Friction-type damper device

A damper, friction-type technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of wear and noise, and cannot apply related backgrounds, etc., and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

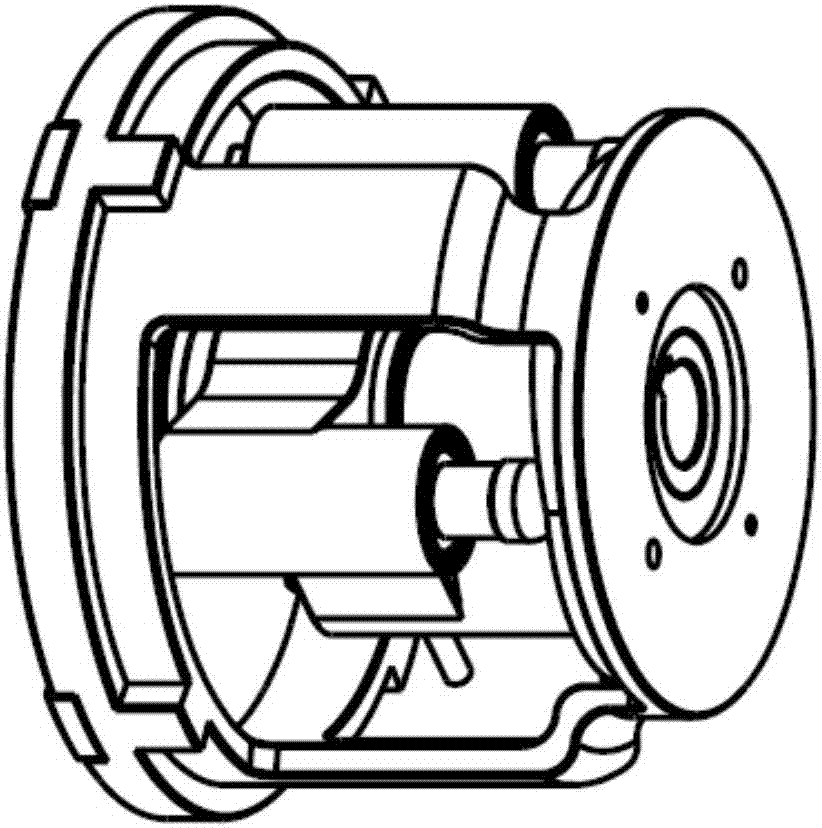

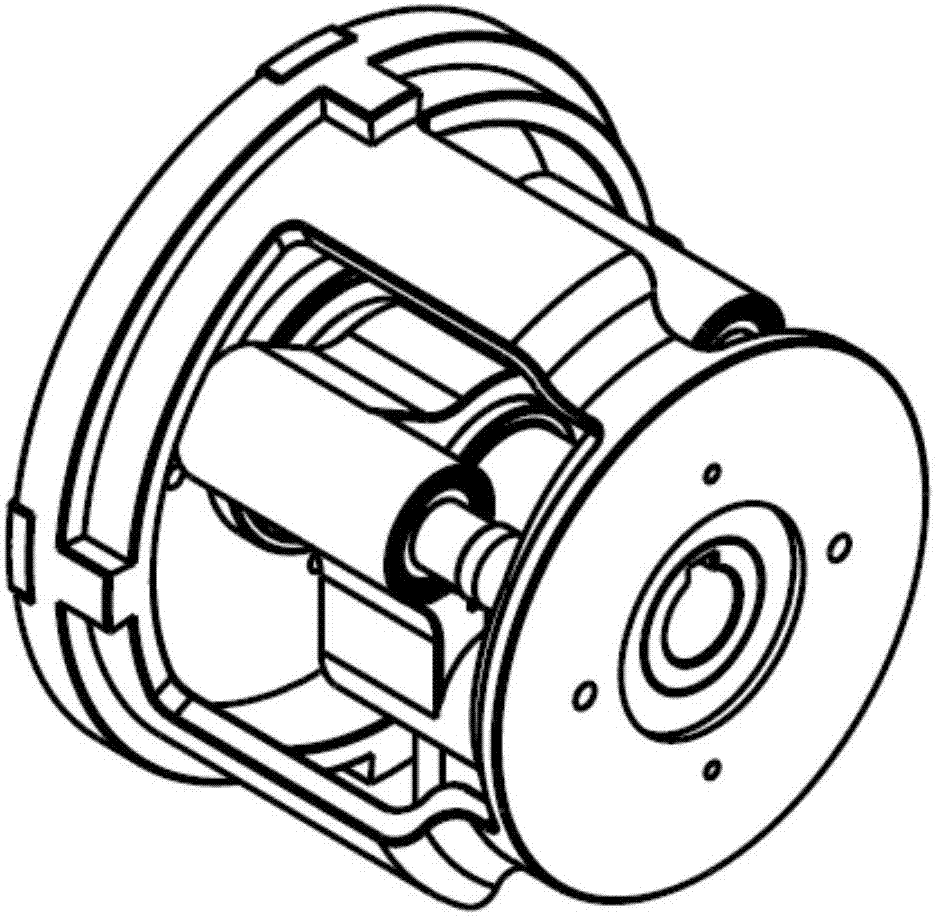

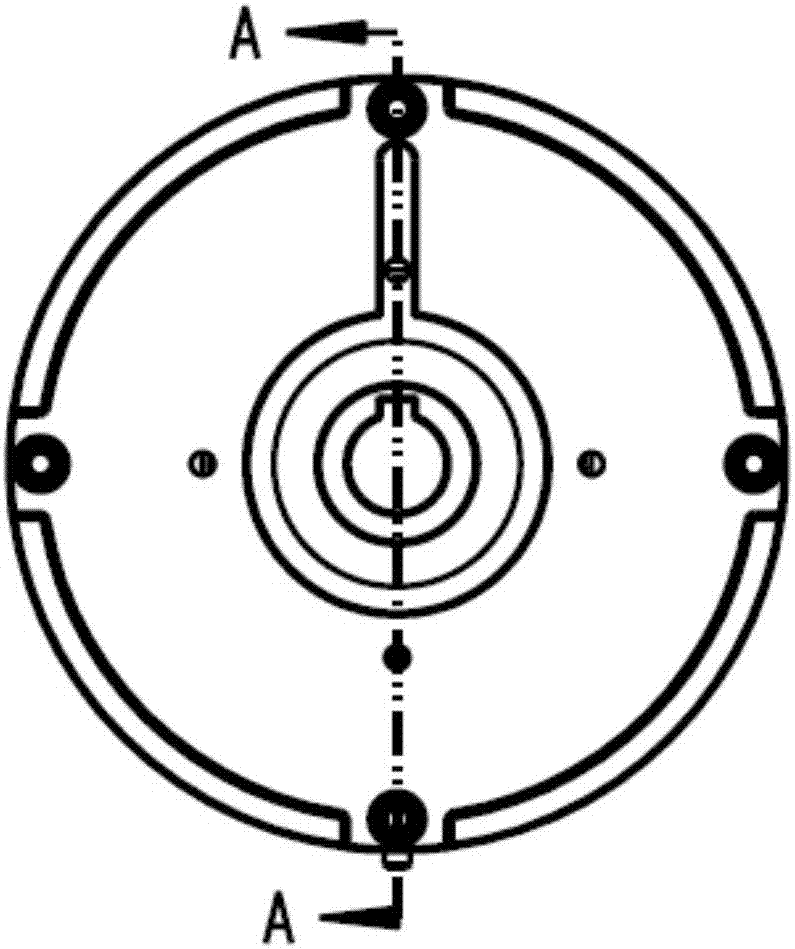

[0031] Based on the in-depth study of the friction damper, the present invention proposes a friction damper in which the resistance torque is related to the absolute rotation angle of the device. The device is as figure 1 As shown, the friction force is generated through the relative movement of the friction head and the friction disc, and the resistance torque is provided. The device mainly includes: a cover plate 1, a casing 2, an adapter element 3, a friction head 4, a friction plate 5, a bearing 6, a limit nut 7, a pointer 8, a spring 9, a telescopic shaft 10, a rotating shaft 11, and the like.

[0032] The resistance torque of the present invention is related to the absolute rotation angle of the device. The rotation shaft 11 and the cover plate 1 are respectively fixed on the connecting rods on both sides of the joint that needs to provide the resistance torque. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com