Protective boot for universal joint

A bellows and matrix technology, applied in the field of bellows, can solve the problem that the bellows cannot satisfactorily solve the load moment and the like, and achieve the effects of improving axial rigidity and resistance torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

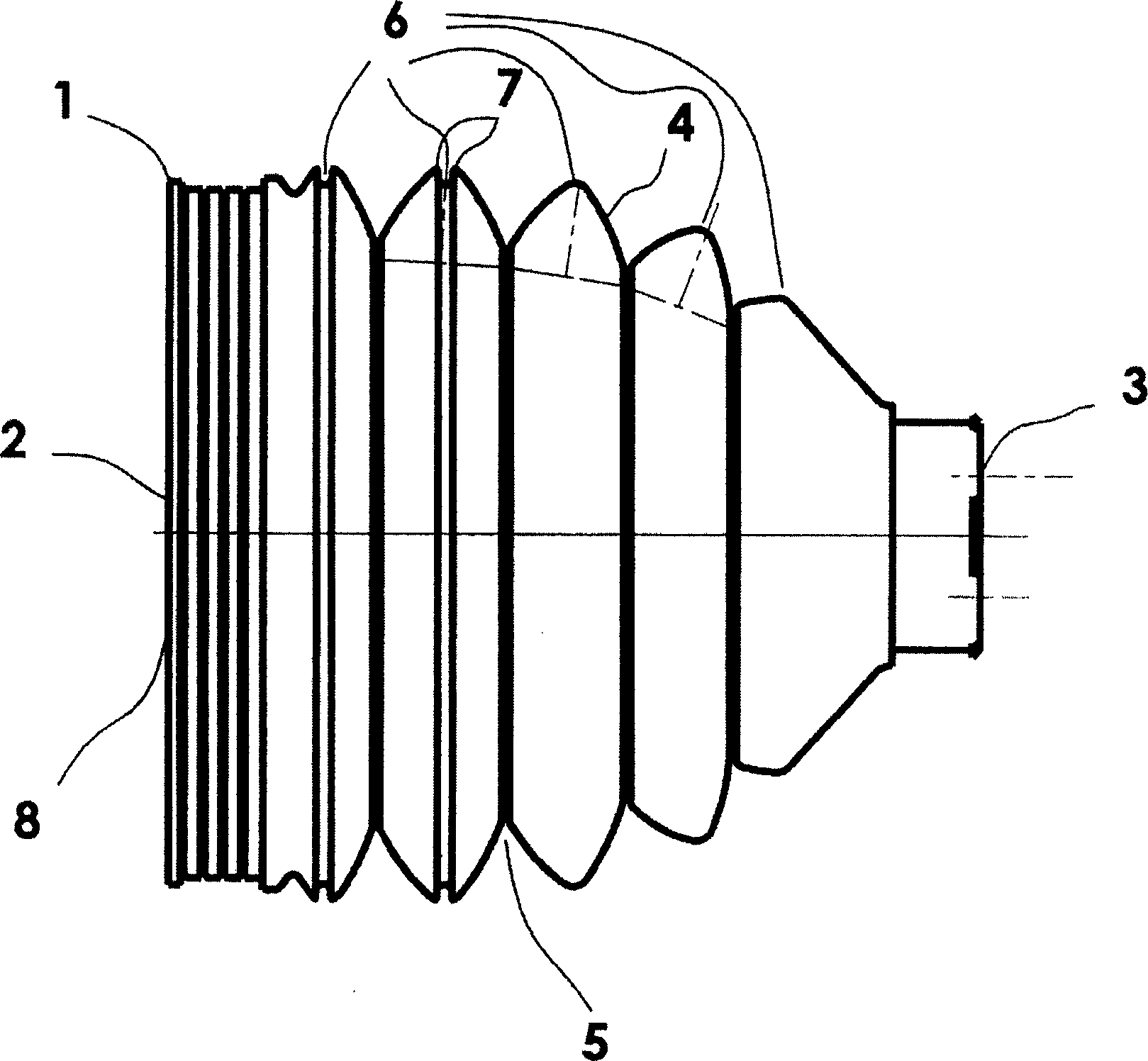

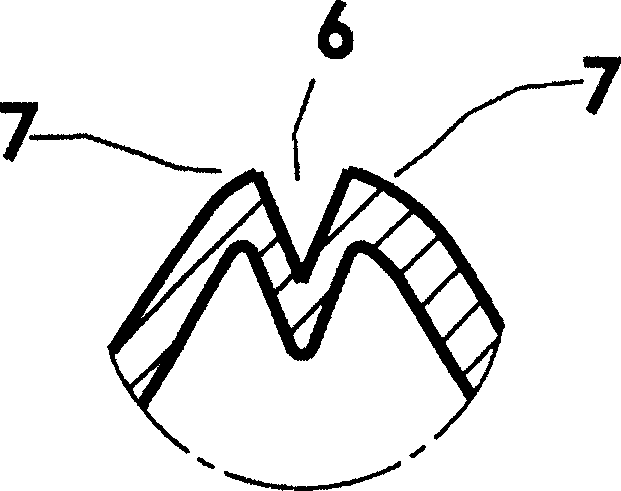

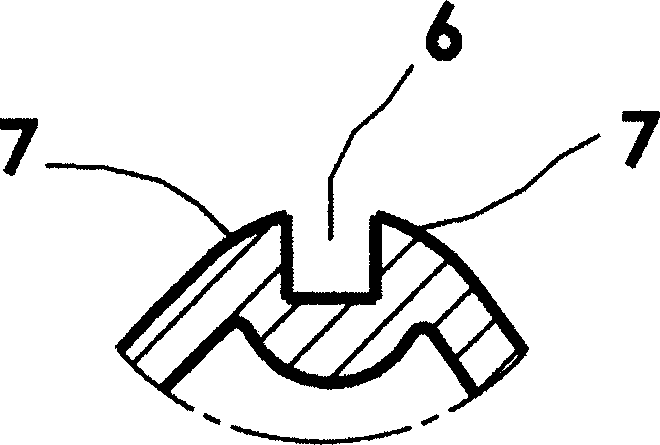

[0038] figure 1 Represents a bellows having a base body 1 with a first end 2 and a second end 3, wherein the ends 2, 3 are movable relative to each other, forming a plurality of circumferential The arches 4 are spaced apart from each other by first indentations 5 and a second indentation 6 is formed on at least one of the arches 4 . In this case, the width of the second undercut 6 has a value at most corresponding to the value of its depth. The second constriction 6 is surrounded by two ribs 7 . The first indentation 5 and the second indentation 6 are arranged concentrically to the axis passing through the ends 2 , 3 . The second indentation 6 is formed in the outermost peripheral region of the dome 4 .

[0039] The base body 1 is designed to be rotationally symmetrical. The ends 2 , 3 are designed as ends 2 , 3 of an axial through-hole 8 on the base body 1 . The base body 1 is designed at least partially in the shape of a truncated cone.

[0040] figure 2 Indicates a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com