Waterproof processing construction method for framework bridge butt-connecting part

A technology of waterproof treatment and construction method, which is applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of insufficient vibration, waterstop penetration, poor impermeability, etc., to ensure the waterproof effect and improve the combination. Dense, high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

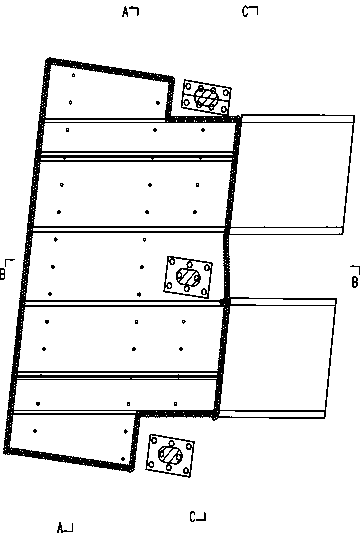

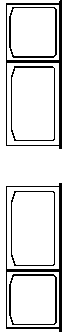

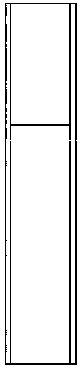

[0018] The technical scheme of the present invention is described below in conjunction with accompanying drawing and embodiment:

[0019] When the technical solution of the present invention is adopted, the concrete at the end of the existing frame is chiseled before the new frame is jacked, with a height of 35 cm and a width of 25 cm, and an "L" shape is sequentially built along the top plate, side wall and bottom plate of the existing frame. Groove 1, the size of "L"-shaped groove 1 is 25cm in plane width parallel to the frame axis, and 35cm in plane width perpendicular to the frame axis. After the groove, set the expansion bolts 3 at a distance of 30cm on the plane of the "L" groove parallel to the axis of the frame, and then smooth the plane with mortar, and the plane perpendicular to the axis of the frame remains rough. After the smoothed mortar reaches the design strength, apply two-component polysulfide sealant 4 to solve the problem of the combination of the waterstop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com