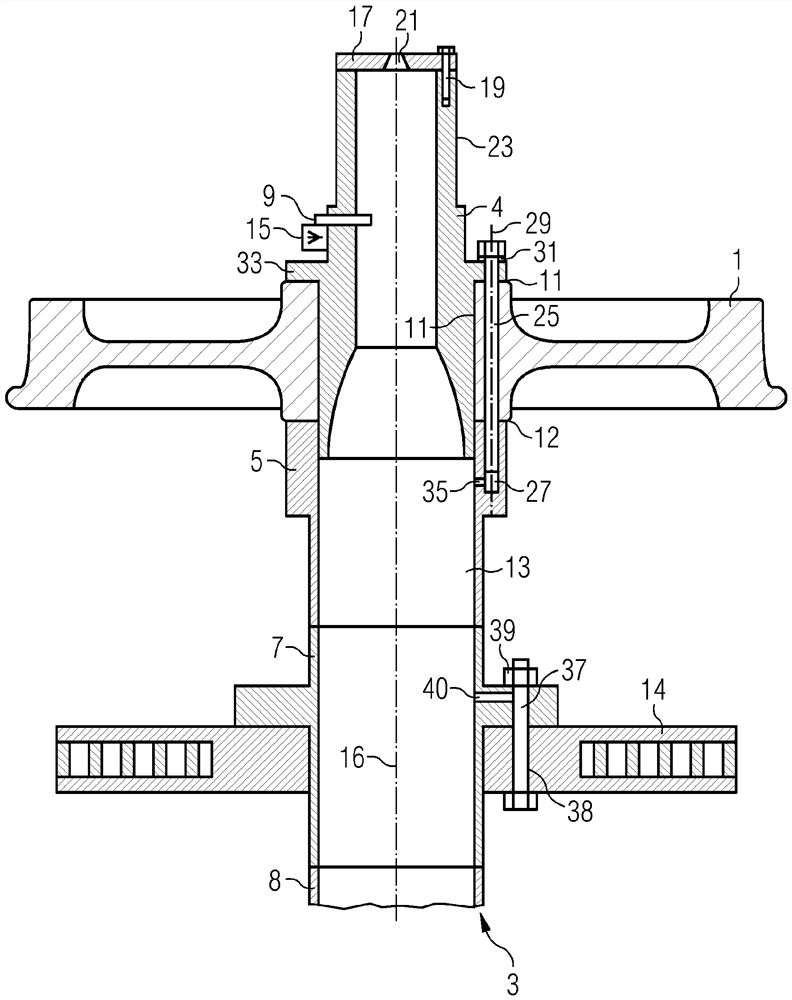

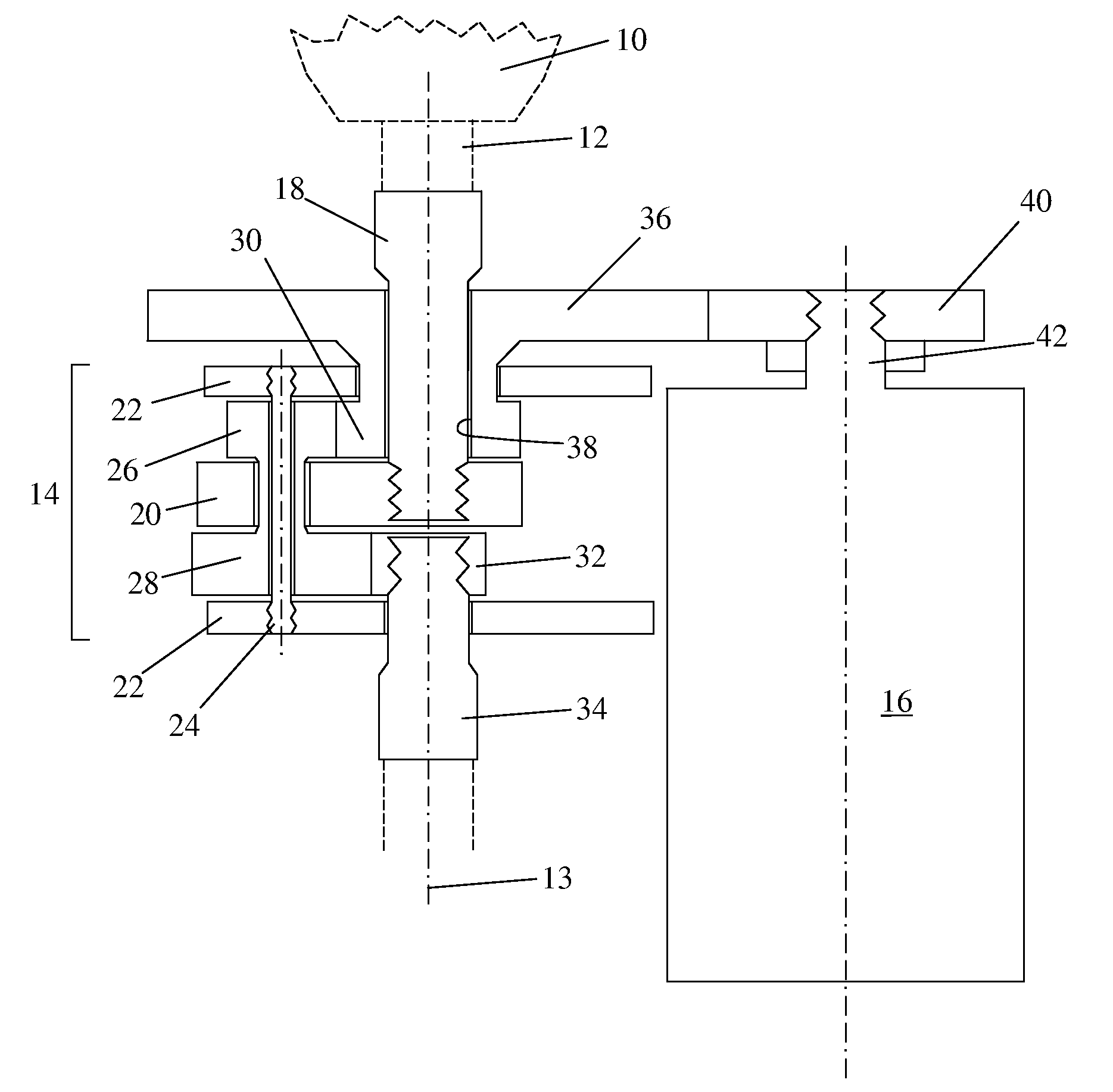

Device for increasing the functional reliability of a hydraulic circuit of a hydraulically operable clutch

InactiveUS7419456B2Low operating pressureFacilitated DiffusionFluid actuated clutchesEngine controllersContact pressureHydraulic circuit

A known device for increasing the functional reliability for a hydraulic circuit of a hydraulic clutch having a pressure reservoir (25) and a release cylinder (5) which comprises a primary piston (14) and a secondary piston (16). A compensation volume is developed in the sense that when the vehicle is at a standstill and the parking brake released, an unintentional release of the clutch is prevented. A pressure-monitoring / pressure-supply device (28) is used for determining a reference operating pressure and establishes a static pressure which, in case of any system error, only allows displacement of the secondary piston (16) such that the contact pressure of the clutch discs, against one another, is still sufficient to maintain the vehicle at a standstill.

Owner:ZF FRIEDRICHSHAFEN AG

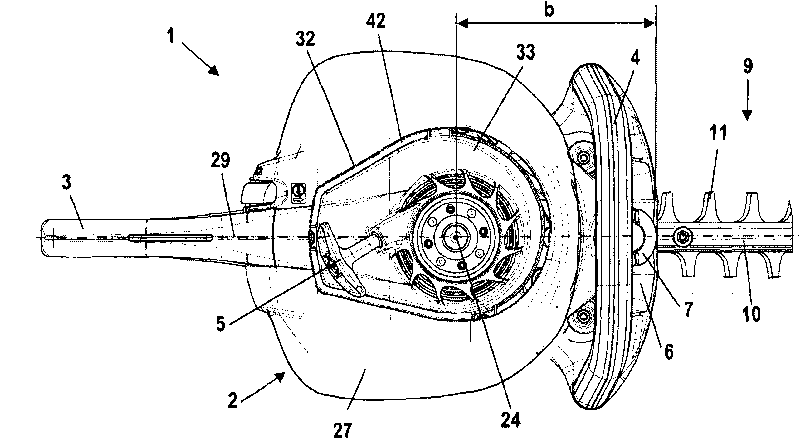

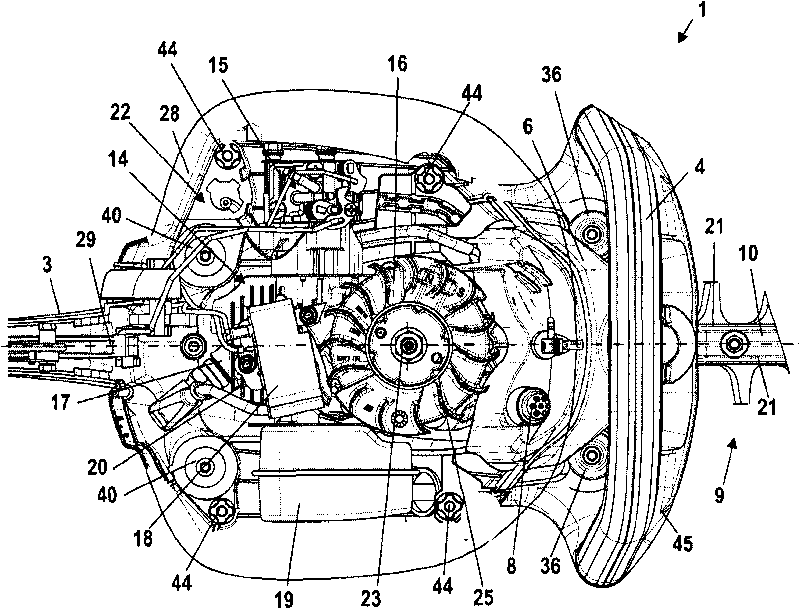

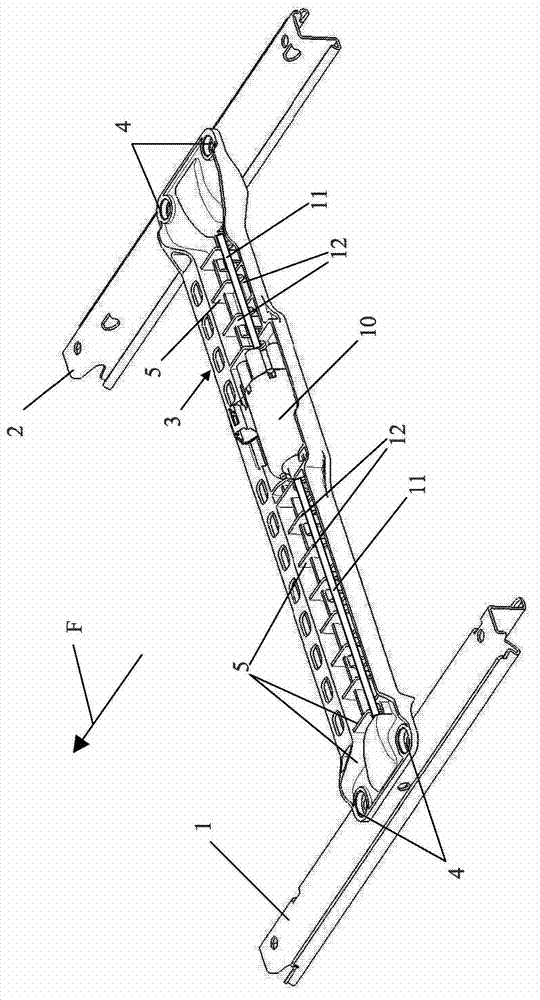

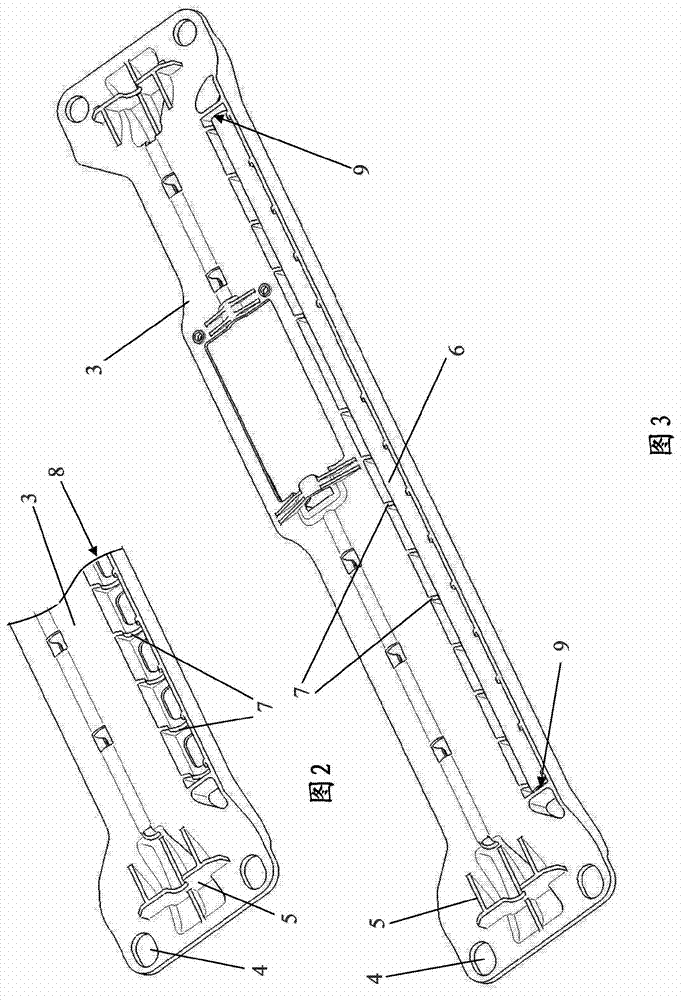

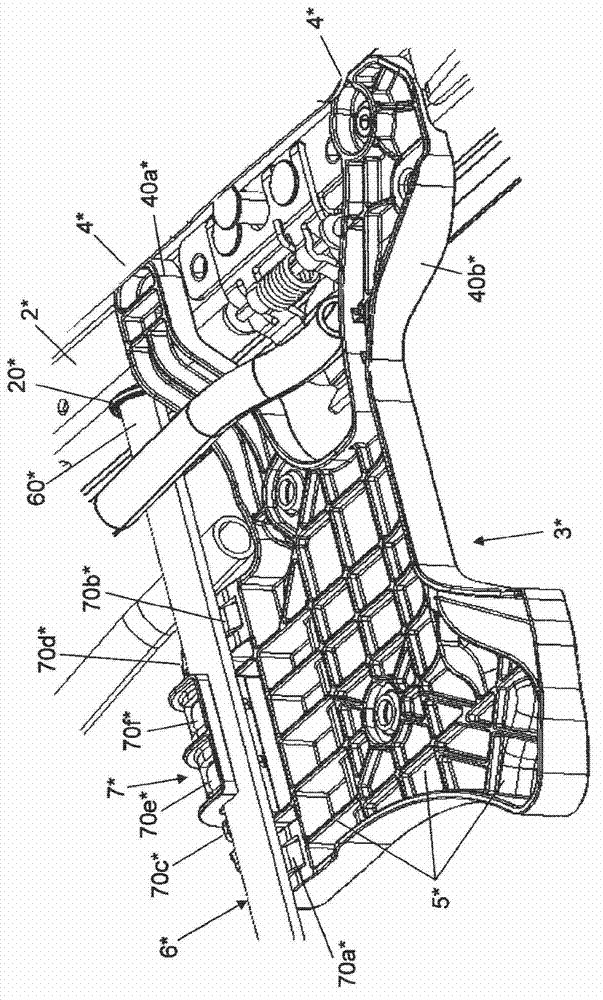

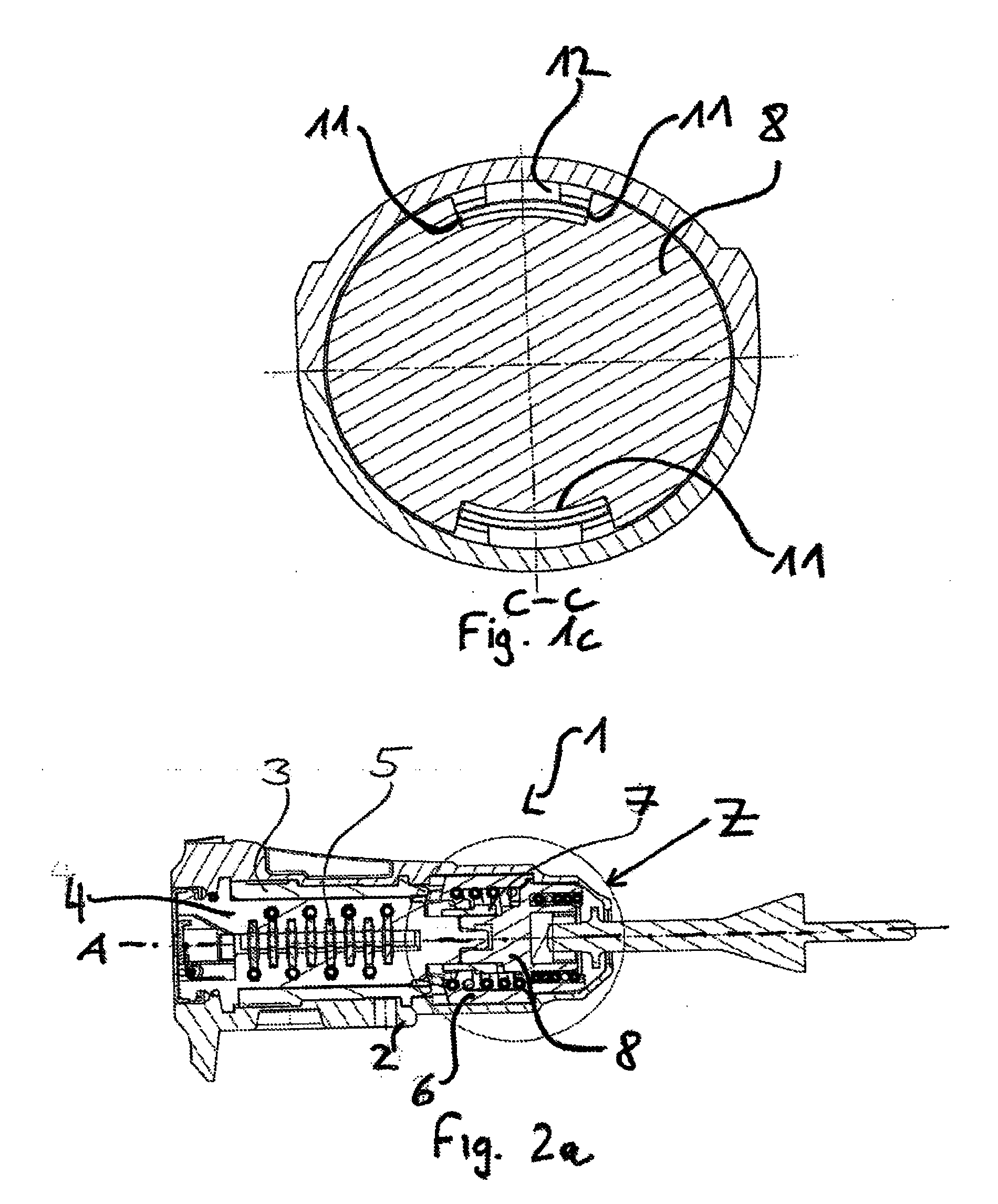

Hedge trimmer

The invention relates to a hedge trimmer 1, having a blade arrangement 9 with at least one cutter bar (11, 12). The utter bar (11, 12) is driven in a reciprocating manner by the drive motor via the gear mechanism 30 in a longitudinal direction. The blade arrangement includes a guide mechanism (10, 10') that extends over at least a part of the length of the cutter bar (11, 12). The cutter bar (11, 12) is longitudinally movably held on the guide mechanism (10, 10'). The guide mechanism (10, 10') is embodied as a molded part that includes a generally flat fastening portion 76 and a profiled guide portion 77. The cutter bar (11, 12) is supported on the guide portion 77, to achieve a high intensity when the weight is lighter.

Owner:ANDREAS STIHL AG & CO KG

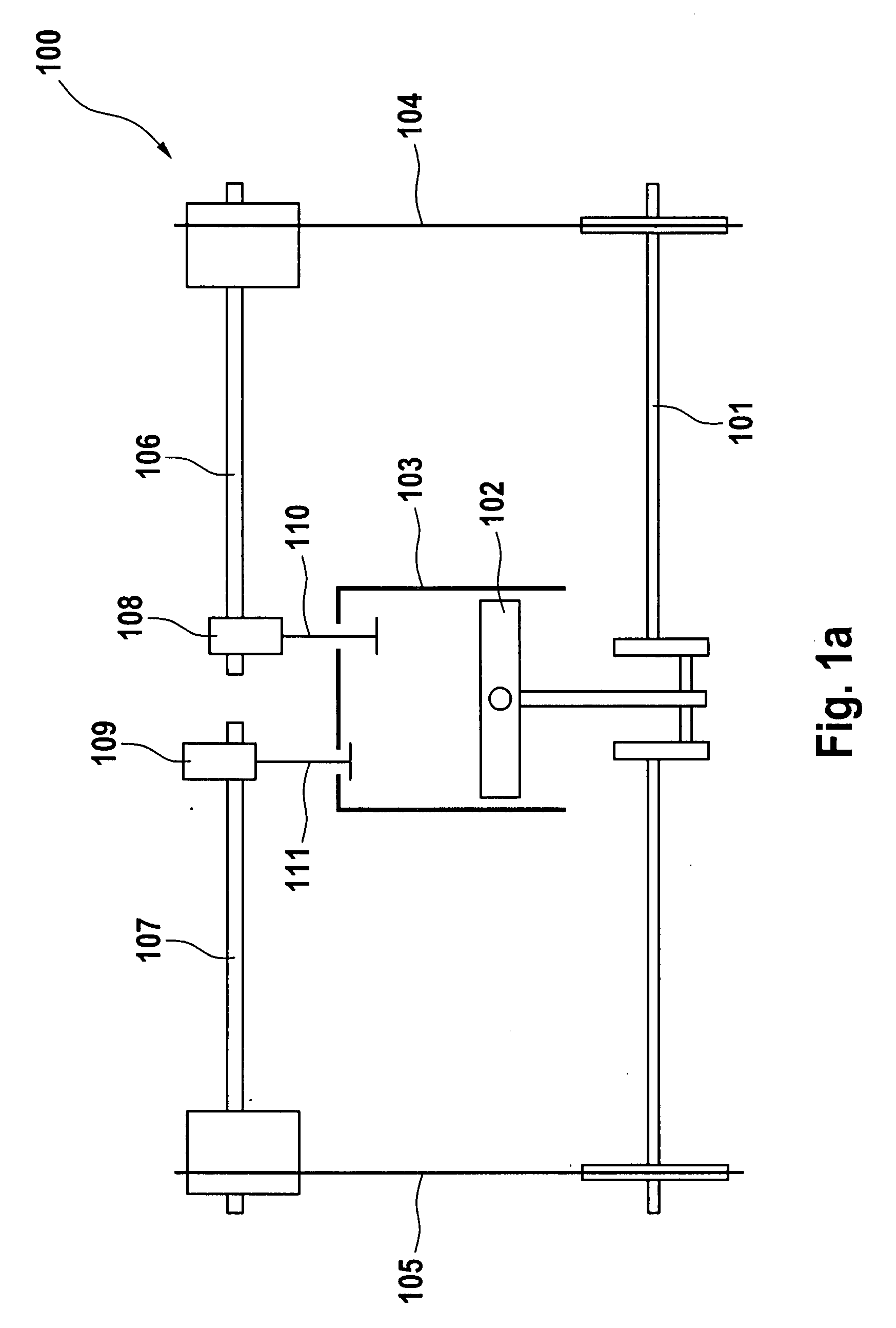

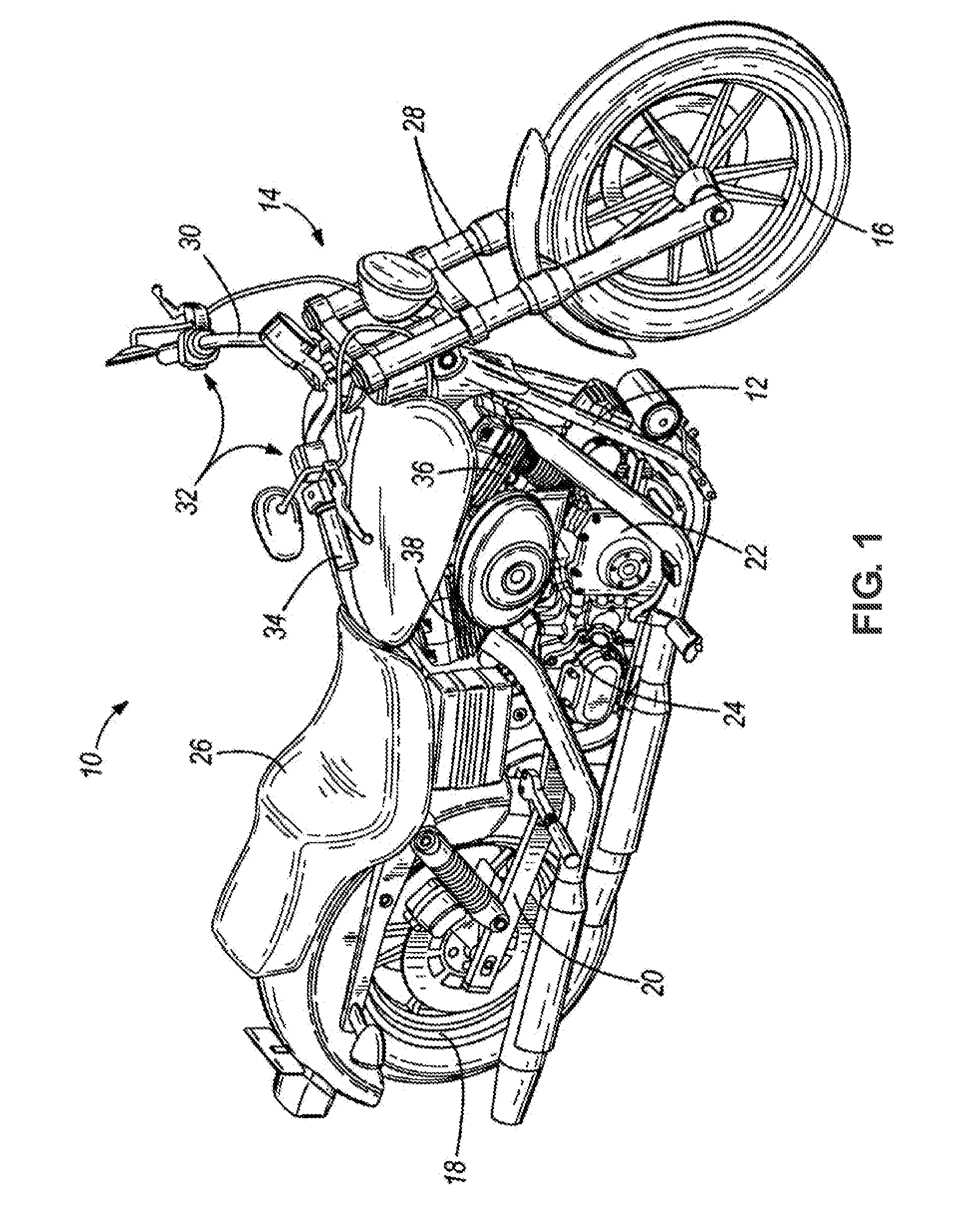

Device For Varying The Control Times Of An Internal Combustion Engine

InactiveUS20090120391A1Reduce weightIncreased resistance torqueValve arrangementsYielding couplingDriven elementCrankshaft

The invention relates to a device (1) for varying the control times of an internal combustion engine (100), having a driving wheel (12), a driven element (8) and a swashplate mechanism (2). The torque of a crankshaft (101) is transmitted by means of a primary drive to the driving wheel (12) and further by means of the swashplate mechanism (2) to the driven element (8) which is connected fixedly in terms of rotation to a camshaft (9).The swashplate mechanism (2) is composed of at least one bevel wheel (3) and a swashplate (5) which is mounted on an adjusting shaft (15).It is the aim of the invention to reduce the mass and the installation space of the device (1).

Owner:SCHAEFFLER KG

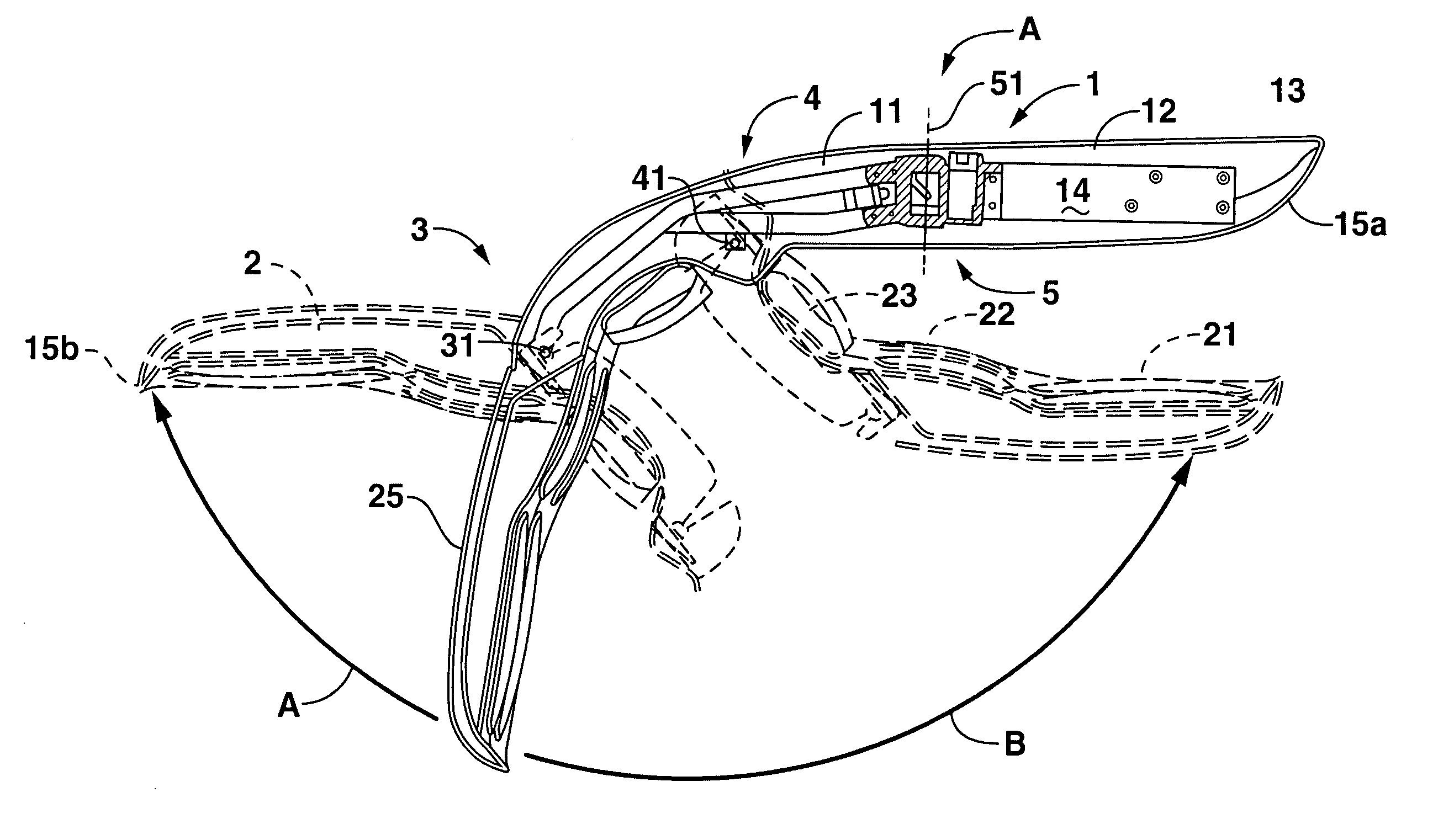

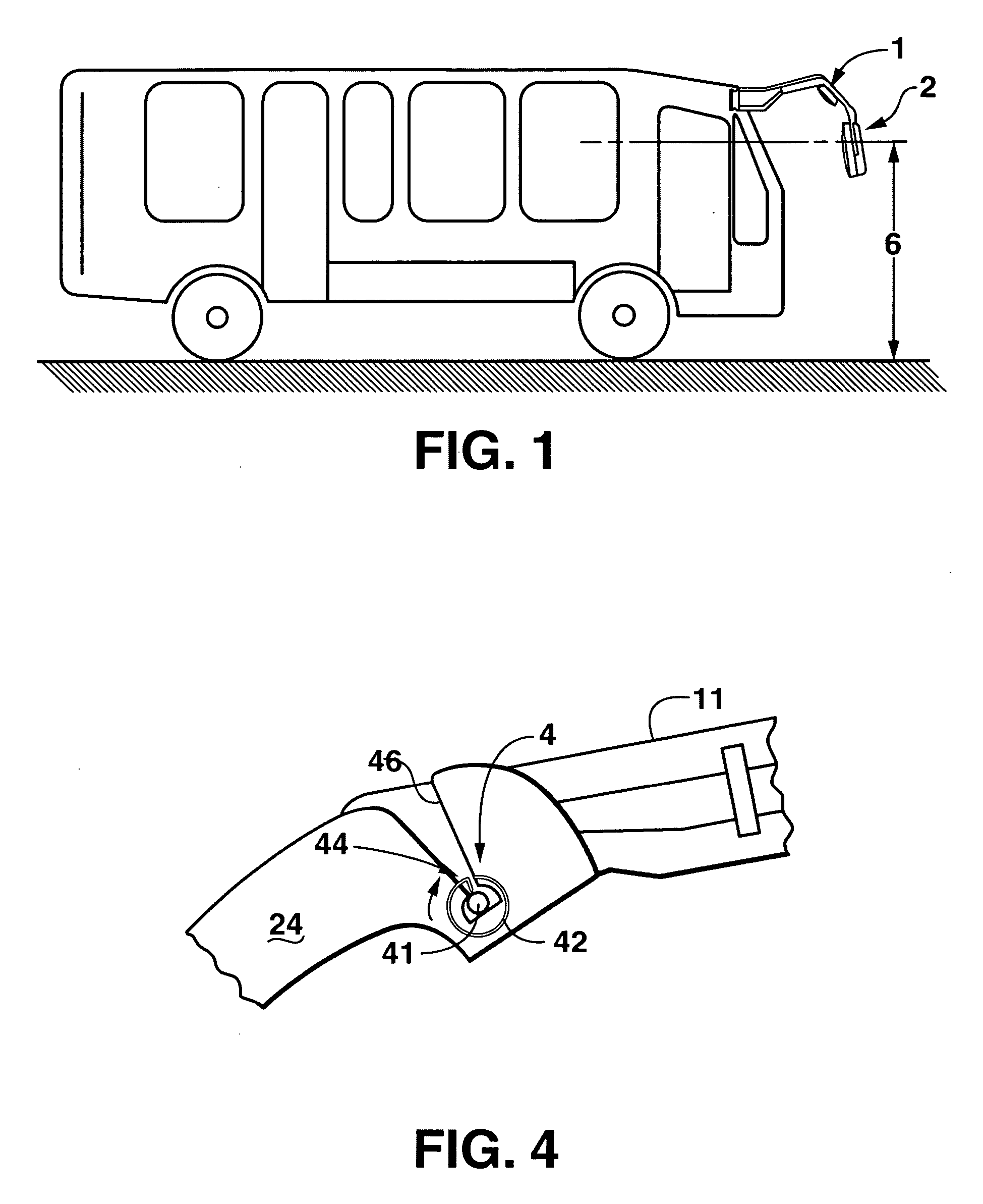

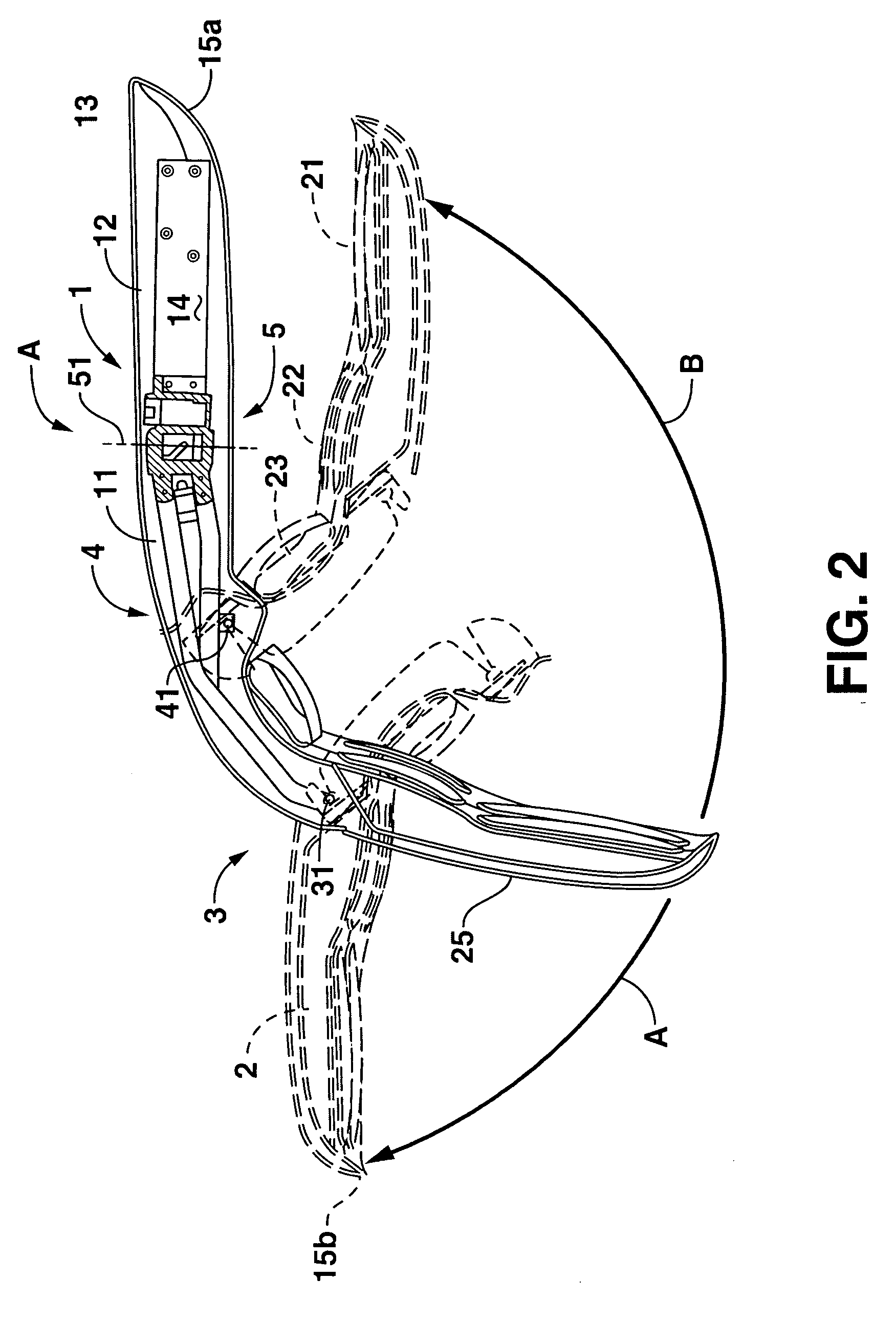

Double pivot vehicle mirror assembly

InactiveUS20060273232A1Increased resistance torqueSmall support forcePicture framesDomestic mirrorsControl theoryCommercial vehicle

A mirror assembly especially designed for commercial vehicles including a support arm, a mirror head pivotally affixed to the support arm by first and second hinges having a pivot axis. The axes extend horizontally and transverse to the direction of vehicle travel. The first hinge allows a pivoting of the mirror head about its pivot axis only in a first direction A and the second hinge permits a pivoting of the mirror head only in a second direction B which is opposite to the direction A. By this means, it is possible that the two hinges can be simple and rugged in construction.

Owner:LANG MEKRA NORTH AMERICA LLC

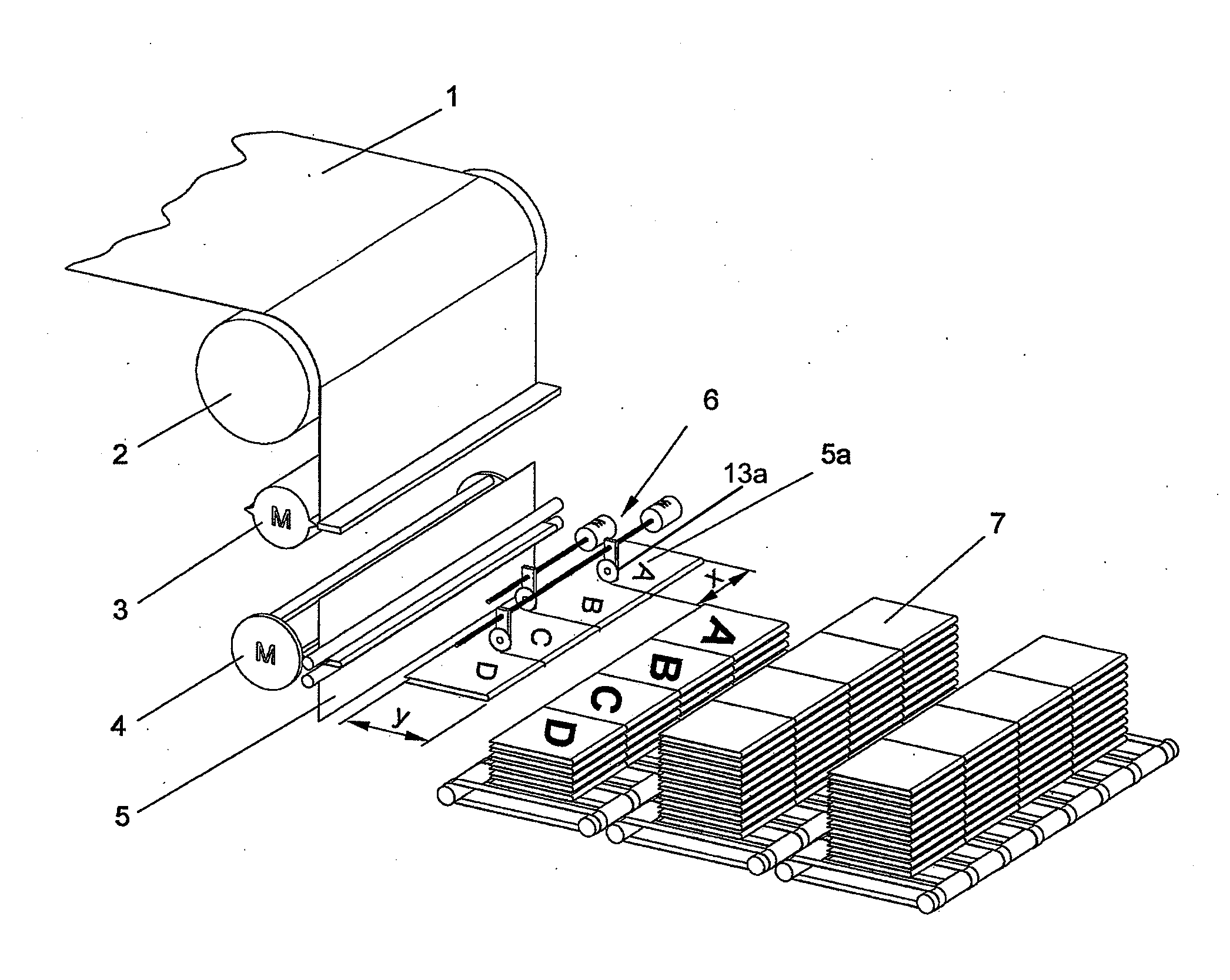

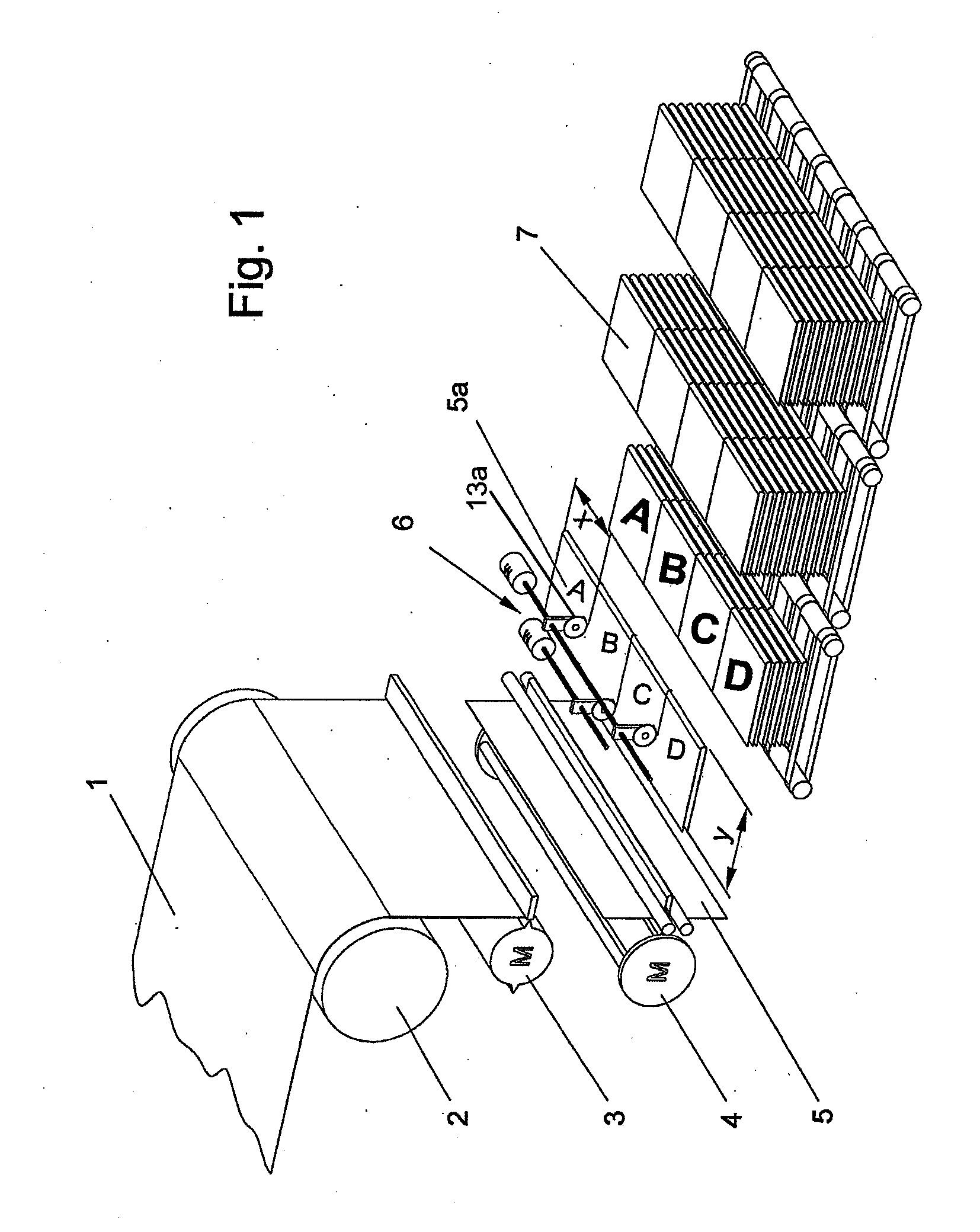

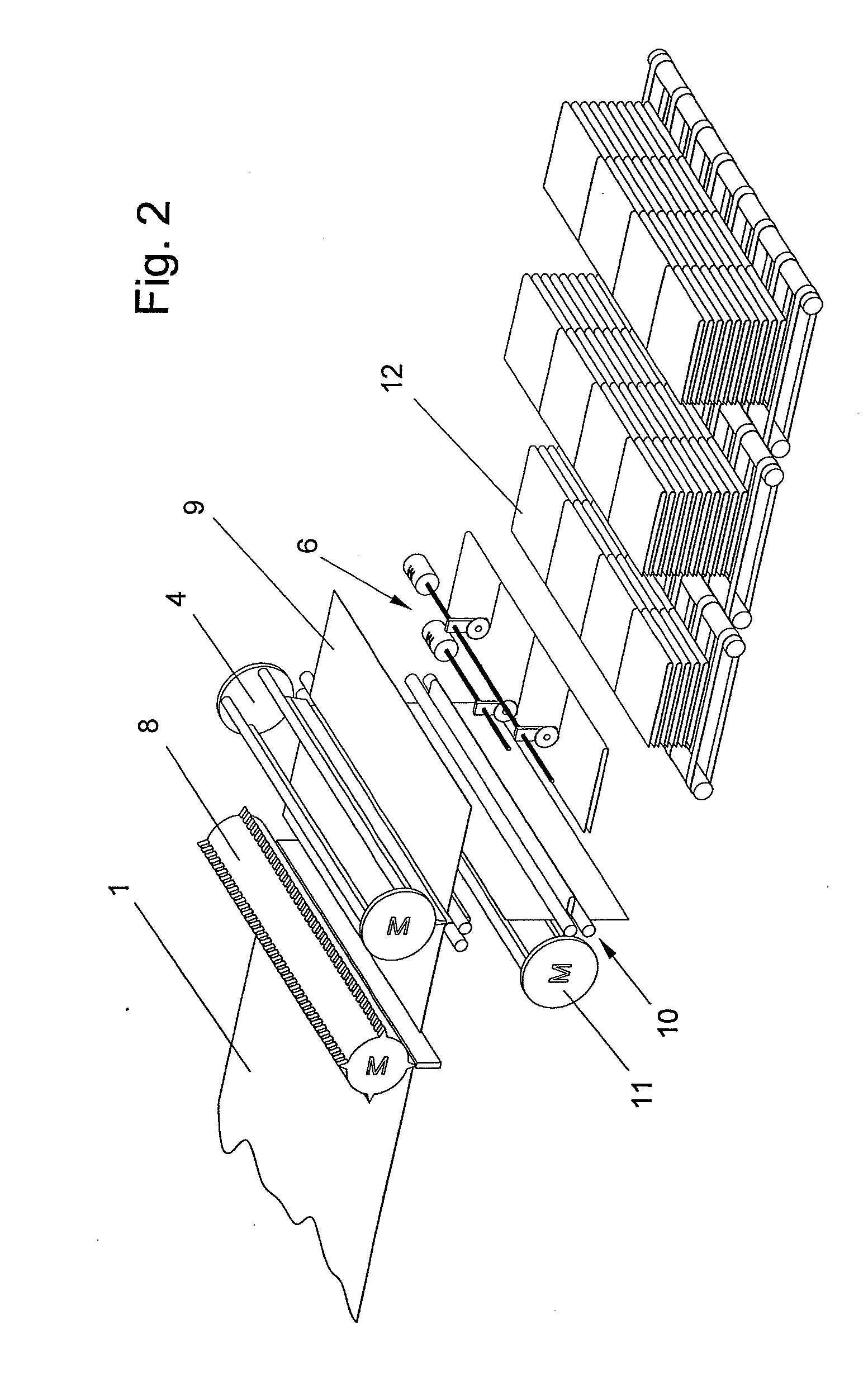

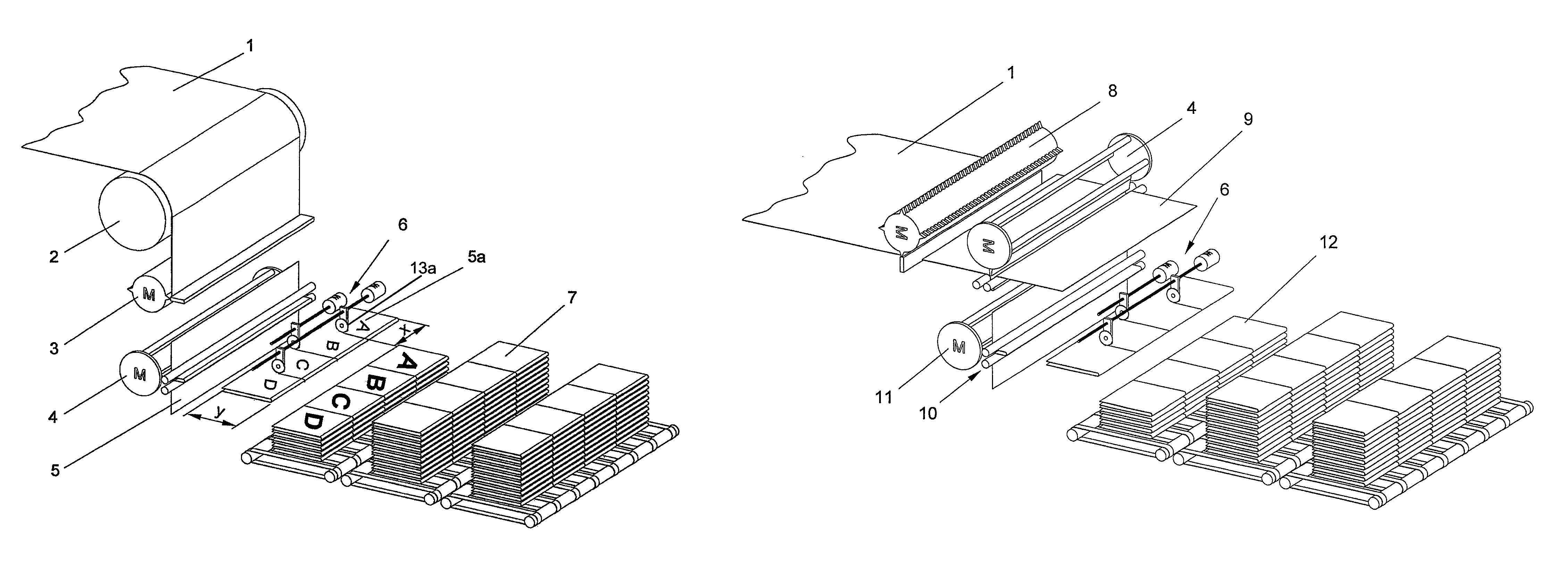

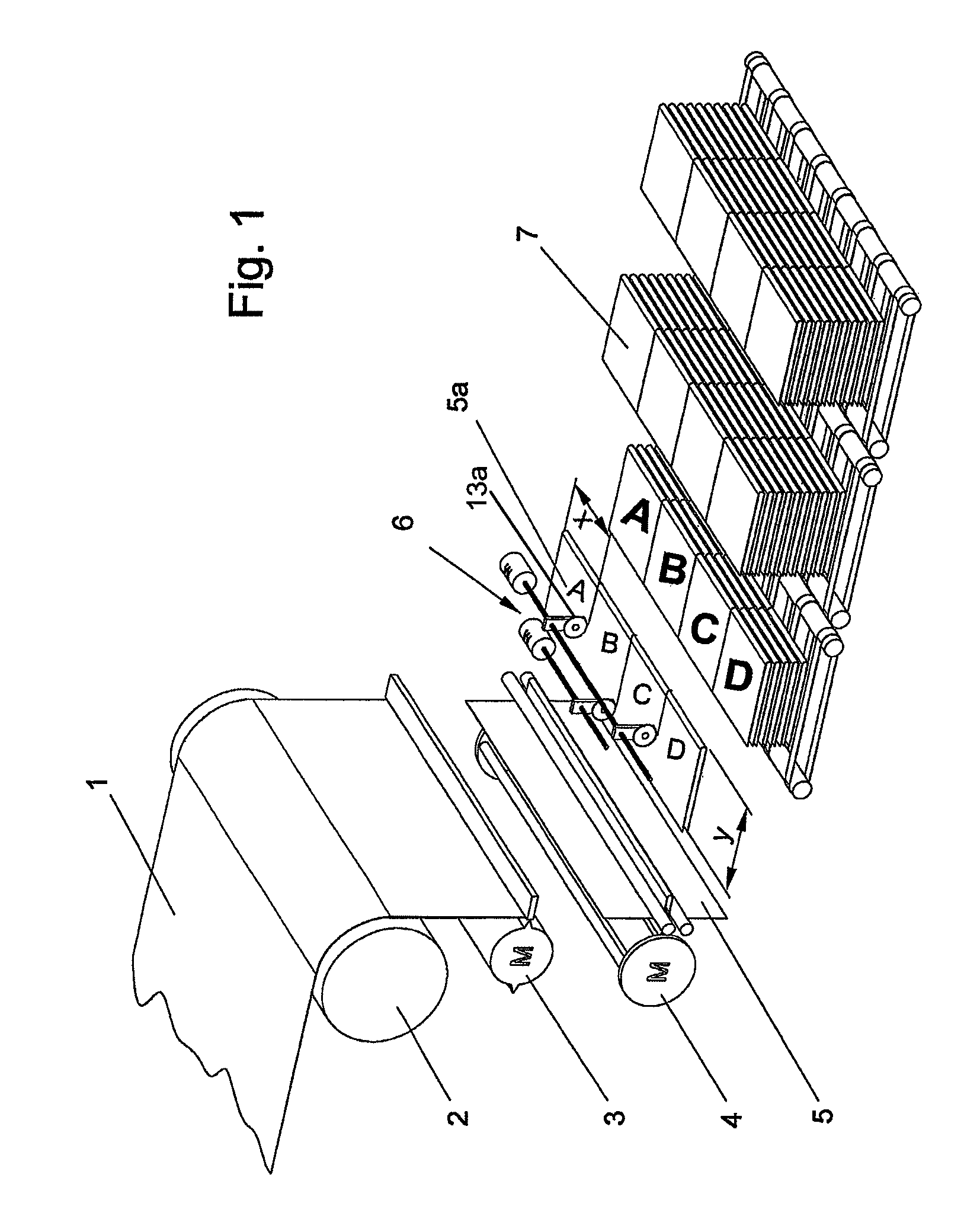

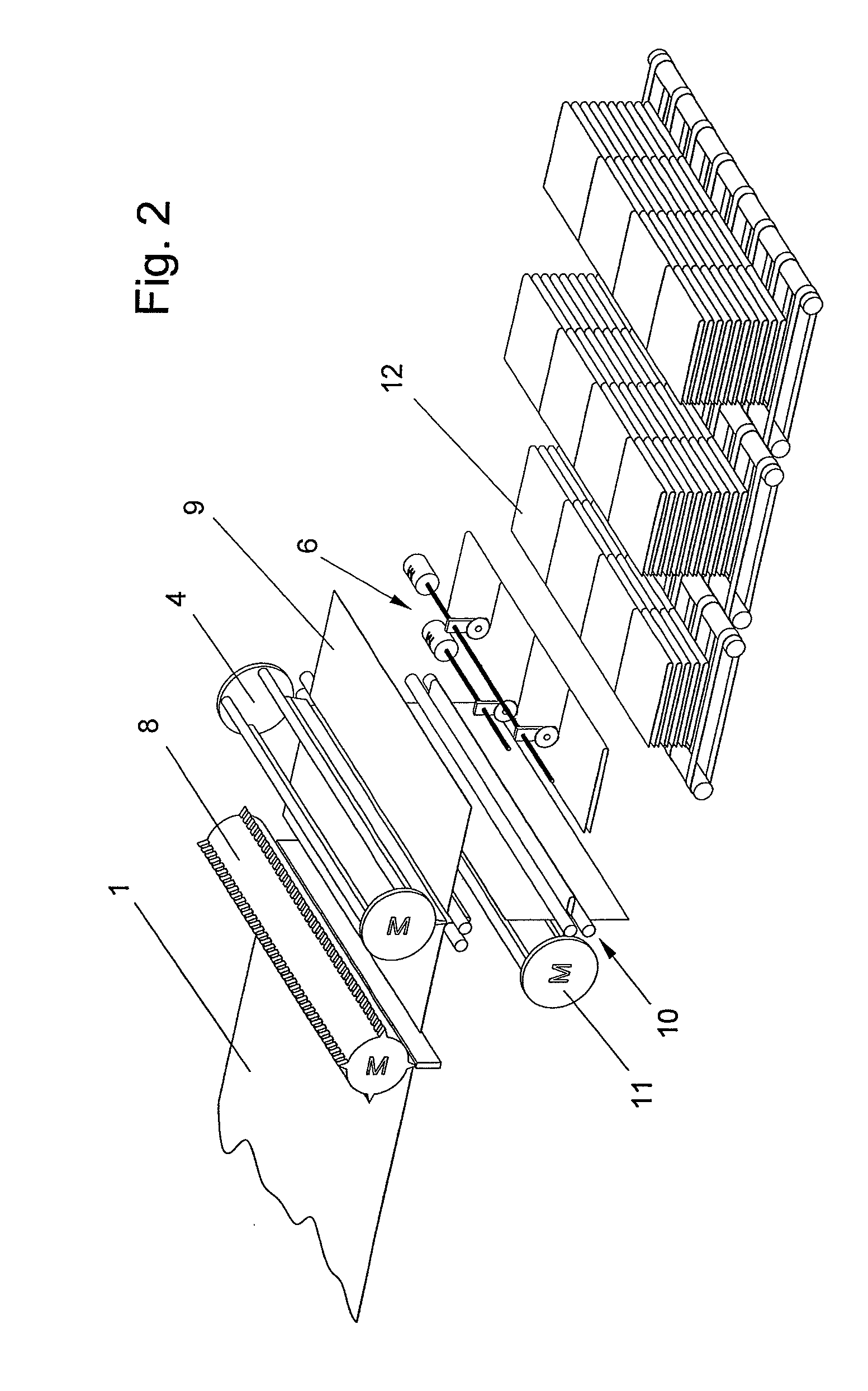

Method for producing a printed product

ActiveUS20110098169A1Maximize widthIncreased resistance torqueMechanical working/deformationPaper/cardboard articlesPaper sheetEngineering

A method for producing a printed product in which a complete content of the printed product is printed sequentially in series on one or both sides along a paper web having a width based on a multiple of a width of a finished printed product, including cutting the paper web in a direction crosswise to a longitudinal direction of the paper web to produce a cut-off section having a length based on a multiple of a length of the finished printed product, folding the cut-off section at least once in the crosswise direction in a location based on the length of the finished product, and cutting one of the folded cut-off section subsequent to the folding or the paper web prior to the crosswise cutting, to form a plurality of partial webs each having a width based on the width of the finished printed product.

Owner:MULLER MARTINI HLDG

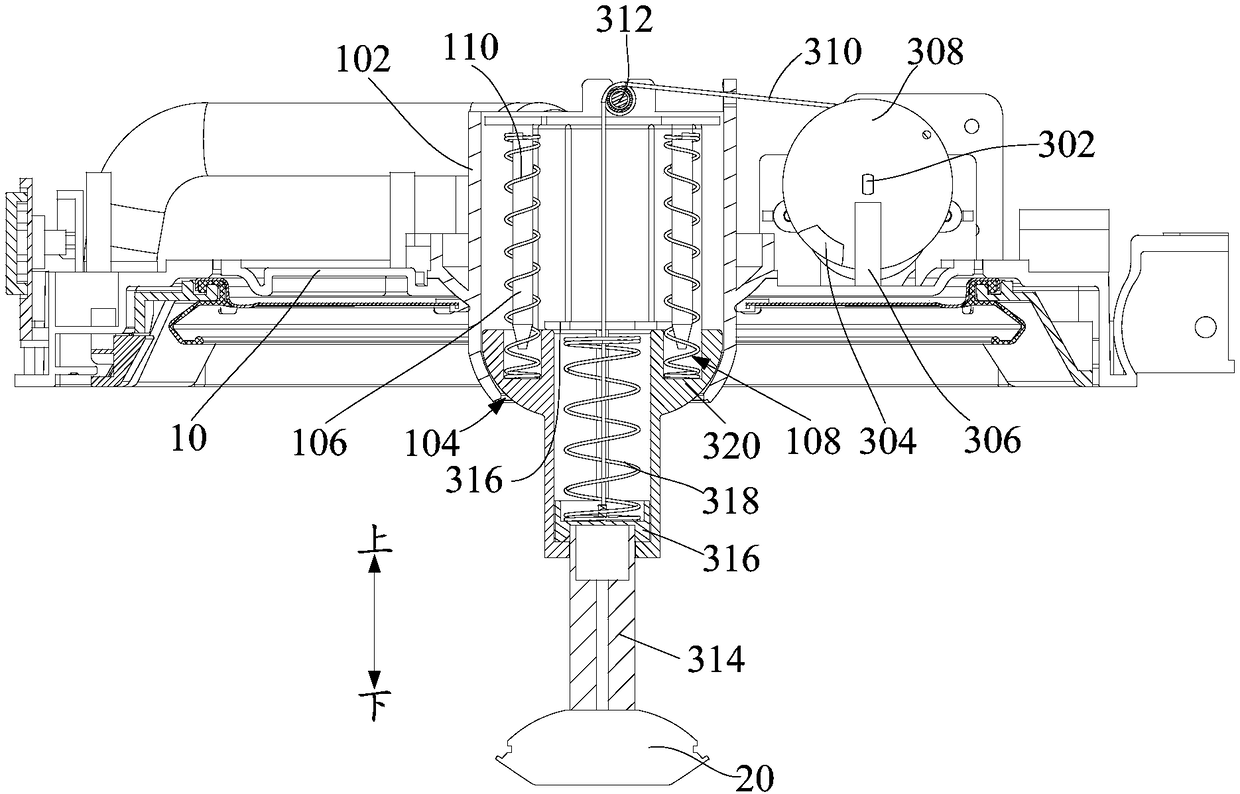

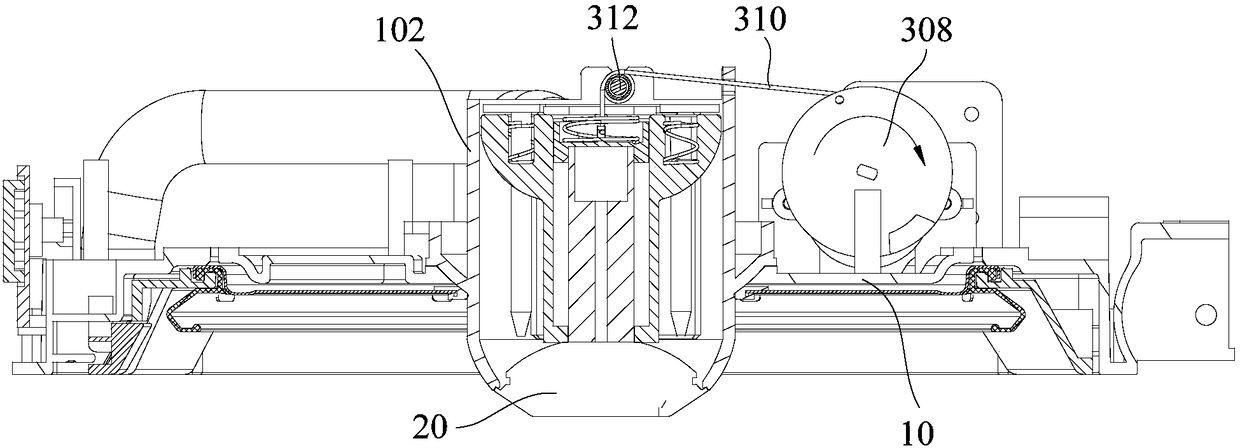

Cooking utensil

PendingCN109419298AThere will be no increasing stroke deviationNo precise controlBeverage vesselsSteam cooking vesselsReciprocating motionEngineering

The invention provides a cooking utensil. The cooking utensil includes an upper cover, an inner pot, a cleaning assembly, and a stroke control device; the inner pot is located below the upper cover and used for carrying water and materials; the cleaning assembly can reciprocate between a first position and a second position that are between the upper cover and the inner pot; a driving device is connected to the cleaning assembly and used for driving the cleaning assembly to reciprocate; and the stroke control device is connected to the driving device and can make the driving device stop running when the cleaning assembly moves to the first position and to the second position to control a movement stroke of the cleaning assembly. The cooking utensil is additionally provided with the strokecontrol device, so that the time of stopping the operation of the driving device is accurately corresponding to an endpoint position of the movement stroke of the cleaning assembly, thereby ensuring that the cleaning assembly can accurately move to the first position and the second position, and various adverse effects caused by excessive movement or improper movement of the cleaning assembly in the prior art are effectively avoided, and the usage reliability and safety of a product are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

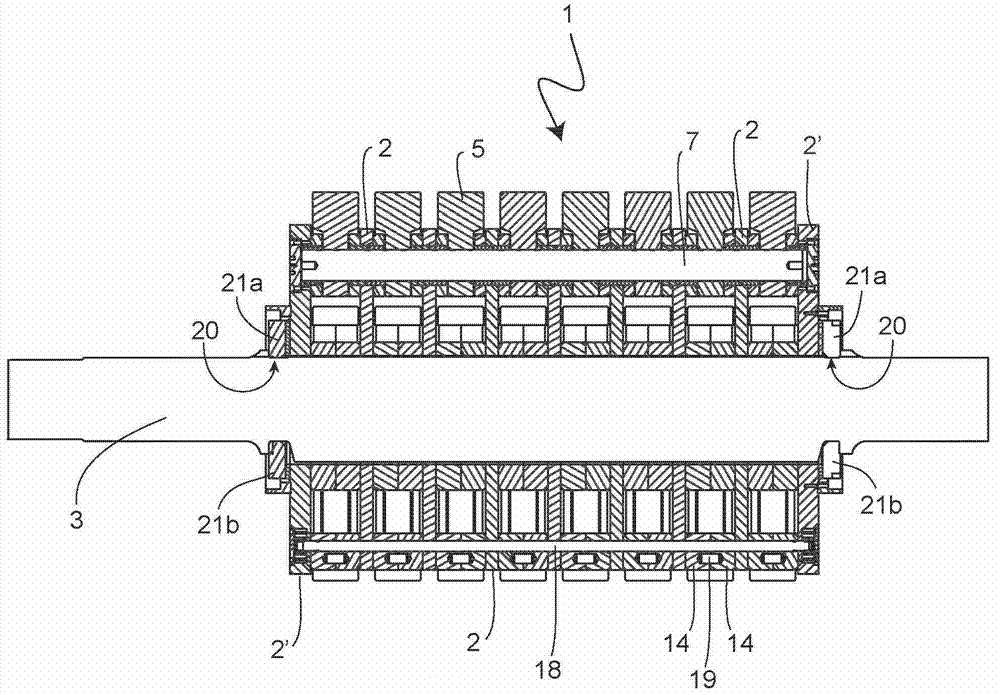

Continuously variable transmission

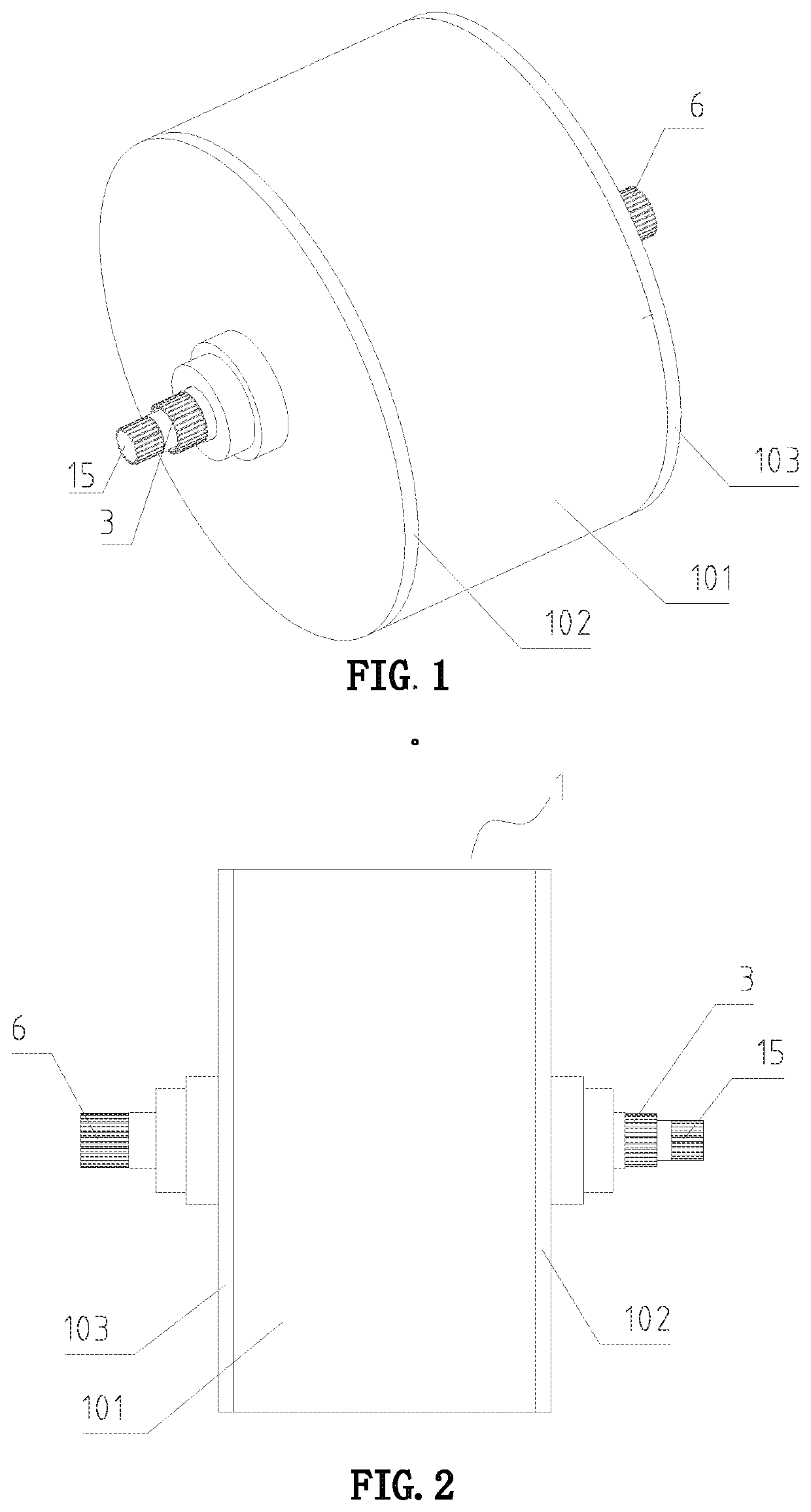

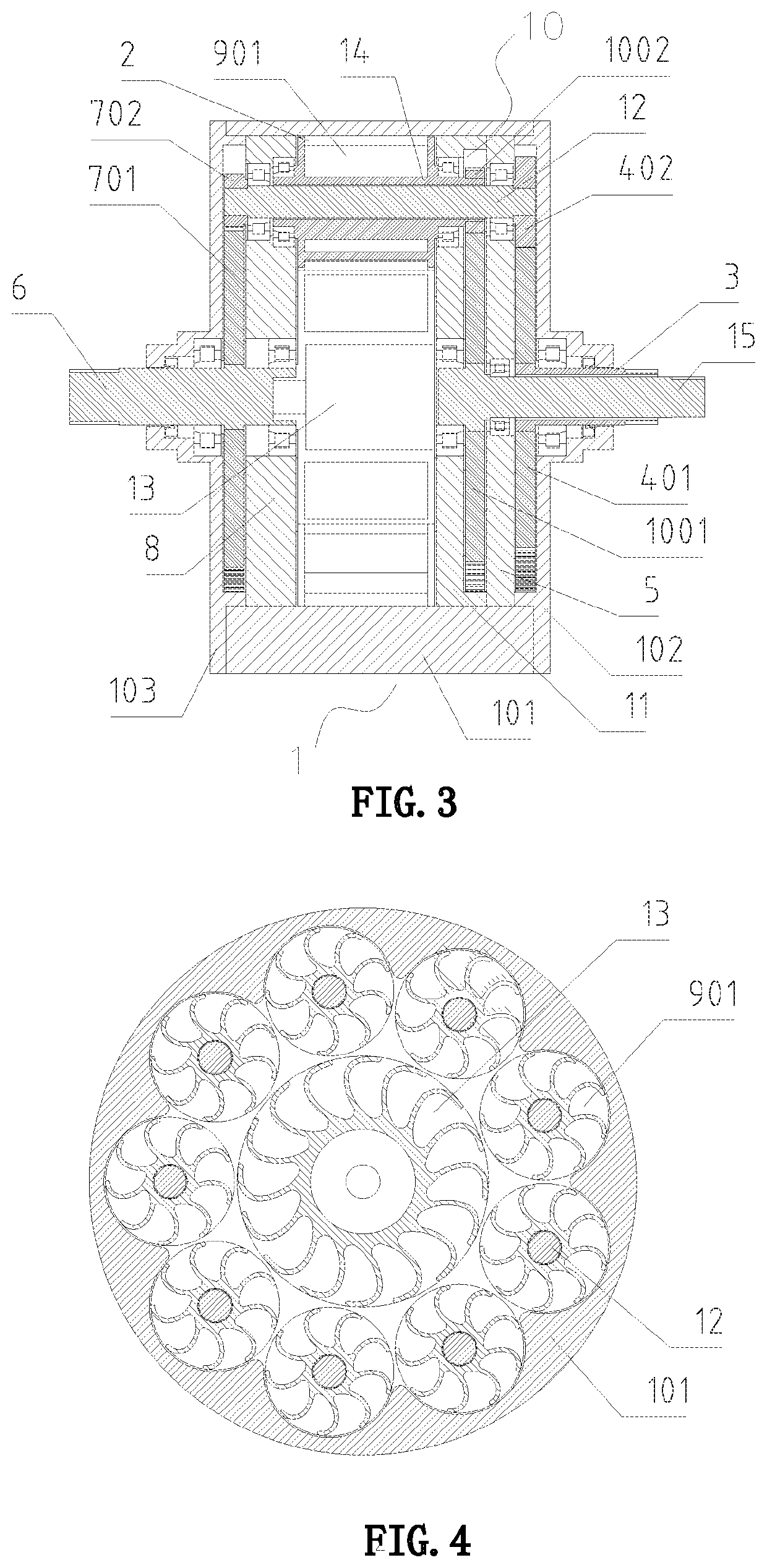

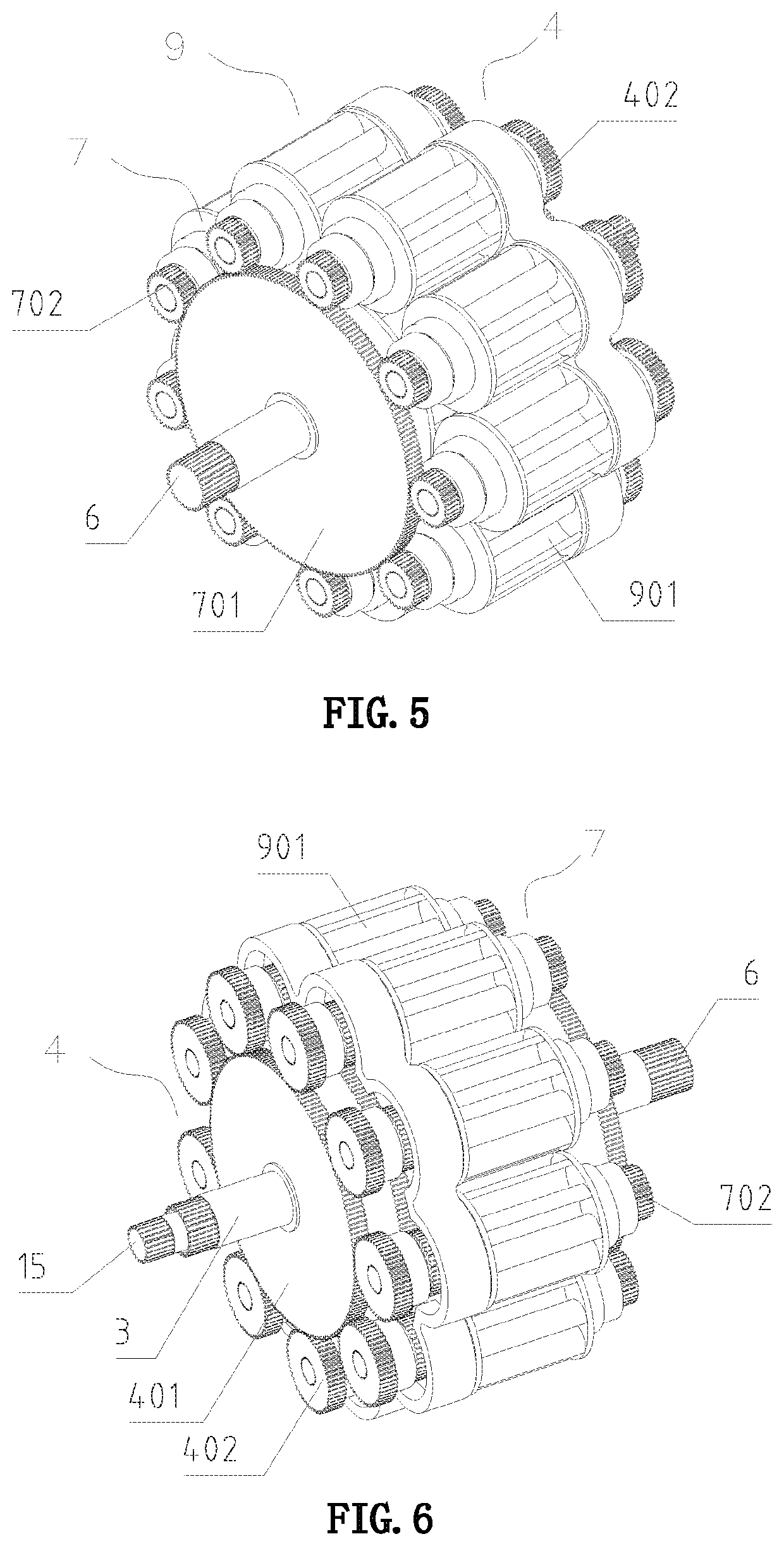

PendingUS20220107017A1Multiple functionsIncreased resistance torqueToothed gearingsFluid gearingsGear wheelEngineering

A continuously variable transmission, provided with an outer housing (1), wherein an intermediate housing (101) is arranged in the middle of the outer housing, and a first end cover (102) and a second end cover (103) are arranged on the two sides of the intermediate housing; a first shaft (3) with a hollow interior is arranged in the middle of the first end cover in a penetrating mode, a first sun gear (401) is fixedly arranged on the first shaft, and a first planetary gear set (4) is formed by a first planetary gear (402) and the first sun gear; a second shaft (6) is arranged in the middle of the second end cover in a penetrating mode, a second sun gear (701) is fixedly arranged on the second shaft, and a second planetary gear set (7) is formed by a second planetary gear (702) and the second sun gear; a bucket wheel planetary gear set (10) is formed between the first planetary gear set and the second planetary gear set; and a third shaft (15) is fixedly arranged in the middle of a bucket wheel sun gear (1001) and penetrates a first supporting frame (5) and the first shaft. The described continuously variable transmission solves the technical problem of, when a bucket wheel of a continuously variable transmission rotates, the bucket wheel allocates the input torque or increases the resistance torque, and the bucket wheel cannot be controlled by means of the external force. The described continuously variable transmission may be widely used in the field of transmission.

Owner:WEIHAI TUANZHONG TRANSMISSION CO LTD

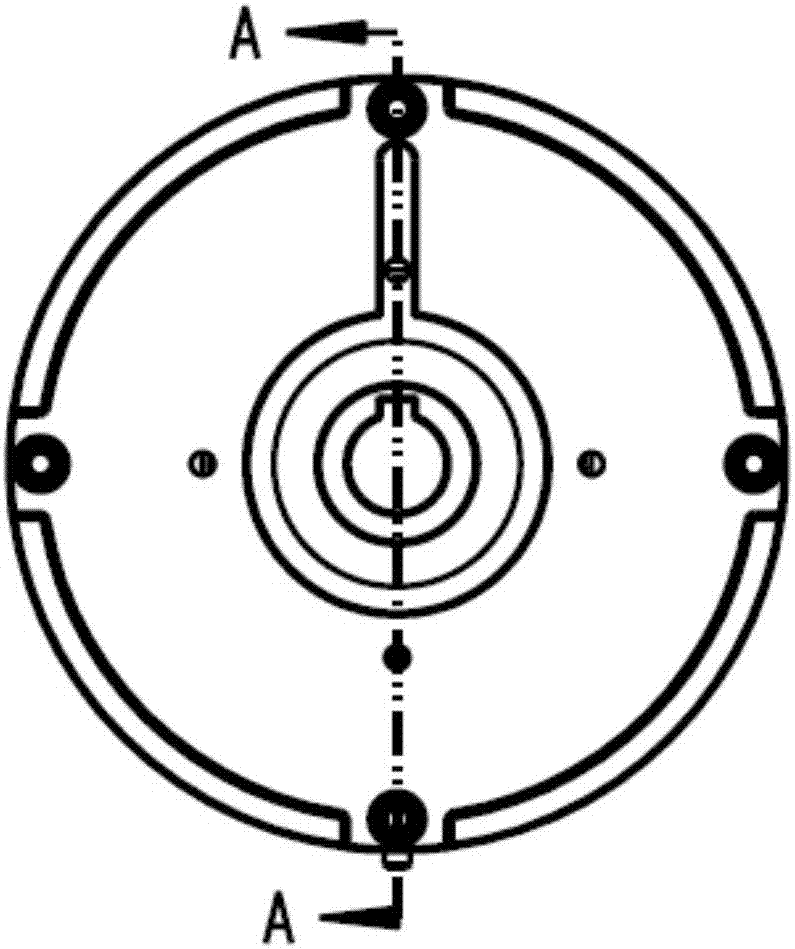

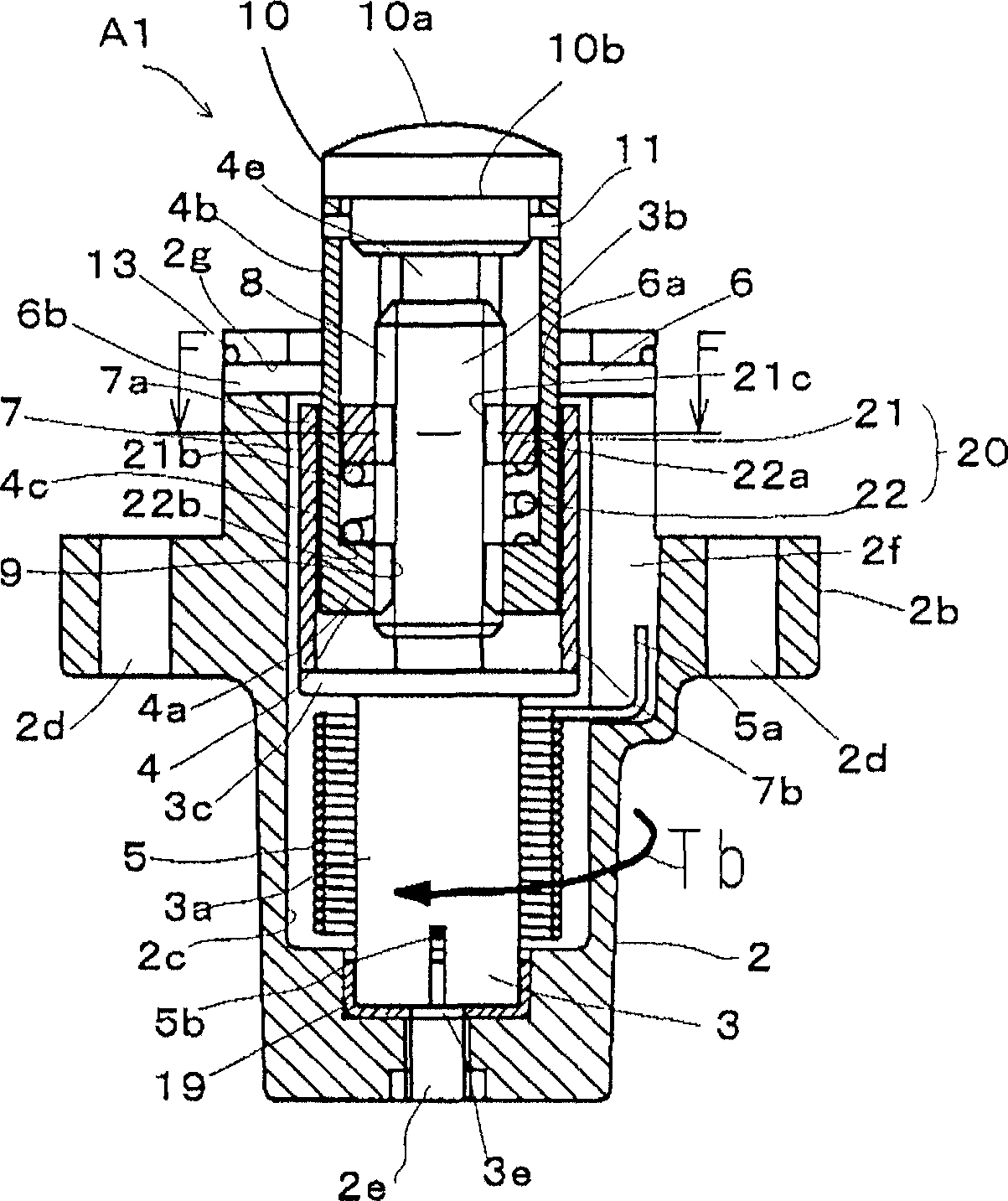

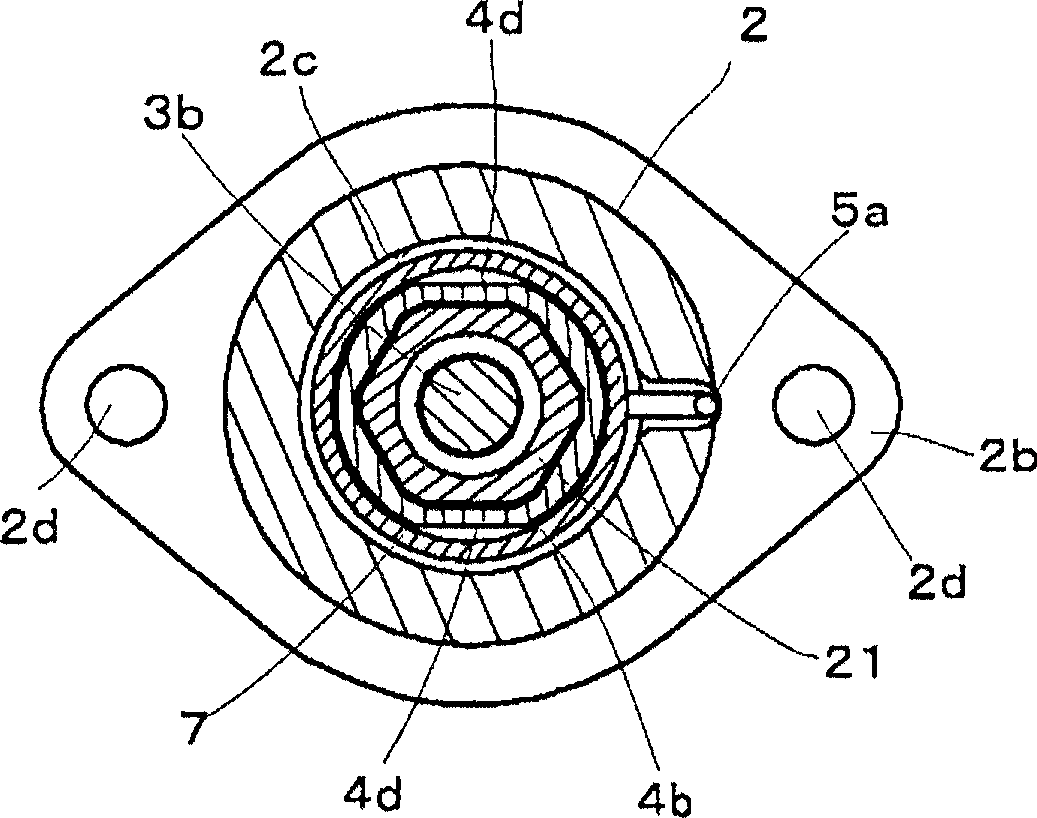

Friction-type damper device

ActiveCN107218339AIncreased resistance torqueReduce volumeSpringsShock absorbersAbsolute rotationEngineering

Provided is a friction-type damper device. The friction-type damper device mainly comprises a cover plate, an outer shell, a transfer element, a friction head, a friction disc, two bearings, a spring, a telescopic shaft and a rotating shaft. The rotating shaft and the cover plate are fixed onto connecting rods on the two sides of a joint capable of providing resisting moment correspondingly, the rotating shaft is fixedly connected with one connecting rod, and the cover plate is fixedly connected with the other connecting rod; the cover plate and the friction disc are oppositely arranged and fixedly connected together through the outer shell; the rotating shaft penetrates through a circular hole in the center of the transfer element and is fixedly connected with the transfer element, and the rotating shaft and the transfer element are together arranged between the cover plate and the friction disc; the telescopic shaft penetrates through the portion, around the rotating shaft, of the transfer element, the friction head is arranged at the top of the telescopic shaft, and the friction head abuts against the friction disc; and the rotating shaft is connected with the cover plate through one bearing, and the other end of the rotating shaft is connected with the outer shell through the other bearing located at the center of the friction disc. According to the friction-type damper device, the resisting moment of the damper has nothing to do with the rotating speed or the external force and is only related to the absolute rotation angle where the device is located, and the blank of the friction-type damper is filled in.

Owner:BEIJING MECHANICAL EQUIP INST

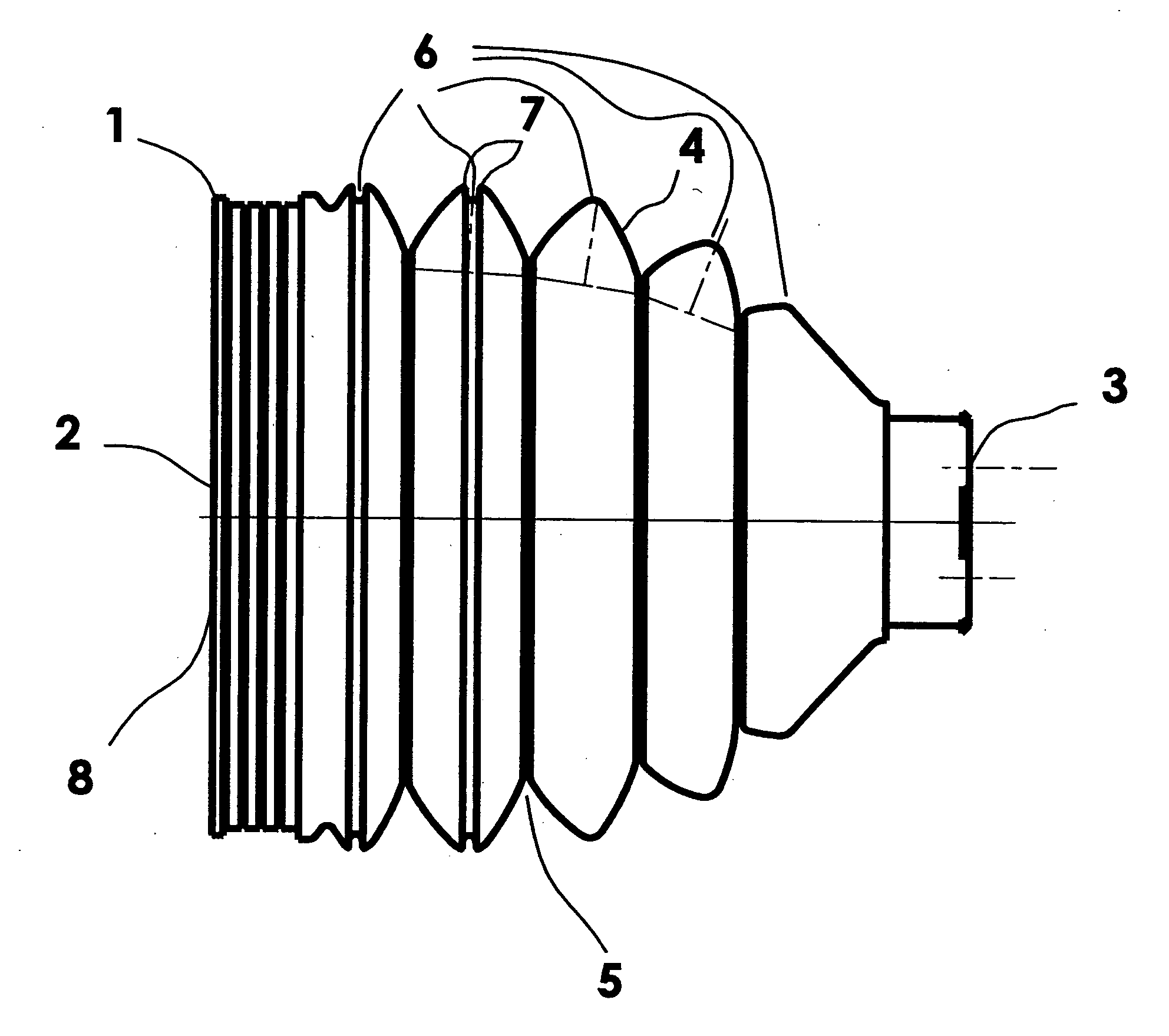

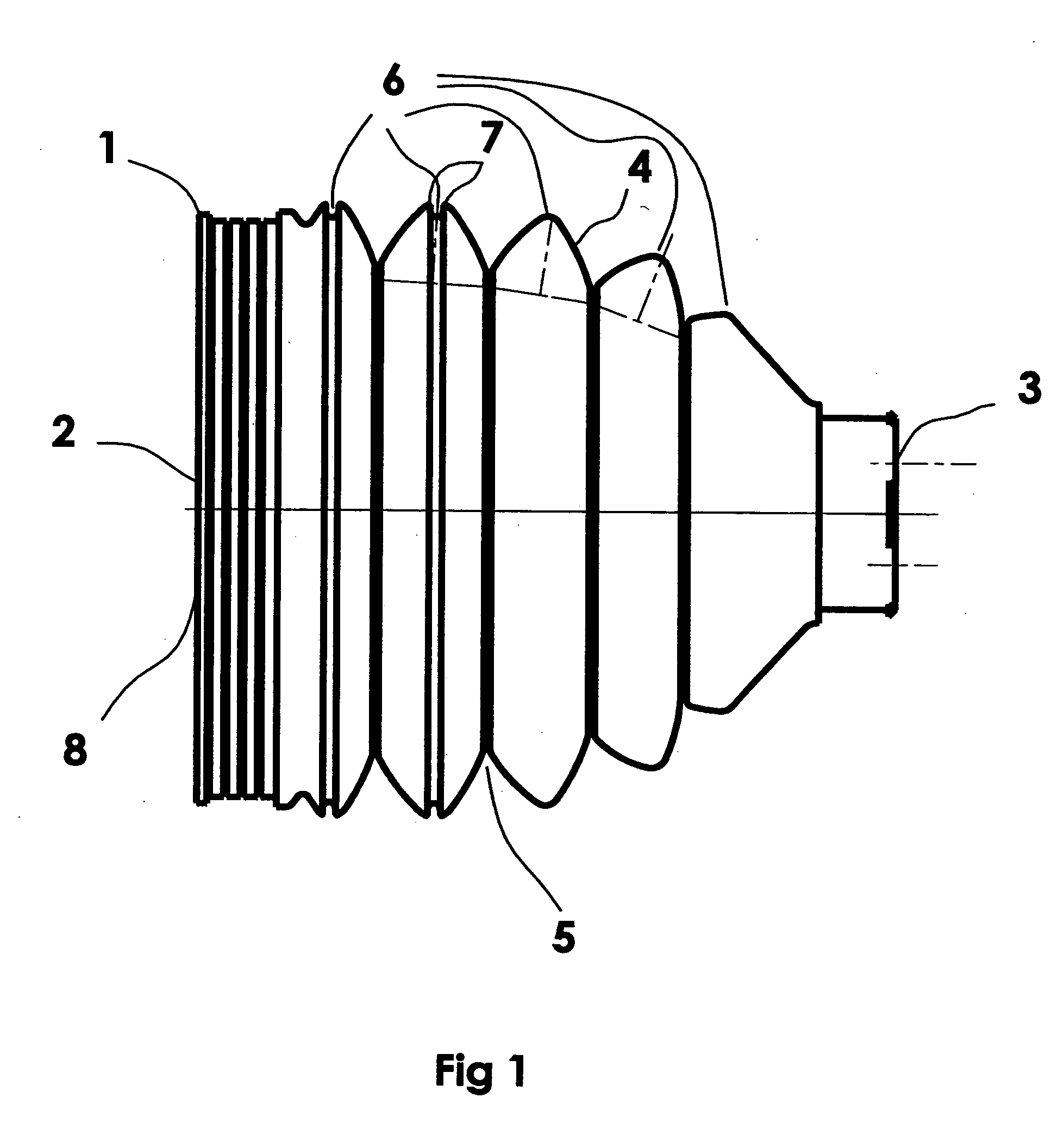

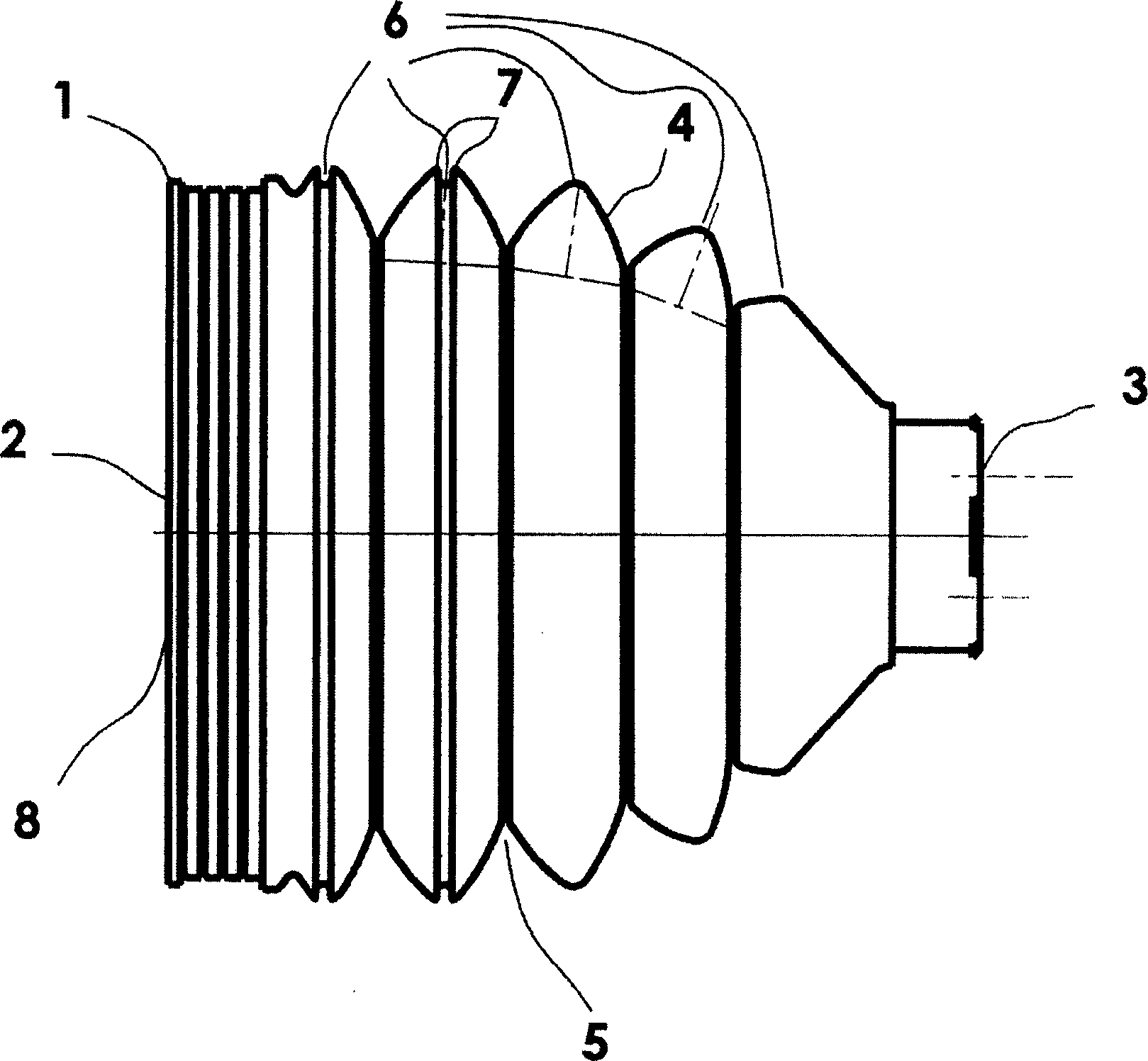

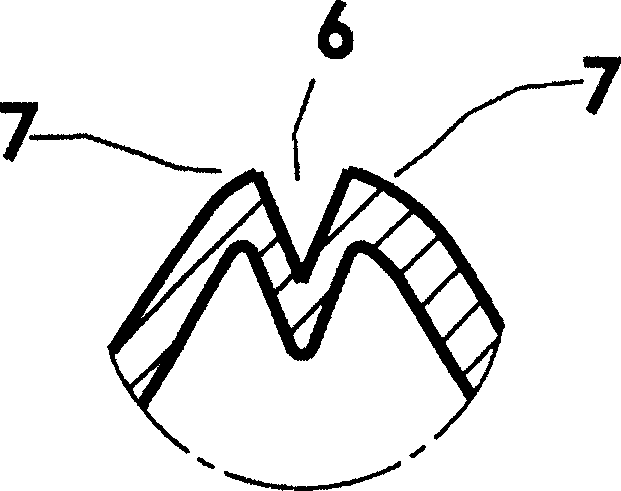

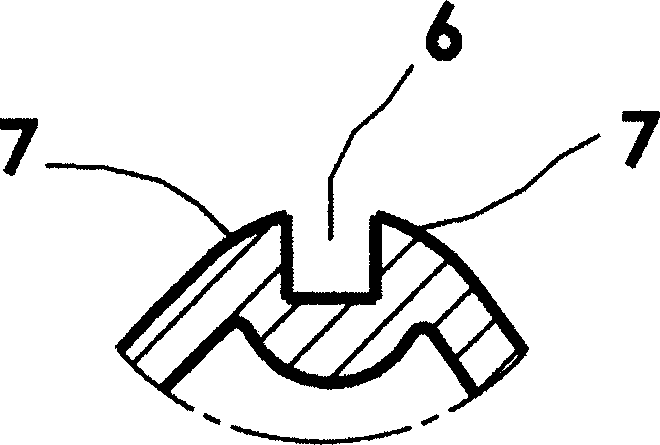

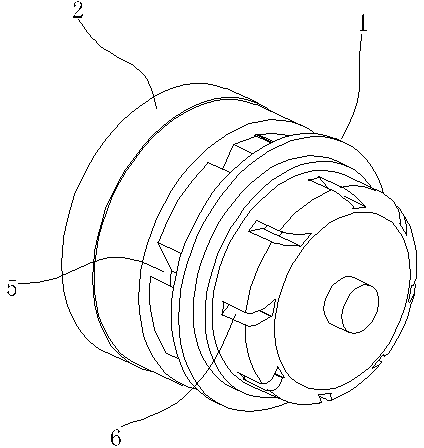

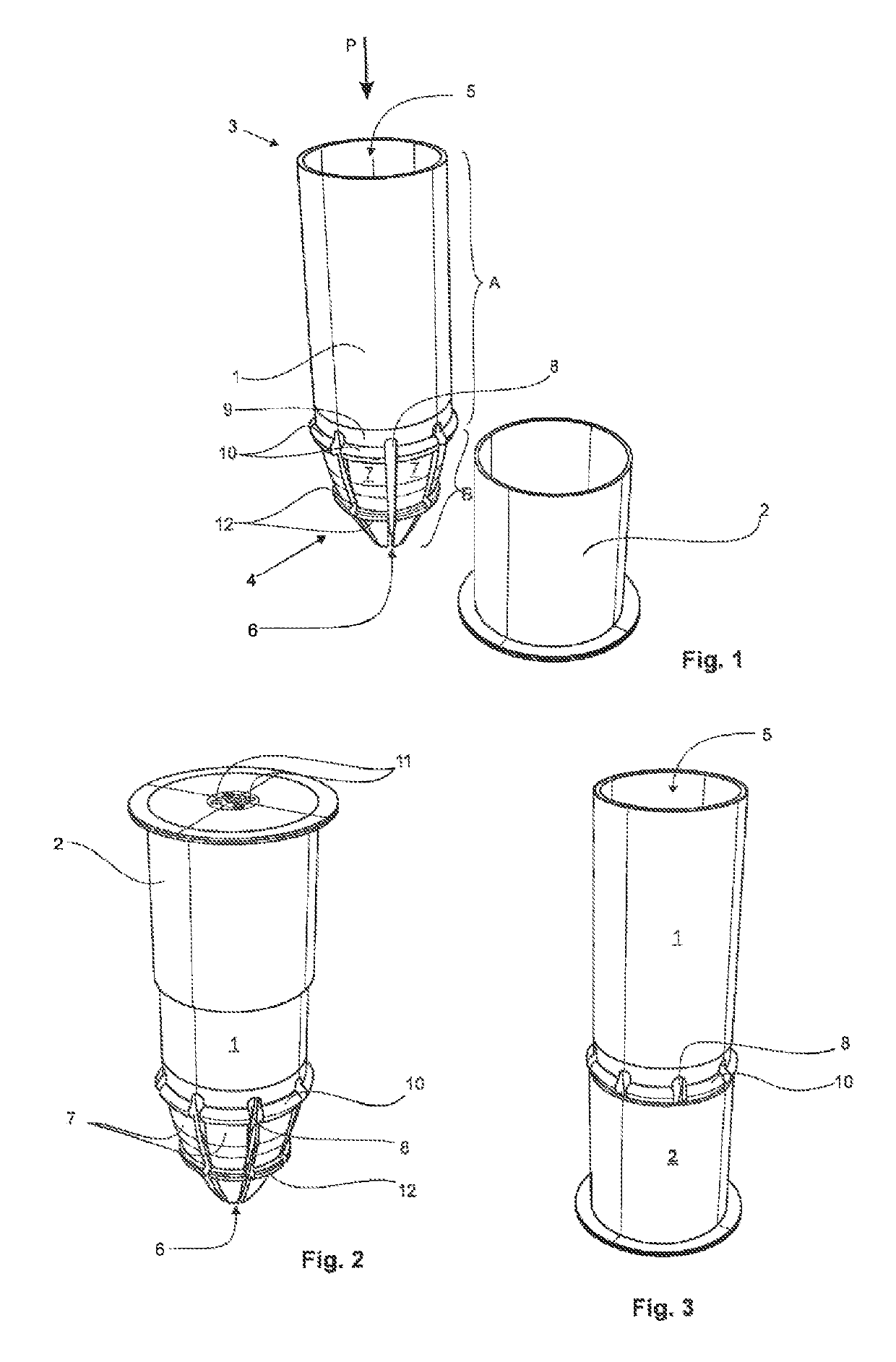

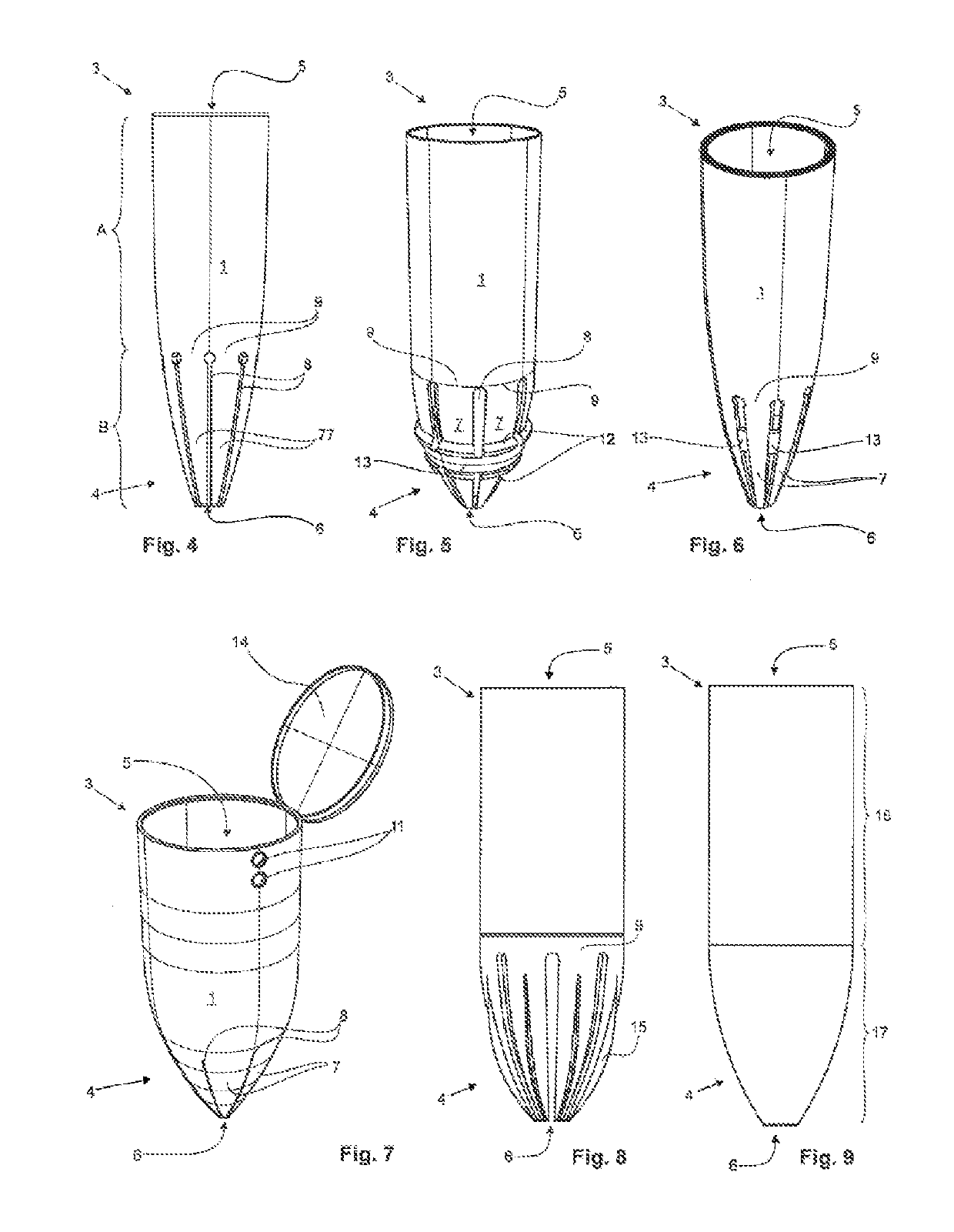

Bellows for articulated joints

InactiveUS20060273528A1Reduce axial stiffnessImprove radial stiffnessEngine sealsBellowsEngineeringBellows

A bellows having a substructure including a first end and a second end, the ends being movable relative to one another, circumferential bulges, which are spaced apart by first constricted regions, being formed in the substructure between the ends, and a second constricted region being formed in at least one bulge. The width of the second constricted region corresponds at least to its height in order to reduce the axial stiffness and increase the radial stiffness.

Owner:CARL FREUDENBERG KG

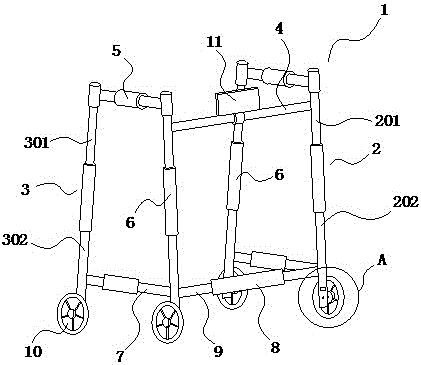

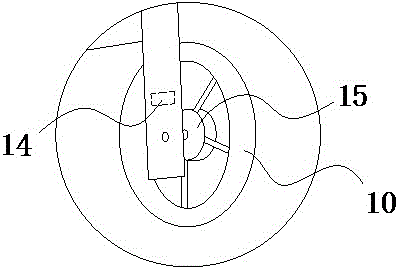

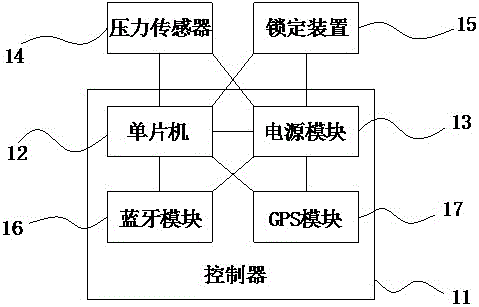

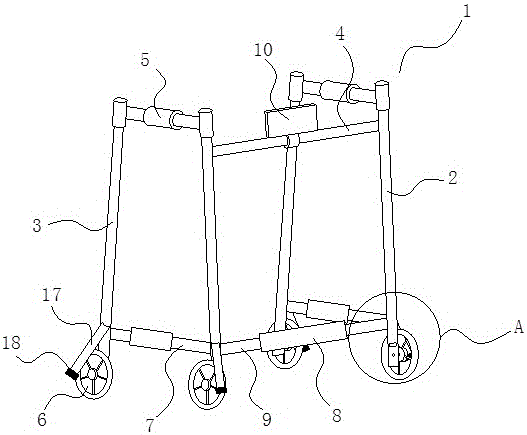

Walking aid

The invention relates to the field of a recovery assistive device, and particularly relates to a walking aid; the walking aid comprises a bracket; the bracket comprises two front supporting rods, two back supporting rods, a front gear rod and a handle; the front supporting rod and the back supporting rod are composed of separated upper section and lower section; the upper section is connected with the lower section through an elastic device; the handle and the front gear rod are fixed on the upper section. The walking aid can effectively absorb and buffer the impact energy generated when a user is fallen down, and avoid the falling condition along with the user, effectively support the user; the walking aid is suitable for the aged and some patients with some troubles of walking, and the disabled.

Owner:DEYANG LIJIU YUNZHI KNOWLEDGE PROPERTY OPERATIONS CO LTD

Protective boot for universal joint

InactiveCN1873263AReduced axial rigidityIncreased resistance torqueBellowsUniversal jointRelative motion

Owner:CARL FREUDENBERG KG

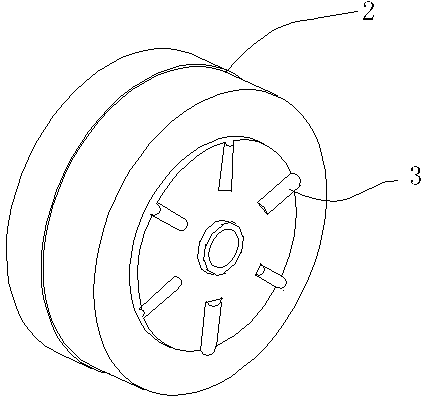

Impeller box

ActiveCN103471660AIncreased viscous friction resistance torqueIncrease resistanceVolume/mass flow by dynamic fluid flow effectImpellerEngineering

The invention discloses an impeller box which comprises a casing, a gear box located above the casing, a plurality of upper base ribs, lower base ribs, a plurality of water outlets and a plurality of water inlets. The ends of the inner sides of the plurality of upper base ribs form circles, the radius of every circle is 1 / 6 to 1 / 3 of the inner diameter of the casing, the height of every upper base rib is larger than 4mm, the height of every lower base rib is 2-4mm, an included angle between every two adjacent lower base ribs is larger than or equal to 10 degrees and smaller than or equal to 45 degrees, the sum of areas of upper openings of the plurality of water outlets is 1 / 3 to 2 / 3 of the area of the end face of a side wall of the casing 1, the sum of widths of water inlet ends of the plurality of water inlets is 1 / 3 to 1 / 2 of the length of an outer periphery of the casing, the sum of widths of water outlet ends of the plurality of water inlets is 1 / 3 to 1 / 2 of the length of an inner periphery of the casing, and the height of every water inlet exceeds 1 / 2 of the height of every blade. Compared with the prior art, the impeller box can simultaneously reduce measurement errors of a water meter during large flow and small flow, measurement precision of the water meter is improved, and the measuring span of the water meter is expanded.

Owner:NINGBO WATER METER

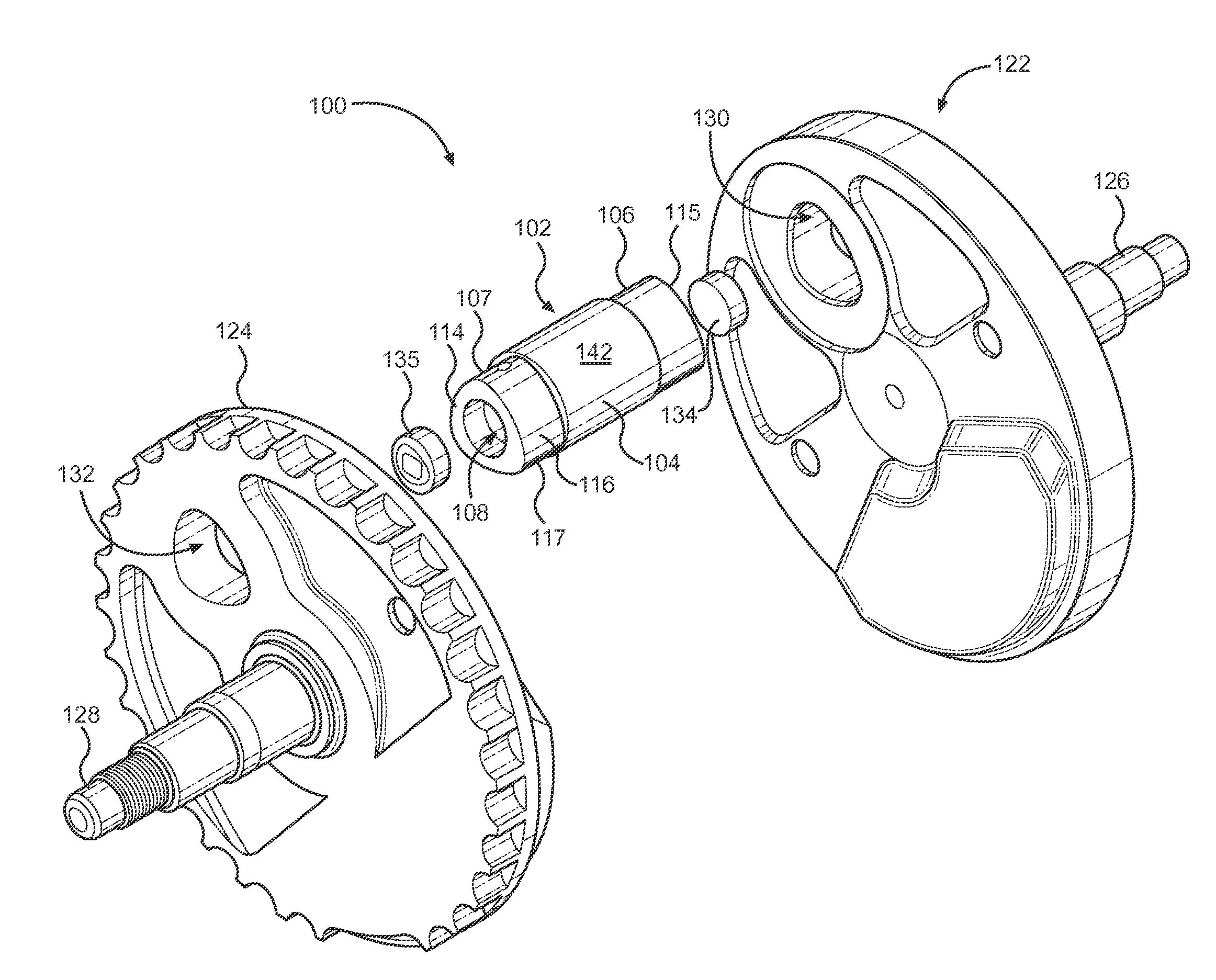

Crankshaft assembly with polygon crank pin

ActiveUS20160265579A1High strengthIncreased resistance torqueConnecting rod bearingsInertia force compensationEngineeringMechanical engineering

A crankshaft assembly for a motorcycle includes a first flywheel half with a polygonal-shaped aperture therein and a second flywheel half with a polygonal-shaped aperture therein. The first and second flywheel halves are interconnected by press-fitting opposing first and second polygonal shaped end portions of a crank pin into respective polygonal-shaped apertures of the first and second flywheel half. A bearing is positioned at least partially on a surface of a cylindrical central portion of the crank pin and a connecting rod has an aperture at least partially receiving the bearing.

Owner:STOFFEL POLYGON SYST INC

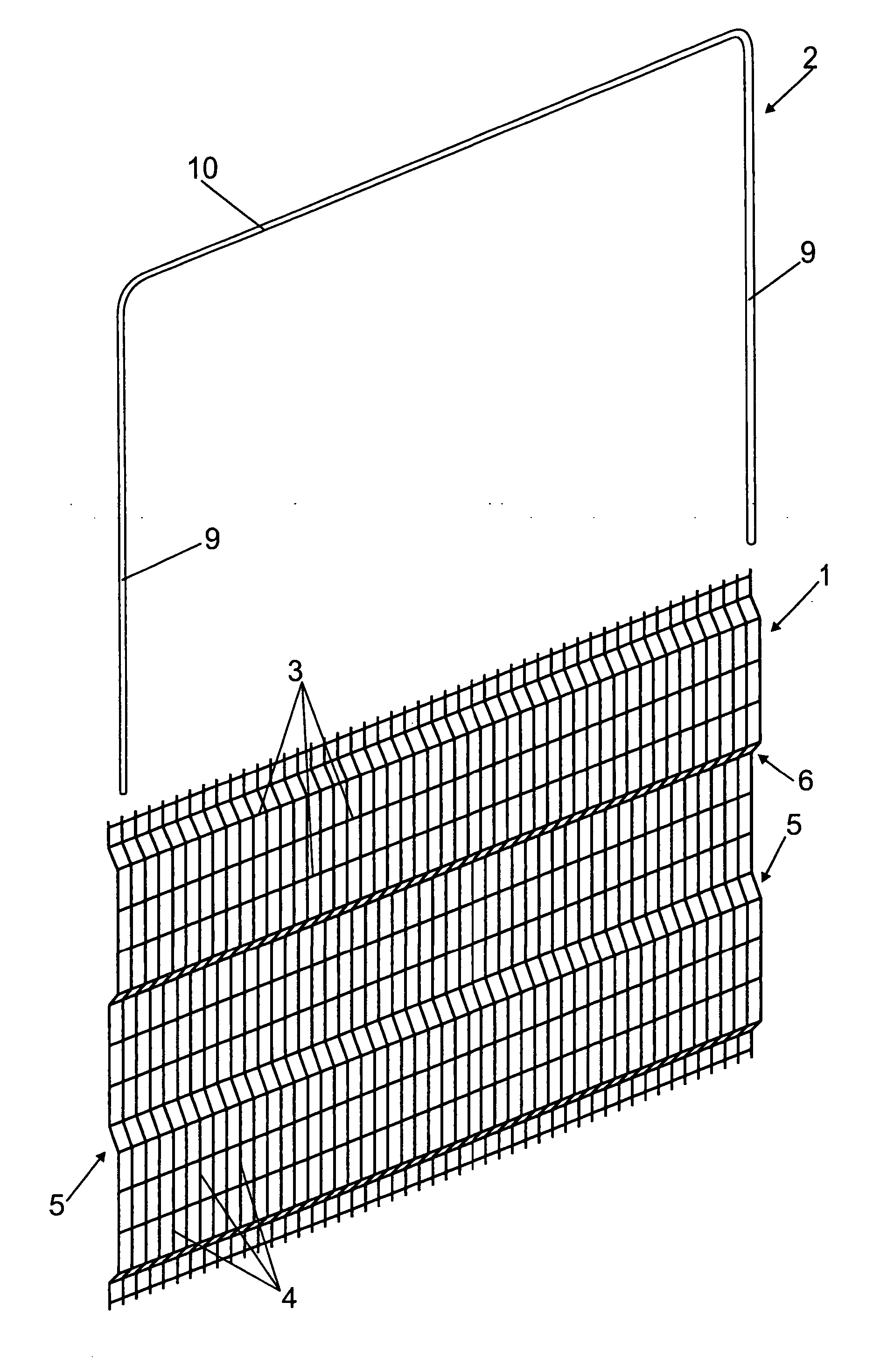

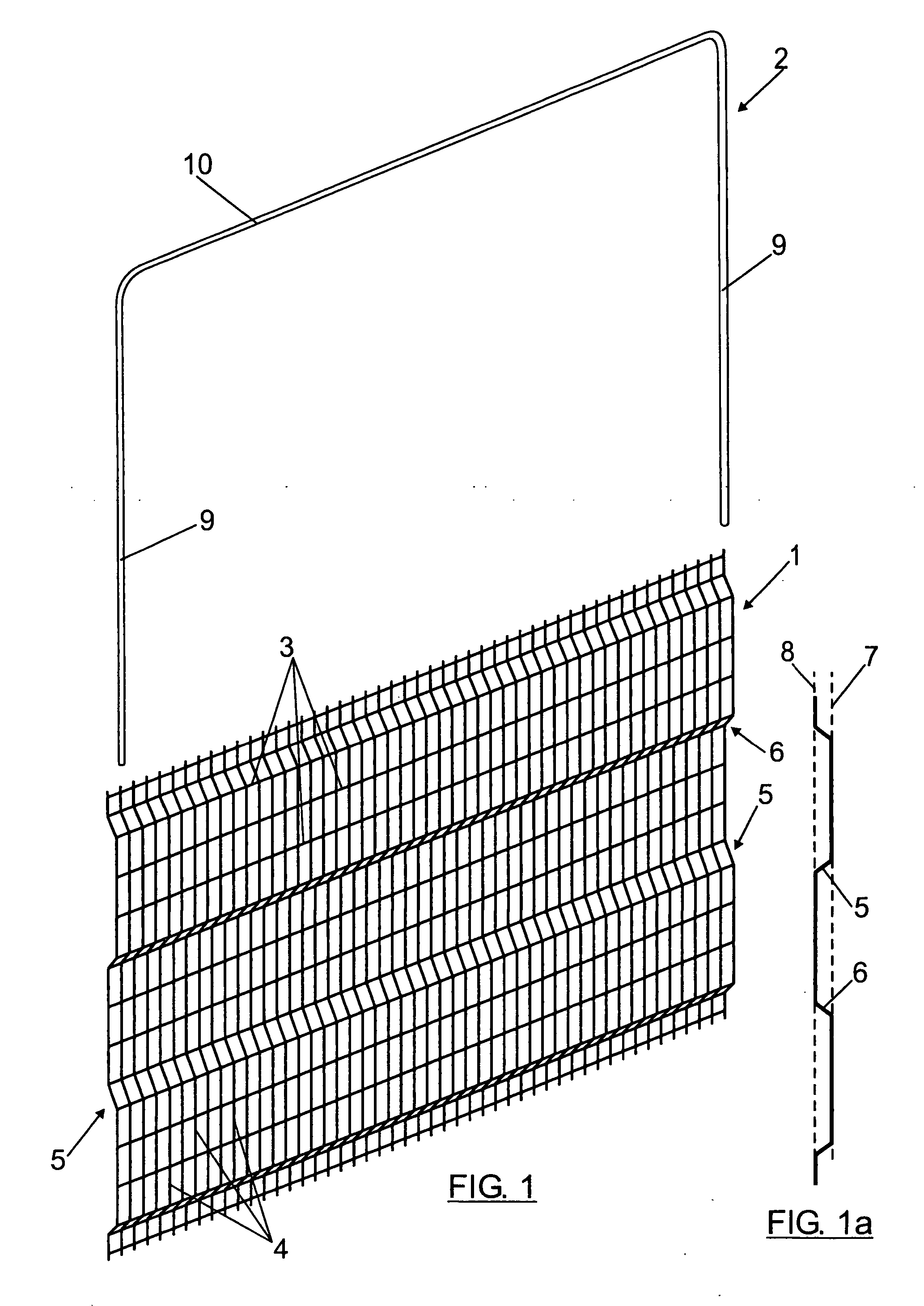

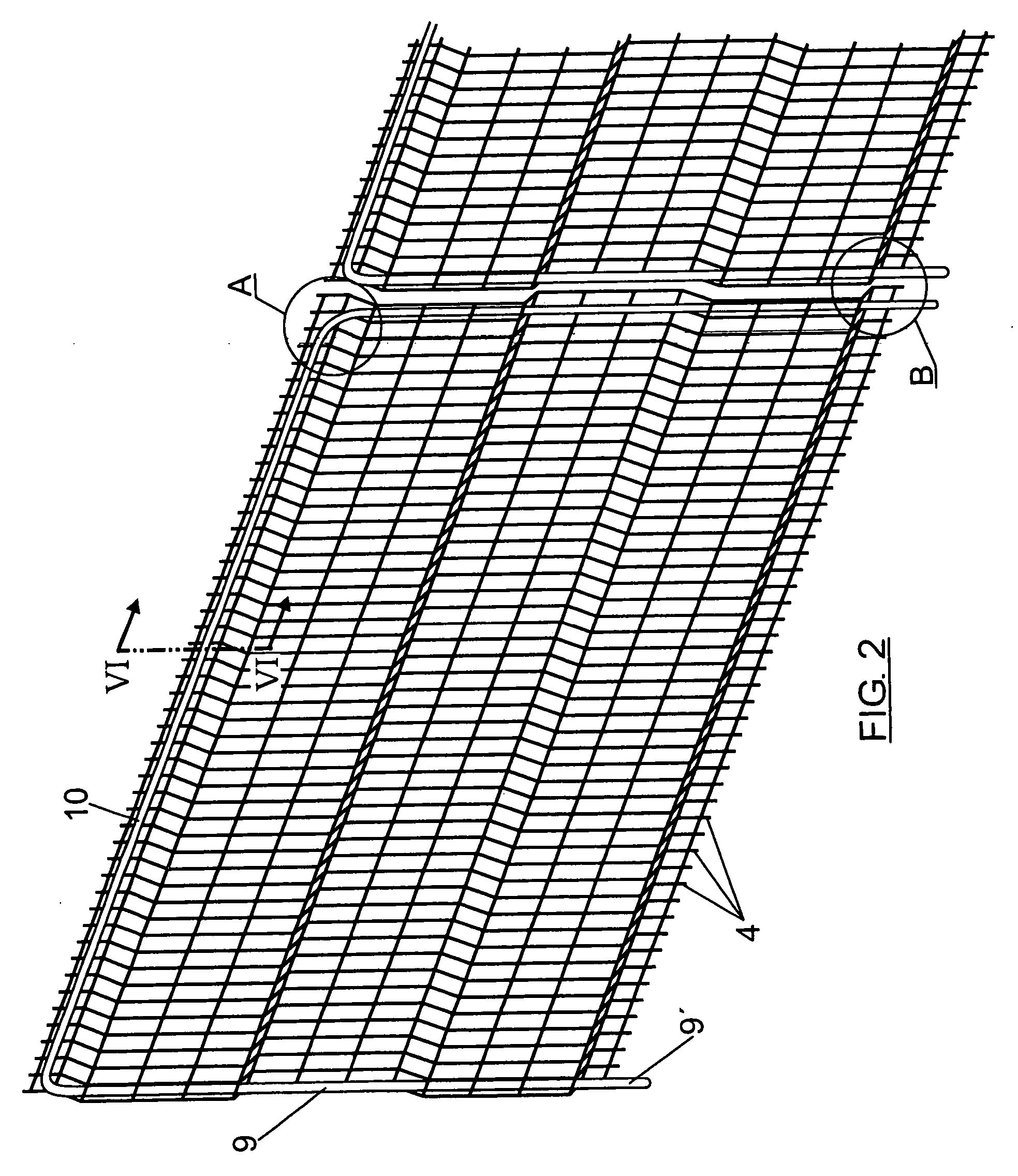

Arched reinforced fence

InactiveUS20070272908A1Increased resistance torqueIncrease in to bucklingFencingWire networkPalisadeSide branch

The invention relates to an arched reinforced fence, formed by mesh panels of metal rods, with vertical formations, and by anchoring elements made up of a U-shaped rod or profile, the side branches of which are introduced between the horizontal rods located in different planes, whereas the central branch runs along one of the longitudinal edges of the panel, the side branches projecting from the opposite longitudinal edge of the panel.

Owner:SOTILLOS JORGE ANTONIO SAURA

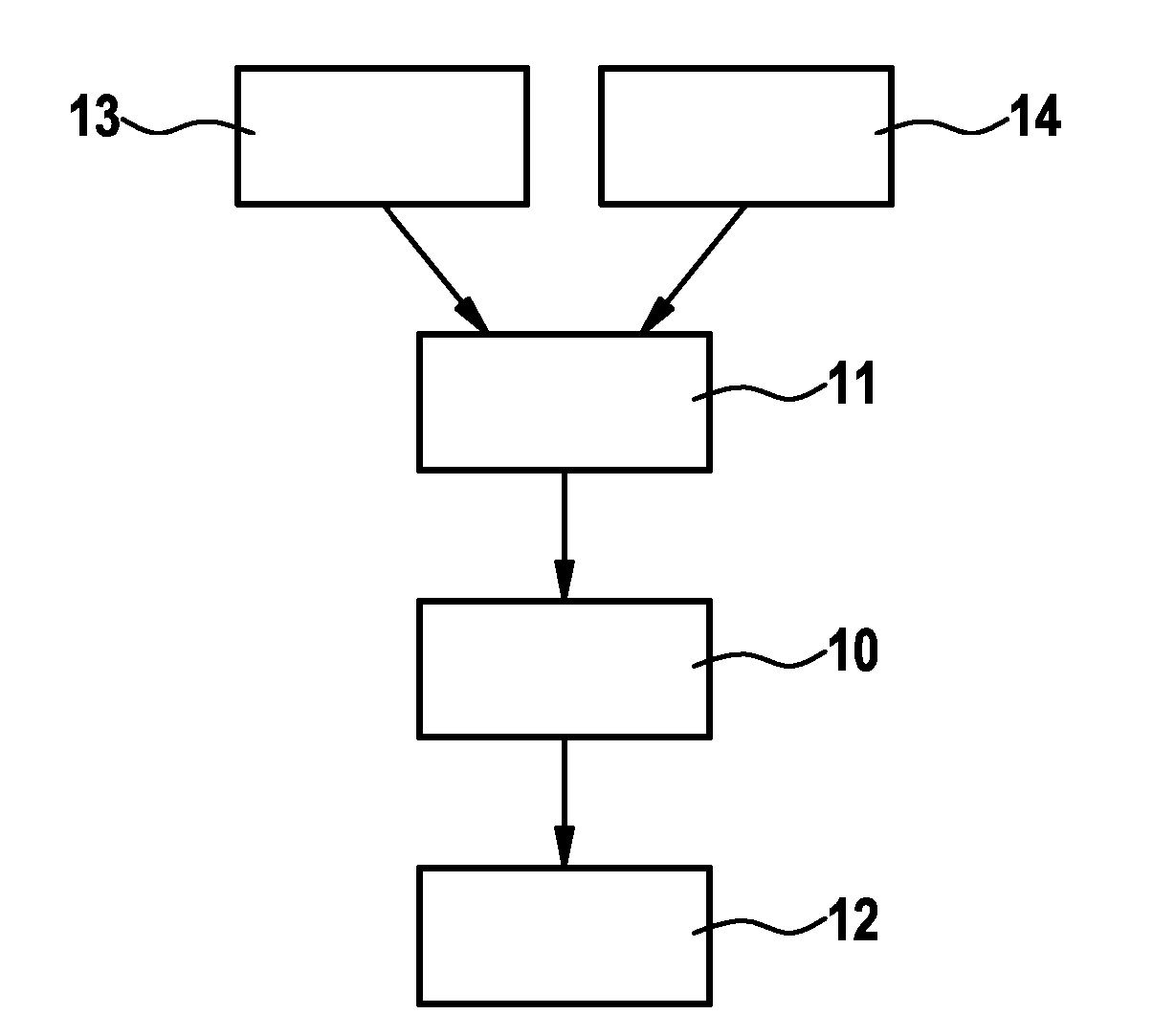

Method for regulating a drag torque of a motor vehicle driven by an electric motor in consideration of the friction coefficient present on the roadway surface, and device for carrying out such a method

InactiveCN102066174AReduced tendency to lockPrevent slippingHybrid vehiclesElectrodynamic brake systemsDrag torqueControl theory

The invention relates to a method for regulating a drag torque of a motor vehicle driven by an electric motor, wherein a regulating device influences the drag torque with a corresponding change in the position of the accelerator pedal, wherein a sensor device senses a tire on a roadway surface on which the motor vehicle is present and provides the information to a computer, wherein the computer prompts the regulating device to adjust the drag torque as a function of the friction coefficient. The invention further relates to a device having means suitable for carrying out such a method.

Owner:ROBERT BOSCH GMBH

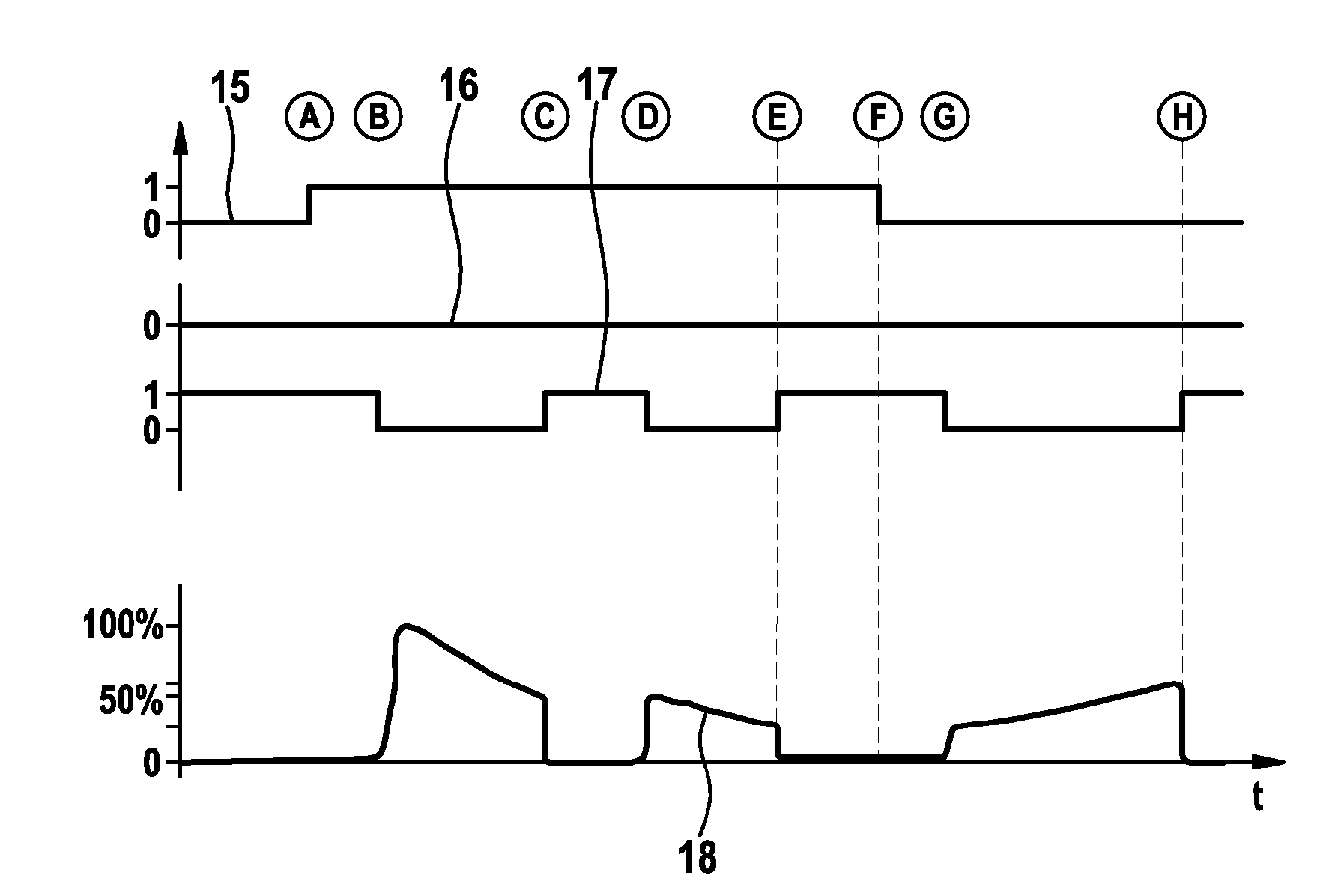

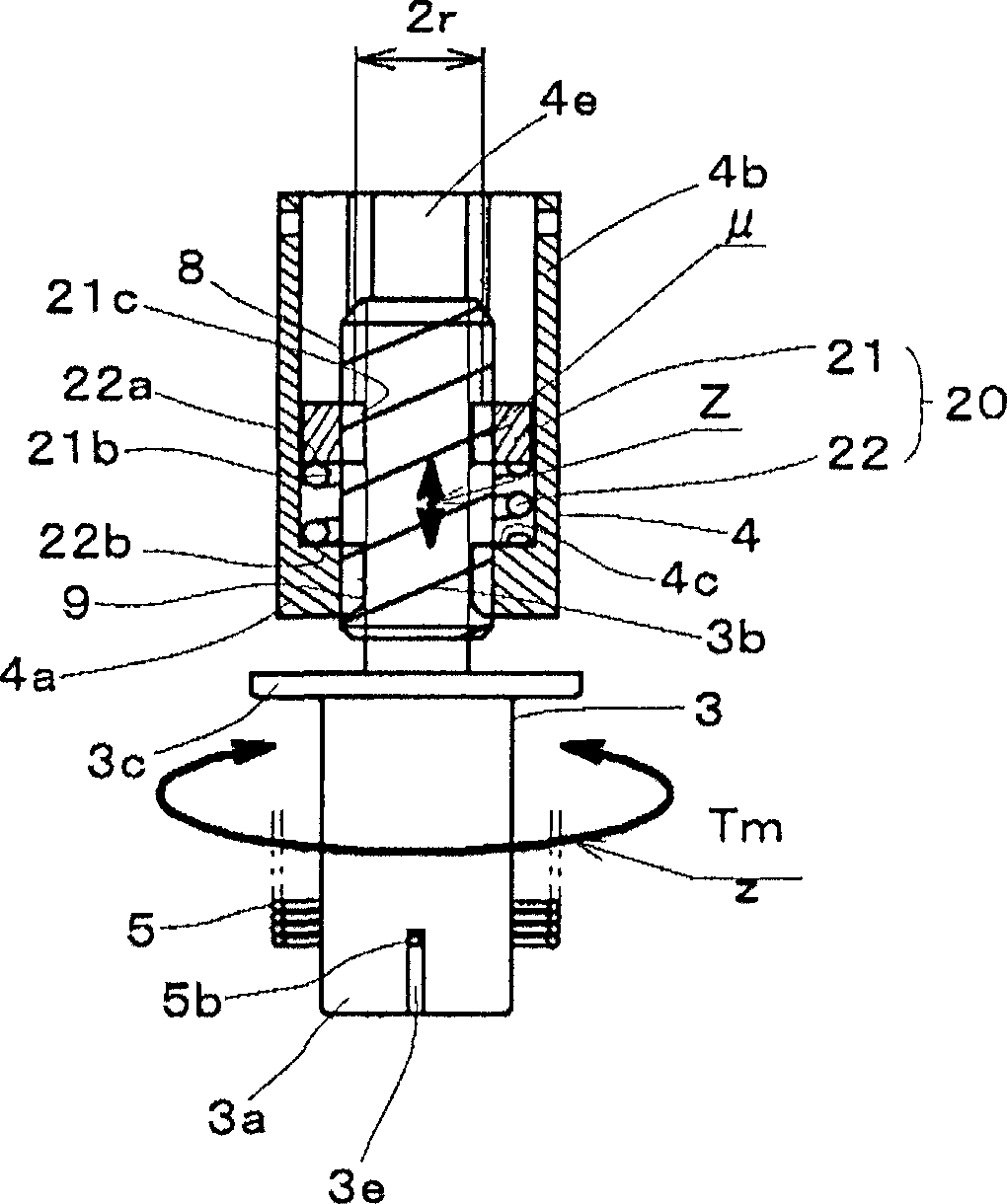

Tensioner

InactiveCN1829871AReduce the forward and backward amplitudeIncrease propulsionGearingDrag torqueTorsion spring

The present invention provides a tensioner capable of stably suppressing the amplitude of both extension and return operations in a wide range of engine speeds even against a strong input vibration load from the engine. The first shaft member (3) and the second shaft member (4) screwed together by the threaded parts (8, 9) are accommodated in the housing (2), and the first shaft member (3) is forced to A torsion spring (5) that rotates in one direction. The rotation of the second shaft part (4) is restricted, and the rotational force of the torsion spring (5) is converted into the propulsion force of the second shaft part (4). Between the first shaft member (3) and the second shaft member (4), there is a resistance that always generates a resistance moment against the external input load input to the second shaft member (4) during both the extension operation and the return operation. The torque adding mechanism (20) can suppress the vibration amplitude of the second shaft member (4) extremely finely and stably.

Owner:NHK SPRING CO LTD

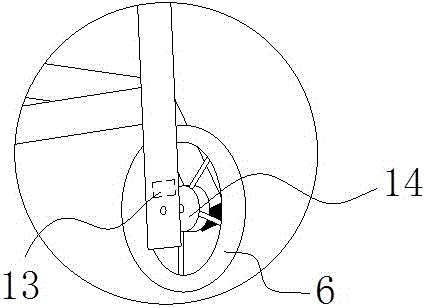

Turnover prevention walking aid

InactiveCN106726375AIncreased resistance torqueReduce risk of tipping overWalking aidsEngineeringBack support

The invention relates to the field of rehabilitation assistance devices, in particular to a turnover prevention walking aid. The turnover prevention walking aid comprises a support. The support comprises two front supporting rods, two back supporting rods, a front gear lever and a grip. The bottoms of the front supporting rods and the bottoms of the back supporting rods are provided with trundles. Side reinforcing ribs are fixedly arranged between the bottoms of the front supporting rod and the back supporting rod on the same side. Counter weights are arranged on the side reinforcing ribs. According to the turnover prevention walking aid, the dead weight of the support is increased, and the center of gravity is lowered, so that the resisting moment generated when the support is likely to turn over is effectively increased, the overall stability of the support is improved effectively, the trip reliability of a user is improved through the support, and the turnover prevention walking aid is suitable for the old, some cripple patients and the disabled.

Owner:DEYANG LIJIU YUNZHI KNOWLEDGE PROPERTY OPERATIONS CO LTD

Method for producing a printed product

ActiveUS8556789B2Increased resistance torqueIncrease flexibilityMechanical working/deformationPaper/cardboard articlesPulp and paper industryGobio gobio obtusirostris

A method for producing a printed product in which a complete content of the printed product is printed sequentially in series on one or both sides along a paper web having a width based on a multiple of a width of a finished printed product, including cutting the paper web in a direction crosswise to a longitudinal direction of the paper web to produce a cut-off section having a length based on a multiple of a length of the finished printed product, folding the cut-off section at least once in the crosswise direction in a location based on the length of the finished product, and cutting one of the folded cut-off section subsequent to the folding or the paper web prior to the crosswise cutting, to form a plurality of partial webs each having a width based on the width of the finished printed product.

Owner:MULLER MARTINI HLDG

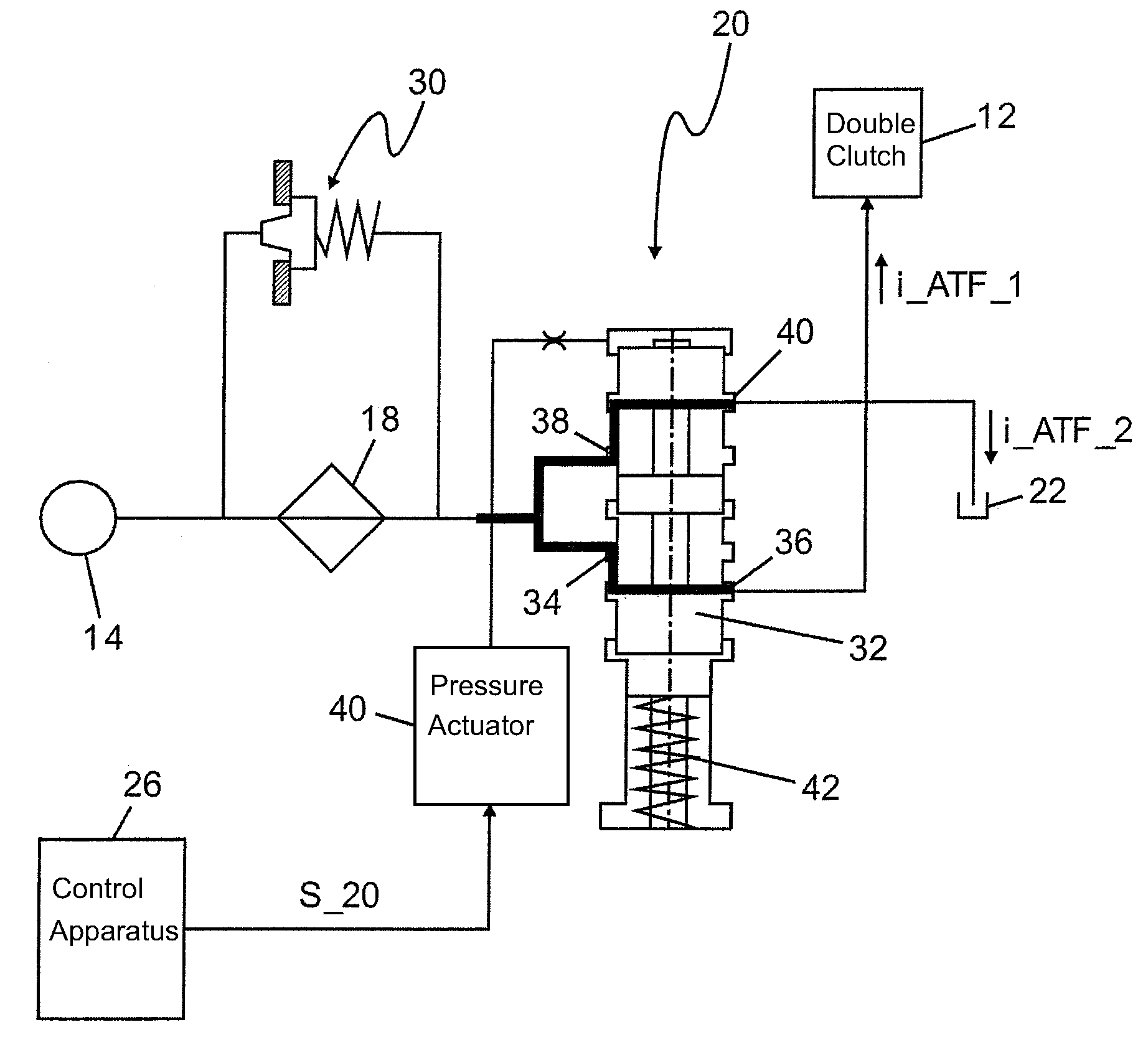

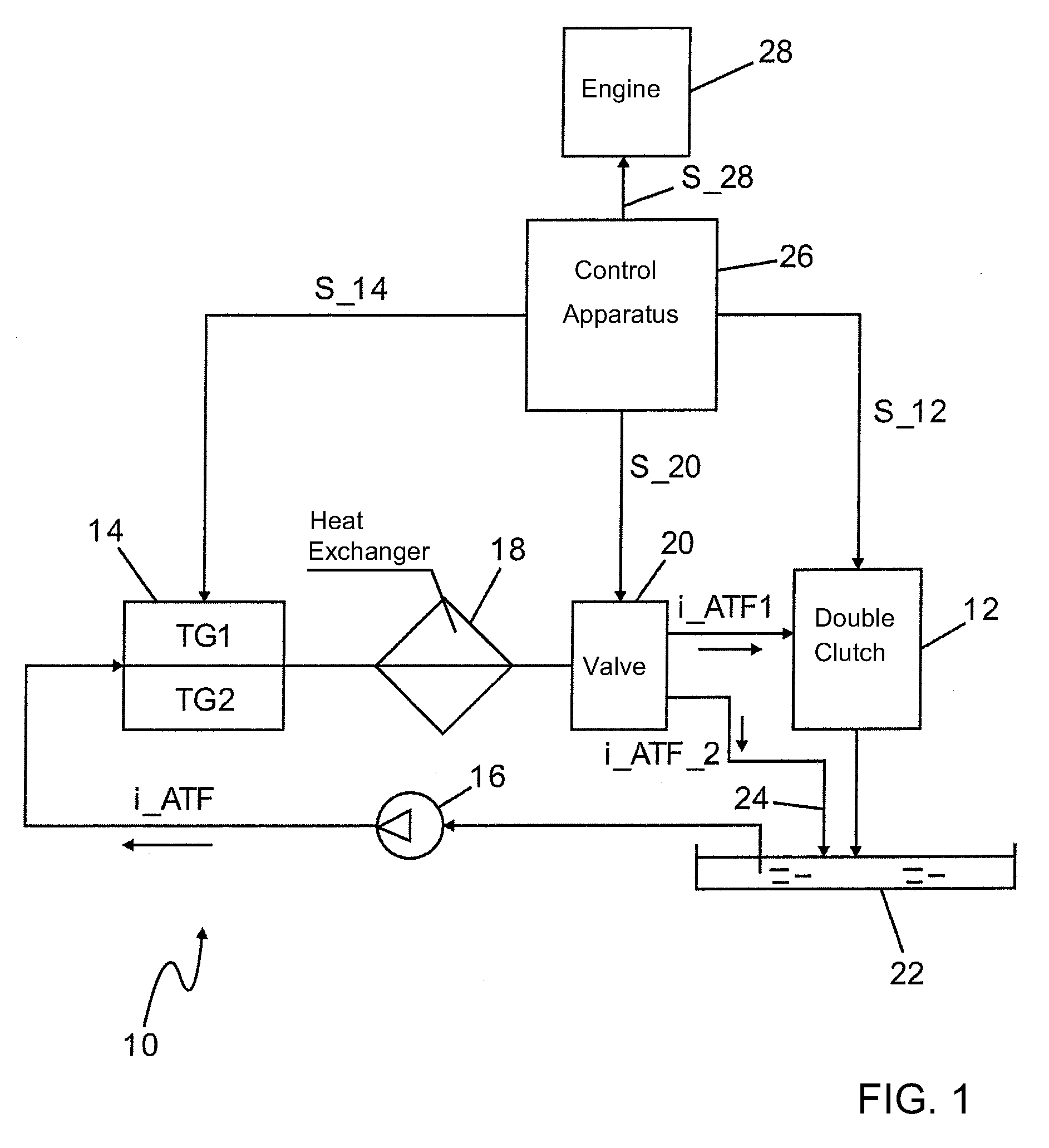

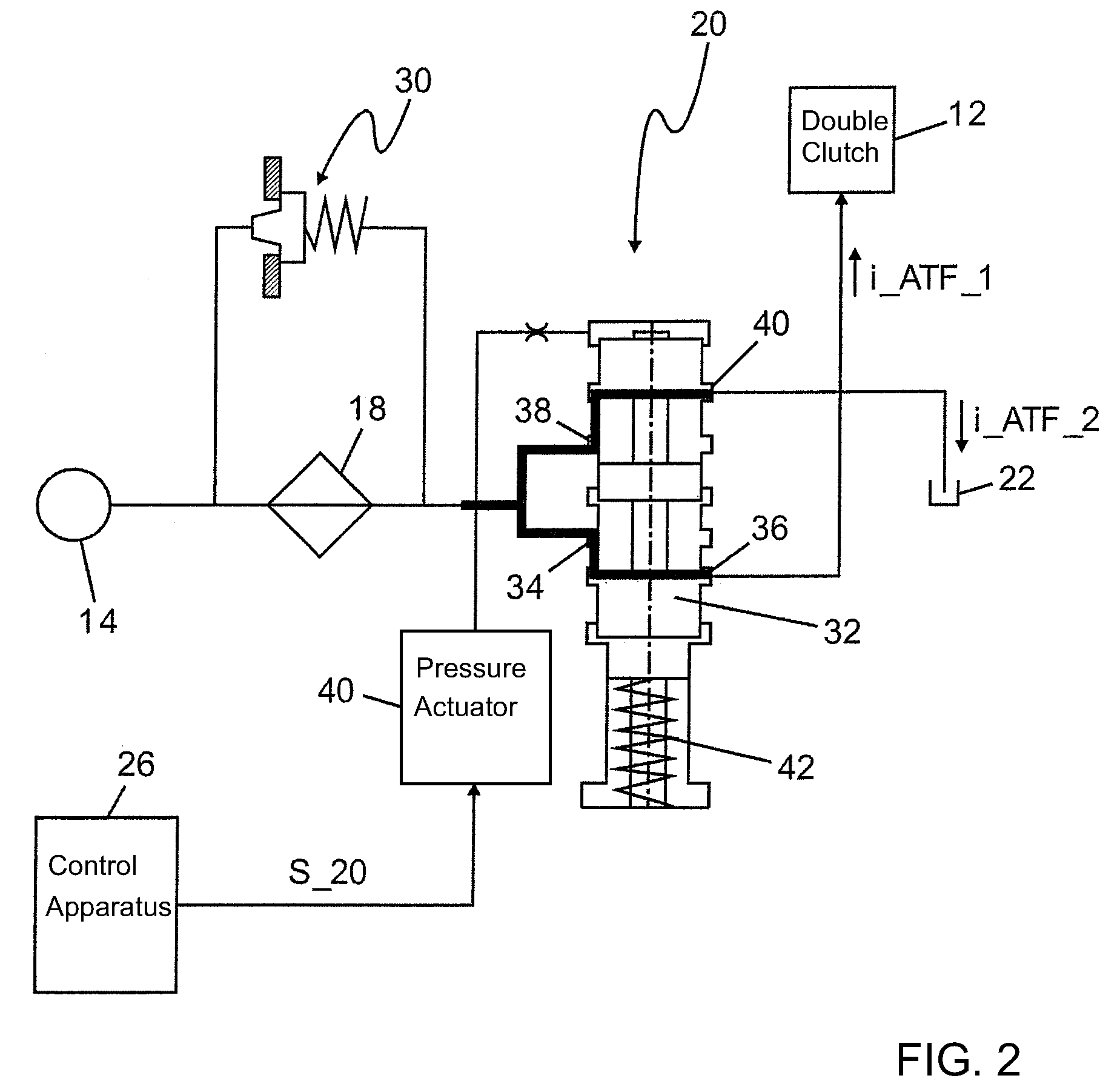

Hydraulic system of a clutch of a motor vehicle transmission

InactiveUS20090188767A1Reduces power effectiveIncreased resistance torqueFluid actuated clutchesGearing controlStream flowEngineering

A hydraulic system for a clutch has a pump conveying a hydraulic fluid stream via a heat exchanger to a controllable hydraulic valve which divides the hydraulic fluid stream into a first part stream and a second part stream. The first part stream flows to a reservoir via friction linings of the clutch and the second part stream flows to the reservoir via a hydraulic path bypassing the friction linings. The hydraulic system is set up for upgrading a cooling of the clutch by increasing the first part stream at the expense of the second part stream and for reducing the cooling of the clutch by increasing the second part stream. The system is set up for temporarily upgrading the cooling of the clutch in the event of a changeover of torque transfer from transfer via a first part transmission to transfer via a second part transmission of the transmission.

Owner:DR ING H C F PORSCHE AG

Wheelset for vehicles

PendingCN113677541ASimplify the maintenance processPrevent seepageShaftsRailway vehiclesControl theoryMechanical engineering

The invention relates to a wheelset for vehicles, particularly for rail vehicles, comprising a first wheel (1), a second wheel (2) and an axle (3), wherein the axle (3) comprises at least a first shaft portion (4), a second shaft portion (5) and a third shaft portion (6) which are connected to one another, wherein at least one shaft portion of the at least first shaft portion (4), the second shaft portion (5) and the third shaft portion (6) is designed as a hollow shaft which can be filled with a fluid, or at least comprises a cavity which can be filled with fluid. According to the invention, at least the first shaft portion (4) is detachably connected to the second shaft portion (5) to create advantageous construction conditions. This provides a wheelset system which can be flexibly designed and allows for component integrity monitoring.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

Brush cap

ActiveUS10517387B2Increase clamping forceLess elastically actingBrushesOther artistic work equipmentsPolymer scienceMedicine

Owner:SAVANT GMBH

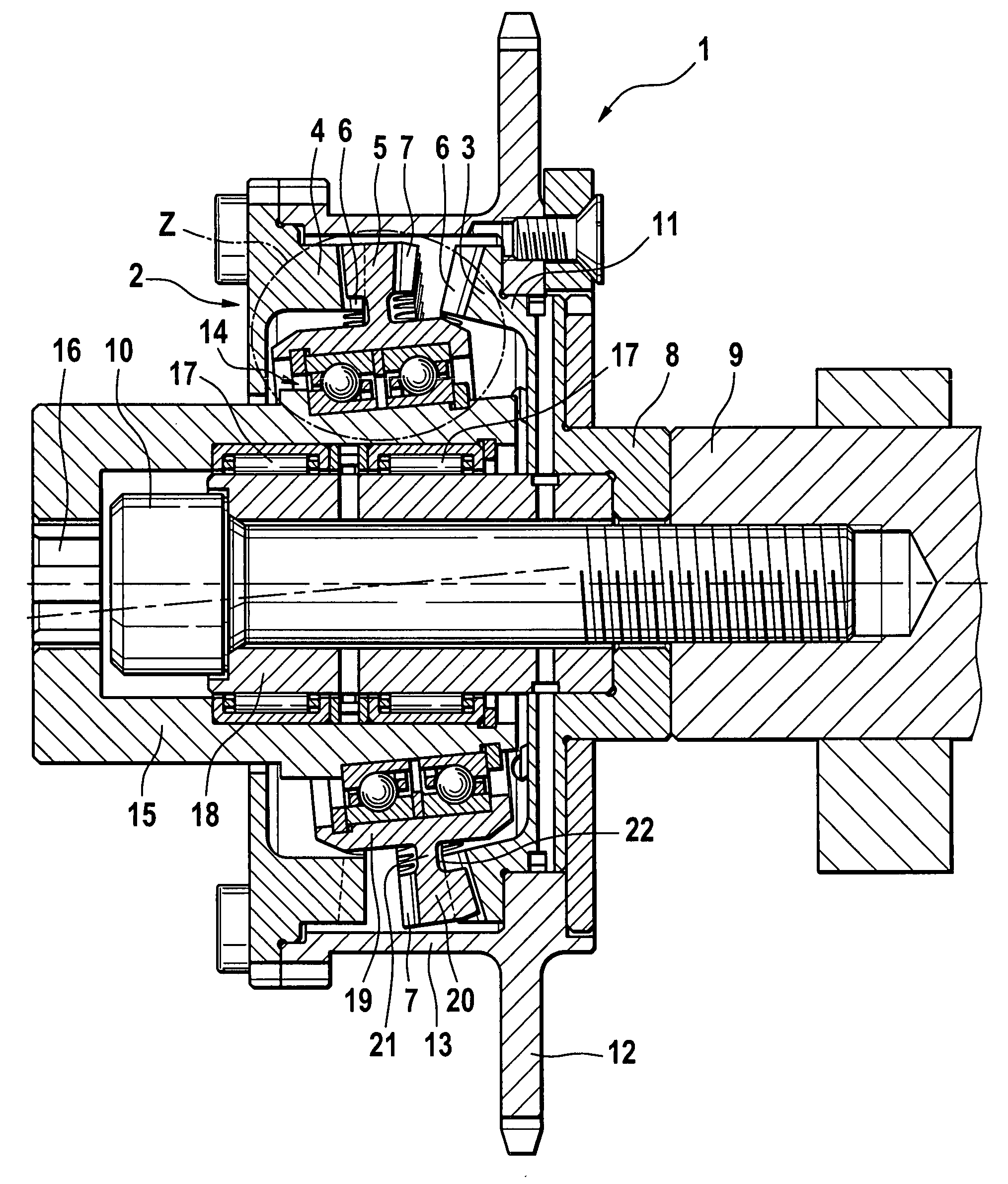

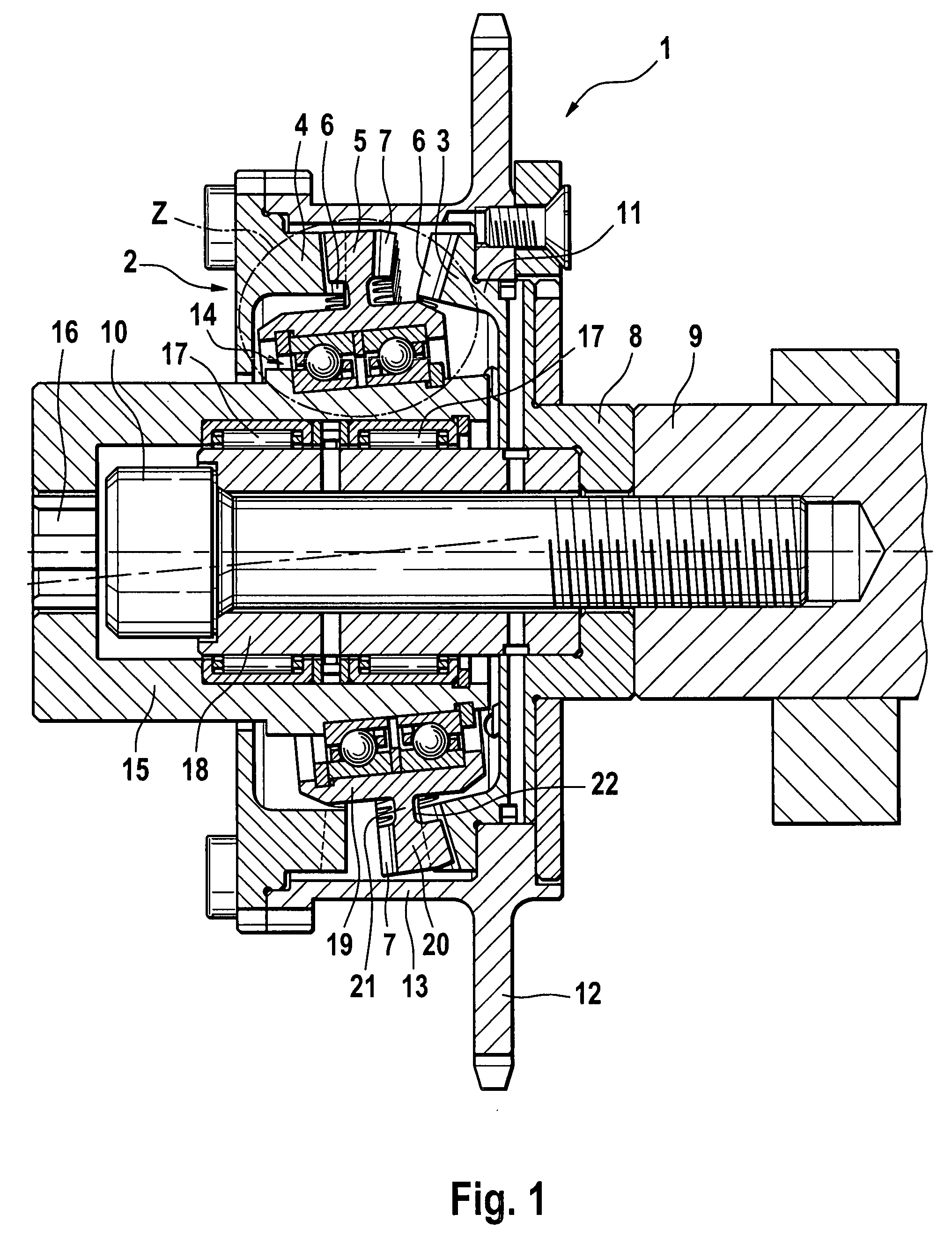

Transmission with Resistance Torque Control

InactiveUS20080153663A1Increased resistance torqueLimit movement of pistonToothed gearingsEngine controllersDrag torqueVariator

The transmission includes a minimal-orbiter gear complex and a single infinitely-variable rotary control device. The minimal orbiter includes only a control gear and an output gear interconnected by the different gearing portions of at least one cluster gear supported by an orbiting web responsive to an input drive provided by a primary engine. The rotary control device may be any kind of apparatus that is capable of providing resistance torque that can match the torque of the primary engine to slow and stop the control gear of the orbital complex. In a preferred embodiment disclosed, the rotary control device is a hydraulic jack machine having a drive shaft connected to an adjustable swash plate that provides primary control of the flow of fluid through the machine.

Owner:TORVEC INC

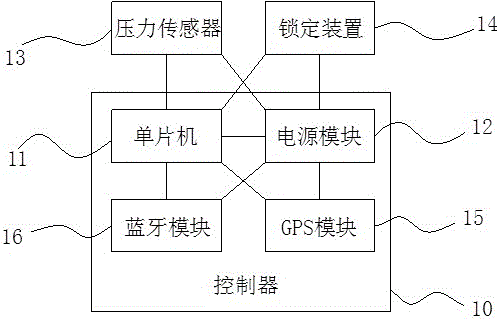

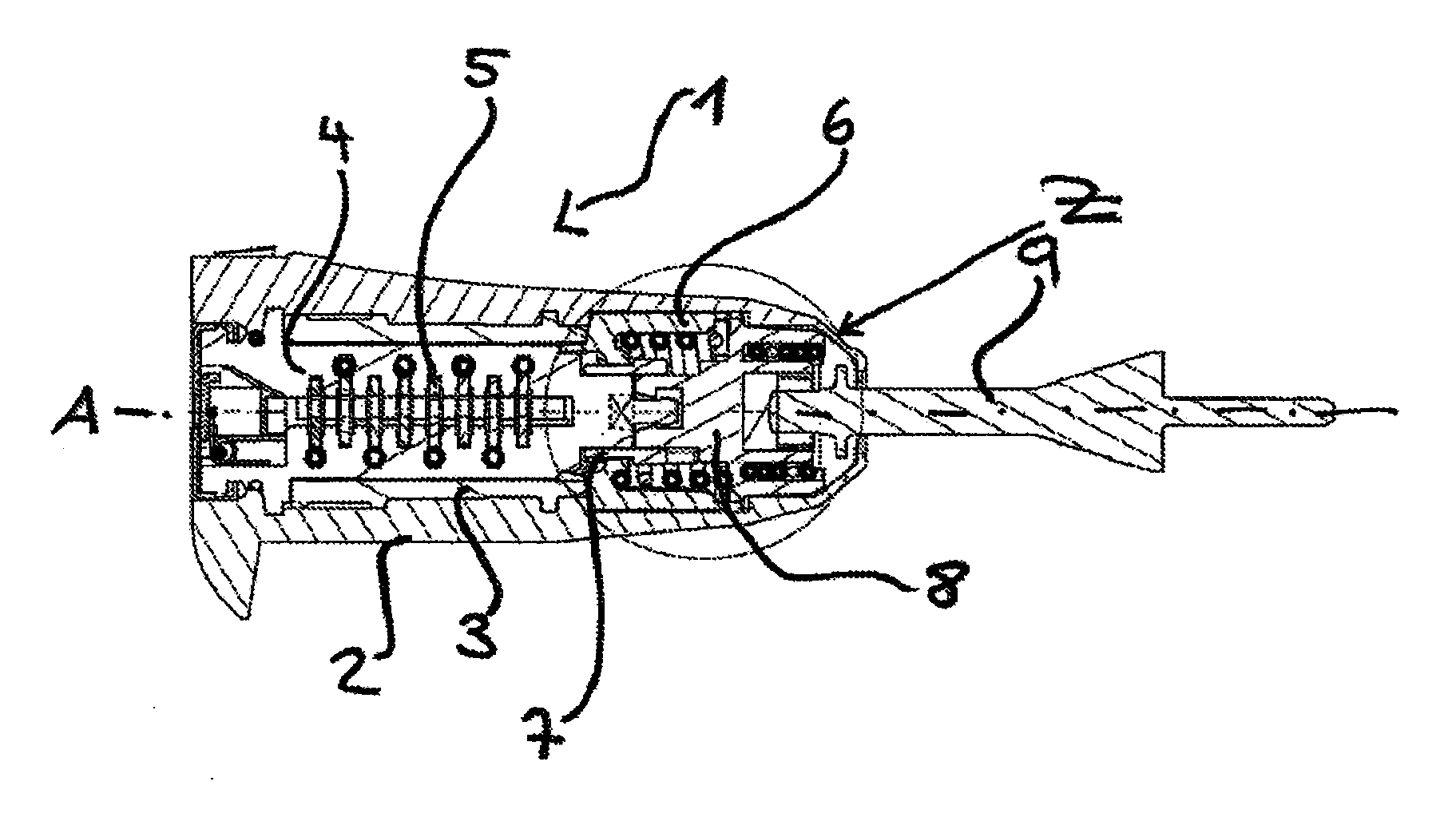

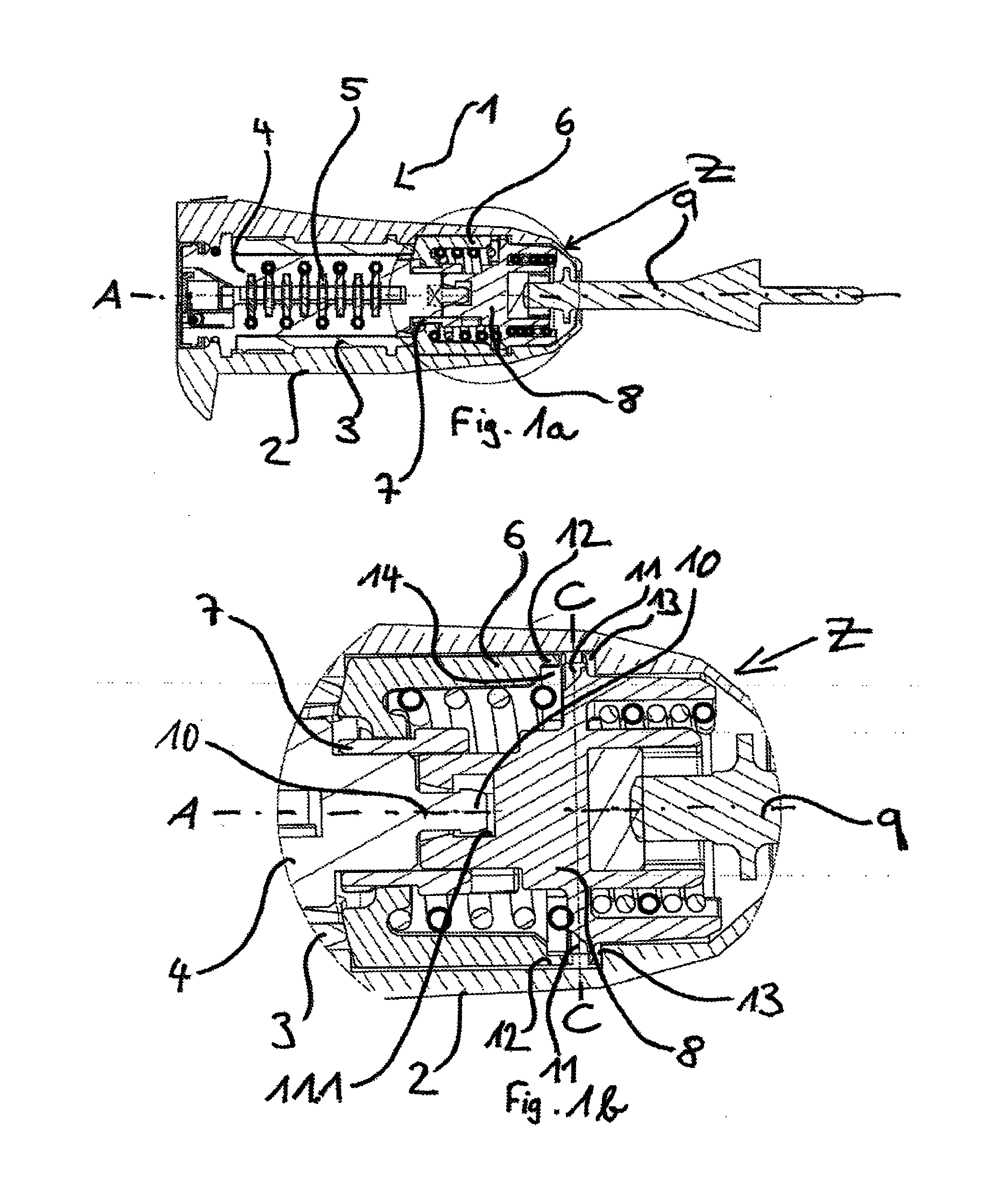

Lock Cylinder

InactiveUS20140137613A1Prevents forcible openingImprove securityLock casingsCylinder locksCouplingEngineering

A lock cylinder includes a housing, in which a sleeve having a cylinder core accommodated therein is rotatably supported. The cylinder core has spring-loaded tumblers forming a form closure with recesses arranged in the sleeve when a key engaging the tumblers is removed. Inside the housing, the sleeve is coupled to a coupling element by means of a disengaging sleeve. The coupling element is supported inside the housingand connected to a bearing in a rotationally-fixed manner. The bearing supports an output element. At least one of the sleeve and the coupling element forms a form closure with the bearing to block the rotation of the output element if an improper object is used in operative connection with the cylinder core.

Owner:HUF HULSBECK & FURST GMBH & CO KG

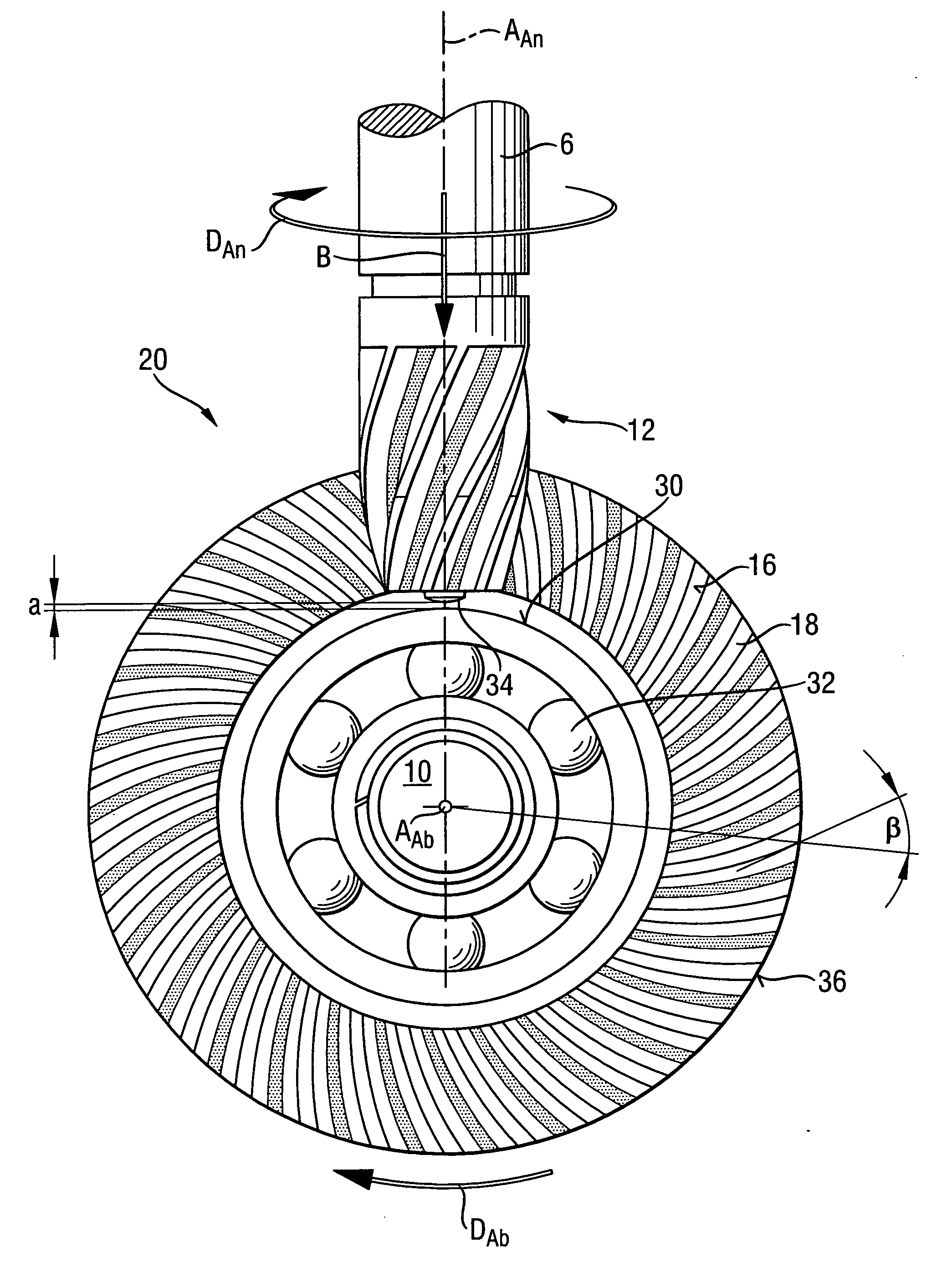

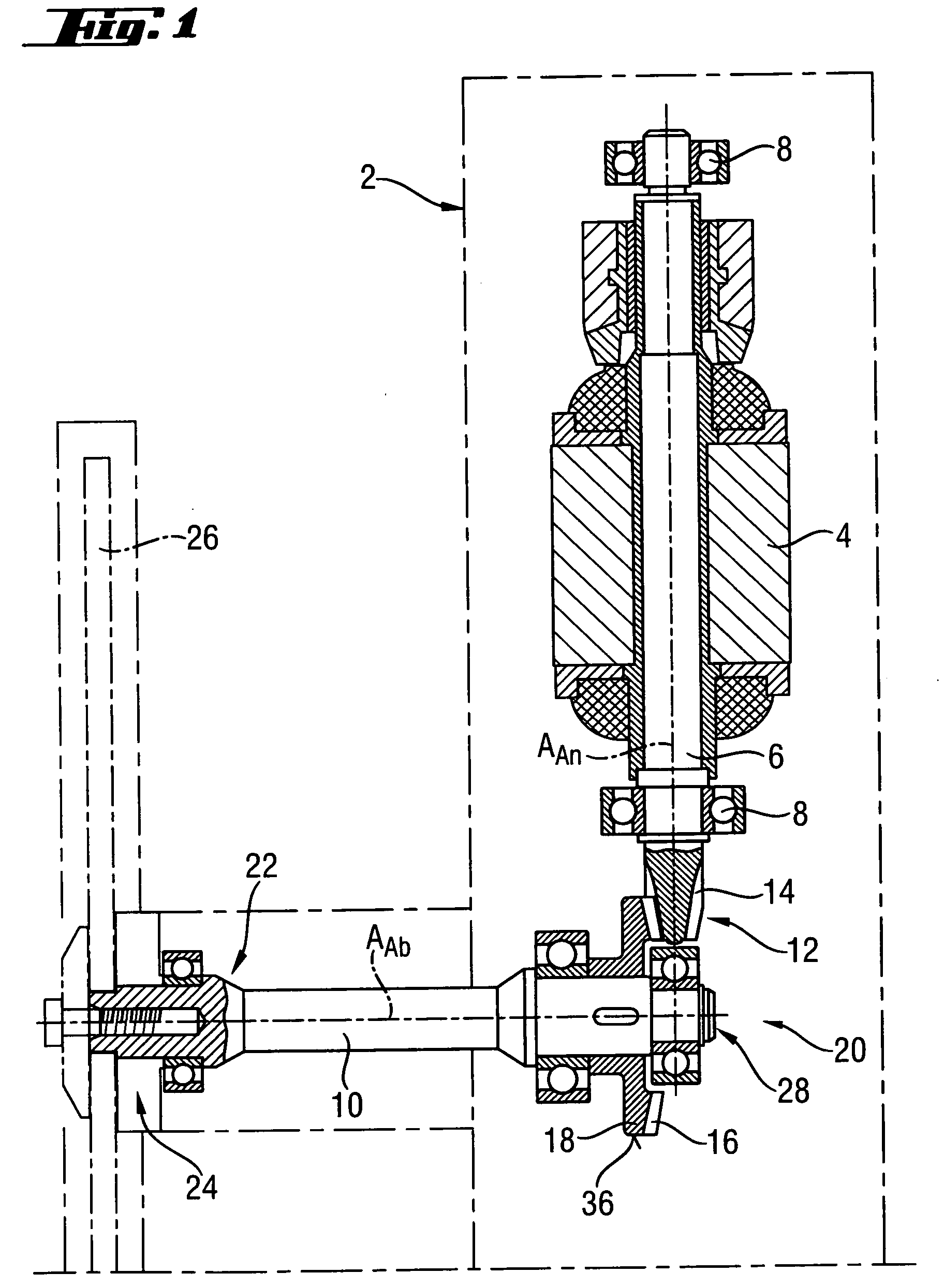

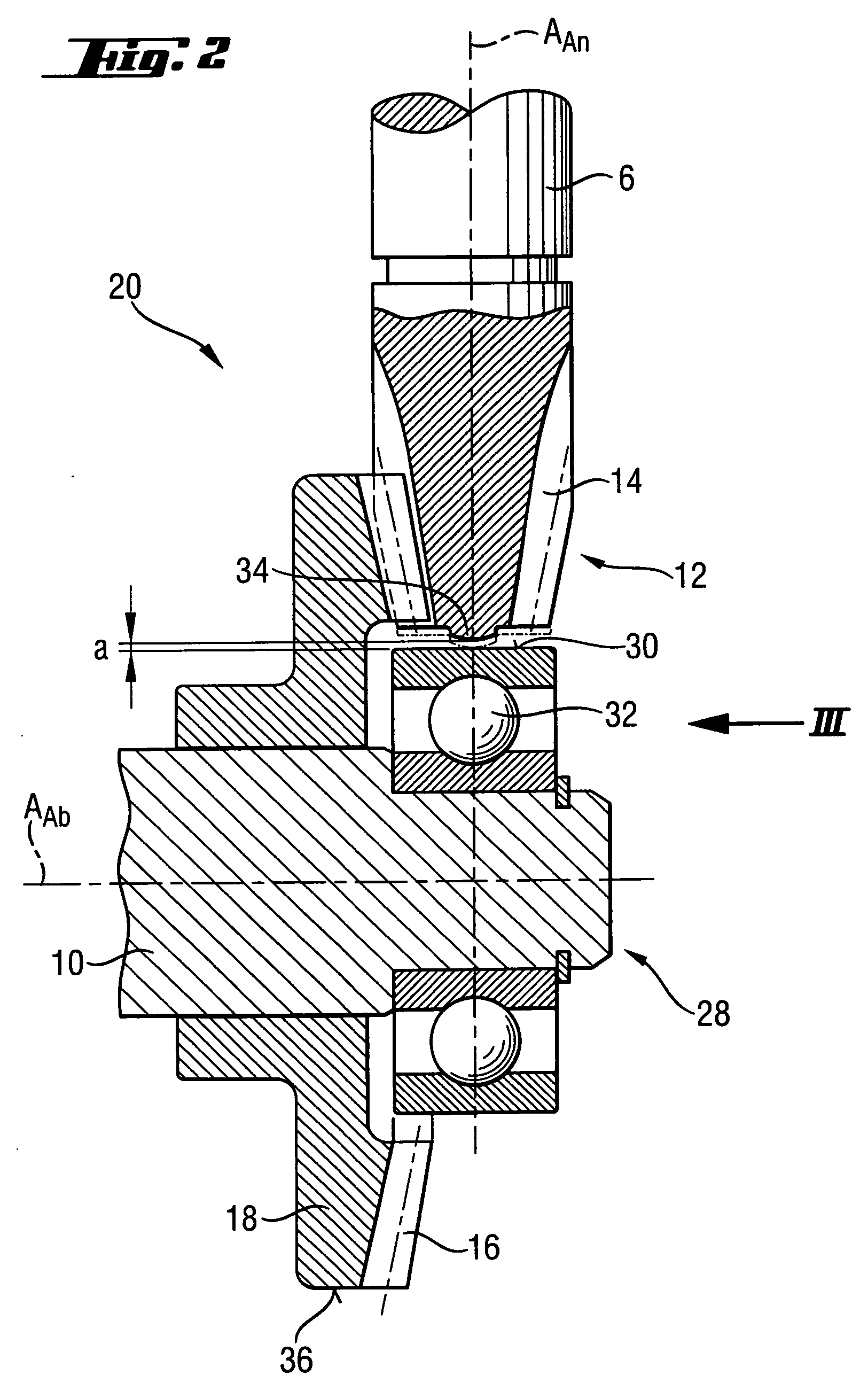

Hand-held power tool with angle drive

InactiveUS20070068299A1High degree of quietnessMinimal backlashMetal sawing devicesToothed gearingsAxial displacementMotor drive

A hand-held power tool (2) includes an angle drive (20) for connecting the motor-driven driving shaft (6) and the driven shaft (10) connected with a tooth holder (24) for joint rotation therewith, and having drive toothing (14) provided on the drive shaft (6) and driven toothing (16) provided on the driven shaft and cooperating with the drive toothing (14) for driving the driven shaft (10) in the driven direction (DAb) in response to the drive shaft (6) being driven in the drive direction (DAn), with the driven toothing (16) being inclined over its circumference (36) in a direction opposite the driven direction (DAb), and with the driven shaft (10) having an axial stop (30) for limiting an axial displacement backlash of the drive shaft (6) relative to the driven shaft (10).

Owner:HILTI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com