Patents

Literature

71results about How to "Combined dense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

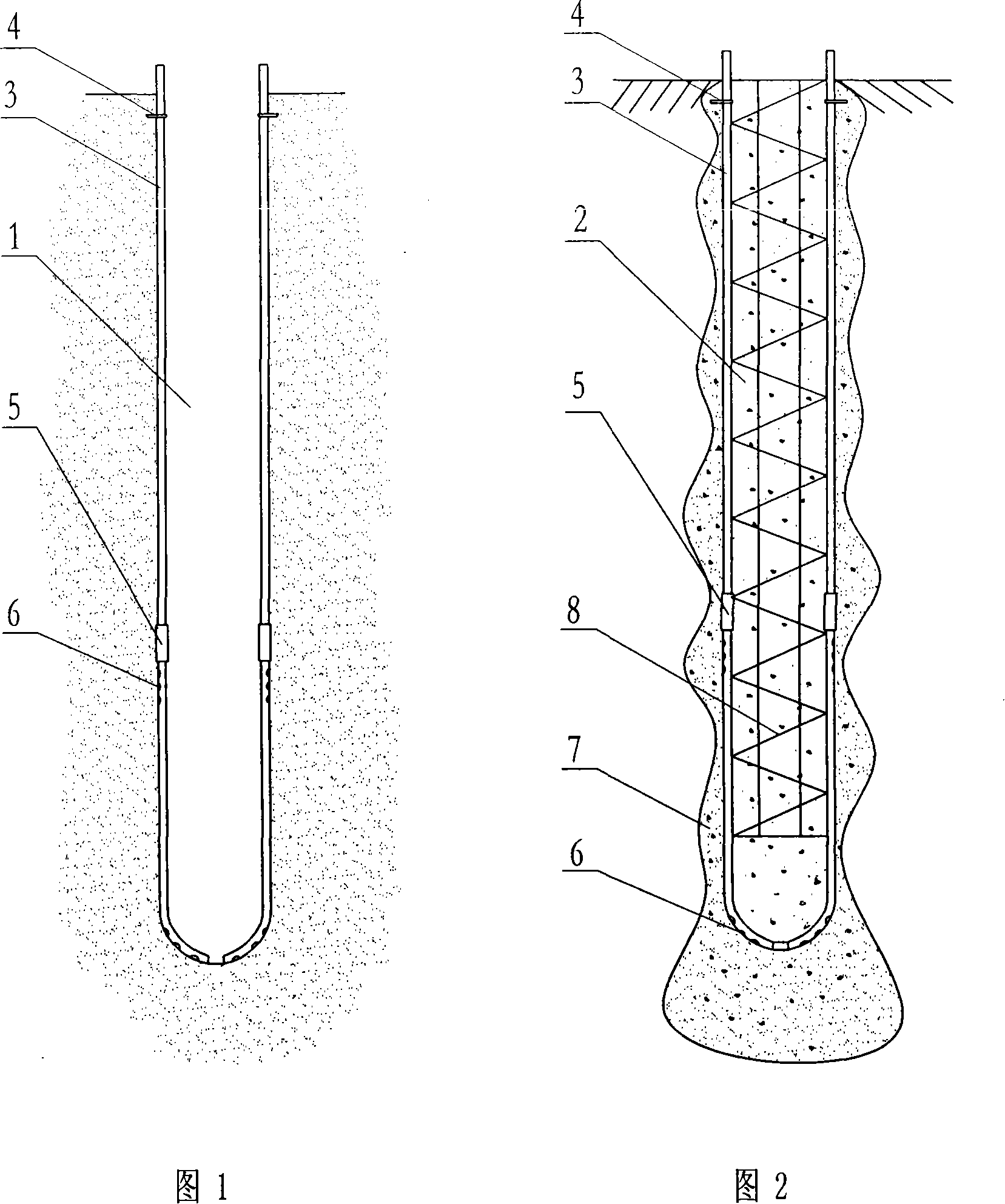

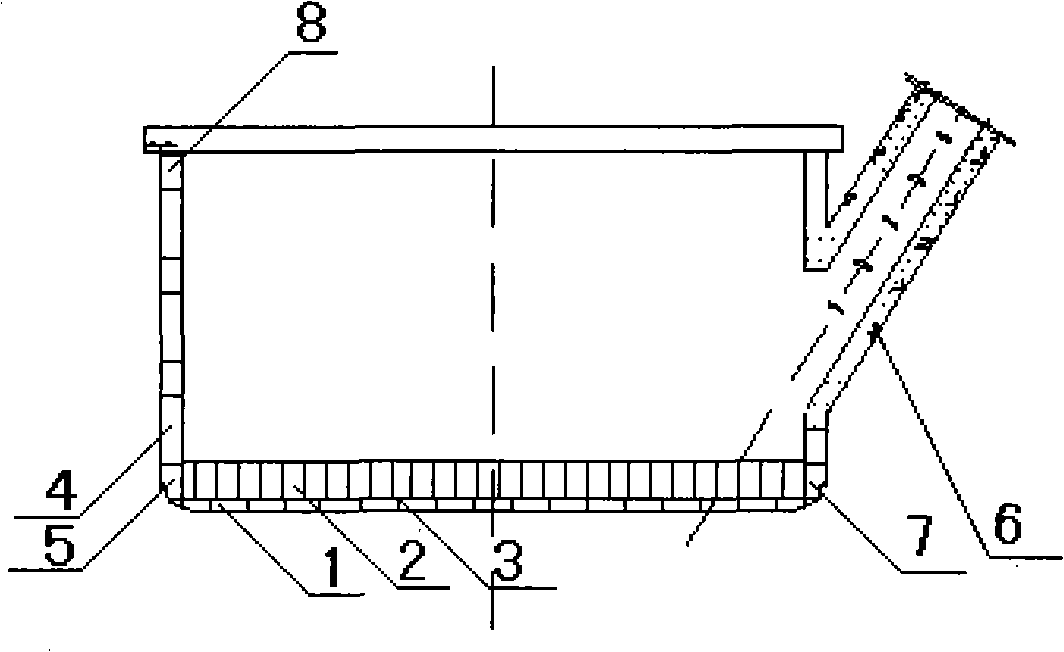

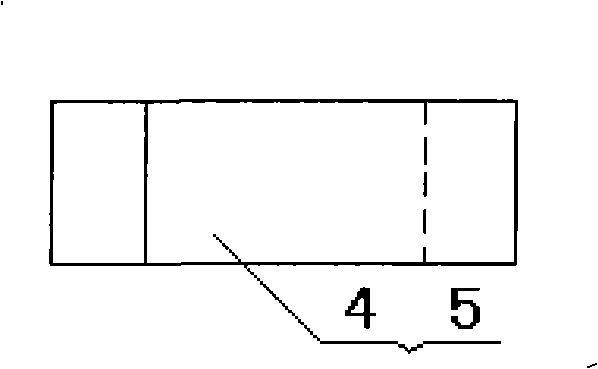

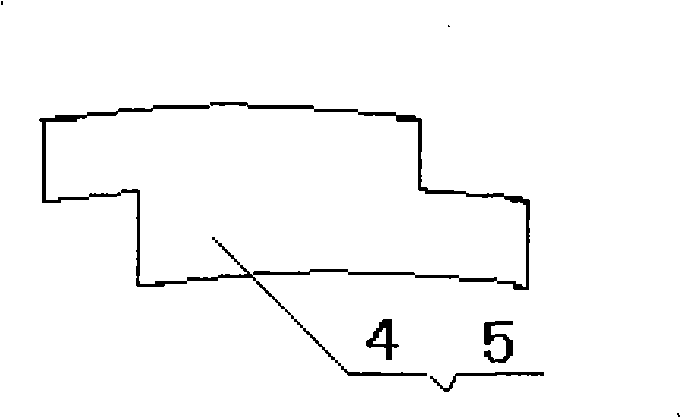

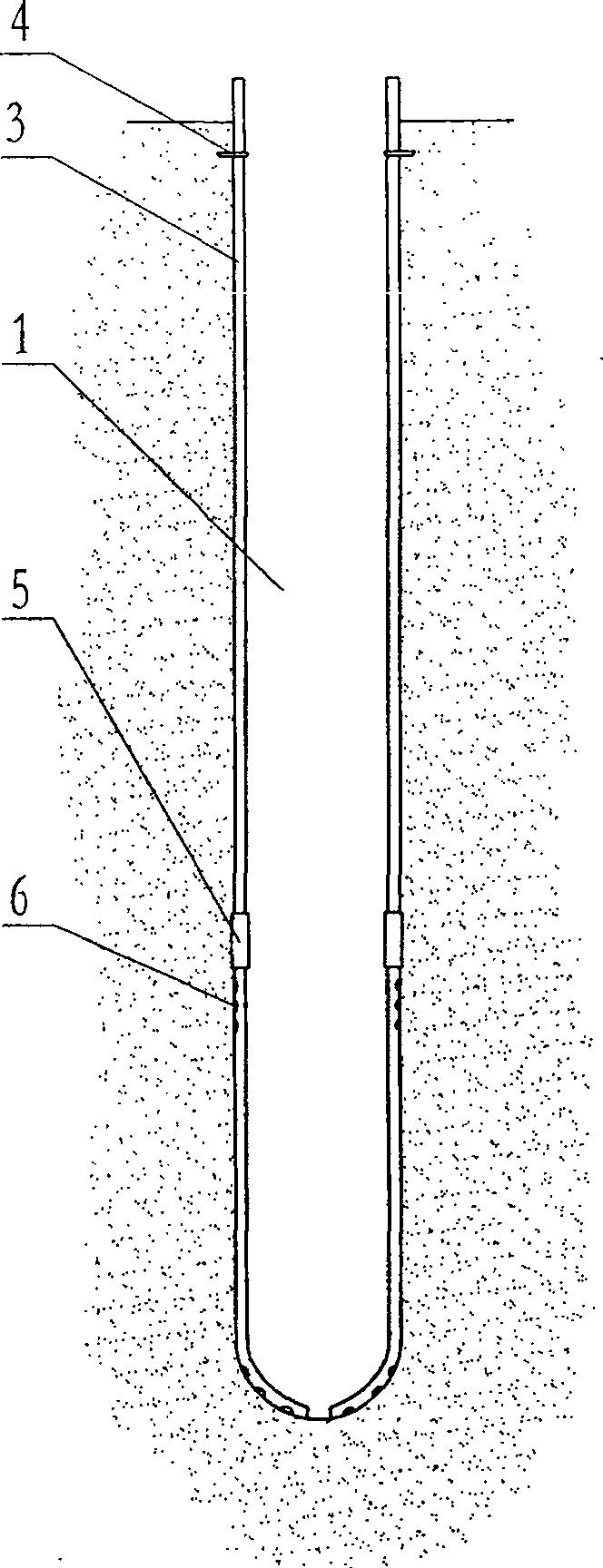

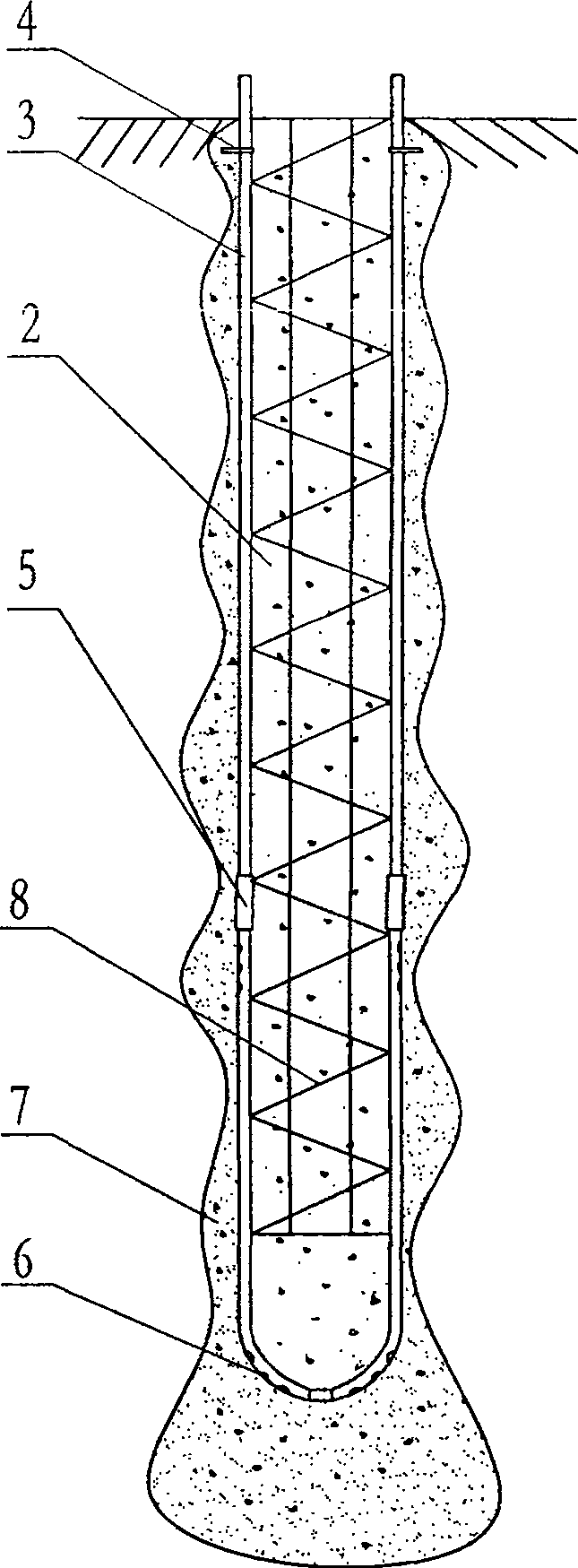

Construction method for increasing dry auger boring pouring pile bearing capacity

InactiveCN101148874AIncrease frictionImprove pile end bearing capacityBulkheads/pilesPressure groutingRebar

The construction process of raising the bearing capacity of auger boring pile includes setting two grouting pipes symmetrically beside the side wall of pile hole, setting reinforcing cage and grouting concrete with concrete pumping agent in 1-1.5 wt% of cement, and pressure grouting cement slurry with concrete pumping agent in 1 wt% of cement and concrete expanding agent in 5 wt% of cement in the pumping pressure of 200-300 kg / sq cm in 8-24 hr after filing until cement slurry overflows from the top end beside the pile. The process can raise the bearing capacity of the pile by over 1 time, reduce the length of the pile, save material, lower cost and reduce construction pollution.

Owner:李树源

Concreting method with different intensity grades for beam column nodes

A different intensity-level concretes casting method used for the beam-column nodes belongs to the construction technology field. A vertical dense-mesh steel-wire net is arranged around the beam-column node; column concrete cement with the intensity level high than that of the floor concrete is adopted to cast the beam-column node in the steel-wire net while the floor concrete is cast. The invention is simple, can be constructed easily and also can largely enhance the intensity of the beam-column nodes of the floor; the intensity level of the high-intensity wall column concrete is preserved; the intensity level of the high-intensity column-node concrete applied to the horizontal structure beam plate and column nodes is also preserved; the high-intensity concrete is not wasted and the construction joints between the borders of different intensity-level concretes can be avoided; the cold joints can be avoided; the combination is dense; and the construction quality can be guaranteed.

Owner:JIANGSU JIANGDU CONSTR GRP

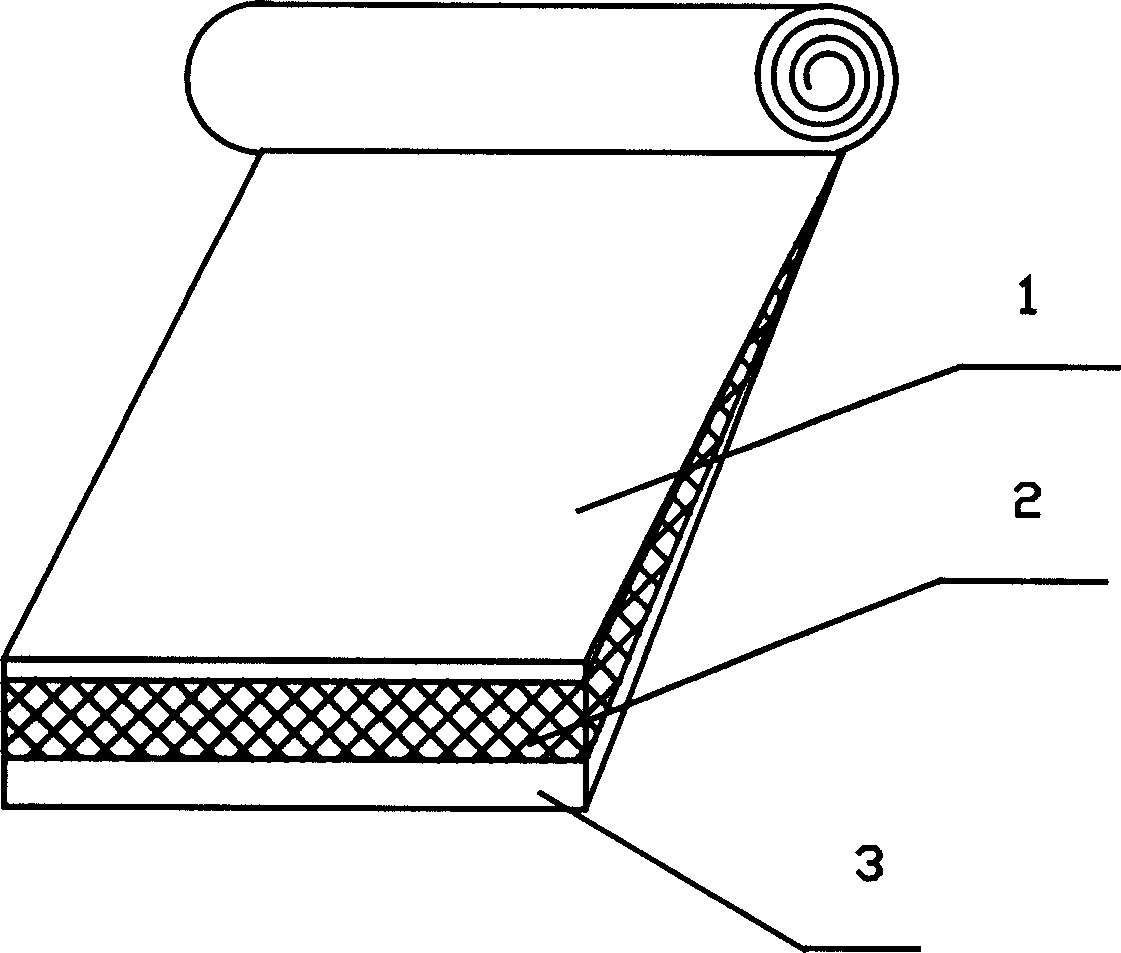

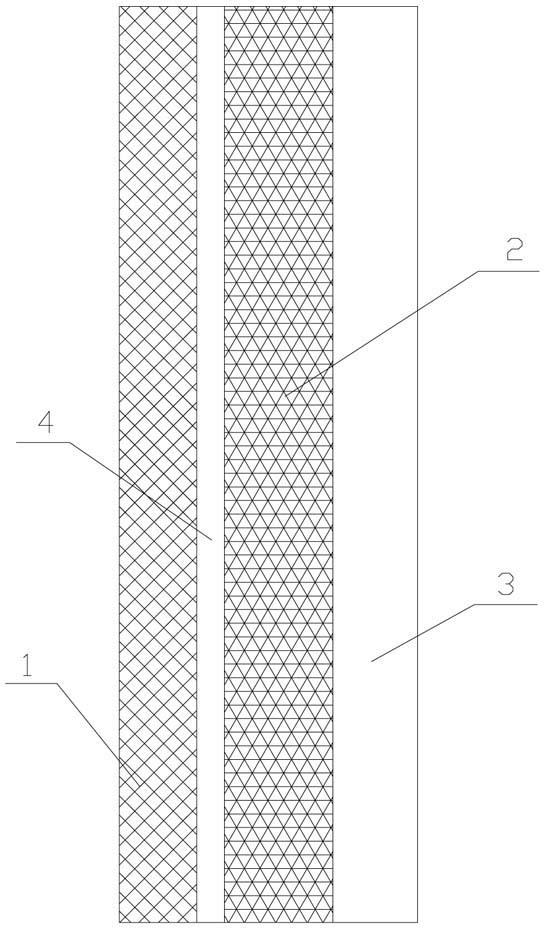

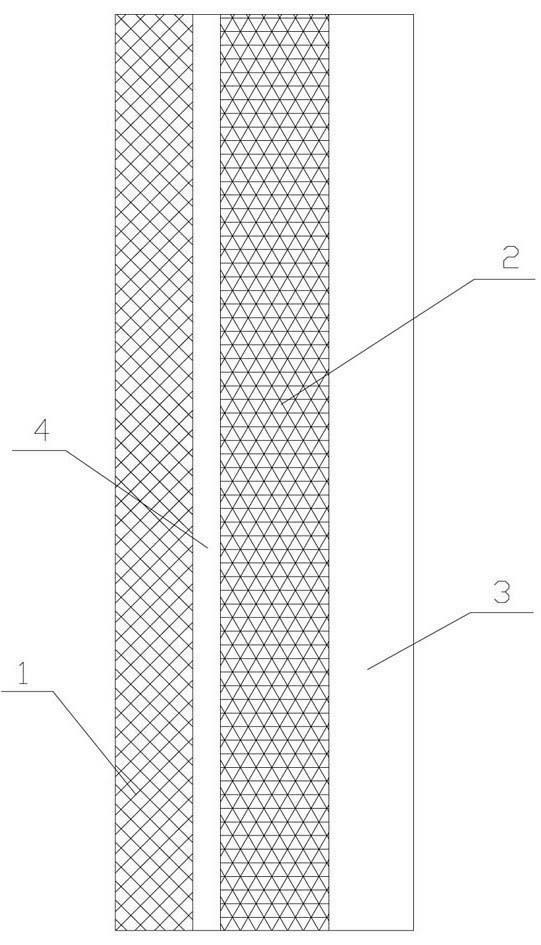

Self-adhesive aluminium plastic compound water-proof anti-corrosion coiled material

InactiveCN1869375AFacilitates instrument leak testingPrevent hidden dangers in construction qualityRoof covering using flexible materialsProtective foundationPliabilityAluminium

The invention discloses a self-adhesive aluminum plastic compound waterproof antisepsis coiled material that includes self-adhesive non-woven enhancing rub asphalt layer, whose upper layer has aluminum plastic film and the down surface has anti-seizing paper. It has the advantages of excellent effect to avoid water and gas filtering, strong concrete cementation force, strong flexibility, high stretching resistance and high tension stress, etc.

Owner:韩永来

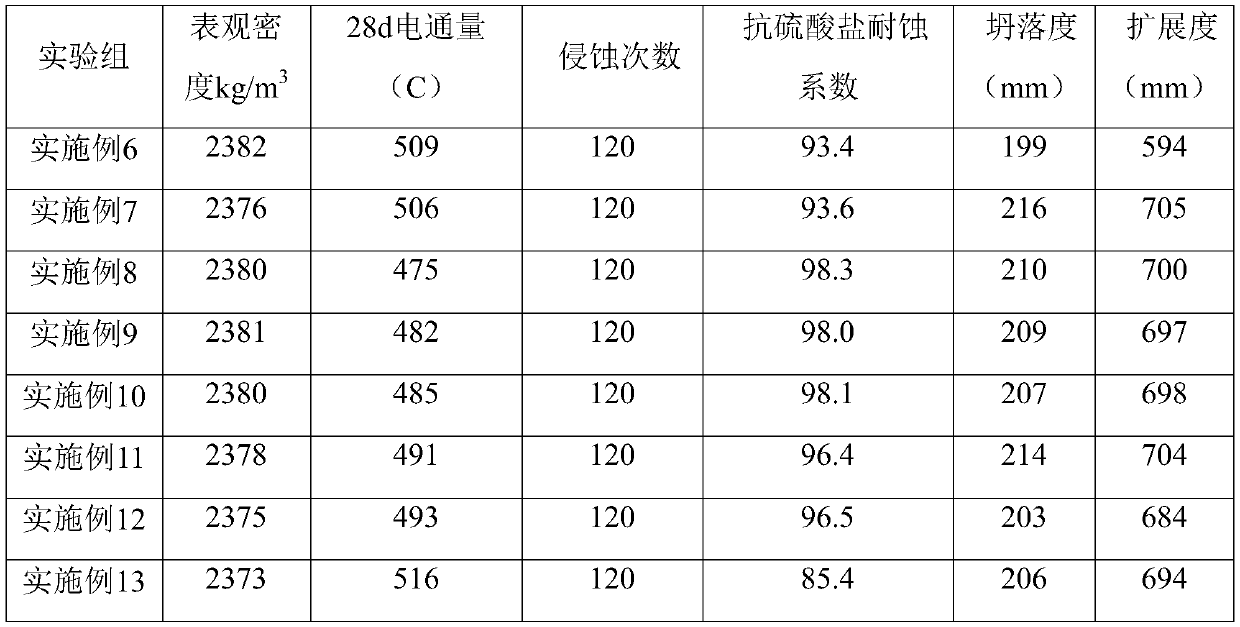

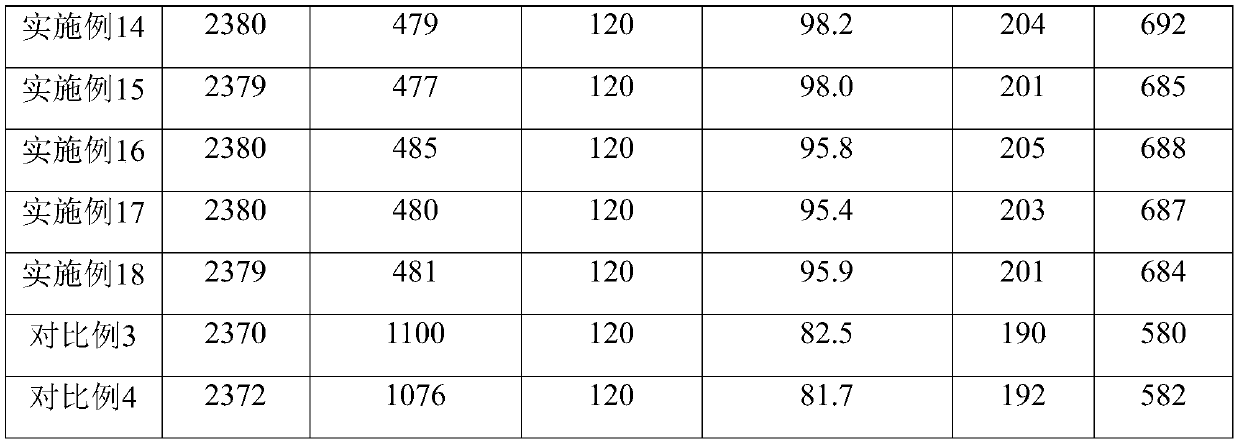

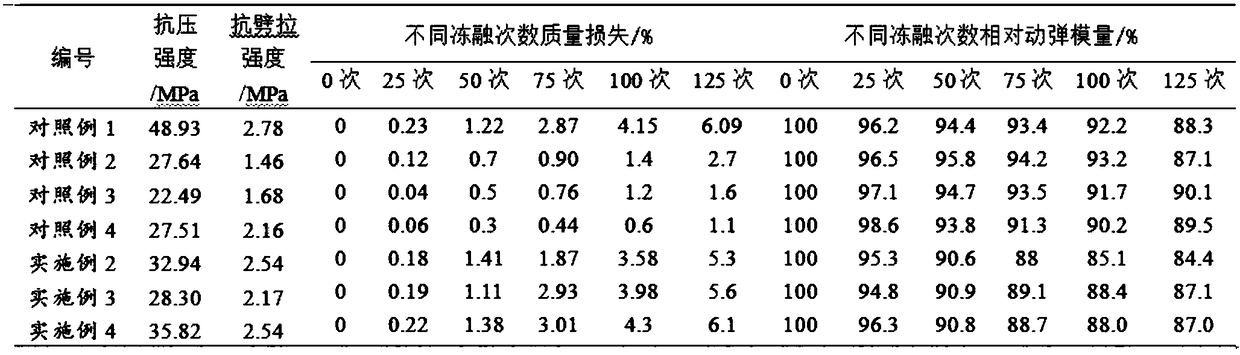

Corrosion-resistant iron tailing aggregate, corrosion-resistant concrete and preparation method thereof

InactiveCN110698098ANot prone to deviation fluctuationsControllableSolid waste managementCorrosion resistantTailings

The invention discloses a corrosion-resistant iron tailing aggregate, corrosion-resistant concrete and a preparation method thereof and belongs to the technical field of concrete production. Accordingto the technical scheme, the corrosion-resistant iron tailing aggregate comprises the following components: six graded tailing ores of which the particle sizes are 25-27mm, 18-20mm, 15-17mm, 8-10mm,4-5mm and 2-3mm, wherein the mass percentages of the graded tailings ores are 4-6%, 18-22%, 24-26%, 24-26%, 18-22% and 4-6% respectively. The void fraction of the aggregate can be significantly reduced, the compactness of the iron tailing aggregate is high, and the effect of enhancing the corrosion resistance of the iron tailing aggregate is achieved. The invention further discloses corrosion-resistant concrete which comprises the corrosion-resistant iron tailing aggregate. The corrosion resistance, fall resistance and durability of the concrete can be improved.

Owner:中建西部建设北方有限公司 +1

Special color heat-pressing label for resin grinding wheel

The invention discloses a special colored hot-press label of a resin grinding wheel. The special colored hot-press label comprises a black paperboard or a copper printing paper substrate, a bottom layer, a pattered oil layer and a protective layer, wherein the bottom layer, the pattered ink layer and the protective layer are offset-printed on the substrate. Aiming at realizing small color change amplitude after a finished product label and the grinding wheel are sintered and vulcanized together, ink for the pattered ink layer is scientifically prepared from materials, such as polydimethylsiloxane phenolic resin, a chemical corrosion resisting agent, an anti-friction agent, tung oil, organic pigment, and the like, crude ink is modified, the high-temperature softening point of the ink layeris improved, the adhesive film hardness of the surface of the ink layer is increased, and an adhesive film gap on the surface of the ink layer is sealed. The special colored hot-press label has the advantages that: a brand name and various technical data of the grinding wheel are printed with various colors of ink by utilizing the appropriate substrate and then die-cut and formed, and directly hot-pressed on the surface of the substrate in the production process of the grinding wheel, and the grinding wheel is discharged from a furnace after dried in a high-temperature vulcanizing kiln for 30h at 186 DEG C, therefore, the mark of the label is very distinct, not powdered and obscure, and the color change amplitude is less than 10 percent.

Owner:郑州市晶森彩印有限公司

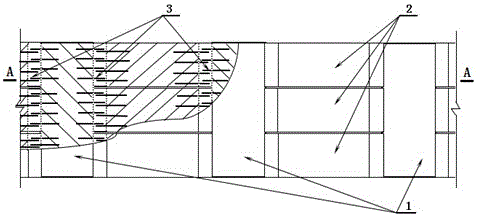

Waterproof processing construction method for framework bridge butt-connecting part

InactiveCN103628406AEffective controlSolve intractableBridge structural detailsBridge erection/assemblyRebarWaterstop

The invention relates to a waterproof processing construction method for a framework bridge butt-connecting part. The waterproof processing construction method for the framework bridge butt-connecting part is particularly applied to the process of waterproof processing construction between a new framework and an existing framework bridge butt-connecting part after the new framework is ejected in place. The waterproof processing construction method for the framework bridge butt-connecting part comprises the following steps of removing concrete of an existing framework in a chiseling mode (steel bars are reserved), leveling the chiseled plane part of the existing framework through mortar, laying waterstop bands, erecting a formwork and pouring concrete, ejecting the framework in place, installing waterstop bands, pouring L-shaped groove concrete, cleaning impurities in stretchable seams, injecting waterstop materials, carrying out detachable waterstop band construction, carrying out EVA mortar construction, and laying top plate with waterproof coiling material wrapping outside. The waterproof processing construction method for the framework bridge butt-connecting part resolves the problems that the under water level is high and waterproof construction is difficult in the area, guarantees tight combination between the waterstop bands and an existing concrete surface of the old framework and adopts concrete with high an-seepage level, the concrete is vibrated fully, the tightness of the combination surface of the waterstop bands and the concrete is improved, and the waterproof effect is guaranteed.

Owner:中铁十局集团第四工程有限公司

Construction method of protective walls of concrete antiskid piles

ActiveCN105862912APromote rapid formationCombined denseArtificial islandsCoastlines protectionEngineeringRebar

The invention discloses a construction method of protective walls of concrete antiskid piles. The method comprises the following steps: according to a demand of a process design, tunneling rock soil and forming concrete antiskid pile grooves at intervals, binding reinforcing steel bars comprising pile body reserved reinforcing steel bars in the concrete antiskid pile grooves, pouring the grooves to form concrete antiskid piles; removing rock soil between adjacent concrete antiskid piles, and embedding prefabricated concrete block bodies manufactured in advance; peeling the pile body reserved reinforcing steel bars for exposing the pile body reserved reinforcing steel bars in certain lengths, and connecting the pile body reserved reinforcing steel bars to the reserved steel bars of the prefabricated concrete block bodies one by one in a binding-welding manner; and in joint regions, vertically arranging template pouring concrete and connecting the concrete antiskid piles to the prefabricated concrete block bodies to form integral wall bodies so as to form continuous retaining wall bodies. The construction method disclosed by the invention can quickly form the protective walls of the concrete antiskid piles in different geological conditions, so that the construction period is shortened, quick formation of the protective walls of the concrete antiskid piles in different geological conditions is ensured, and an intact structure quality effect that the combined walls of the protective walls of the antiskid piles in the concrete structures and surfaces of slope protection are densely combined is realized.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

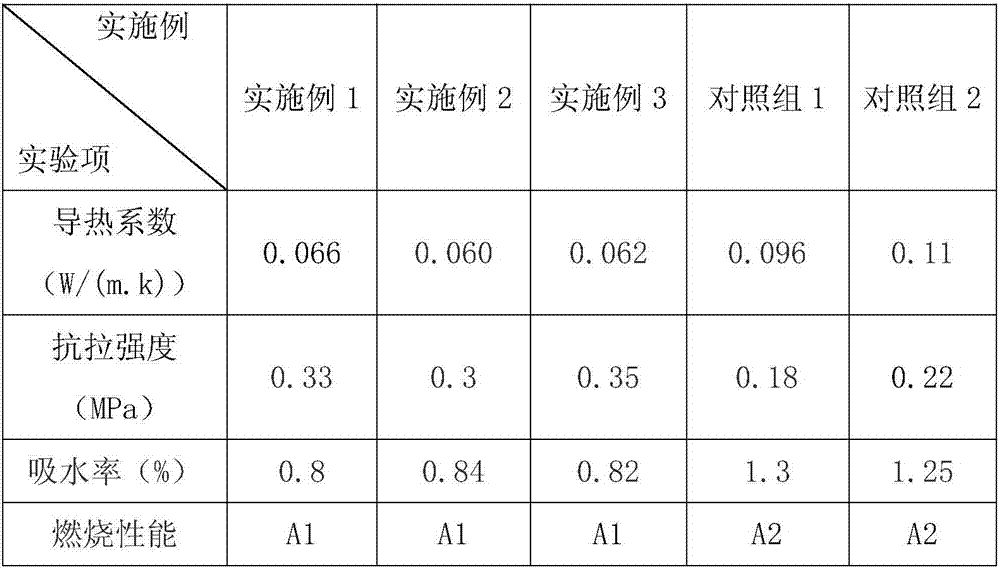

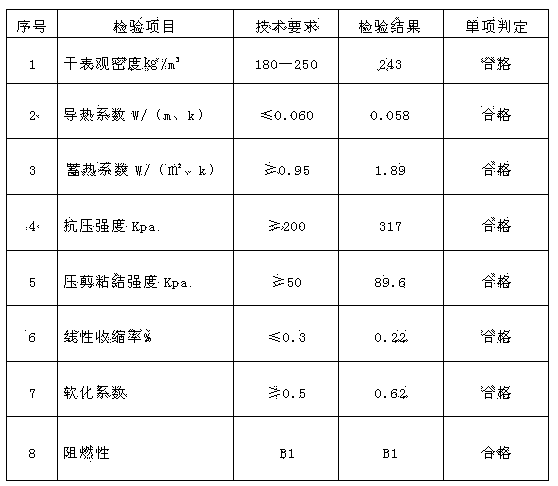

Foamed ceramic insulation board and preparation method thereof

InactiveCN107141014AFireproofHigh temperature resistantCeramic materials productionCeramicwareSodium BentonitePhosphate

The invention discloses a foamed ceramic insulation board and a preparation method thereof. The foamed ceramic insulation board is prepared from the following raw materials by weight: 35-65 parts of waste glass ceramic powder, 20-30 parts of phosphate tailing, 15-35 parts of kaolin, 5-15 parts of sodium potassium feldspar, 8-16 parts of fly ash, 4-10 parts of calcined talc, 2-10 parts of bentonite, 4-12 parts of silicon powder, 1-6 parts of talcum powder, 3-12 parts of calcium carbonate, 2-10 parts of magnesium carbonate, 5-15 parts of water glass, 1-5 parts of a foaming agent, 0.3-0.8 part of an anionic surfactant, and 0.5-1.5 part of a dispersant. The foamed ceramic insulation board provided by the invention has low thermal conductivity, fire prevention, high temperature resistance, aging resistance, low water absorption, weather resistance and other superior performance, and the preparation method is simple and is easy for implementation, therefore the foamed ceramic insulation board can be widely applied in the fields of construction, electricity and environmental protection, etc.

Owner:肥西县碧涛建材有限公司

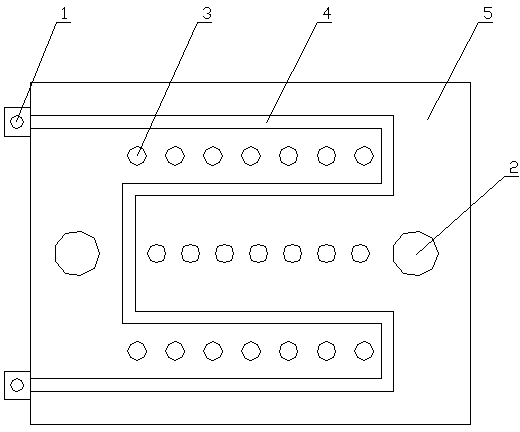

Ceramic electric heating carrier and preparing method thereof

InactiveCN103716923AHigh thermal conductivityEasy to locateHeating element materialsClaywaresElectric heatingElectricity

A ceramic electric heating carrier comprises a heating carrier body, a heating wire is arranged inside the heating carrier body, the two ends of the heating wire are provided with heating wire connectors, the heating carrier body is made of high-temperature ceramic materials, and the heating carrier body is provided with installing holes and heat dissipating holes. A preparing method comprises the steps of preparation of raw materials and gel-casting formation. According to the step of preparation of the raw materials, the formula raw materials are added to a ball grinding machine to be mixed and levigated for 12-14 hours, the raw materials are roasted and synthesized, levigation is carried out for 8-10 hours, and 0.8-1.5% of chitosan is added to the formula materials to be stirred evenly to be a standby after the formula materials are screened through a 160-mesh vibration screen. According to the forming and casting process comprising raw material slurrying and matching, a product mold is placed on a vibration platform to be vibrated for the first time, namely, the mold is taken down from the platform to be paved with the heating wire, the mold is placed on the vibration platform to be poured with a needed amount of slurry, and then the mold is taken down from the platform to stand to be solidified. The ceramic electric heating carrier has the advantages that the carrier body cannot be exploded or oxidized and is even and stable when used for heating in the high-temperature environment, heat transmission is fast, the energy-saving effect is obvious, the mold does not deform, the specification standard is uniform, assembling is convenient, the technology is simple, production efficiency is high, and production cost is greatly reduced.

Owner:王忠厚

Production process of fiber concrete

ActiveCN111993580AAutomatic Orderly JoinImprove the mixing effectMixing operation control apparatusCement mixing apparatusFiberProcess equipment

The invention discloses a production process of fiber concrete. The production process mainly comprises the following processing steps of preparing concrete, putting fibers in and mixing the fibers; processing equipment used during processing of the production process of the fiber concrete comprises a stirring cylinder, a stirring motor is fixed to the outer bottom of the stirring cylinder, a stirring shaft is fixed to an output shaft of the stirring motor, the stirring shaft penetrates through the bottom of the stirring cylinder and extends into the stirring cylinder, and two symmetrically-arranged sleeves are fixed to the circumferential outer wall of the stirring shaft. The production process of the fiber concrete has the advantages that the sleeves are arranged so that stirring bladesare enabled to overturn around the sleeves; and after the stirring motor is started, the stirring shaft drives the stirring blades to rotate and stir, and meanwhile, the stirring blades turn over to stir longitudinally, so that the stirring effect of the concrete is improved, the stirring efficiency is improved, simultaneously, fibers and the concrete are mixed more sufficiently, and the manufacturing quality of the fiber concrete is improved.

Owner:宁夏筑丰源新型建材有限公司

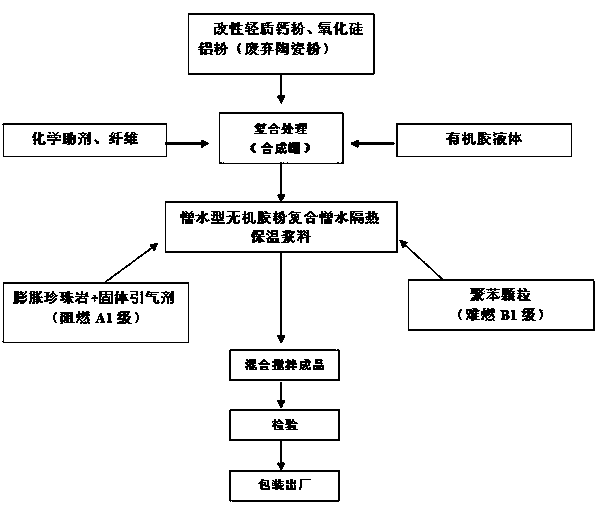

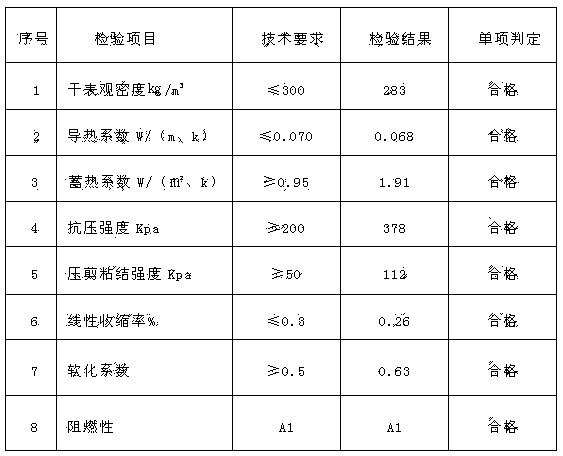

Hydrophobic inorganic gel powder compounded multifunctional insulating mortar, as well as application and preparation method thereof

The invention relates to hydrophobic inorganic gel powder compounded multifunctional insulating mortar, as well as application and a preparation method thereof. The insulating mortar comprises the following raw materials: modified light calcium carbonate powder, monox aluminum powder, an acrylic ester emulsion, an organic polymer cementing material and additives; the raw materials are mixed and prepared to obtain the mortar. The method comprises the following steps: sucking the modified light calcium carbonate powder and the monox aluminum powder into a mixing agitation tank for mixing agitation through vacuum negative-pressure equipment; sucking the acrylic ester emulsion, the organic polymer cementing material and the additives into the mixing agitation tank through the vacuum negative-pressure equipment; finally carrying out mixing agitation at the ordinary temperature to prepare the hydrophobic inorganic gel powder multifunctional insulating mortar. The insulating mortar can be added with different fillers, expanded perlite and polystyrene granules according to the requirements of fire-resistant grades, so as to be compounded into thermal insulation mortar materials for the exterior wall and the roof of a building enclosure. The insulating mortar, the application and the preparation method have the advantages that the energy-saving effect is obvious; the waterproof, air-permeable, fire-resistant and thermal insulation abilities are good; the operation such as mortar and sand pulp production and on-site construction is convenient; the production cost and application cost are low.

Owner:王祥林 +1

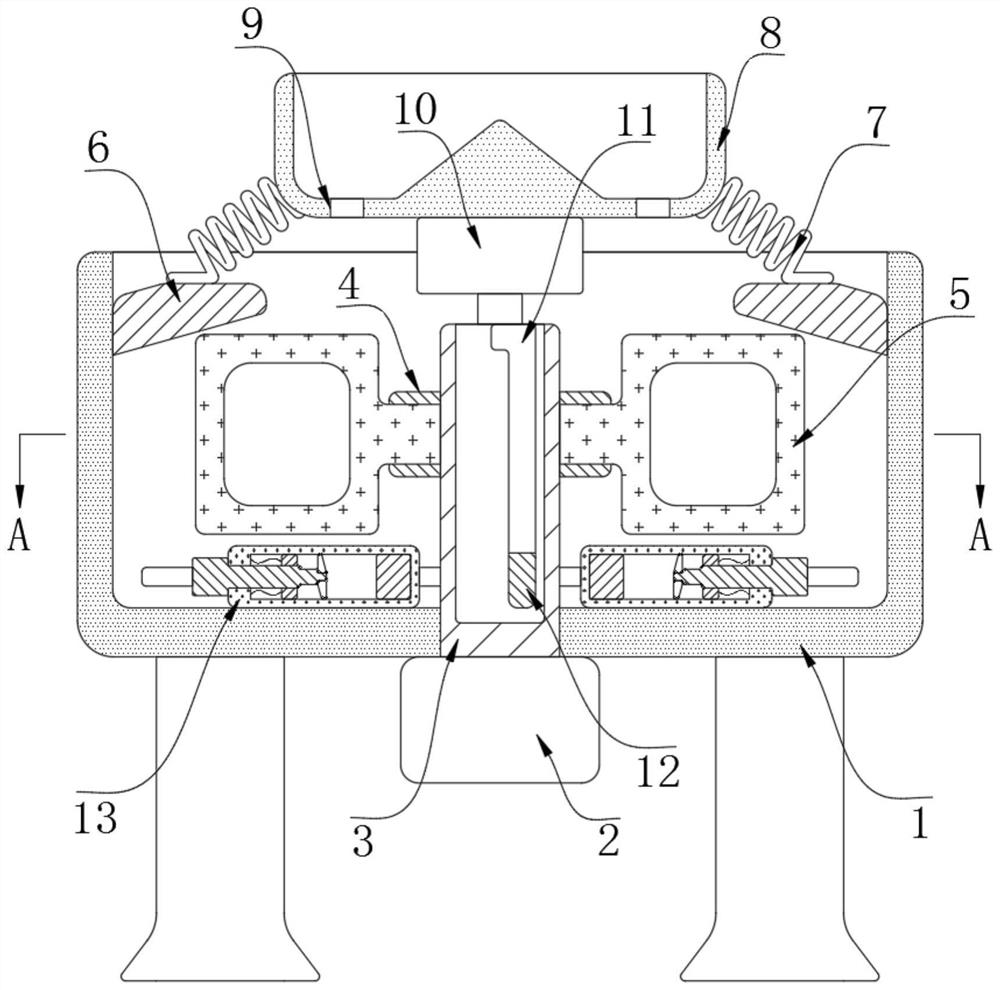

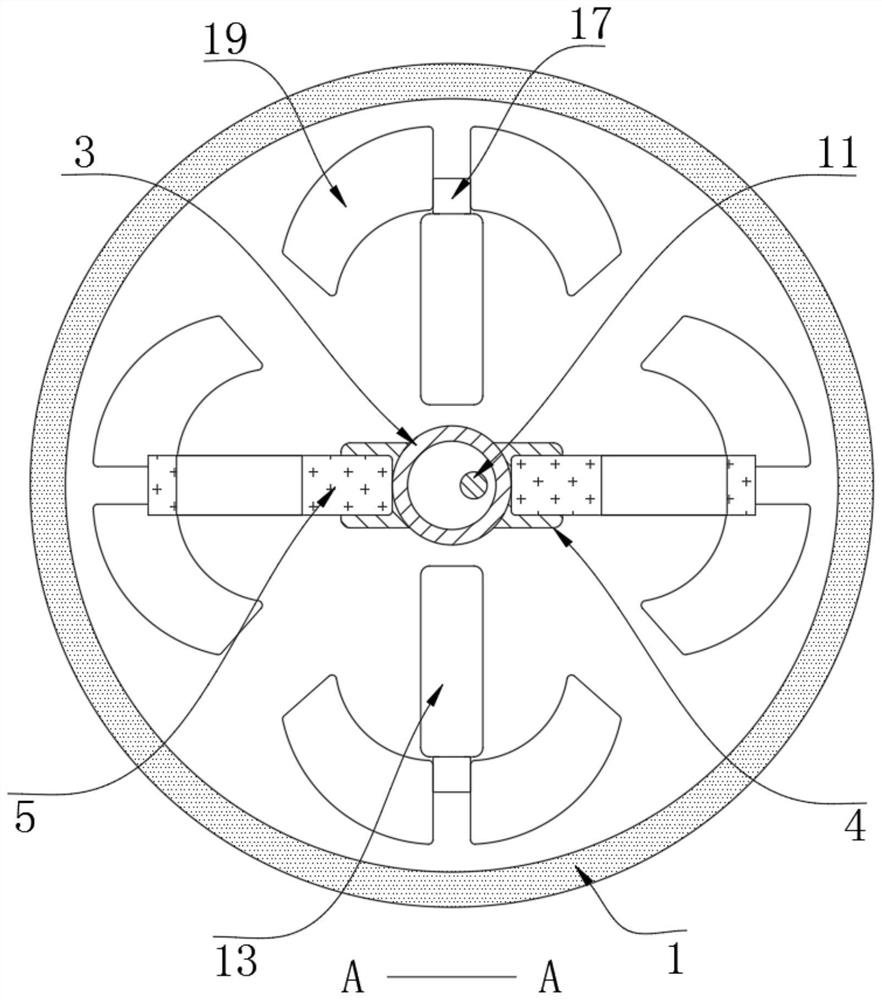

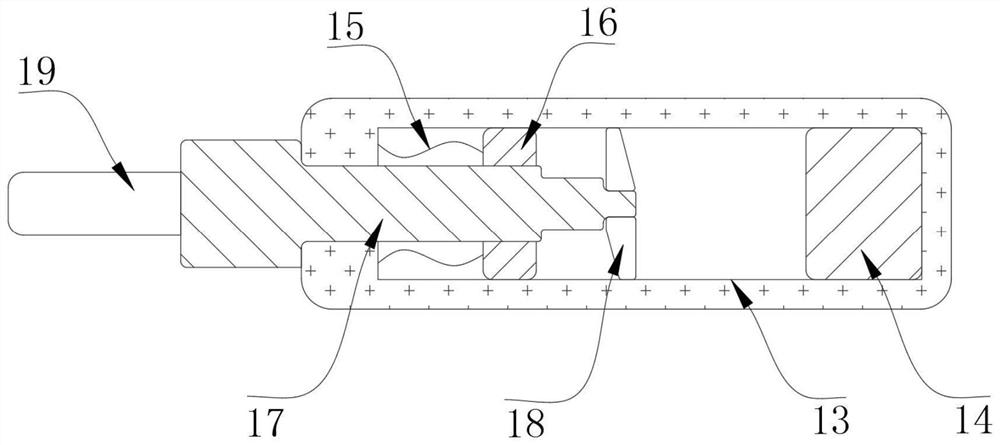

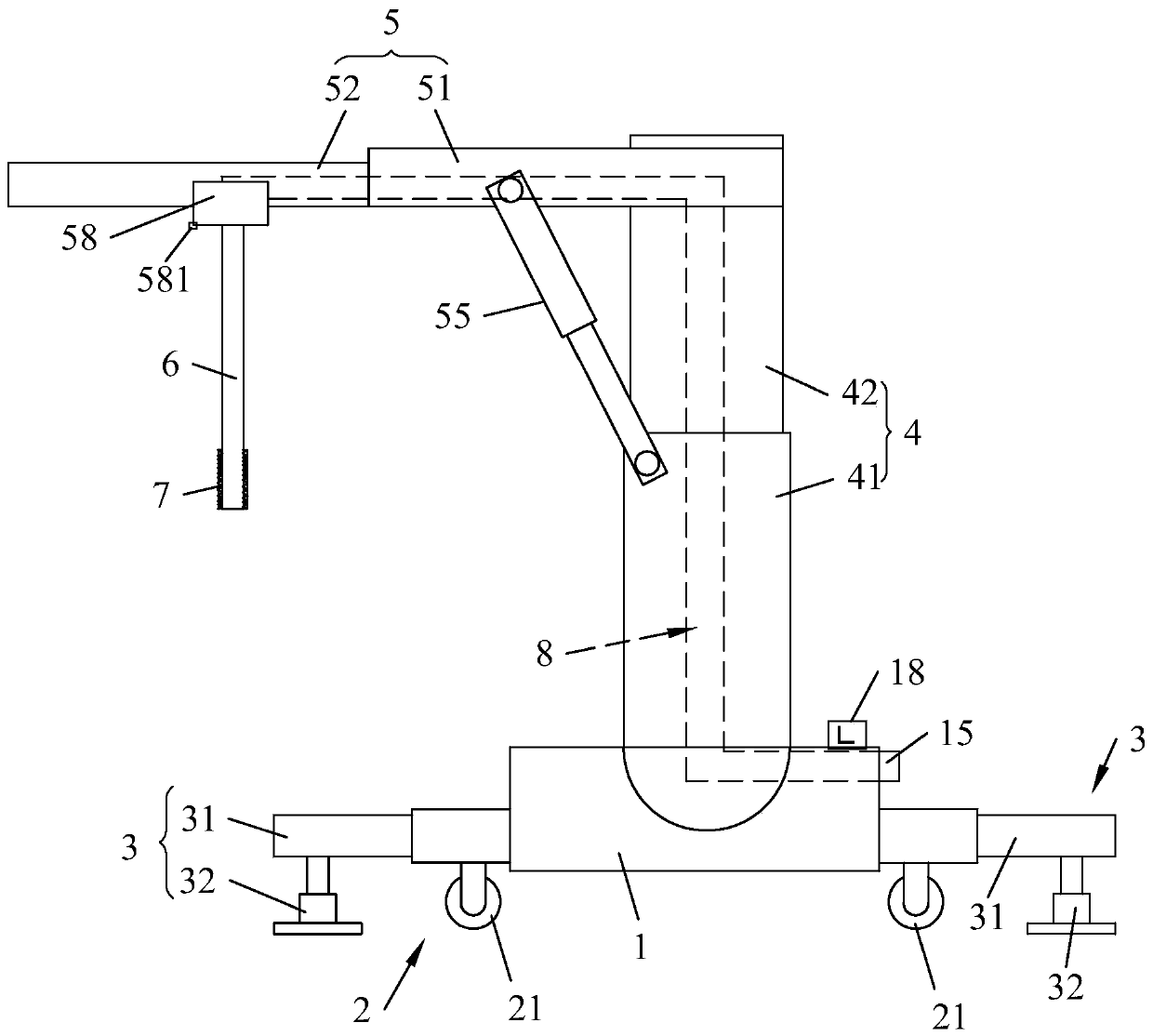

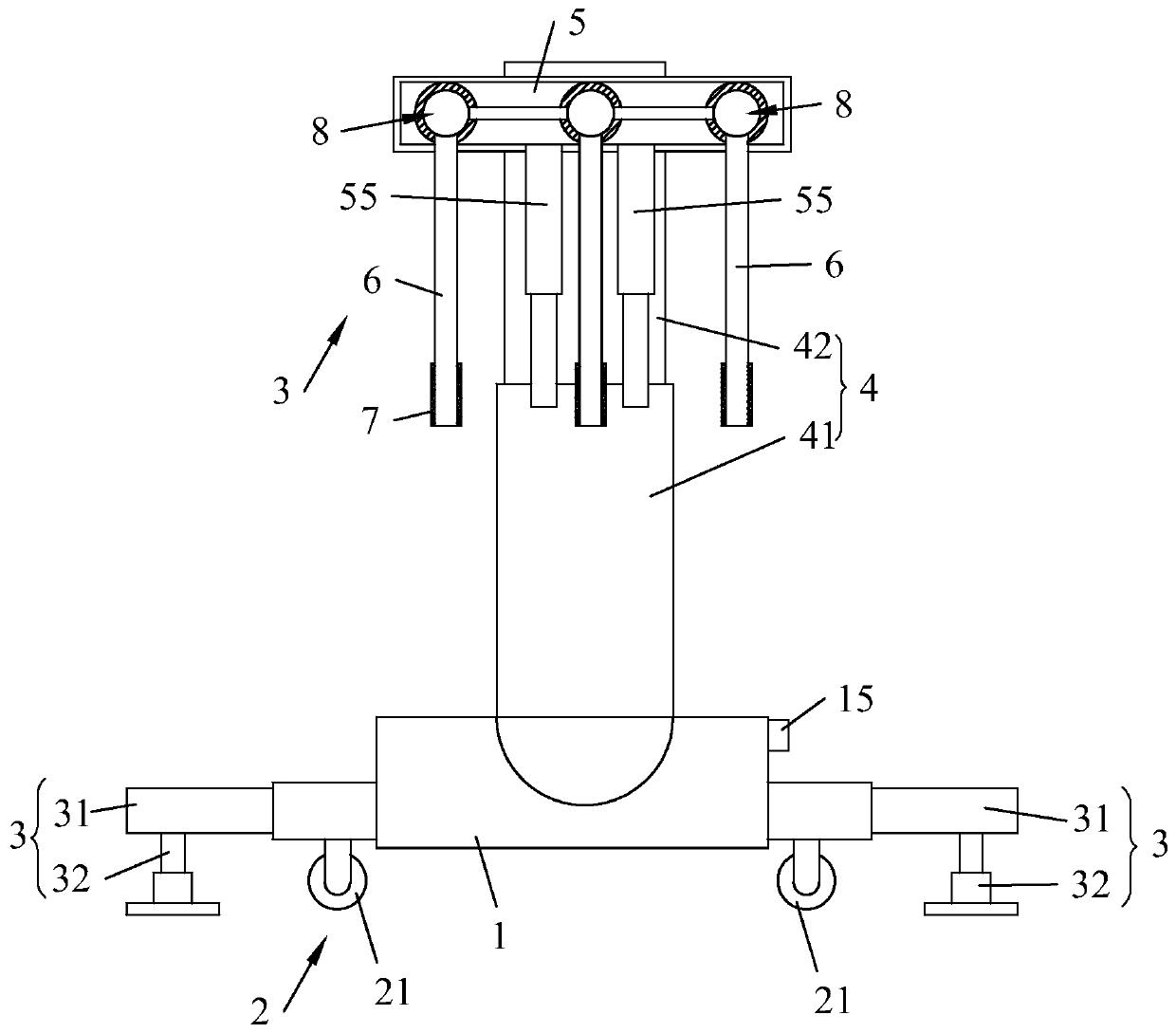

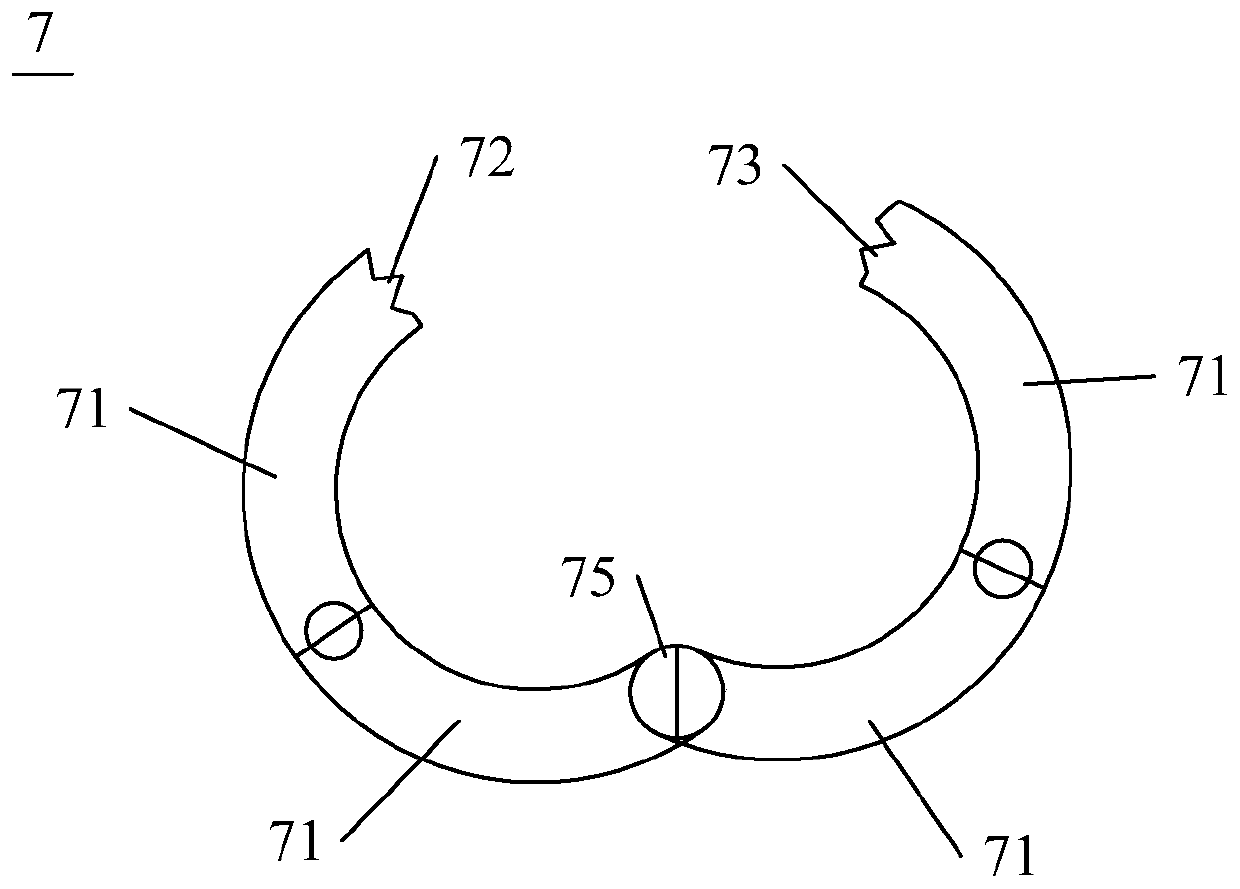

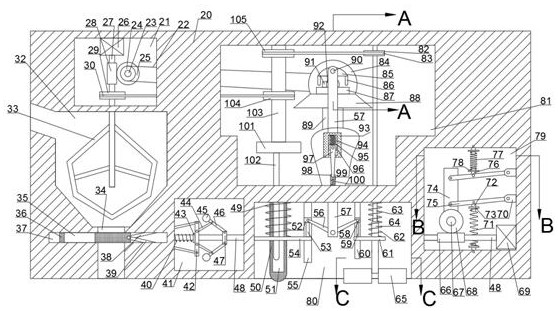

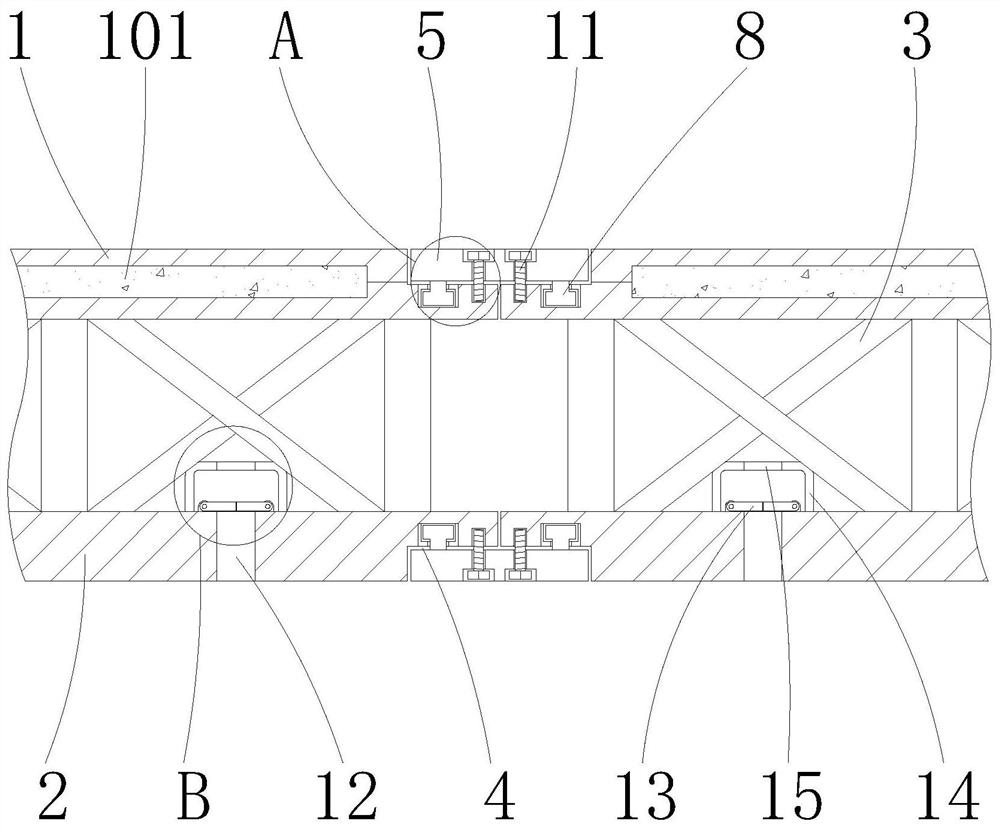

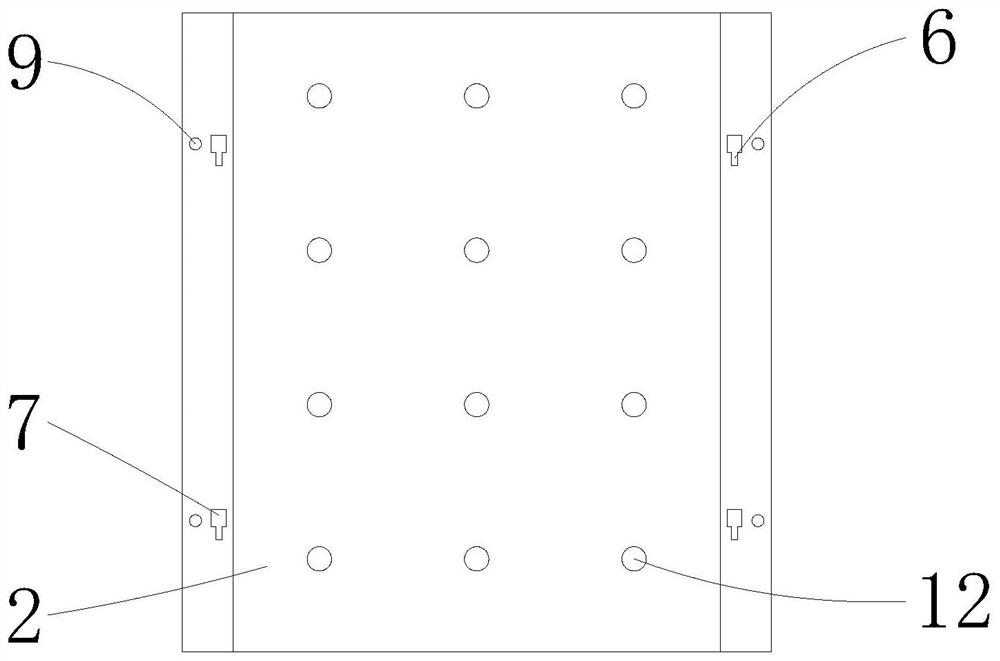

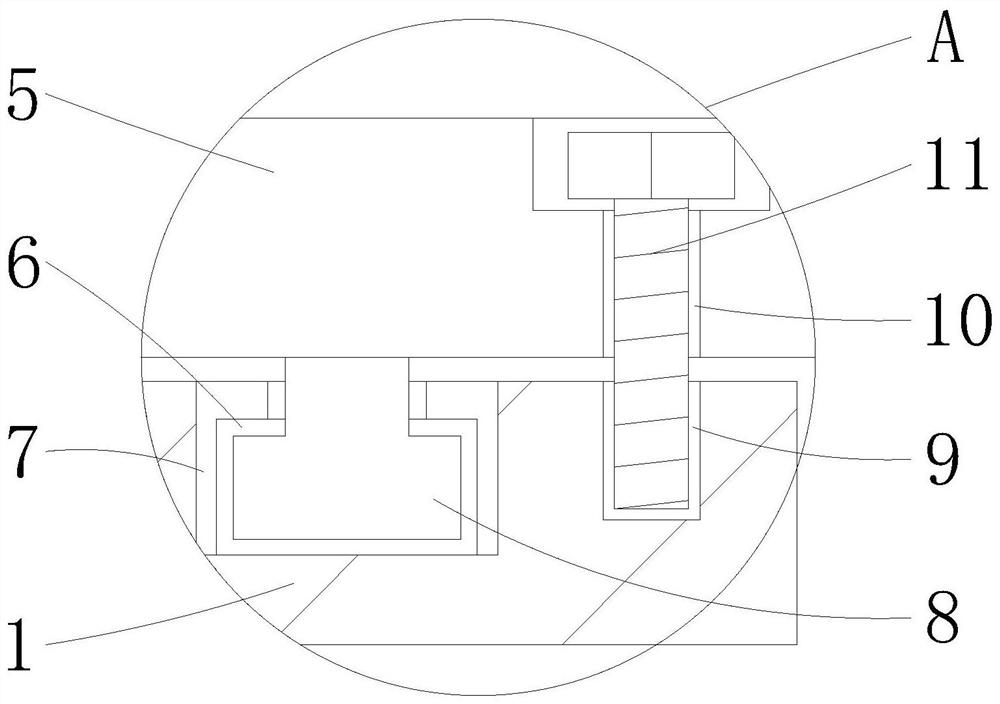

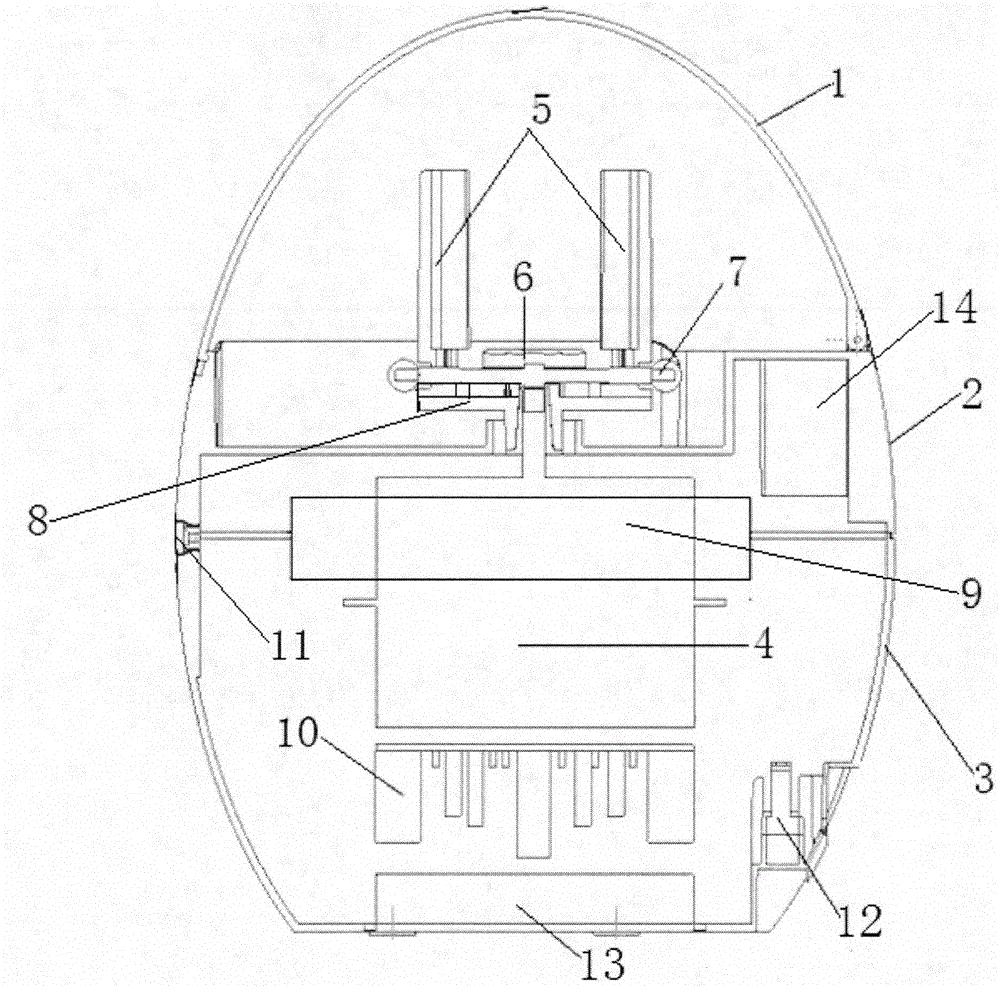

Cementitious material precise distribution and dense operation robot

PendingCN110469114ACombined denseAchieving a vibrating effectBuilding material handlingConstruction industryEngineering

The invention discloses a cementitious material precise distribution and dense operation robot which comprises a main body, a running gear, a pipe frame, a material distributing pipe, an extending-retracting mechanism and a vibrator, wherein the running gear is arranged in the main body to drive the entire cementitious material precise distribution and dense operation robot to move; the pipe frameis fixed on the main body; the material distributing pipe is mounted on the pipe frame and extends downwards; the extending-retracting mechanism is arranged on the pipe frame and controls the material distributing pipe to retract or put down relative to the pipe frame; the vibrator is fixed on the material distributing pipe to drive the material distributing pipe to vibrate; a feeding port is further formed in the base; and the cementitious material precise distribution and dense operation robot is further provided with a feeding passage communicating between the feeding port and the materialdistributing pipe. The cementitious material precise distribution and dense operation robot vibrates through changing the pouring manner while pouring to improve the concrete material combining compactness and ensure the quality of a wall component, can automatically finish wall pouring forming to improve the operation automation and liberate labor force, and is suitable for being popularized inthe construction industry.

Owner:广东山众建筑科技有限公司

Aluminum-chrome-magnesium refractory brick and preparing method thereof

The invention discloses an aluminum-chrome-magnesium refractory brick for glass industries and nonferrous industries and a preparing method of the aluminum-chrome-magnesium refractory brick. The aluminum-chrome-magnesium refractory brick is prepared from, by mass percentage, 10-30% of sub-white corundum with the particle size of 1-3 mm, 10-35% of aluminum magnesium spinel with the particle of 1-2mm, 5-15% of aluminum magnesium spinel with the particle size of 0.088-1 mm, 10-25% of an aluminum-chrome composite material with the particle size of 0.088-1 mm and 25-40% of an aluminum-chrome composite material with the particle size of 0.088 or below. Besides, a binding agent which accounts for 2-7% of the total mass of all the raw materials is added. By means of the prepared aluminum-chrome-magnesium refractory brick, the pollution of hexavalent chromium in residual bricks is reduced, and the problem of shortage of aluminum-chrome raw materials is solved. The aluminum-chrome-magnesium refractory brick has the advantages of being stable in production and preparation process, high in manufacturing yield, and excellent in erosion resistance and thermal shock stability, and can achieve agreat effect when applied to thermal storage chambers of glass kilns or rotary kilns for the nonferrous industries.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Inside lining building method for aluminium electrolysis two-man ladle

The invention relates to a technology to heavily repair the ladle lining of 5t in an aluminum electrolytic industry, in particular to an aluminum electrolytic ladle lining building method which can effectively improve the service life of the aluminum electrolytic ladle lining. The building method disclosed by the invention includes the following steps: 1) eliminating the inside of the ladle shell; 2) building the inner side of the cylinder part of the ladle shell alternatively according to wide type high aluminum special shape bricks and narrow type high aluminum special shape bricks; 3) building the bottom surface of the ladle shell by high aluminum bricks longitudinally and alternatively; 4) adopting high intensity bonding to bond the gaps of the special shape bricks at the cylinder and the bottom part of the ladle shell; 5) welding a hook nail first on the cover and the mouth parts of the ladle; 6) pouring the cover and the mouth of the ladle by high-aluminum low-cement fire-resistant castable material; 7) drying the ladle lining. The invention improves the service life of the ladle lining of 5t, meets the manufacture requirements, simultaneously saves a plurality of repairing cost and reduces the environment pollution. The invention is suitable for the building of the ladle lining in the aluminum electrolytic industry and the building of the linings of any other furnace type.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Automatic pouring and vibrating device for pavement concrete

InactiveCN111733669AImprove uniformityReduce the presence of air bubblesRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses an automatic pouring and vibrating device for pavement concrete. The automatic pouring and vibrating device comprises a machine body, wherein a power space is formed in the machine body; a stirring space with a leftward opening is formed in the lower side of the power space; the lower side wall of the stirring space is communicated with an irrigation space with a downward opening; a regulating space is arranged on the right side of the irrigation space; a vibrating space with a downward opening is formed in the right side of the regulating space; a driving space is arranged on the right side of the vibrating space; a control point space is arranged on the left side of the driving space; the pouring speed of concrete pouring can be automatically regulated and controlled through the driving moving speed of the machine body so that the concrete pouring uniformity is greatly improved when concrete is poured to a road; meanwhile, vibration is directly conducted afterpouring, compared with traditional pouring vibration, bubbles in concrete are greatly reduced, concrete combination is more compact, the strength of concrete is greatly improved, and the quality of aconcrete component is guaranteed.

Owner:YIWU AOLI MASCH TECH CO LTD

Construction method for increasing dry auger boring pouring pile bearing capacity

A construction method for dry screw bored cast-in-place piles. Two grouting pipes are symmetrically arranged on the side walls of the pile holes, a steel cage is placed in the pile holes, and then concrete is poured. After 8-24 hours after the pile is formed, the cement slurry is injected into the soft soil of the pile side and pile bottom through the grouting pipe. The slurry is added with a concrete pumping agent of 1% by weight of the cement and a concrete expansion agent of 5%. The pumping pressure It is 200-300kg / cm2 until the upper end of the pile side has a slurry. The invention can more than double the bearing capacity of the single pile, thereby greatly shortening the length of the single pile, enabling most construction projects to form piles above the groundwater level, saving materials, reducing construction costs and reducing construction pollution.

Owner:李树源

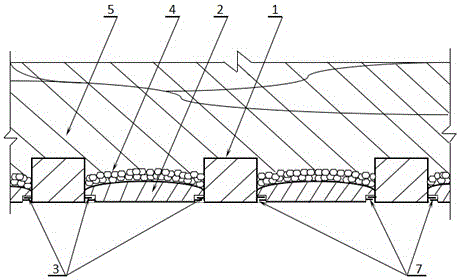

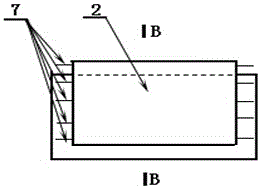

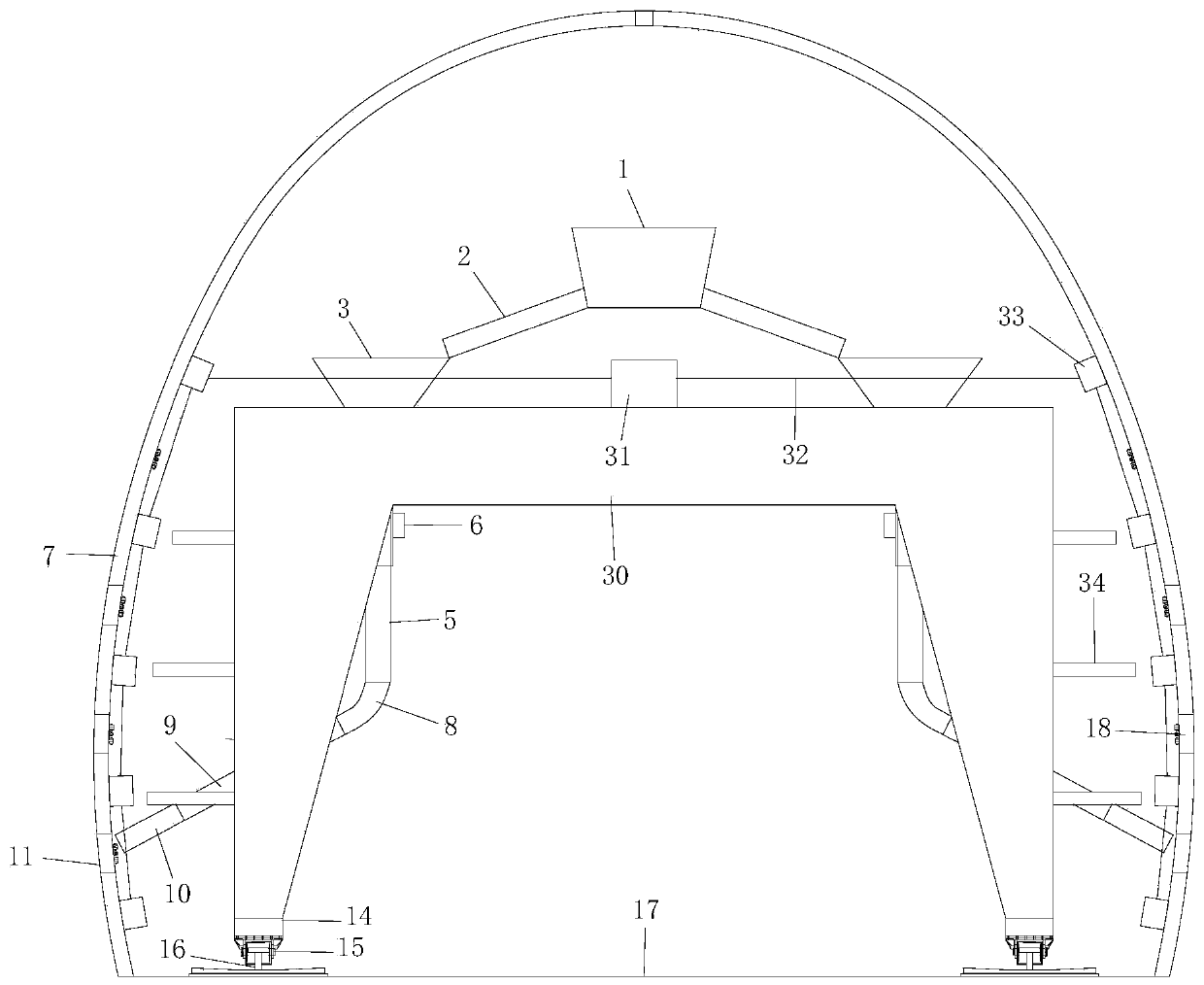

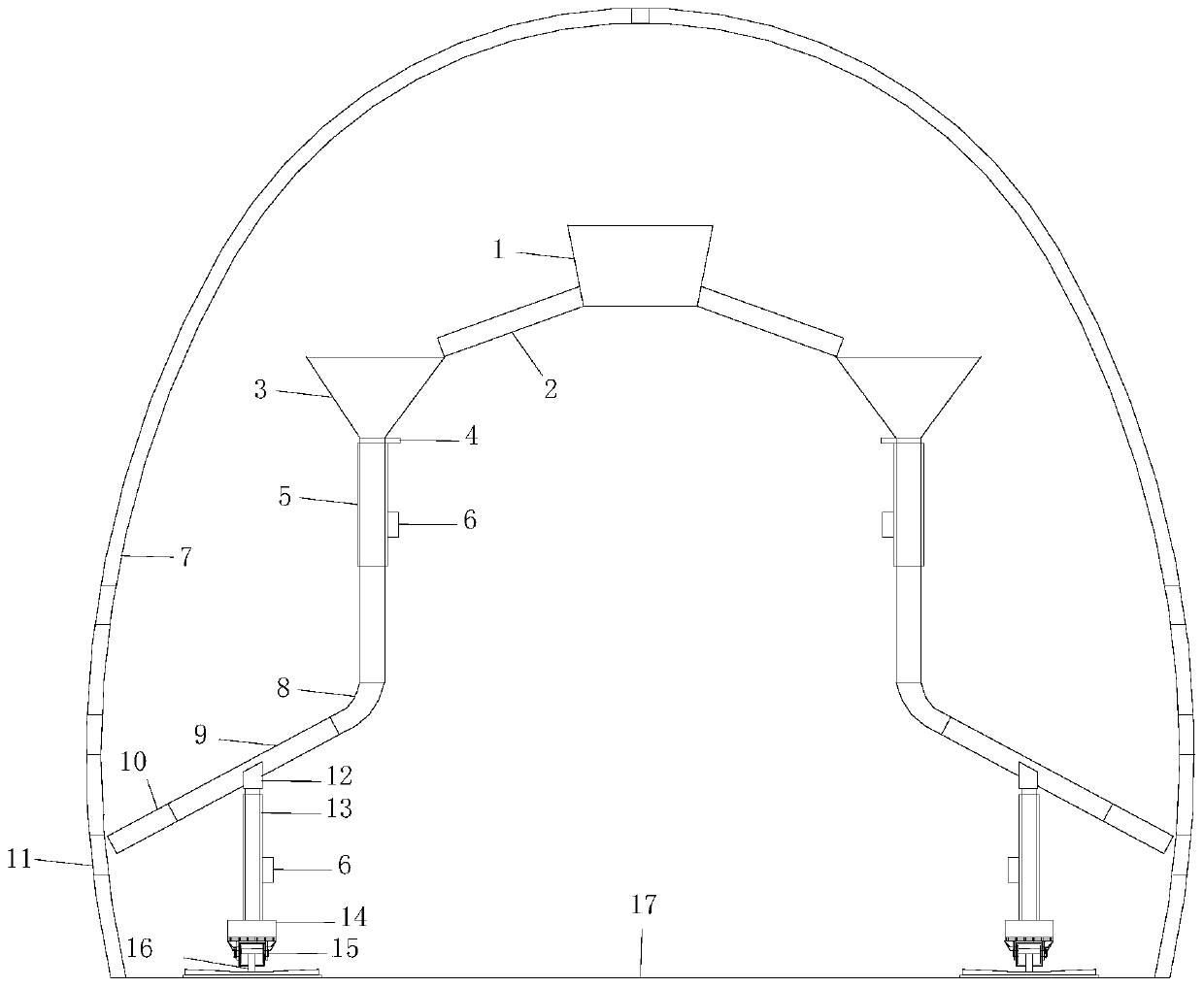

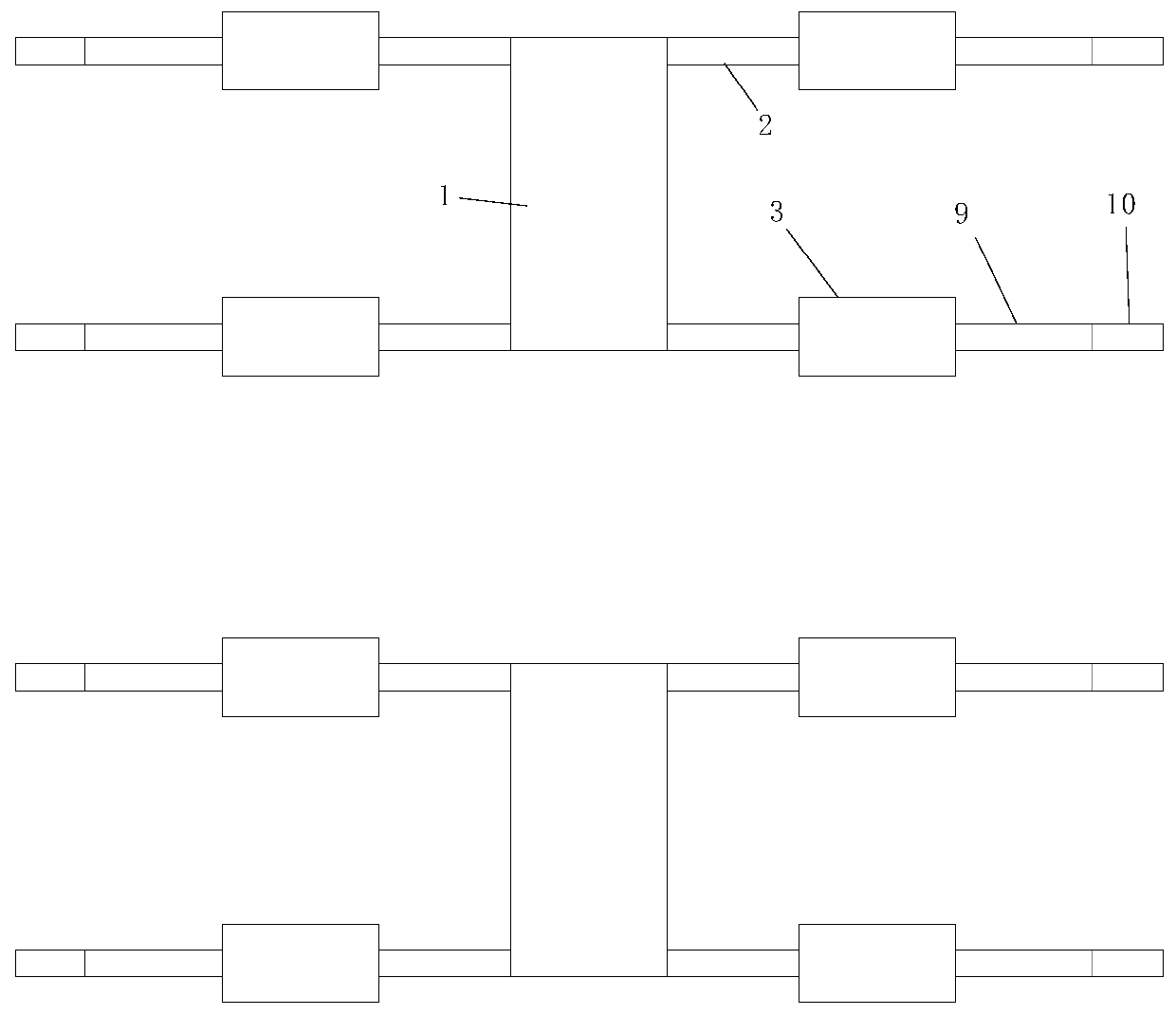

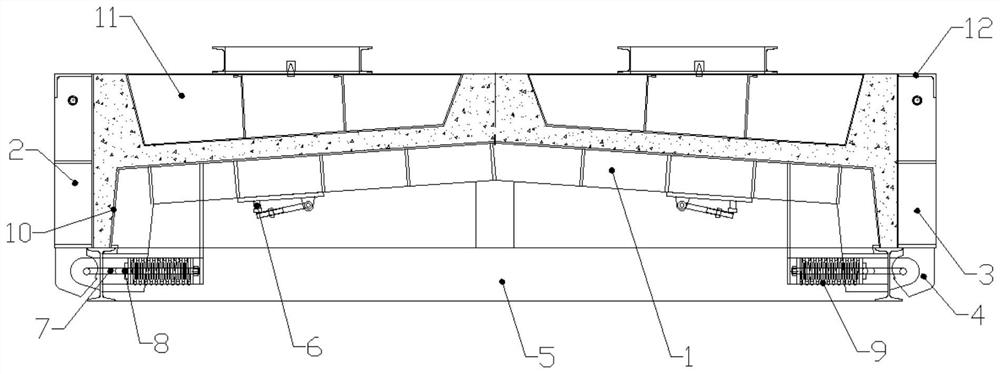

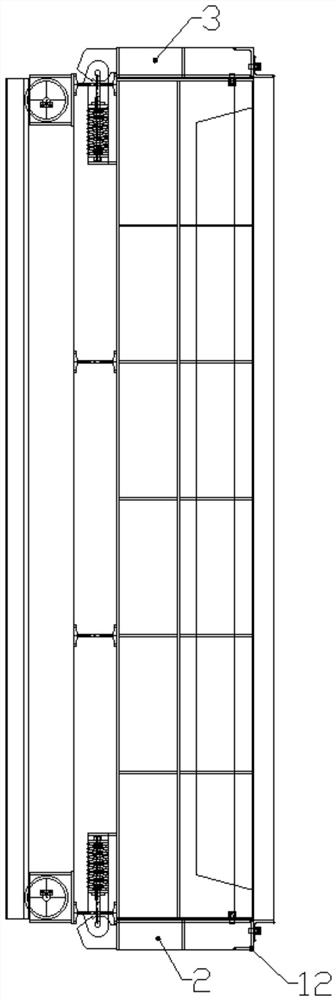

Tunnel second-lining concrete chute pouring system and construction method

ActiveCN110924988ARealize layer-by-layer and window-by-window mold entryQuality improvementUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention relates to a tunnel second-lining concrete chute pouring system. The tunnel second-lining concrete chute pouring system comprises a tunnel second-lining concrete chute system, a rapid closing structure of a lining formwork pouring window and a tunnel second-lining concrete multi-layer synchronous vibrating device. The tunnel second-lining concrete chute system comprises a main hopper, auxiliary hoppers, an inserting plate, a steel formwork, a fixed sling groove, a movable sliding groove, pouring windows, top supports, lifting supporting rods, a track and a tunnel pavement; the rapid closing structure of the lining formwork pouring window comprises the steel formwork, the pouring windows, hinged lug plates, closing plates, hinged bolt holes, fixed bolt holes and rubber sealingrings; and the tunnel second-lining concrete multi-layer synchronous vibrating device comprises the steel formwork, the pouring windows, bottom beams, trolley portals, a power distribution boxes, networking electric wires, attached flat vibrators, and extension platforms. The tunnel second-lining concrete chute pouring system has the beneficial effects that telescopic flow-dividing tumbling barrels and the lifting supporting rods are adopted, the heights of the sliding grooves can be flexibly adjusted to be suitable for pouring windows with different heights.

Owner:ZHEJIANG ZHENGFANG TRAFFIC CONSTR CO LTD

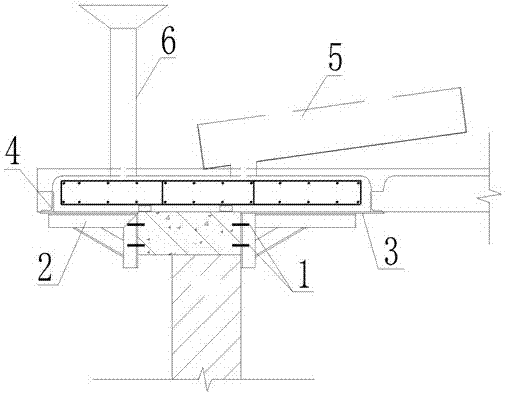

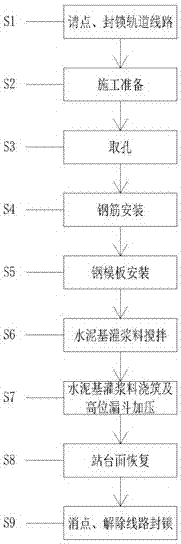

Reinforcing construction method for trough plate platform of operation subway station

InactiveCN108005402AGuarantee operational securityWell distributed holesBuilding repairsRebarSubway station

The invention discloses a reinforcing construction method for a trough plate platform of an operation subway station and belongs to the technical field of reinforcing construction of operation subwaystation structures. The reinforcing construction method comprises the following steps of S1, construction applying and blockage of a track line, S2, construction preparation, S3, hole forming, S4, mounting of steel bars, S5, mounting of steel formworks, S6, stirring of cement foundation grouting materials, S7, pouring of the cement foundation grouting materials and pressurizing of a high funnel, S8, platform surface recovering and S9, applying of construction completion and removing of line blockage. According to the reinforcing construction method for the trough plate platform of the operation subway station, the two holes with the diameter being 90 mm are formed in a trough plate and serve as the pouring hole and the pressurizing hole correspondingly, and not only can the integrity of the overall structure of the trough plate platform and the safety of the operation station be guaranteed, but also the reinforcing construction requirements can be met; the assembled steel formworks areutilized as a part of the reinforcing structure, and convenience and rapidness are achieved; and the reinforcing construction method has the advantages that safety is high, operation is convenient, applicability is high, and manual operation strength is reduced.

Owner:ELECTROMECHANICAL DEVICE INSTALLATION OF CTCE GROUP

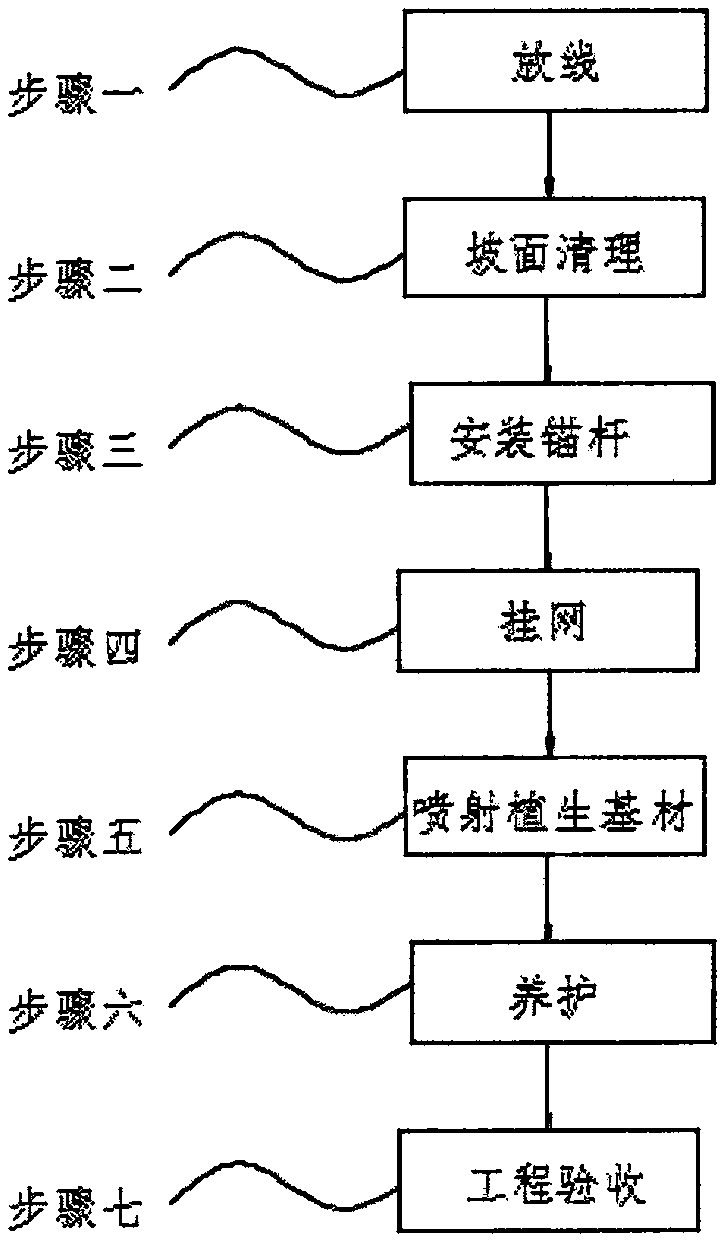

Construction method for sowing grass planting by spraying on side slopes in high-altitude areas

The invention discloses a construction method for sowing grass planting by spraying on side slopes in high-altitude areas. The construction method comprises the following steps of (1) paying off; (2)clearing slope surfaces; (3) installing anchor rods; (4) hanging nets; (5) spraying a plant growing medium; (6) curing; (7) accepting project. The construction method disclosed by the invention has the beneficial effects that by vegetation spray-sowing on the side slopes, the phenomena of washout of rainwater on the side slopes and water and soil loss are effectively prevented; due to formed near-earth microclimate, the driving environment of expressways is effectively improved, and the acceleration of the greening and beautifying processes of the environment in surrounding areas can be promoted; the mechanical degree is high, and the construction speed is fast; by stirring and spraying of a spray-sowing machine on materials such as soil, organic fertilizer, water-retaining agents, adhesives, water and the like, the uniformity of grass seeds is high, and after combination with the soil, the compact effect is achieved; after grass grows out, the coverage rate is high, and the grass andiron-wire meshes on the slope surfaces form a whole, so that the resistance to rainwater washout is greatly improved.

Owner:青海生源园林绿化工程有限公司

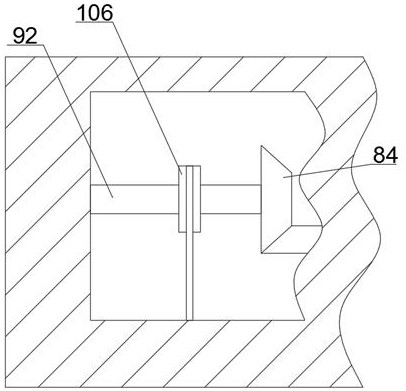

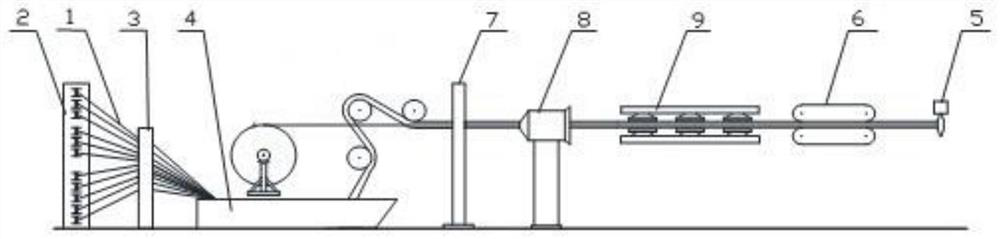

Preparation device and preparation process of Brillouin sensing intelligent rib

PendingCN114459629ACombined densePoint segment controllableThermometers using physical/chemical changesUsing optical meansYarnFiber

The invention discloses a preparation device of a Brillouin sensing intelligent rib, and relates to the technical field of protective doors. Comprising a traction device and a fiber creel, the fiber creel fixes one end of a fiber yarn bundle, the other end of the fiber yarn bundle enters a resin tank through a guide plate, the resin tank merges the fiber yarn bundle and passes through a creel, the creel merges the passing fiber yarn bundle with a sensing optical fiber, and the sensing optical fiber passes through the creel. And the fiber yarn bundle and the sensing optical fiber pass through a combined mold. The device has the advantages that the sensing optical fiber and the fiber yarn bundle are synchronously transmitted, the sensing optical fiber is arranged in the center of the intelligent rib, and the sensing optical fiber and the fiber yarn bundle body of the intelligent rib are compactly combined; an advanced ultraviolet irradiation curing process is adopted, irradiation point positions are sectionally controllable, irradiation light intensity is sectionally adjustable, curing quality and production efficiency are improved, the defect that a previous drying tunnel is too long is overcome, and the whole production line is smoother and more compact.

Owner:上海派溯智能科技有限公司 +2

Modified rubber concrete

InactiveCN109503058AEvenly distributedAvoid water repellencyPolymer scienceUltimate tensile strength

The invention discloses modified rubber concrete. According to the modified rubber concrete, the weight ratio of cement to water to sand to stone to modified rubber particles is 430:151.7:(593.75-531.25):1160:(13.76-41.3), wherein a preparation method for the modified rubber particles comprises the following steps that (1) rubber particles are soaked in tap water and are taken out 7-10 days later;(2) an accelerator and the cement are uniformly mixed according to the ratio of 1:4; (3) the rubber particles wetted in the step (1) and powder obtained in the step (20 are mixed and stirred until the slump of a mixture is 6-10; and (4) mixture particles obtained in the step (3) are dried and then are maintained in water, and when needed, the mixture particles are taken out and aired until the surfaces of the particles are offwhite. Compared with the strength of standard common concrete, the reduction range of the strength of the modified rubber concrete is decreased, and compared with the strength of standard rubber concrete, the strength of the modified rubber concrete is obviously improved.

Owner:中交天津港湾工程设计院有限公司

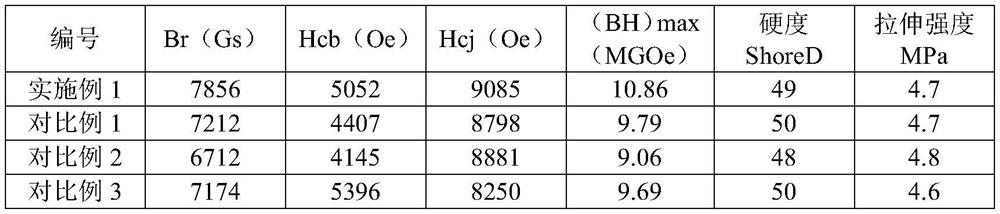

Flexible neodymium-iron-boron magnet as well as preparation method and application thereof

PendingCN112563011AEasy to fillImprove magnetic propertiesMagnetic materialsPermanent magnet manufactureVulcanizationMixed materials

The invention discloses a flexible neodymium-iron-boron magnet as well as a preparation method and application thereof. The preparation method of the flexible neodymium-iron-boron magnet comprises thefollowing steps: mixing neodymium-iron-boron magnetic powder, rubber and auxiliary materials; crushing and tabletting the mixed material to obtain a sheet; carrying out heating and magnetic field orientation on the sheet; and calendering, vulcanizing and carrying out surface treatment to obtain the flexible neodymium-iron-boron magnet. Magnetic field orientation is carried out on the high-temperature neodymium-iron-boron sheet by heating the sheet, the magnetic performance of the flexible neodymium-iron-boron magnet can be effectively improved, and the obtained flexible neodymium-iron-boron magnet has good magnetic performance, mechanical performance and corrosion resistance.

Owner:GUANGZHOU GOLDEN SOUTH MAGNETIC MATERIAL

A kind of production method of fishing rod film

The invention relates to a production method of a fishing rod film. The method comprises the following steps: selecting polypropylene of which the isotacticity is over 96 percent for serving as a major raw material, adding 0.5-3 percent by mass of anti-blocking agent, 0.5-3 percent by mass of slip agent and 0.5-3 percent by mass of high-temperature-resistant aid into the polypropylene raw material, and mixing uniformly; adding the mixed raw materials into an extruder, forming three layers of stretched films through co-extrusion and stretching, and performing eight segments of preheating, four segments of stretching, two segments of sizing and two segments of cooling in two areas. The fishing rod film can be prevented from being bonded during hot molding at the high temperature below 150 DEG C, does not contract transversely, is combined firmly on a cloth layer, does not contain air bubbles, is easy to peel after cooling and molding, can be applied to manufacturing of various products such as ball arms and ski sticks, and is wide in application.

Owner:YANTAI TIANSU PACKAGING MATERIAL CO LTD

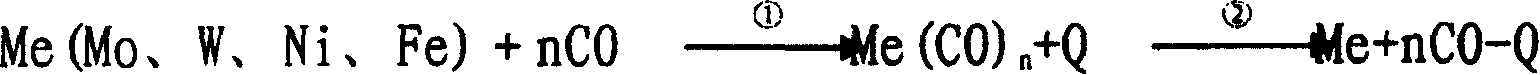

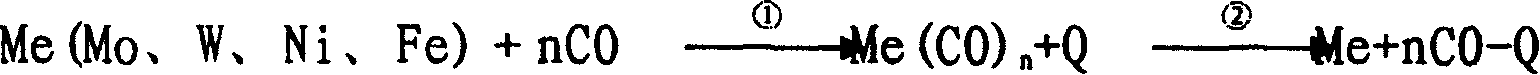

Method for preparing solid self-lubricating material

The present invention relates to a preparation method of solid self-lubricating material. Said preparation method includes the following steps: firstly, using carbon oxide and metal and making them produce reaction under the action of a certain temperature and pressure to form carbonyl metal compound, then making the carbonyl metal compound undergo the process of thermo-cracking treatment to obtain the metal powder with required size, and making the metal powder be deposited on the surface of solid lubricating agent to coker said surface so as to form compact solid lubricating agent microspheres, making said microspheres be mixed with metal and alloy powder according to a certain ratio to obtain solid self-lubricating raw material, finally press-forming by utilizing isostatic cool pressing technique and sintering by means of vacuum-hydrogen sintering process so as to obtain the invented product. Besides, said invention also provides its application range.

Owner:BEIJING CISRI GAONA TECH

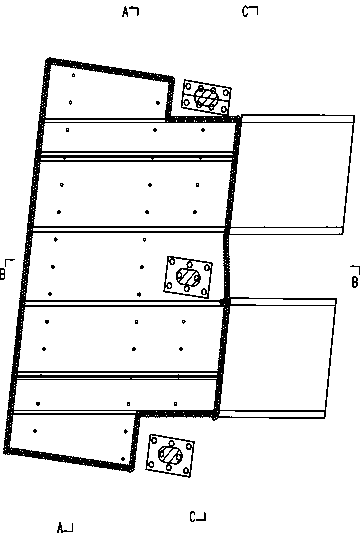

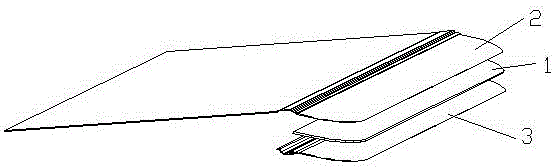

Covering curtain and production process thereof

The invention discloses a covering curtain. The covering curtain comprises a fiber board, wherein an upper cloth curtain and a lower cloth curtain are respectively laminated and attached to the upper surface and the lower surface of the fiber board, and the fiber board is laminated with the upper cloth curtain and the lower cloth curtain by PE adhesive films. The invention also discloses the covering curtain and a production process of the covering curtain. Due to the structure laminated and attached by the PE adhesive films, the covering curtain is high in firmness and strength, and dense in combination, and quick bonding can be achieved after laminating without cooling, so that the production time is shortened.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

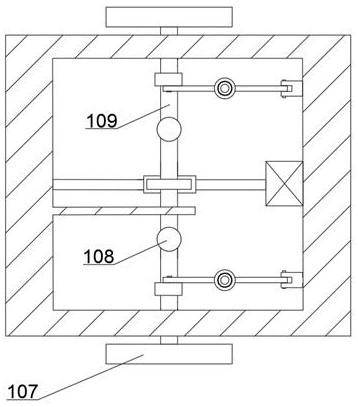

Dung scraping plate mold and dung scraping plate pouring method

ActiveCN111958754AEliminate honeycomb pockmarksCombined denseMouldsCeramic shaping mandrelsHoneycombStructural engineering

The invention discloses a dung scraping plate mold and a dung scraping plate pouring method. The dung scraping plate mold comprises a mold core, a side module, a bottom frame, a vibration plate and anupper forming part. The two sides of the bottom frame are each provided with an elastic moving assembly. A first side mold and a second side mold are hinged to the elastic moving assemblies on the two sides of the bottom frame through two hinges correspondingly. Pouring of a dung scraping plate is conducted through methods including side module adjustment, sealing treatment, pouring, vibration and parting. Flowing constraint is conducted around poured concrete through the upper forming part, the first side mold, the second side mold and the mold core, thus the poured concrete is sized, the vibration plate is further arranged between the mold core and the bottom frame, therefore, the vibration plate can drive the mold core to vibrate during pouring, bubbles in the concrete are removed, thus the concrete is closely combined, honeycomb and scale phenomena of the concrete are eliminated, the bottom frame, the first side mold and the second side mold are connected through the hinges, thereby becoming a whole, and flexibility is high.

Owner:河南辰园装配式建筑有限公司

Building assembly type steel structure building external hanging formwork

The invention provides a building assembly type steel structure building external hanging formwork which comprises a first wallboard. A reinforcing frame is fixed to one side of the first wallboard, asecond wallboard is fixed to the side, away from the first wallboard, of the reinforcing frame, and connecting grooves are formed in the two sides, away from the reinforcing frame, of the first wallboard and the second wallboard, wherein splicing plates are arranged in the connecting grooves. According to the building assembly type steel structure building external hanging formwork, when concreteis poured, a vibrating bar penetrates through vibrating bar inserting holes and a communicating opening to enter the position between the first wallboard and the second wallboard, then the position between the first wallboard and the second wallboard is filled with the concrete, meanwhile, the vibrating bar vibrates, and the vibrating bar drives the concrete to flow, so that the concrete is compactly combined; and through the multiple vibrating bar inserting holes, the vibrating bar can be inserted between the first wallboard and the second wallboard of different layers, bubbles between the concrete are discharged, and the strength of the concrete can be effectively improved.

Owner:杭州铂弘建设有限公司

Novel electric egg mixer

InactiveCN104127138AGuaranteed qualityPreserve the original tasteKitchen equipmentEggshellEngineering

The invention discloses a novel electric egg mixer. The novel electric egg mixer comprises a shell, a clamping device used for clamping an egg body is arranged in the shell, and the clamping device is connected with a motor used for driving. A circuit board used for controlling is arranged below the motor, the circuit board controls the motor to rotate positively and negatively, and the egg white and the egg yolk of the clamped egg body can be mixed under the action of shear force generated in the positive and negative rotation and conversion process. A containing groove is formed in the lower portion inside the shell, and the motor is mounted in the containing groove. By the adoption of the novel electric egg mixer, egg liquid can be fully mixed conveniently and rapidly under the condition that an eggshell is not broken, the phenomenon that containers are cleaned for mixing the egg liquid is avoided, the phenomenon that the egg liquid is exposed to the air is also avoided, meanwhile, the unshelled egg with the mixed egg liquid can be boiled directly, the egg which is golden in color, smooth in mouthfeel and tight in overall structure can be obtained, and thus a new material is brought to creation of egg product dishes; meanwhile, the phenomenon that children and the aged eat dry egg yolks so that suffocation risks can occur is avoided.

Owner:杨威

Processing method of whole grain vermicelli

The invention discloses a processing method of whole grain vermicelli. The processing method comprises the following steps of carrying out drying, cleaning, grading, stone removal and milling processes on whole grain, carrying out ultramicro-crushing to obtain whole grain superfine powder having fineness less than 74 micrometers, carrying out adjustment on water content of the whole grain superfine powder until the water content is in a range of 10 to 50%, feeding the whole grain superfine powder with water content of 10 to 50% into an extruder for one-step pasting extrusion noodle forming, setting extrusion conditions, wherein a first zone temperature is in a range of 40 to 60 DEG C; a second zone temperature is in a range of 60 to 80 DEG C; a third zone temperature is in a range of 80 to 120 DEG C; a forth zone temperature of 80 to 120 DEG C; a fifth zone temperature is in a range of 120 to 150 DEG C; and a sixth zone temperature is in a range of 70 to 90 DEG C, carrying out extrusion, and carrying out hang drying, cooling, cutting and packaging processes on extruded whole grain noodles to obtain whole grain vermicelli products. The processing method adopts a superfine powder crushing technology and a twin-screw boiling-extrusion physical modification vacuum degassing one-step forming technology to produce the whole grain vermicelli products so that various original nutrientcomponents of natural grain are retained; storage time is prolonged; and whole grain food processing quality and whole grain food edible quality are improved.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

High-ultraviolet-resistance rubber material

The invention discloses a high-ultraviolet-resistance rubber material which is prepared from the following raw materials in parts by weight: 30-55 parts of ethylene-propylene rubber, 20-40 parts of acrylate rubber, 2-10 parts of chlorosulfonated polyethylene, 2-8 parts of styrene-butadiene rubber, 1-2 parts of tert-butyl peroxide, 1-4 parts of phthalic anhydride, 20-40 parts of titanium dioxide-corn stalk fiber composite, 5-15 parts of cork flour, 45-65 parts of attapulgite, 5-12 parts of allophane, 2-6 parts of sodium illite, 1-6 parts of aluminium borate whisker, 2-4 parts of sodium antimonate, 0.5-2 parts of trimethyl phosphate, 0.2-0.8 part of epoxy fatty acid methyl ester, 0.1-0.6 part of plasticizer DBP, 0.5-1.2 parts of diethylene glycol benzoate, 1-2 parts of zinc stearate, 1-2 parts of poly-p-nitrosobenzene, 0.5-1.5 parts of antioxidant 1010, 0.5-1.5 parts of antioxidant DLTP and 1-2 parts of ultraviolet absorbent UV-531.

Owner:TIANCHANG KANGNING PLASTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com