Flywheel for internal combustion engine

A technology of internal combustion engine and inertial flywheel, applied in the field of inertial flywheel, can solve the problems of increasing complexity and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

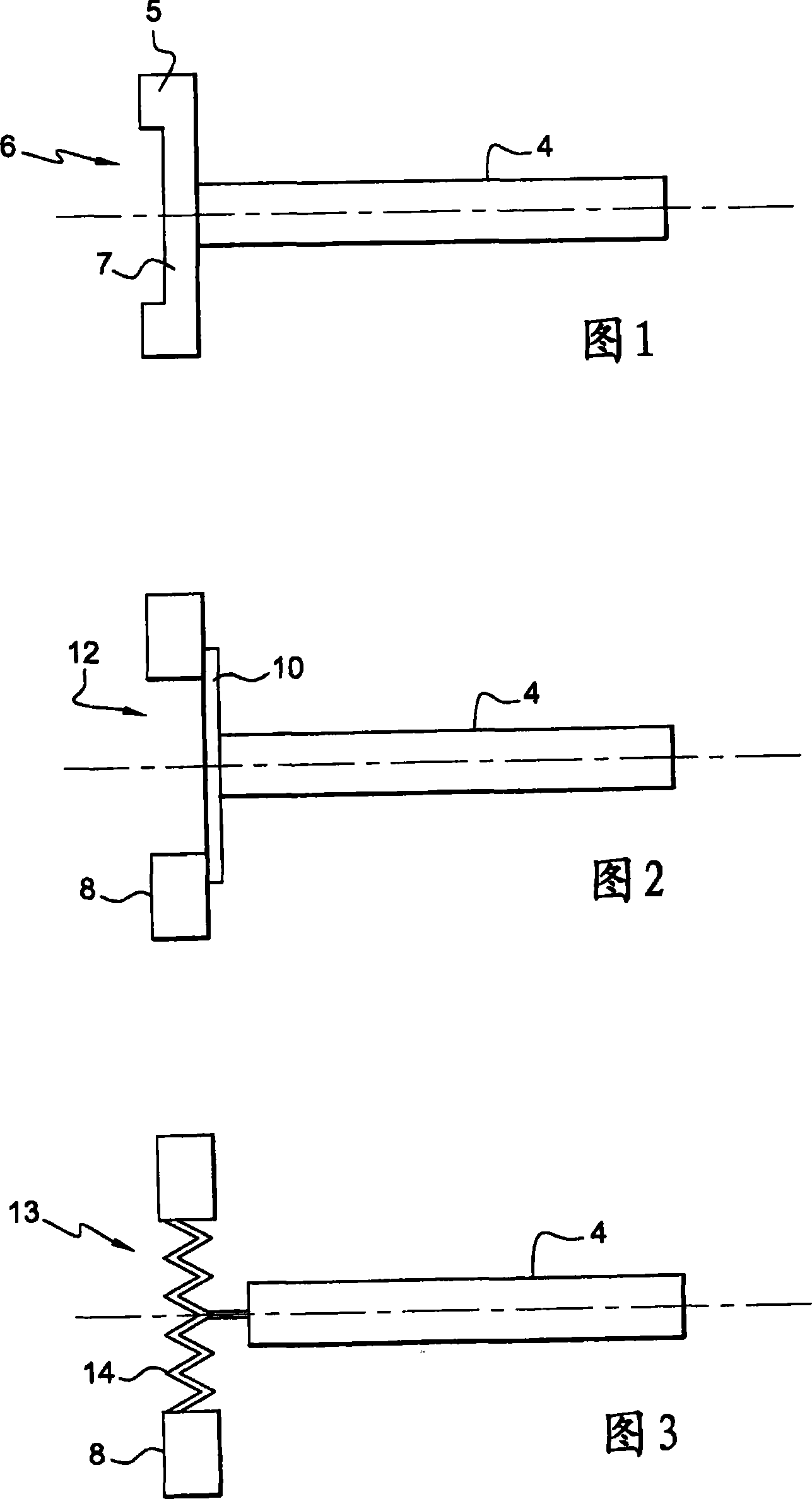

[0035] [34] The schematic diagram in FIG. 1 shows a rigid inertial flywheel 6 which is generally made of cast iron and is fastened to the crankshaft 4 of an internal combustion engine, in particular a motor vehicle internal combustion engine. The flywheel generally comprises a radially outer portion 5 of greater thickness, which imparts a high inertia, and a coupling part 7 between the radially outer portion 5 and the crankshaft 4 . The coupling part 7 is fastened to one end of the crankshaft 4 by means of screws, not shown, arranged along a pair of circles centered on the shaft.

[0036] [35] The schematic diagram of FIG. 2 shows a curved flexible inertial flywheel 12 comprising a ring 8 usually made of cast iron fixed to the outer periphery of an annular plate 10 . Said plate 10, screwed to the crankshaft 4, makes the flywheel 12 flexible, allowing bending about an axis, which is perpendicular to the axis of the crankshaft, and exhibiting a surge movement (mouvement de pomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com