Full-automatic bending pipe production feeding line and bending pipe production method thereof

A feeding line, fully automatic technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of low feeding efficiency and high labor costs, and achieve the effect of reducing area occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

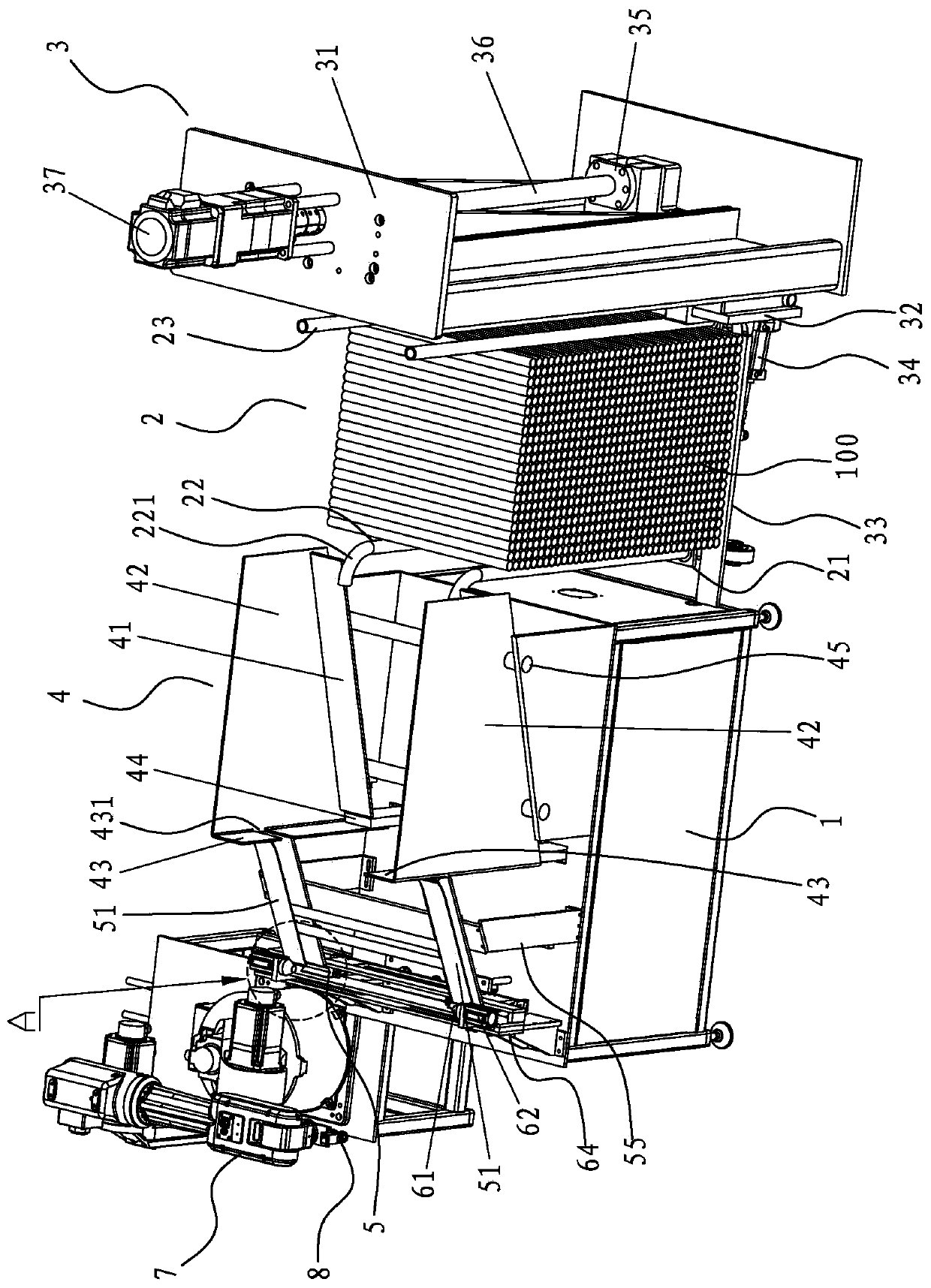

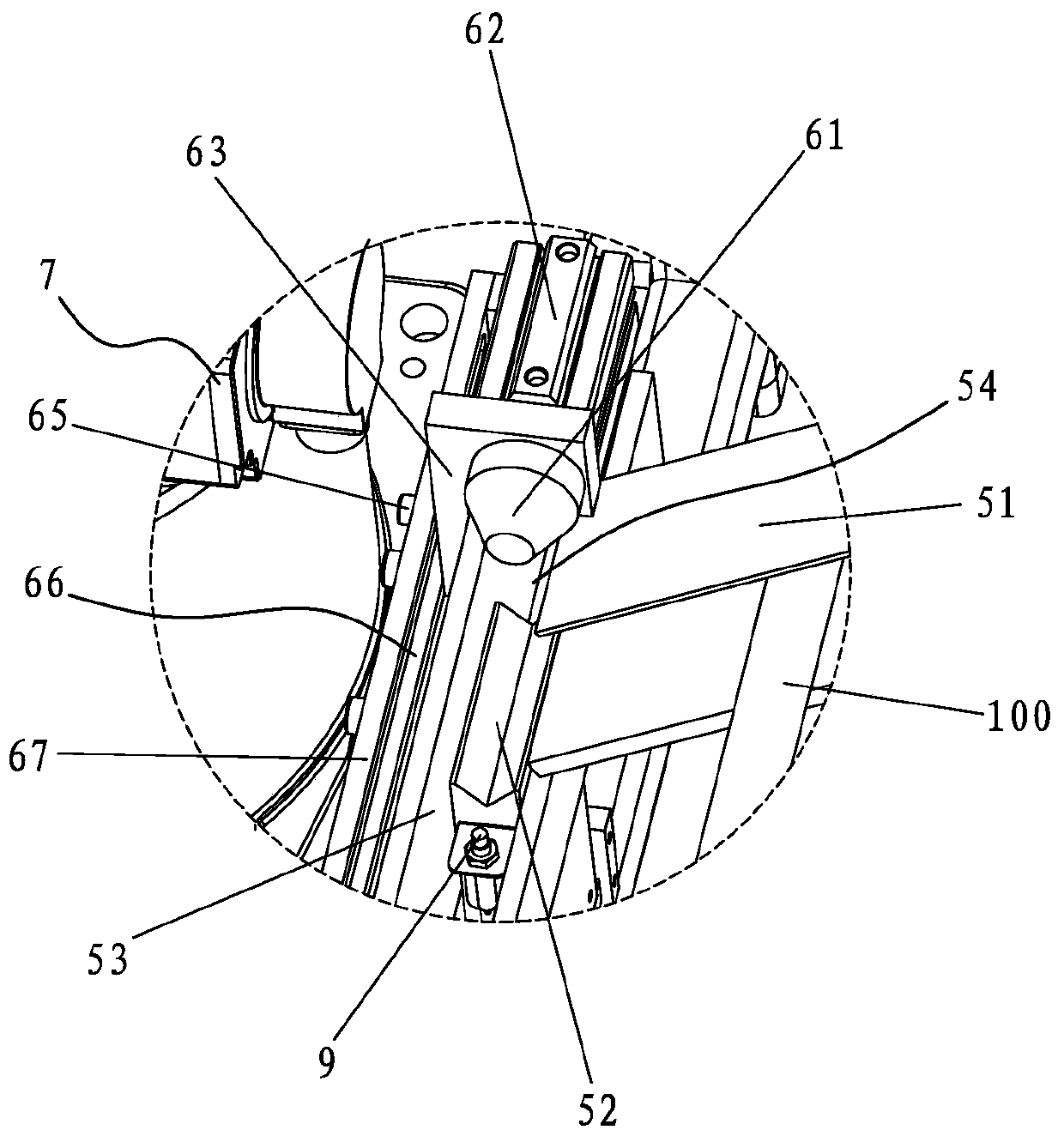

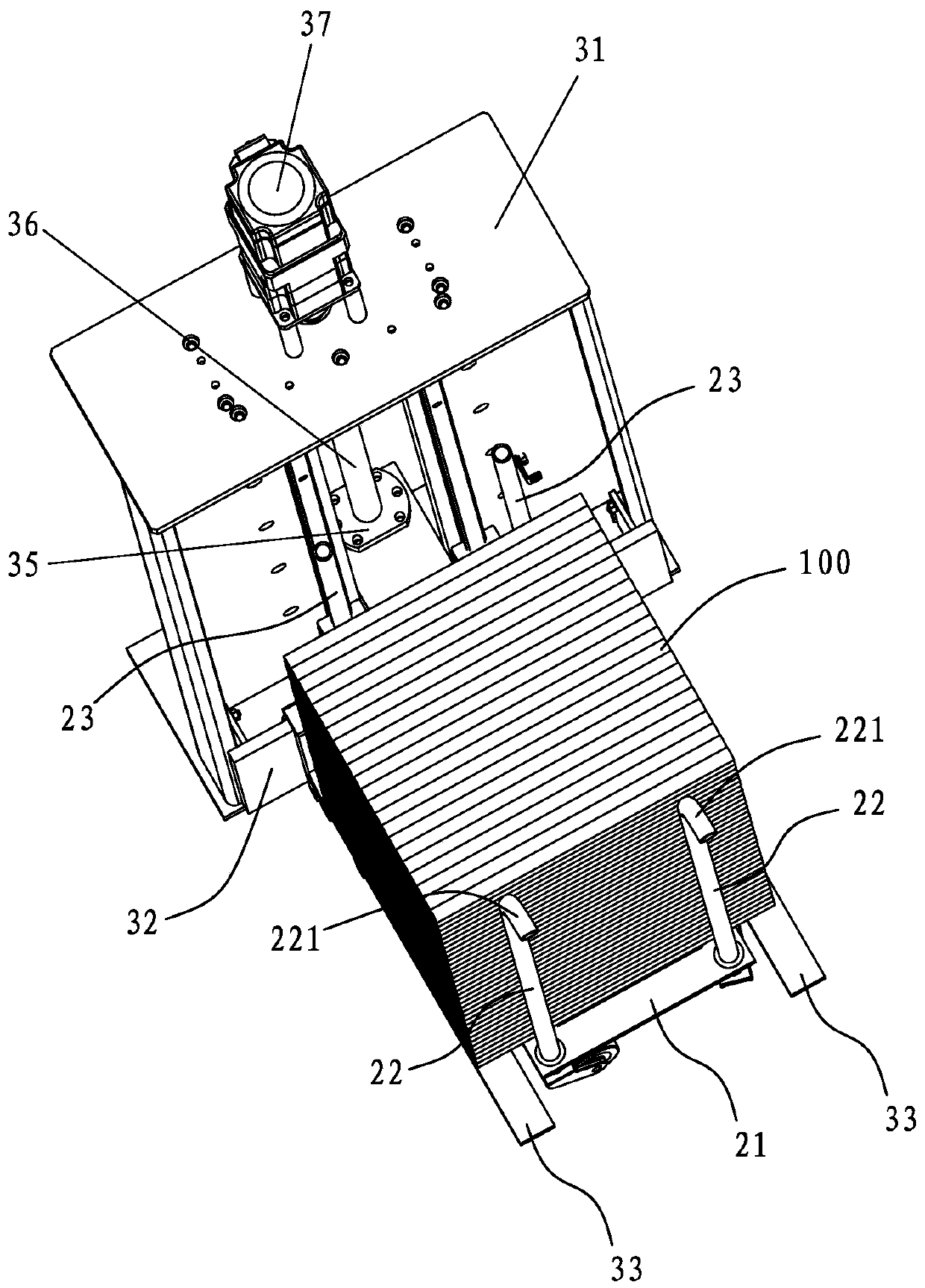

[0050] Such as Figure 1 to Figure 7 A kind of fully automatic curved pipe production and feeding line shown includes a delivery platform 1, and the right side of the delivery platform 1 is provided with a trolley 2 that can be pulled back and forth and used to carry a straight pipe 100, and the trolley 2 includes The car base 21 for the straight pipe 100 to lie down is provided with a left railing 22 and a right railing 23 for blocking the straight pipe 100 from the left and right sides on the car base 21, and the right railing 23 is higher than the left railing 22. The right side of cart 2 is provided with the fork-up mechanism 3 that can fork up straight pipe 100 from below the straight pipe 100 on the cart 2. After the top of the railing 22, it falls from the left railing 22 side under the action of gravity. The transport platform 1 is provided with a storage hopper 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com