Hydrophobic inorganic gel powder compounded multifunctional insulating mortar, as well as application and preparation method thereof

A technology of inorganic rubber powder and thermal insulation slurry, which is applied in the energy-saving field of building envelope structures, can solve the problems of out-of-control thermal insulation quality, lack of water-repellent function, hollowing and delamination of materials, etc., so as to ensure safety quality, reduce dust pollution, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

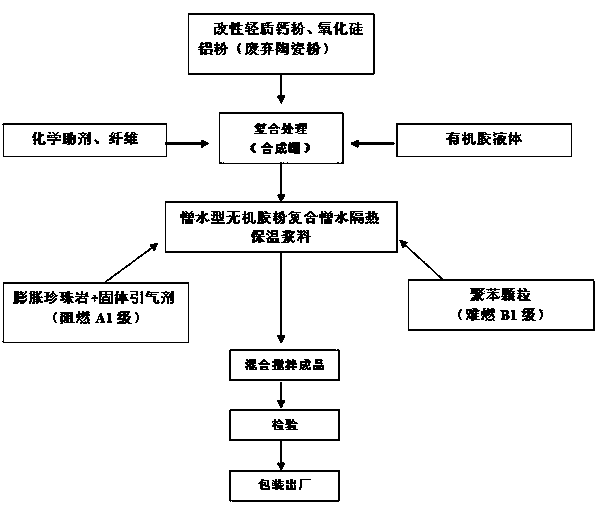

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: It is a basic embodiment of a hydrophobic inorganic rubber powder composite multifunctional thermal insulation slurry of the present invention. Its raw materials include 48-58% of modified light calcium carbonate powder, 5-10% of silica-alumina powder, 2-5% of acrylate emulsion, 25-35% of organic polymer gelling material and 0.4-0.8% of additives. The raw materials are mixed to form a slurry.

Embodiment 2

[0041] Embodiment 2: is the further embodiment of embodiment 1. The modified light calcium carbonate powder is modified by wrapping light calcium molecules with sodium stearate in a high-temperature molten state, and belongs to a hydrophobic inorganic heat-insulating material. The silica-alumina powder is a ceramic powder, which is processed from waste ceramic sheets containing silica and alumina polymers. The acrylate emulsion is a modified acrylate multi-polymer polymer emulsion; the organic polymer gelling material is alginate and hydroxypropyl methylcellulose, which respectively account for 15-20% of the total weight of the thermal insulation slurry and 10-15%; the seaweed gel is made of a polymer organic gelling material made from marine algae plants after chemical treatment; the hydroxypropyl methylcellulose is a water-retaining thickener. The auxiliary agent is polypropylene fiber and preservative, respectively accounting for 0.2-0.4% of the total weight of the thermal...

Embodiment 3

[0042] Embodiment 3: It is the basic embodiment of the preparation method of the hydrophobic inorganic rubber powder composite multifunctional thermal insulation slurry of the present invention. First use vacuum negative pressure equipment to inhale modified light calcium carbonate powder and silica aluminum powder into the mixing tank for mixing and stirring, then inhale acrylate emulsion, organic polymer gelling material and additives through vacuum negative pressure equipment to mix and stir tank, and finally mixed and stirred at room temperature to prepare a hydrophobic inorganic rubber powder multifunctional thermal insulation slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com