Hedge trimmer

A technology of hedge trimmers and cutting tools, which is applied in the field of hedge trimmers, can solve the problems of heavy hedge trimmers, and achieve the effect of light weight and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

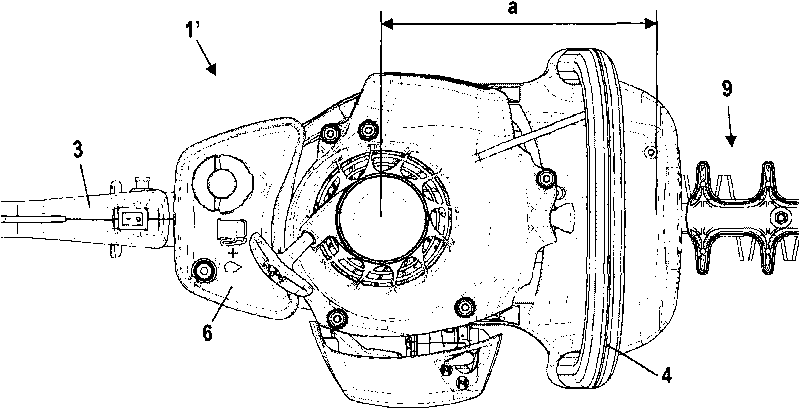

[0031] figure 1 A hedge trimmer 1' according to the prior art is shown. The hedge trimmer 1' has a rear handle 3 with a knife unit 9 on the side opposite the motor housing. A handle tube 4 is arranged on the side facing away from the rear handle 3 . A fuel tank 6 is provided between the rear handle 3 and the motor housing. The internal combustion engine of the hedge trimmer 1' faces the handle 3 with the crankcase, and faces the cutter device 9 with the cylinder. The distance a between the axis of rotation 24 of the crankshaft and the tool arrangement 9 is therefore relatively large.

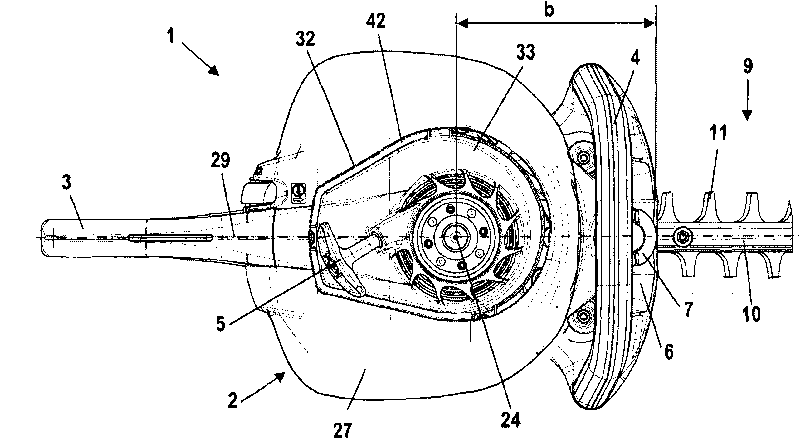

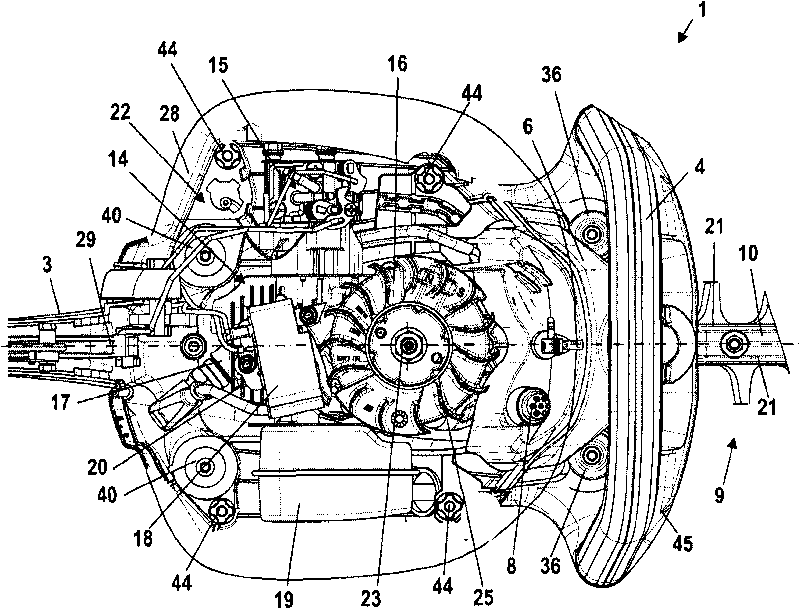

[0032] exist figure 2 The shown hedge trimmer 1 according to the invention has a handle housing 2 on which a rear handle 3 and a handle tube 4 are arranged for guiding the hedge trimmer 1 . On the side of the handle housing 2 facing away from the rear handle 3 a knife device 9 projects forward. The tool device 9 has a guide 10 and two tool holders, wherein the first tool holder 11 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com