Injection units for molding machines

A technology of injection unit and molding machine, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as difficulty in adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

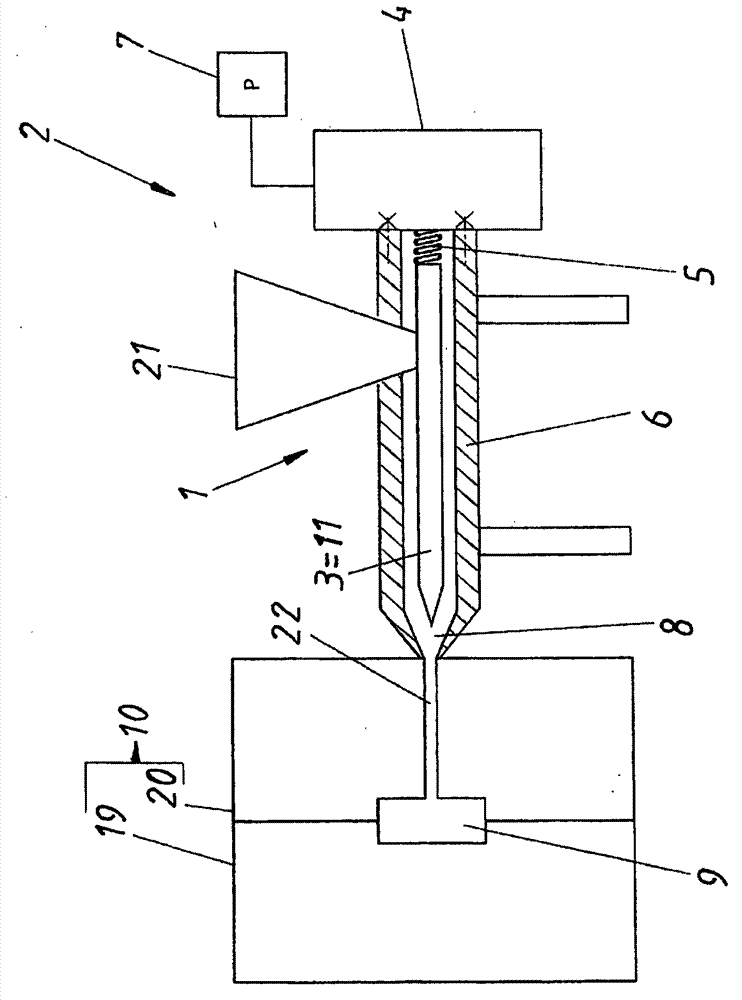

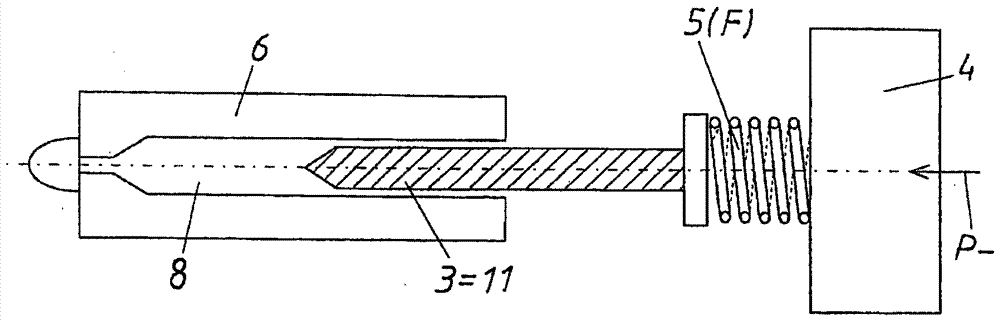

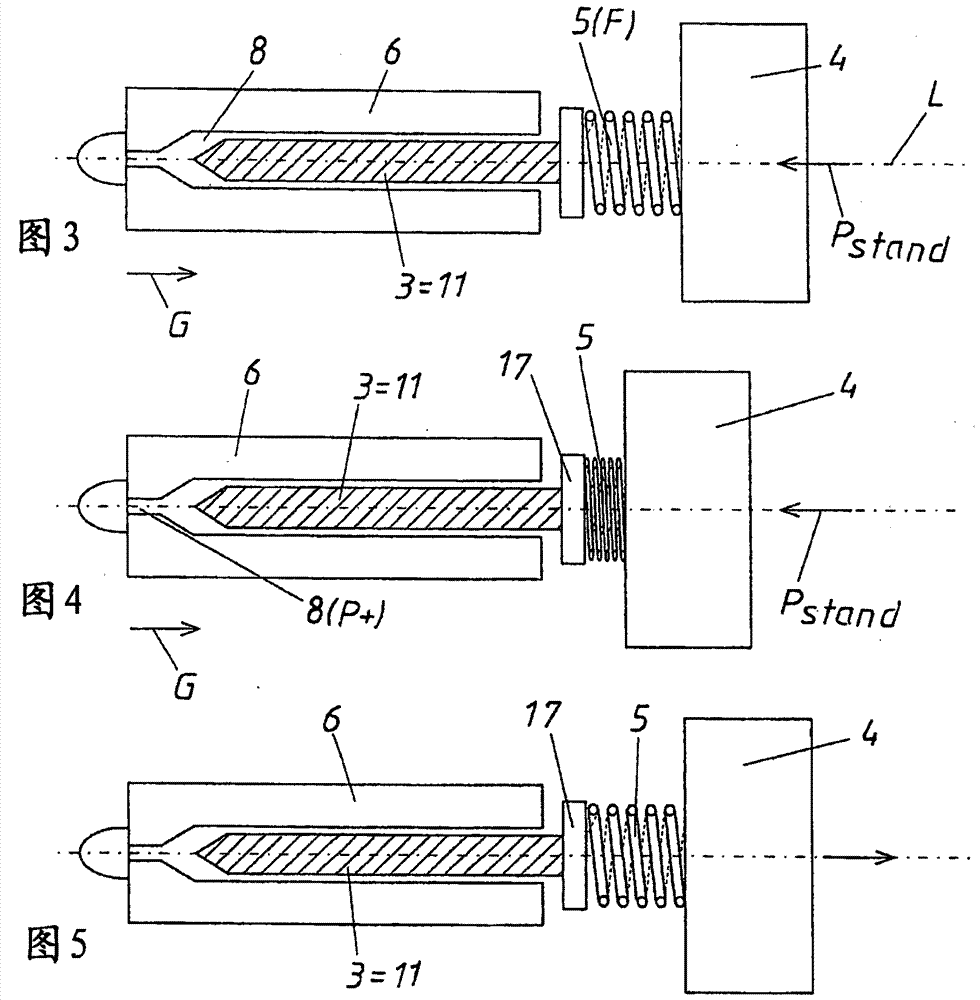

[0024] figure 1 A molding machine 2 is shown schematically, which has an injection unit 1 and a molding tool 10 as essential components. Furthermore, such a molding machine 2 normally also includes a mold clamping plate and a crank mechanism, not shown. To form molded parts or injection molded parts, the raw material (such as plastic granules, metal or ceramic powder, additional fillers such as glass fibers, additional liquids or mixtures if necessary) is first introduced via the injection funnel 21 into the In the intermediate chamber between cylinder 6 and injection piston 3. If the injection piston 3 is designed as an injection worm 11 , the raw material is melted by rotating the injection worm 11 . A rotational movement is introduced into the injection worm 11 by means of the drive 4 . Injection takes place after melting is complete, for which the drive 4 moves the injection worm 11 pistonically or in translation, so that the accumulated molten injection material 8 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com