Inside lining building method for aluminium electrolysis two-man ladle

A technology of inner lining and aluminum electrolysis, which is applied in the field of aluminum electrolytic ladle lining masonry, can solve problems such as short service life of ladle lining, damage of ladle lining, and insufficient strength, so as to improve the corrosion resistance of molten aluminum and Anti-penetration performance, stable primary aluminum quality index, and the effect of resisting the penetration of molten aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

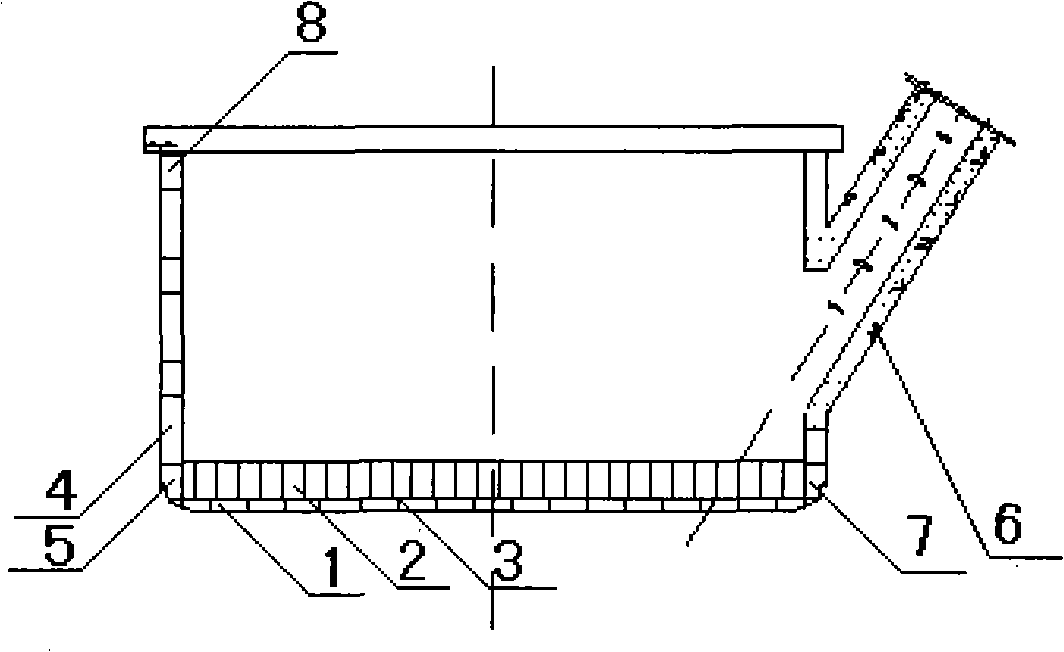

[0051] Described masonry method comprises the steps:

[0052] 1) Clear the inner wall of the ladle shell 8; check the inner wall of the ladle, and only the ladles that pass the inspection can be used for lining masonry;

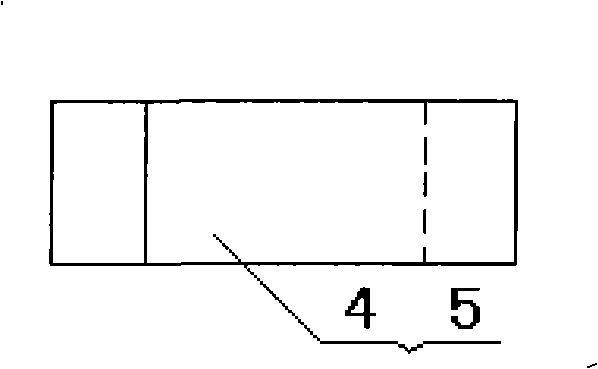

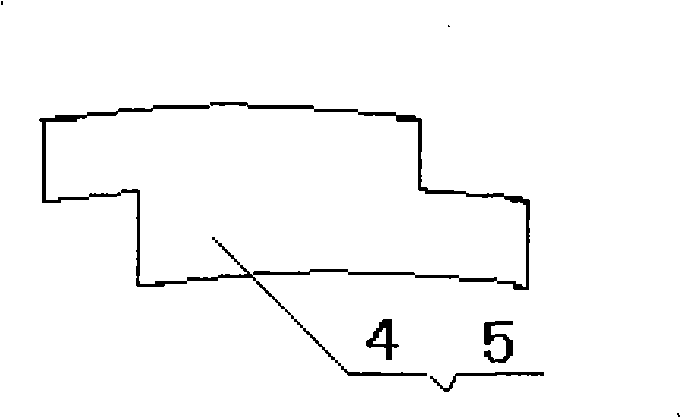

[0053] 2) Use wide-shaped high-aluminum special-shaped bricks 4 on the inner wall of the cylinder part of the cladding shell 8. Apply high-strength welding agent 3 on the curved convex surface of high-alumina special-shaped bricks 4 and the stepped bosses on the left and right sides according to every two wide-shaped high-aluminum bricks. The convex and concave surfaces on both sides of the special-shaped brick 4 are interlocked, that is, a lock-type horizontal masonry layer, and the high-strength welding agent 3 is applied to the curved convex surface of the narrow high-alumina special-shaped brick 5 and the stepped bosses on the left and right sides. The convex and concave surfaces on both sides of the high-alumina special-shaped brick 4 are interlocked, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com