Rotor of a hammer crusher

A technology of hammer crusher and rotor, which is applied in the direction of grain processing, etc., to achieve the effect of high performance and high transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

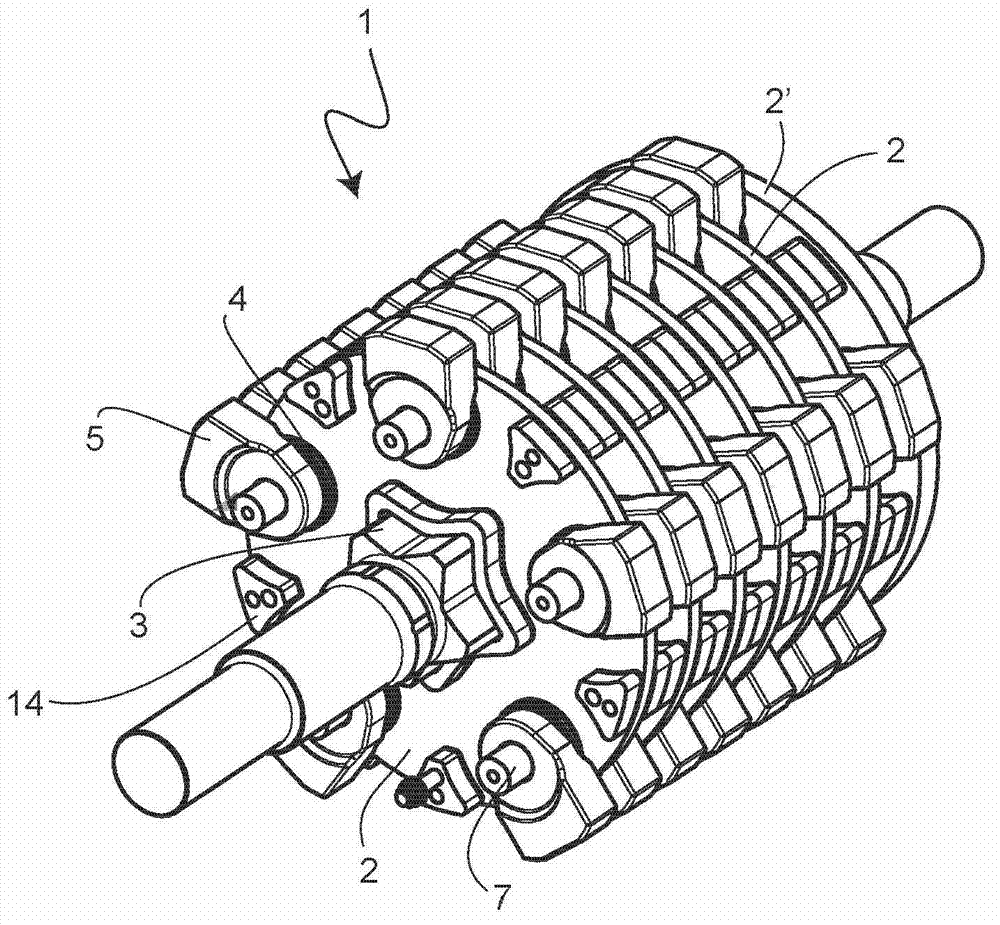

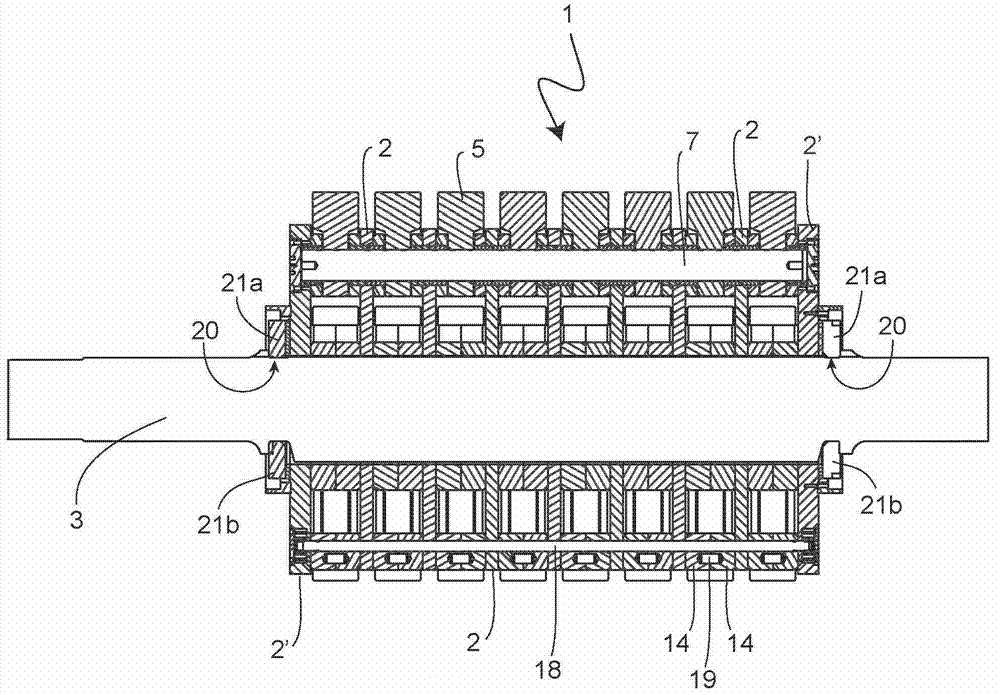

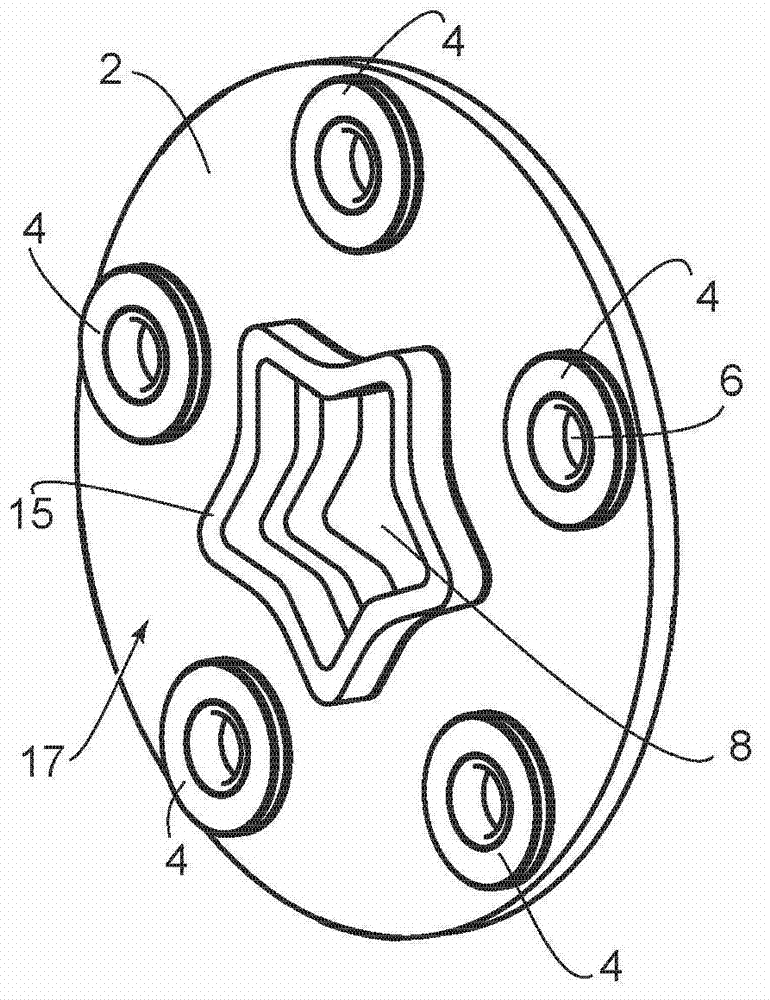

[0028] The rotor of the hammer crusher, marked with reference number 1 in general, is in figure 1 Chinese and Israeli stereograms and in figure 2 Shown in cross-sectional view. The rotor 1 is a part of a single-rotor or multi-rotor hammer crusher or vibratory crusher. The rotor 1 basically has a plurality of circular rotor disks 2 with a small axial width, wherein, for reasons of overview, in figure 1 with figure 2Only three rotor disks 2 are provided with reference numerals. The rotor 1 according to the invention has at least more than two rotor disks 2 . The rotor disks 2 are inserted on the shaft 3 in a rotationally fixed manner. Between two adjacent rotor disks 2 , a plurality of striking hammers 5 are arranged evenly distributed over the circumference of the rotor disks 2 , and are mounted in a freely rotatable manner. as especially in image 3 with Figure 4 It can be seen from the figure that the respective rotor disk 2 has a plurality of through-holes 6 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com