Production process of fiber concrete

A technology of fiber concrete and production process, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc. It can solve the problems of low fiber concrete preparation efficiency and achieve the effects of improving manufacturing quality, improving mixing effect, and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

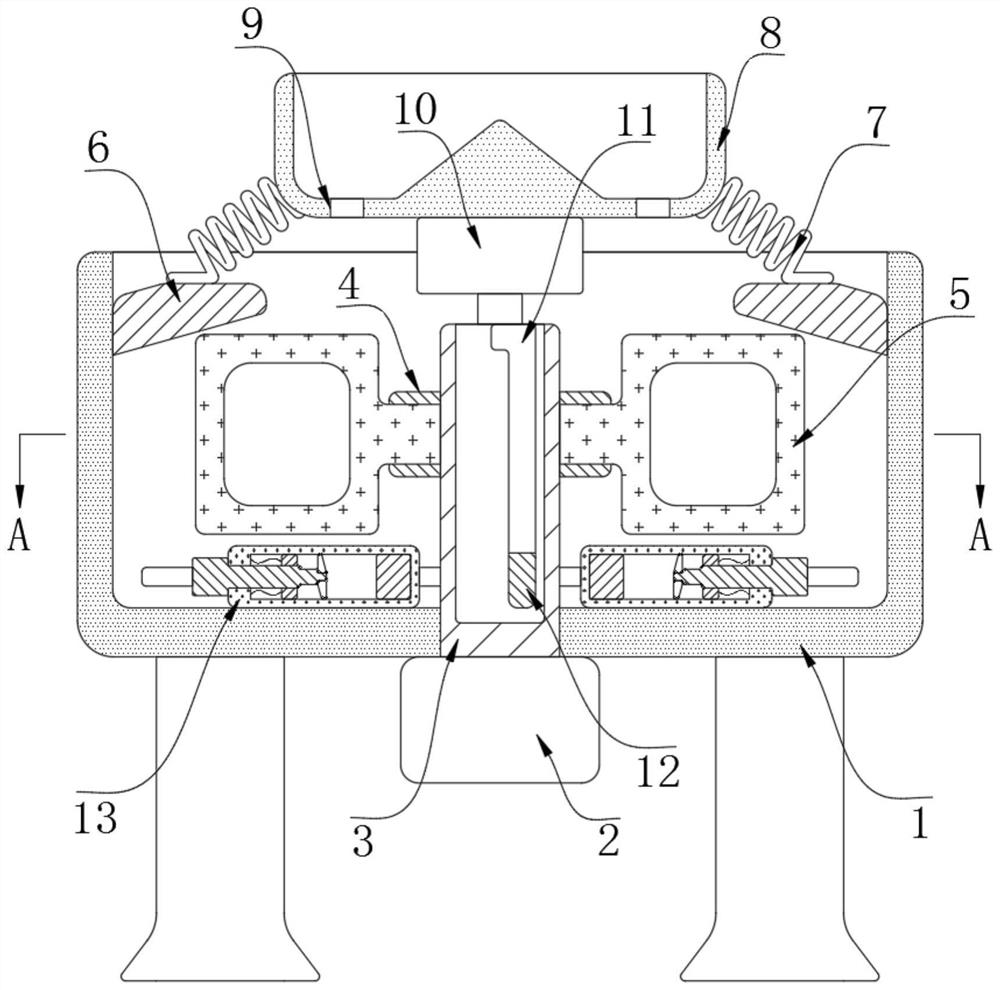

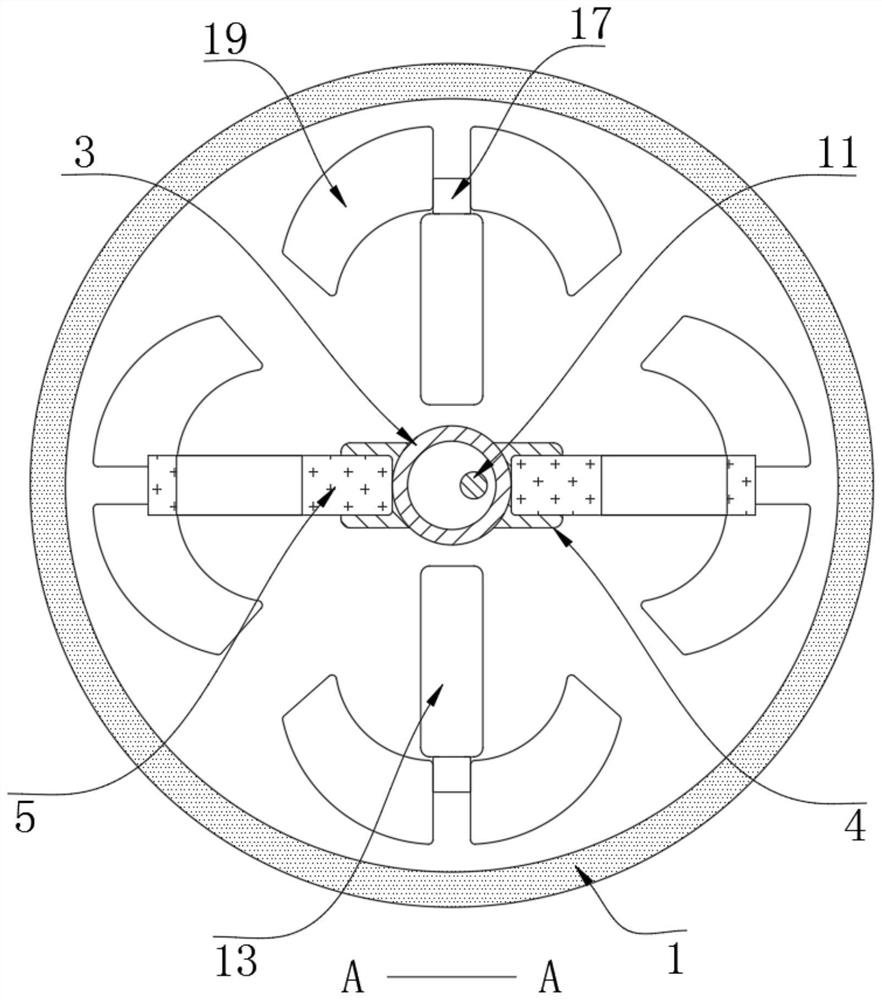

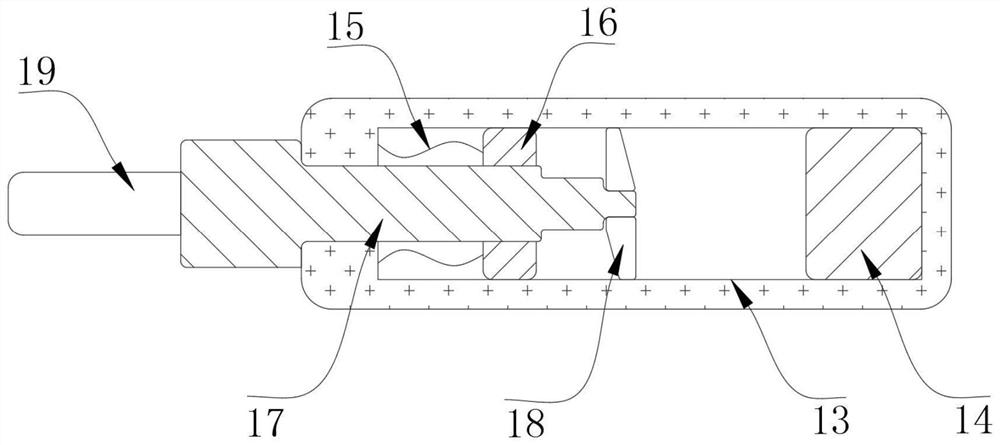

[0022] refer to Figure 1-3 , a production process of fiber concrete, mainly including the following processing steps:

[0023] S1. Concrete preparation: Add the basic concrete ingredients directly into the mixing tank 1, then start the stirring motor 2 to drive the stirring shaft 3 and the stirring blade 5 to rotate, so that the stirring blade 5 can mix and process the raw materials, and then complete the basic preparation of concrete ;

[0024] S2. Fiber feeding: put the prepared fibers into the loading box 8 together, because the fibers are in a chaotic state and are restrained from each other, so that the chaotic fibers cannot directly pass through the blanking hole 9, so that Fiber can be added on demand;

[0025] S3. Fiber mixing: Start the vibrating motor 10 to make it drive the eccentric shaft 11 to rotate, so that the vibrating motor 10 itself drives the loading box 8 to vibrate at high frequency, so that the chaotic fibers adjust their own angles during the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com