Patents

Literature

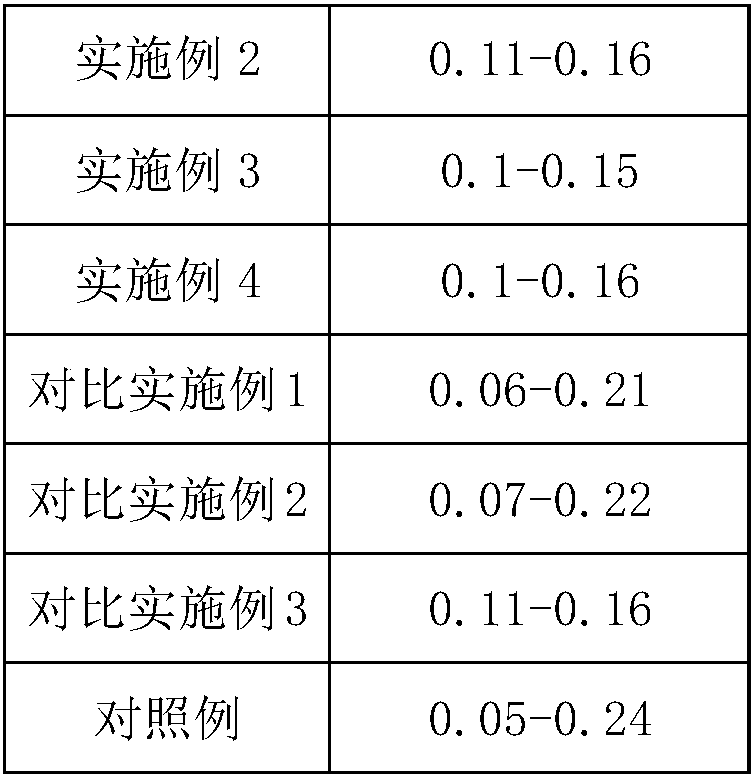

41results about How to "Well distributed holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

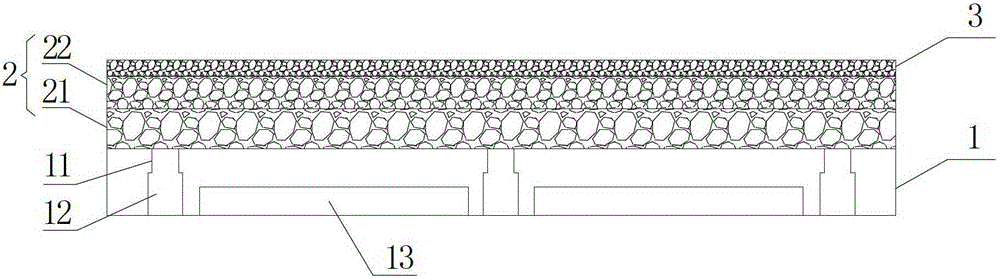

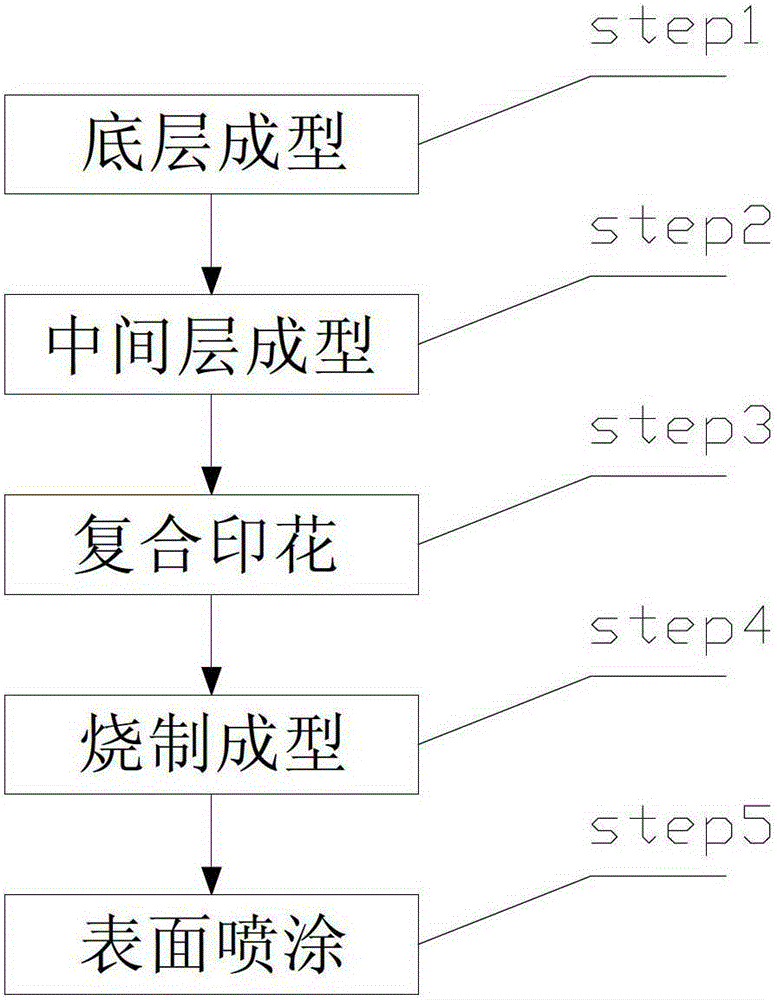

Water permeating and anti-skidding floor tile and manufacturing method thereof

ActiveCN103397767AFill technology gapsImprove the decorative effectLayered productsFlooringSurface layerPorous ceramics

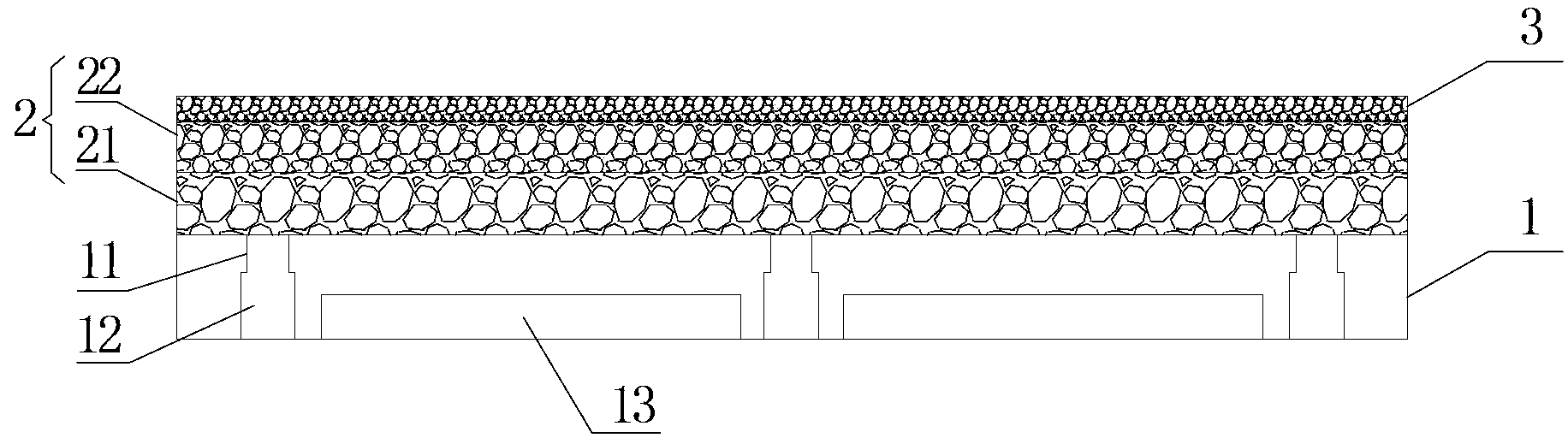

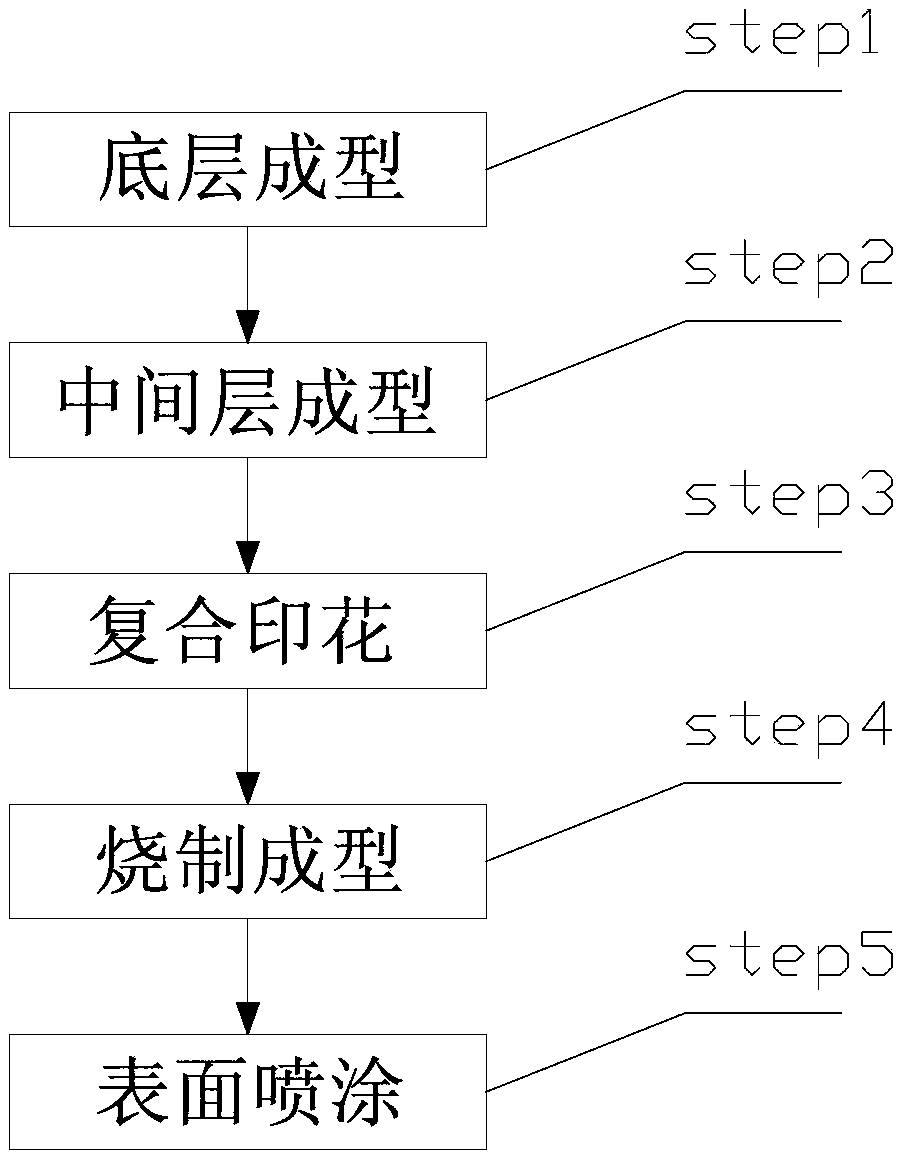

The invention discloses a water permeating and anti-skidding floor tile. The water permeating and anti-skidding floor tile comprises a bottom layer, middle layers and a surface layer all of which are combined together. The bottom layer is a dense ceramic layer, and a water removing hole penetrating through the upper surface and the lower surface of the bottom layer is formed in the bottom layer. The middle layers are porous ceramic layers which are provided with a plurality of through holes, and the effective aperture of each through hole is not larger than that of the water removing hole. The surface layer is a decoration glaze layer, and a plurality of micropores are formed in the decoration glaze layer, and the effective aperture of each micropore is not larger than that of the through holes. Preferably, the middle layers comprise at least two layers, and the effective apertures of the through holes in each layer are reduced gradually from bottom to top. Compared with the prior art, the water permeating and anti-skidding floor tile has the advantages of being good in water permeating performance, anti-skidding effect, mold proofing effect, anti-pollution effect and decorative effect. The invention further provides a manufacturing method of the water permeating and anti-skidding floor tile.

Owner:江显异

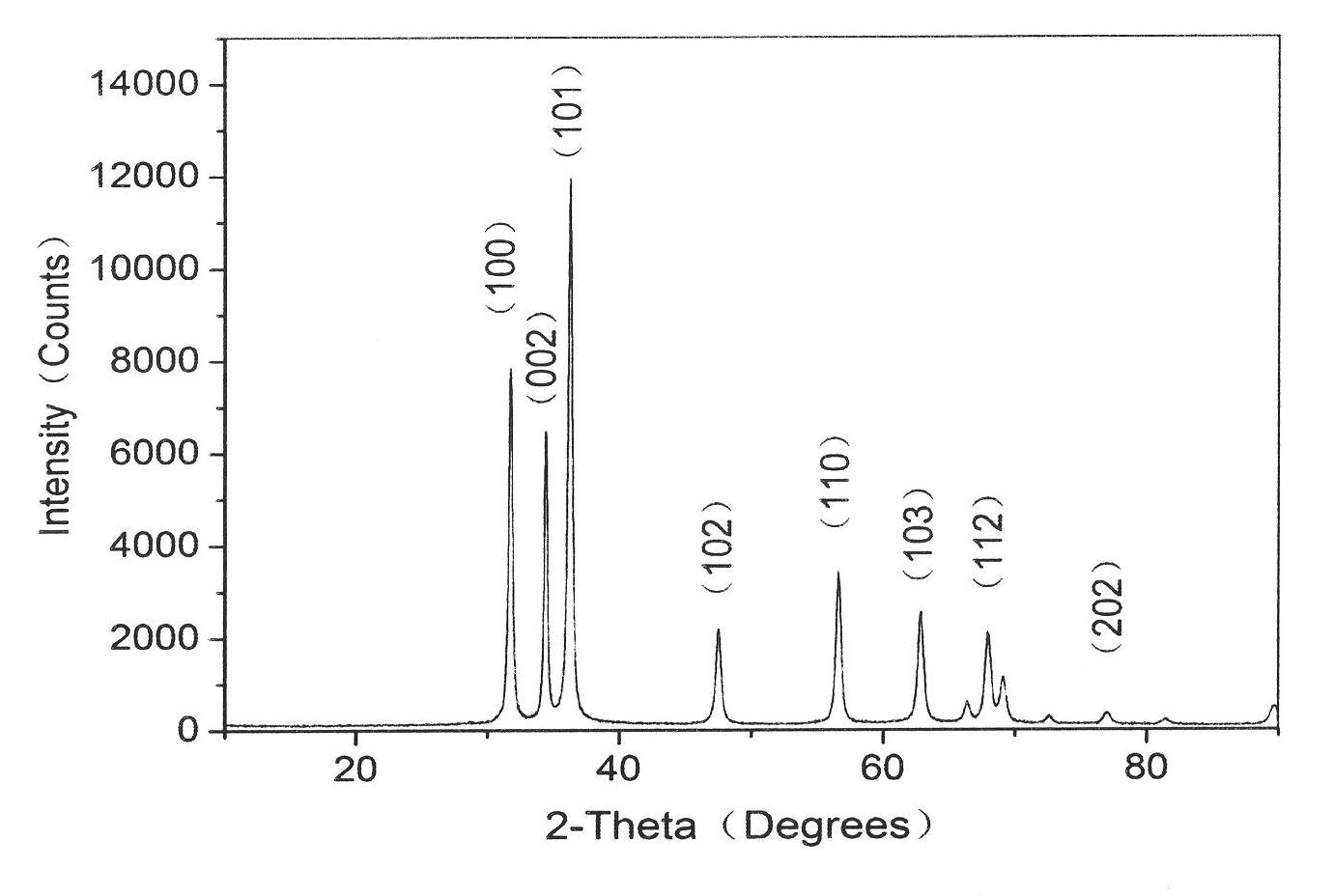

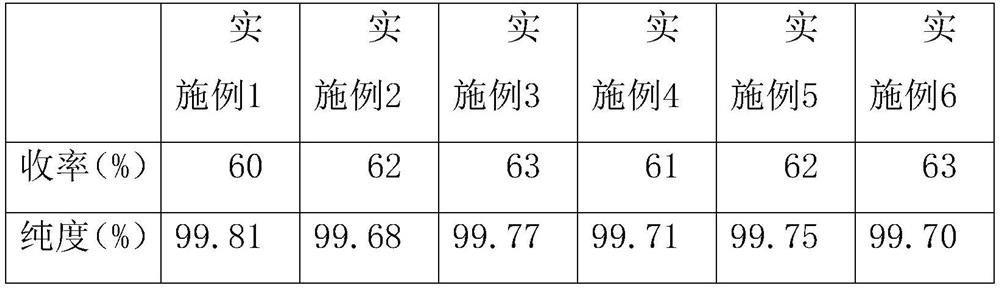

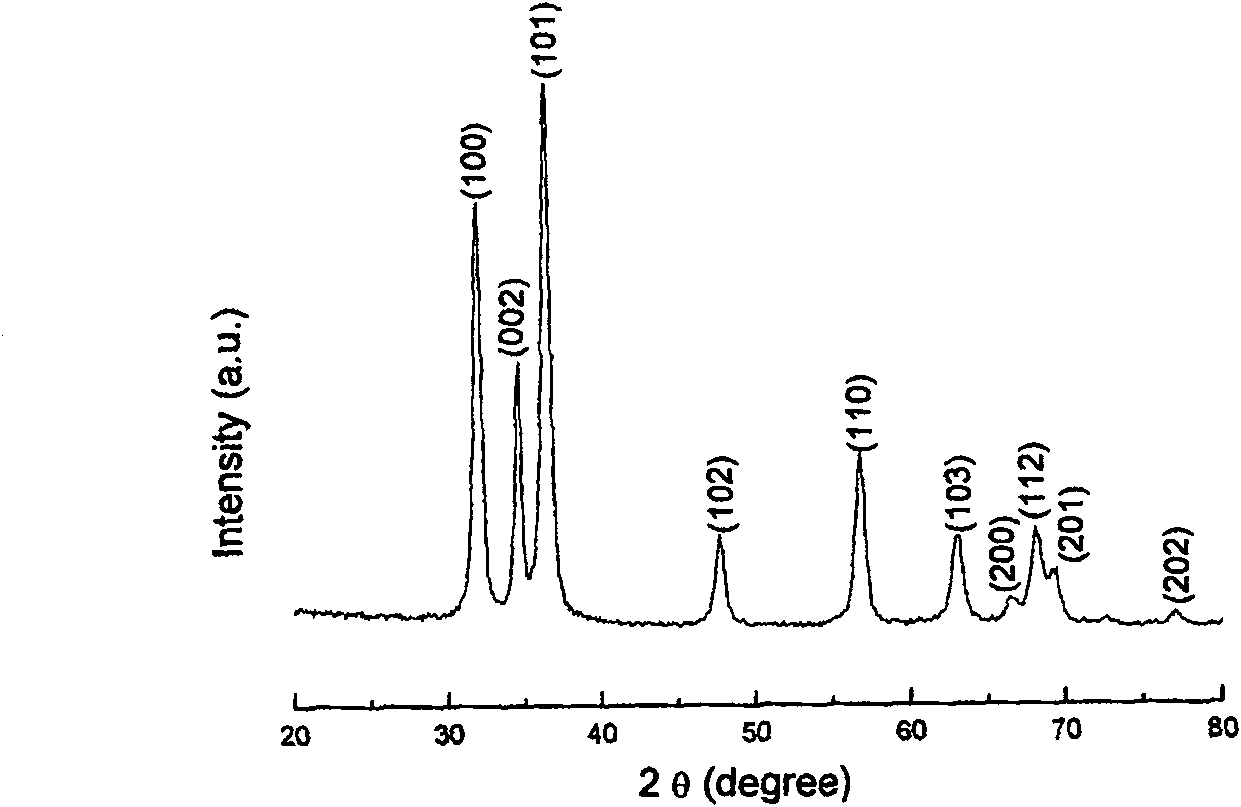

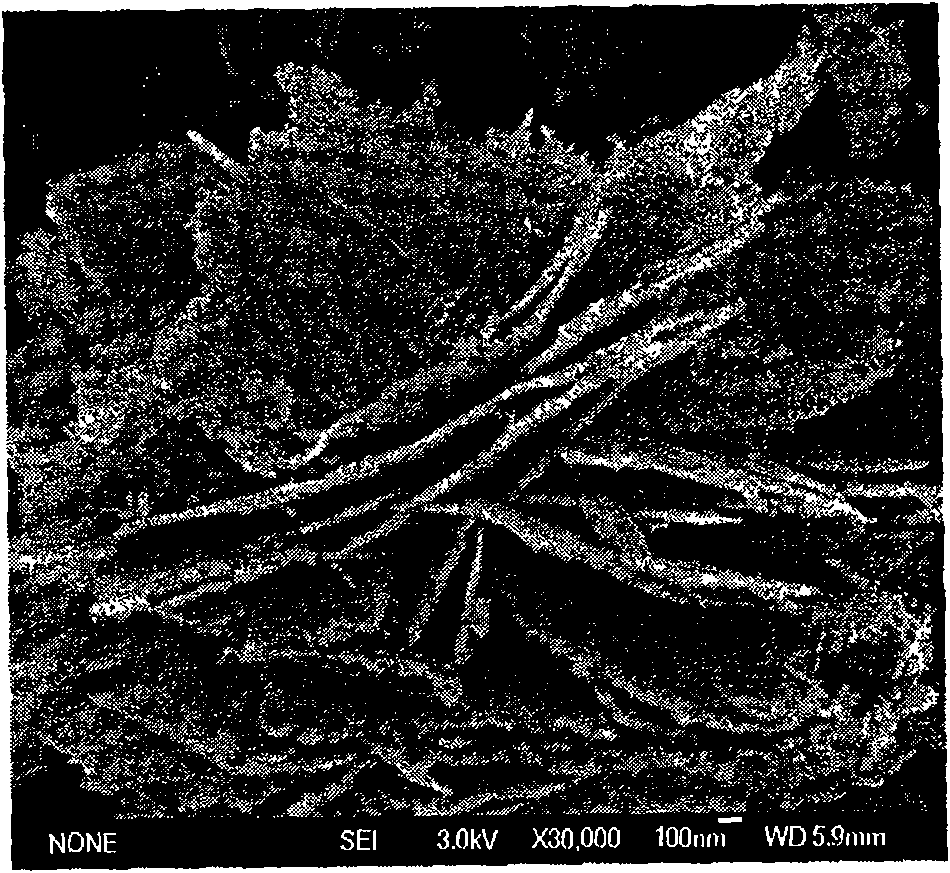

Method for preparing flake porous ZnO nano powder

InactiveCN101786651AHigh crystallinityImprove product qualityZinc oxides/hydroxidesWhite powderZinc nitrate

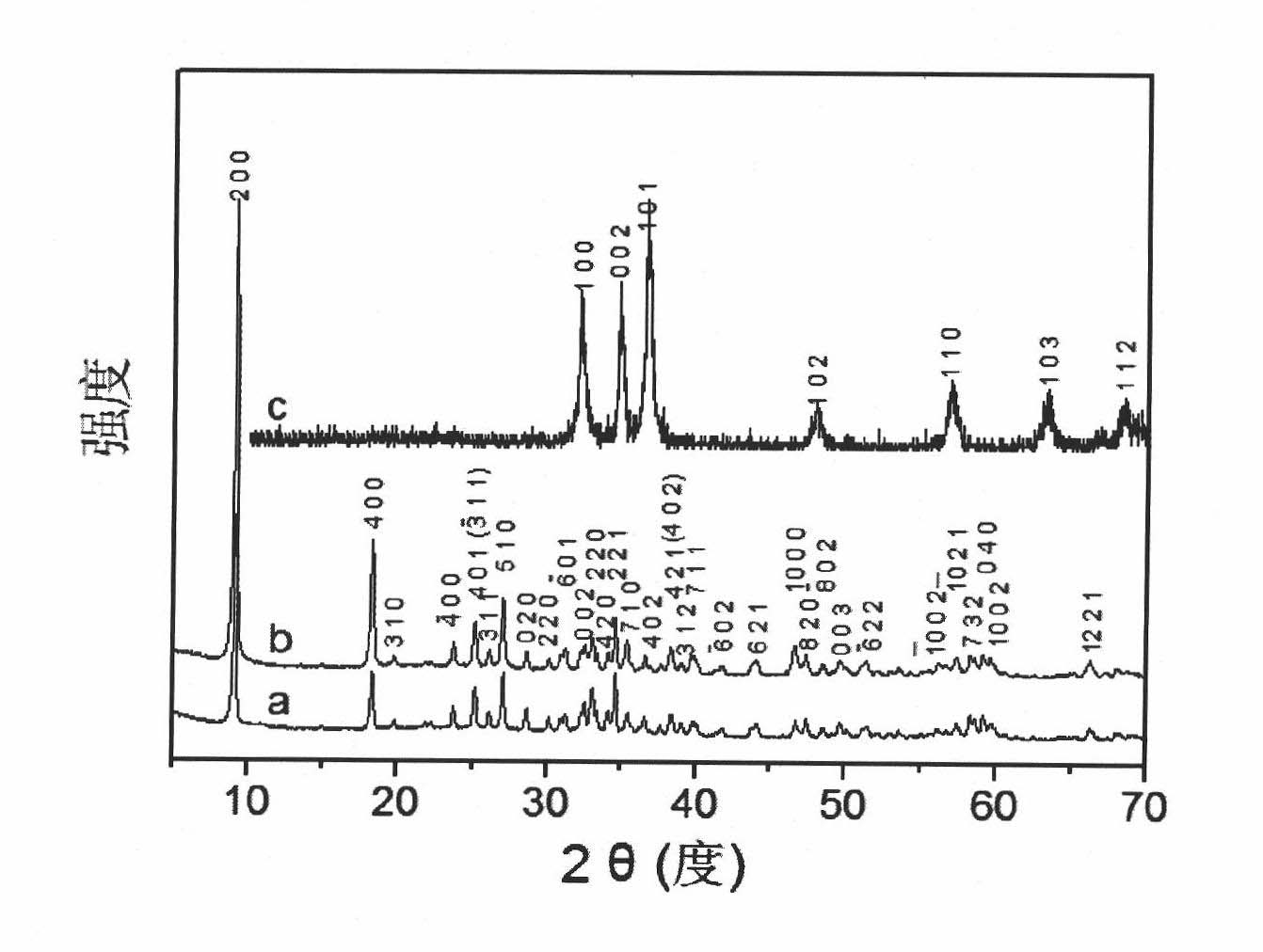

The invention relates to a method for preparing flake porous ZnO nano powder, which comprises the following steps: adding ammonia into solution of zinc nitrate dropwise, and adjusting the pH of the solution to between 6 and 8; under the condition of stirring by magnetic force at the rotating speed of 0 to 180r / m, performing reaction at the temperature of between 0 and 80DEG C for 0.5 to 3 hours; separating, washing and drying the obtained cloudy solution to obtain a crosslinked flake and dispersed flake basic zinc nitrate precursor; and calcinating the basic zinc nitrate precursor with the two appearances at the temperature of between 220 and 500DEG C for 0.5 and 3 hours to obtain the flake porous ZnO nano powder. The nano ZnO product prepared by the method is white powder, belongs to a hexagonal system, has large specific surface area, high purity and good product quality, and responds to gas such as ethanol and acetone sensitively.

Owner:ANHUI NORMAL UNIV

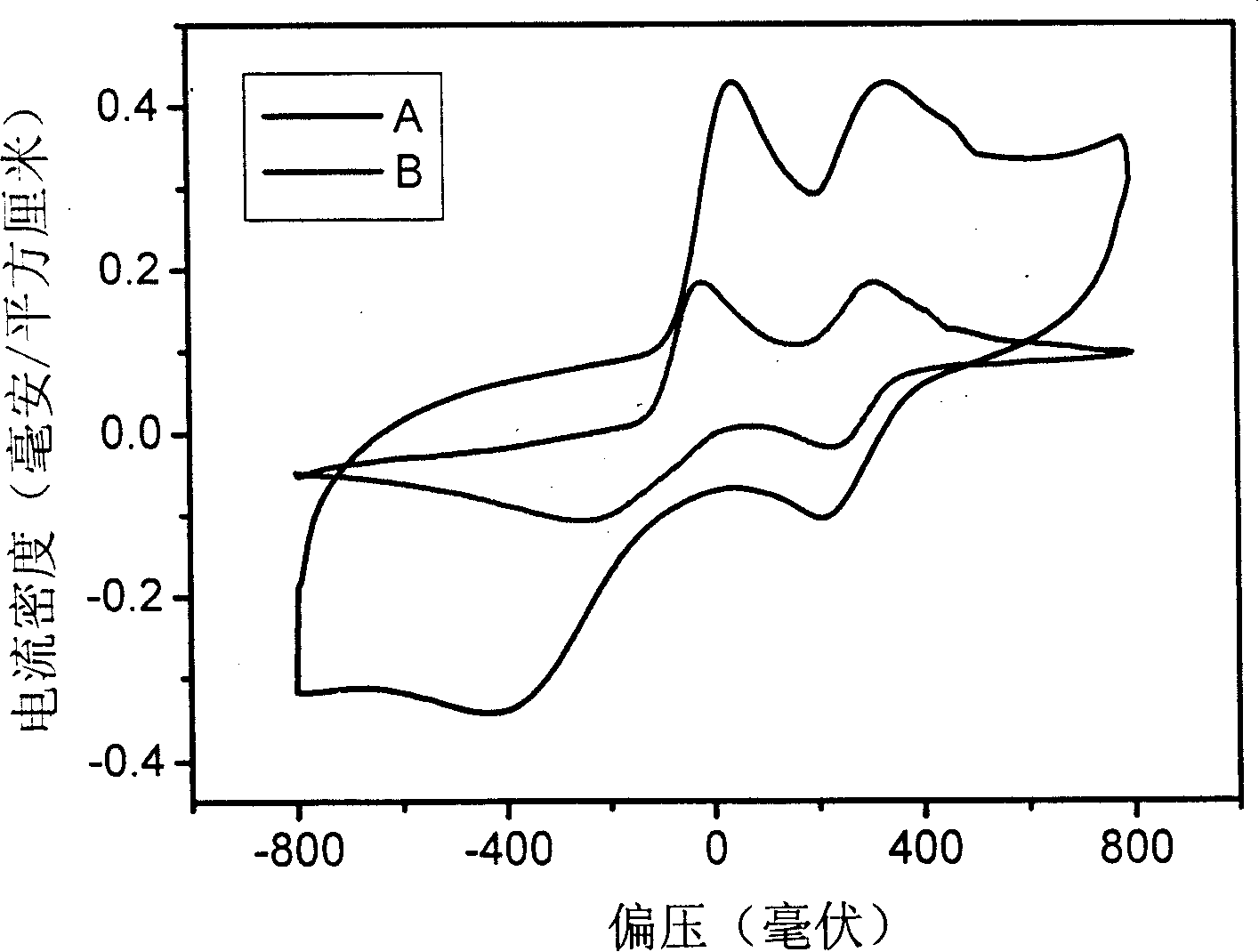

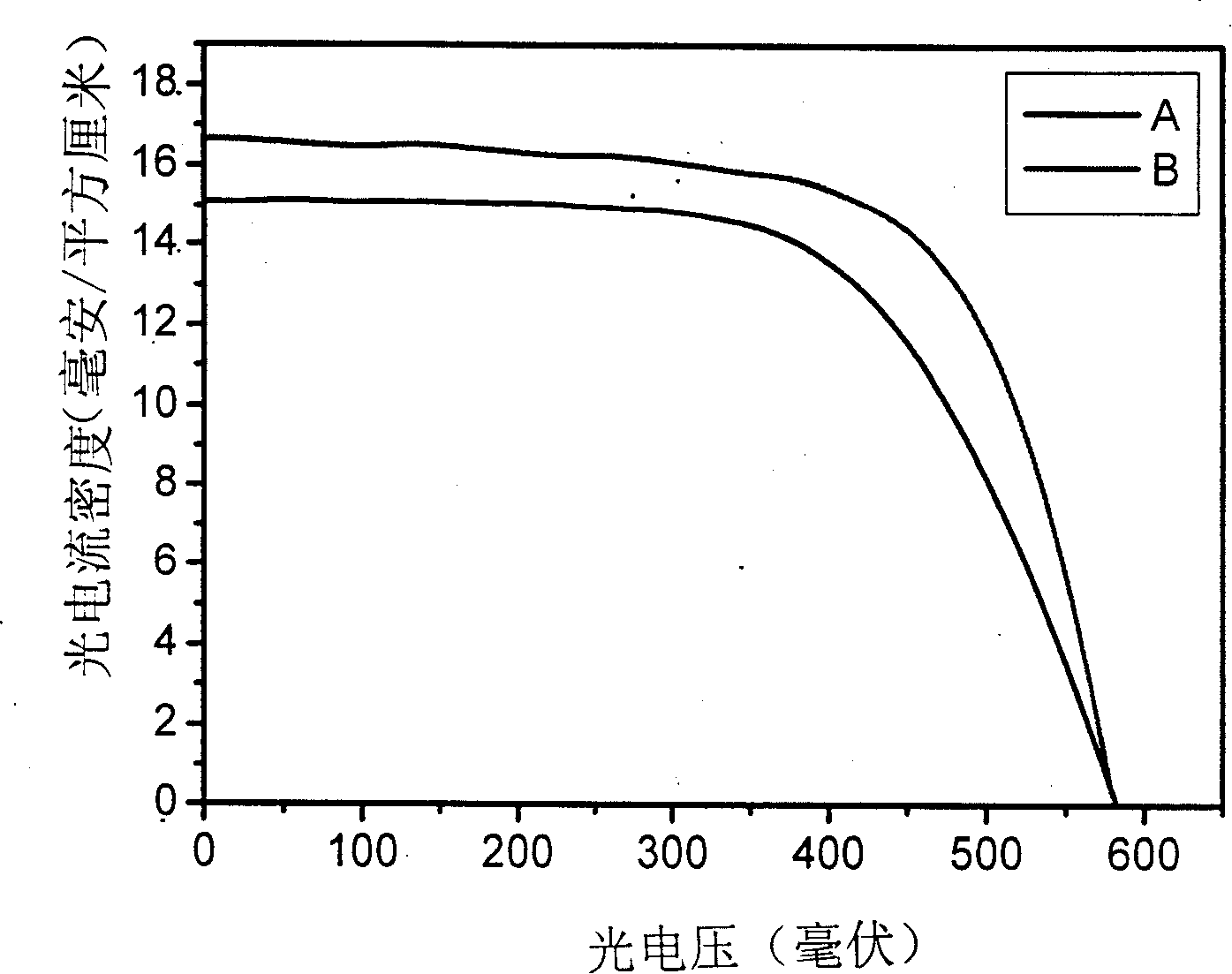

Carbon plasm for electrode of dye sensitization solar battery pair and its making method

InactiveCN101188257ALow viscosityEvenly dispersedLight-sensitive devicesFinal product manufactureSolid carbonSolar battery

The invention relates to carbon paste of electrodes for a dye-sensitized solar cell and a preparation method. The carbon paste comprises liquid mixture and solid carbon powder, wherein, the liquid mixture is 15-95wt percent and the solid carbon powder is 5-85wt percent, wherein, the liquid mixture is mixed by 0.5percent-40wtpercent of viscosity modifier and 20-99.5wtpercent of solvent. Owing to the addition of the viscosity modifier and the solid powder with particle size less than 1mm and 10-2000m<2> / g of specific surface area in the carbon paste, the viscosity of the paste can be controlled, the carbon paste disperses uniformly, and the paste can keep long-term stabilization. Pore inducing materials can be added in the carbon paste, porous solid thin films for batteries can be conveniently prepared by the carbon paste. The thin film is a solid carbon thin film with smooth surface, large surface area, uniform distribution of pores and firm combination with substrates.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

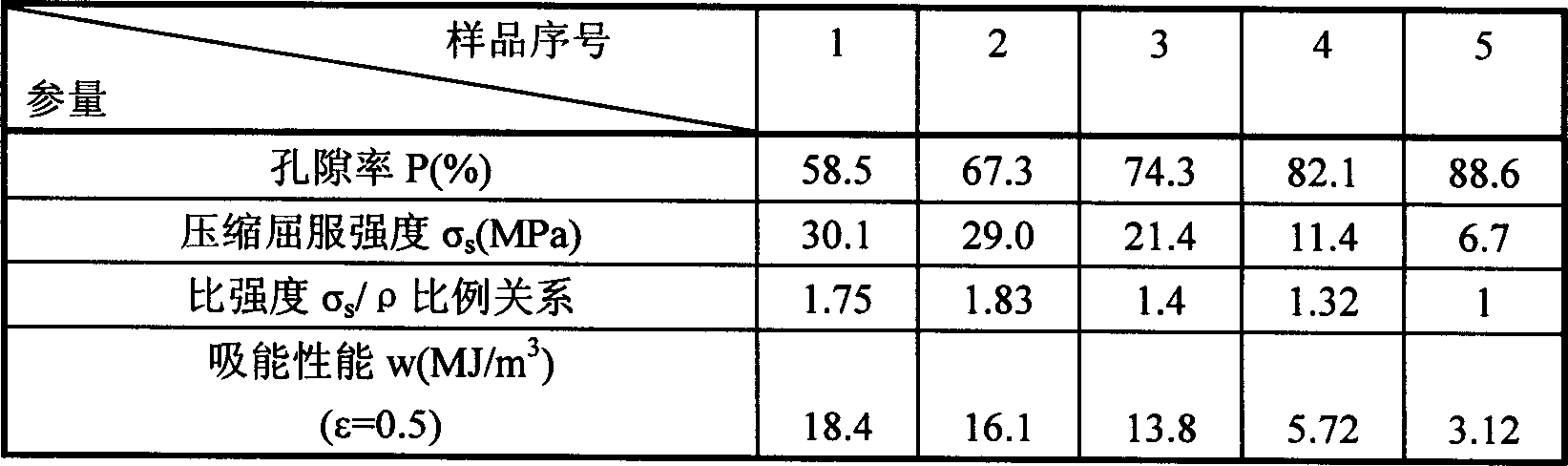

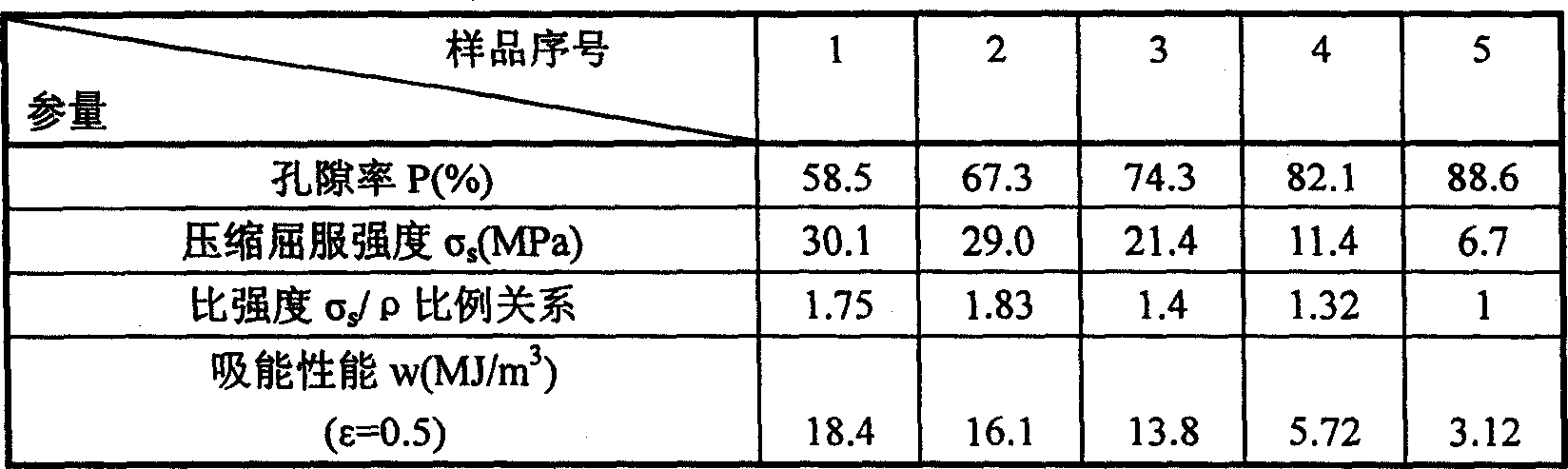

Low porosity closed cell foam aluminum alloy and its preparation method

The invention discloses a low porosity closed cell foam aluminum alloy preparation method comprising the steps of, (1) heating aluminium alloy to melting, (2) charging 0.5-5% thickener, stirring the aluminium alloy to increase thickness, (3) charging foaming agent 0.2-5.0 wt% of aluminium alloy, stirring homogeneously, (4) stirring 10s-180s again, (5) extracting the stirring paddle, (6) subjecting the thermal insulated foam aluminium alloy flux to simultaneous cooling. The invention also discloses a closed cell foam aluminium alloy with low factor of porosity.

Owner:SOUTHEAST UNIV

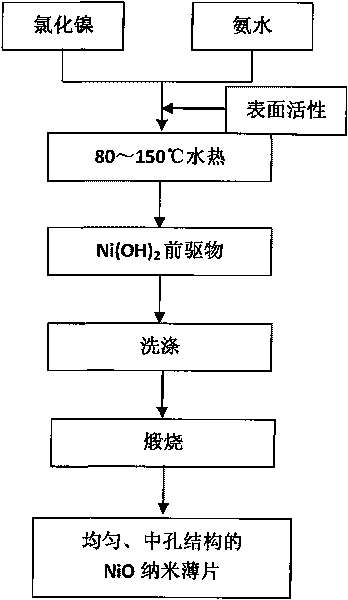

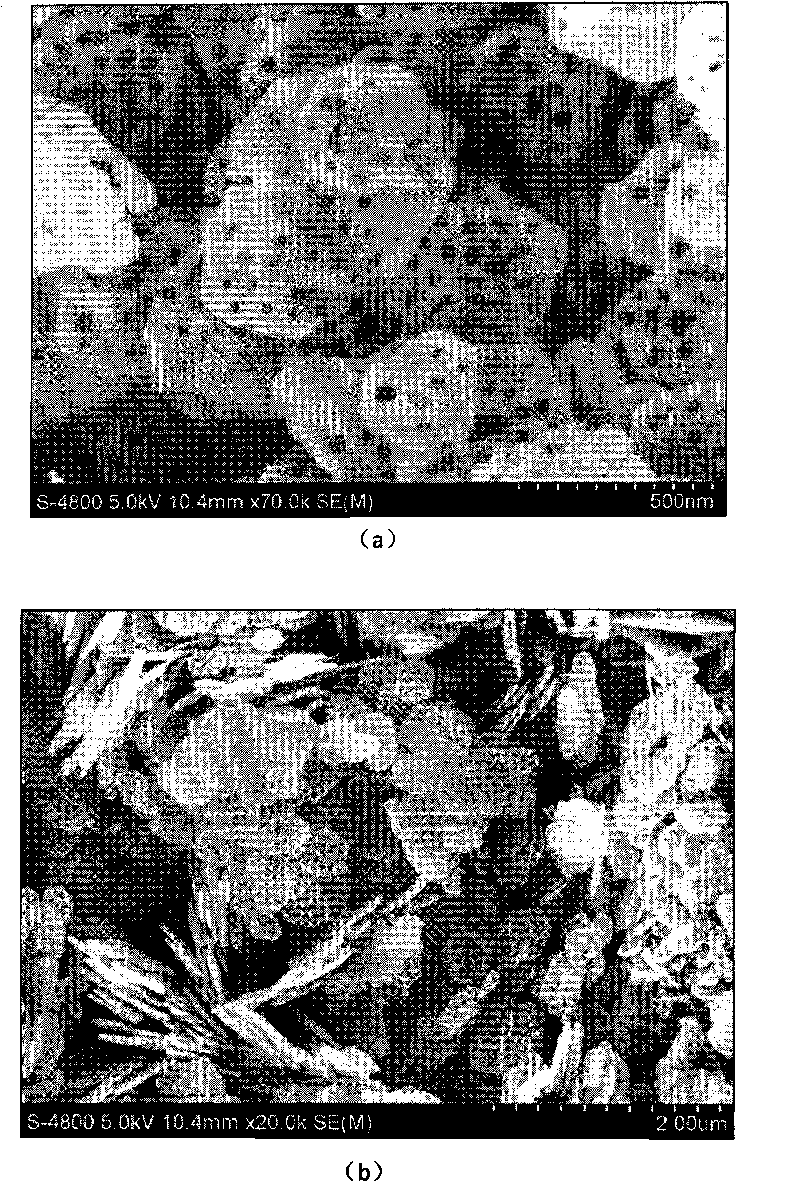

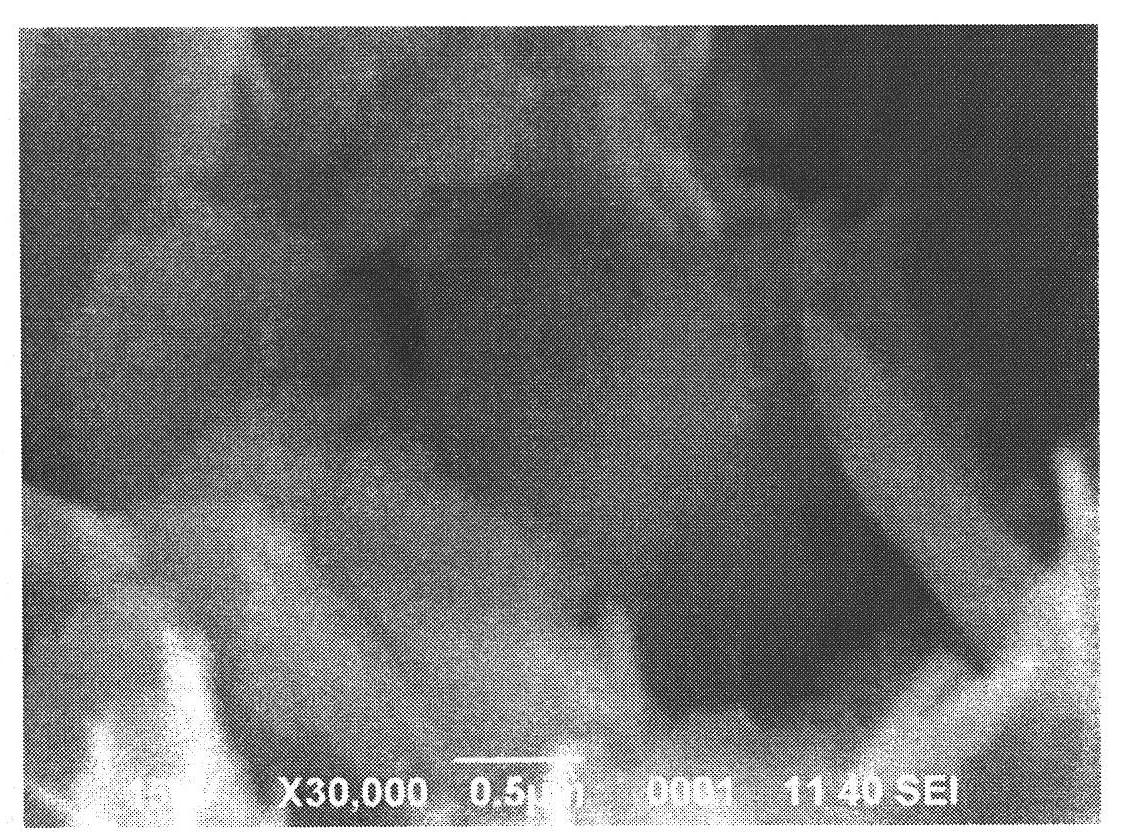

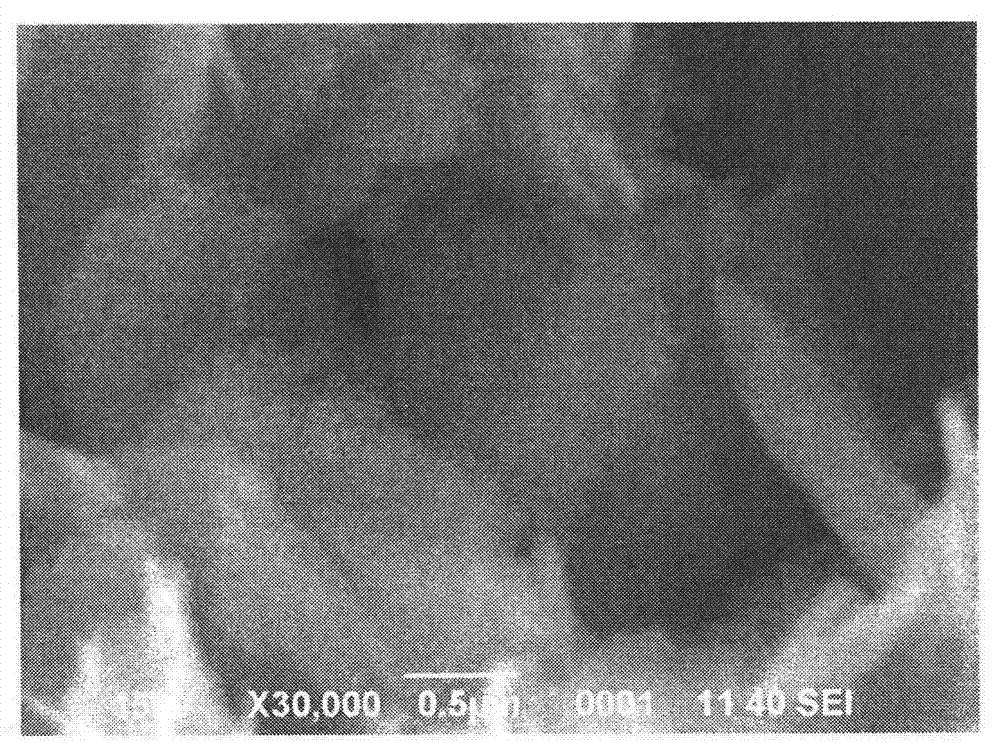

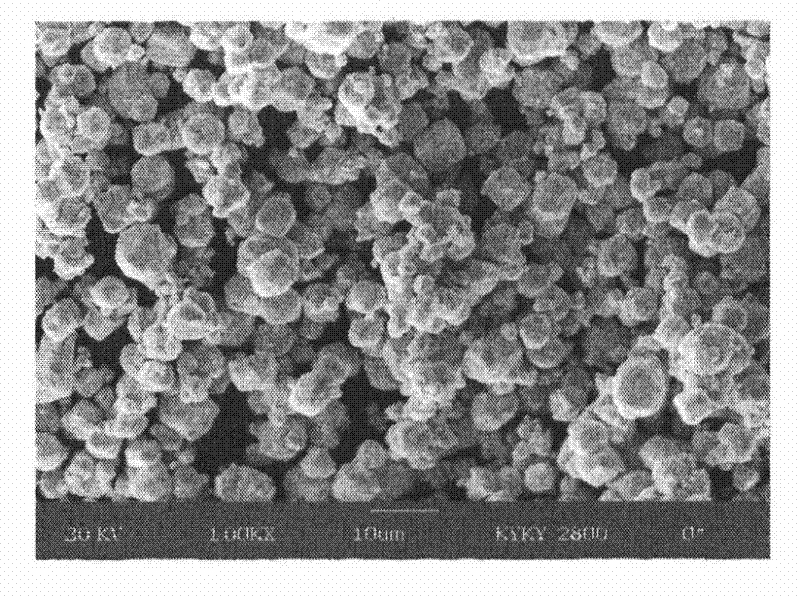

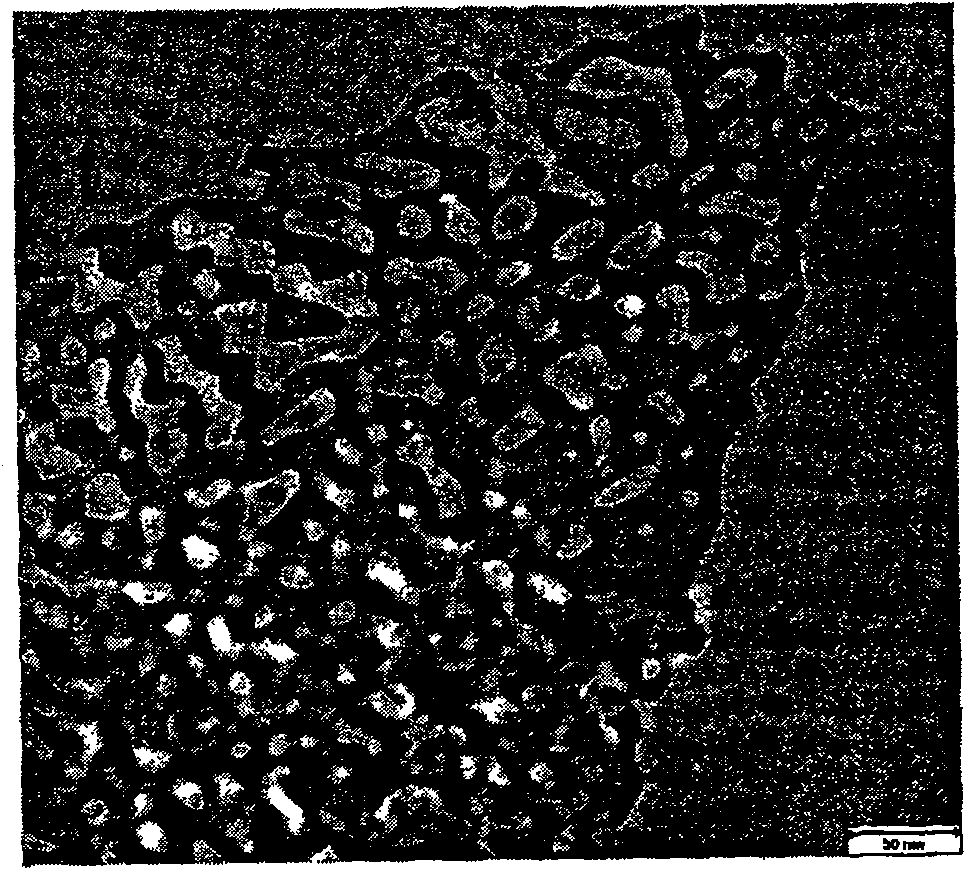

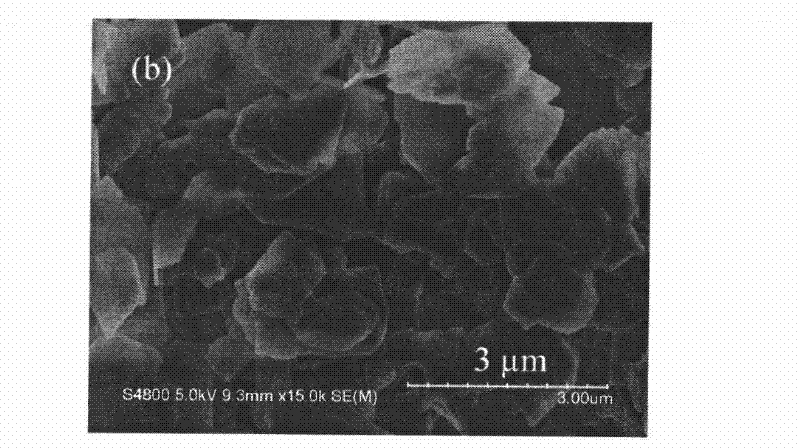

Preparation method of nickel oxide nano flake with uniform and mesoporous structure

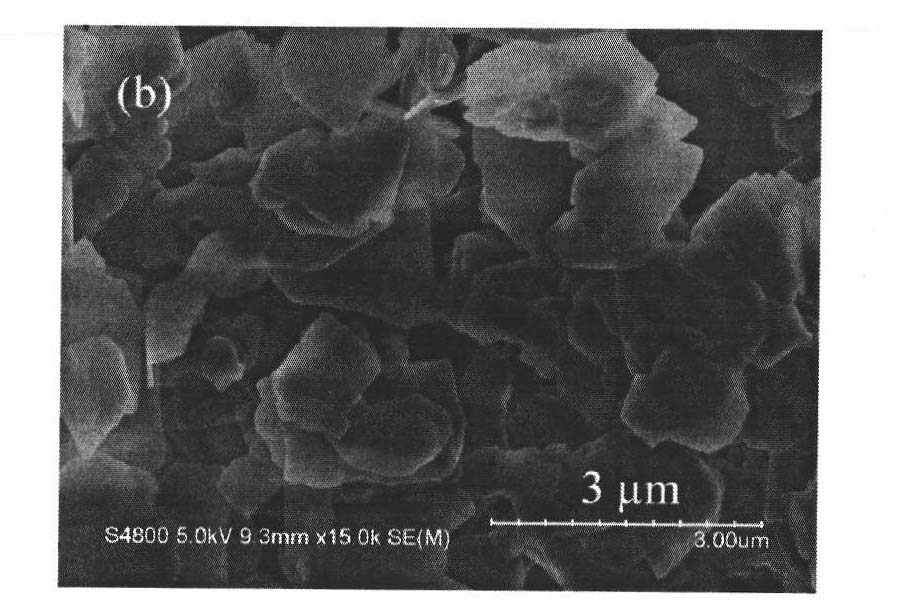

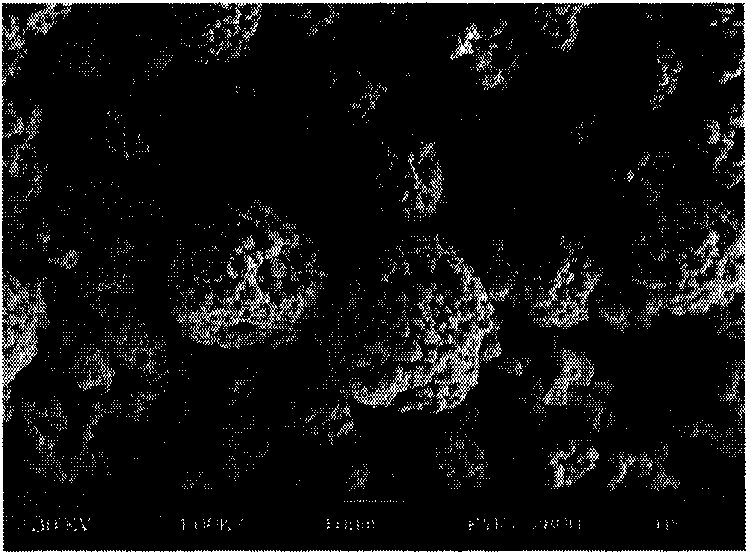

InactiveCN101704558AWell distributed holesHigh purityNanostructure manufactureNickel oxides/hydroxidesInorganic saltsNickel oxide hydroxide

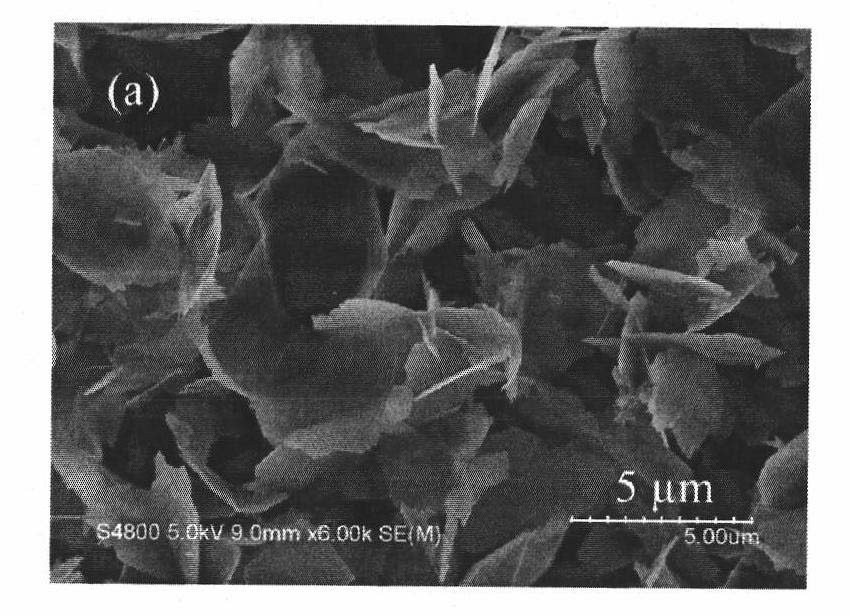

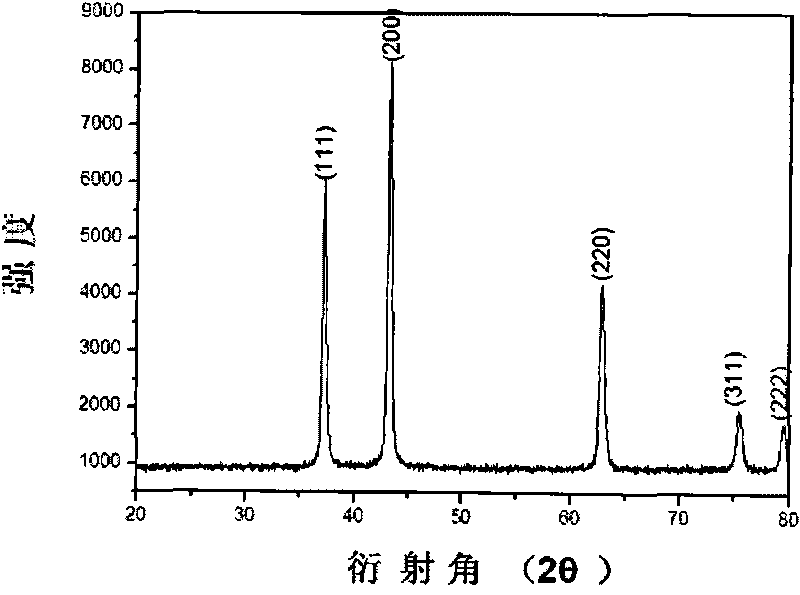

The invention provides a preparation method of nickel oxide nano flake with uniform and mesoporous structure, which is implemented by (1) putting 0.05-0.15mol / L of aqueous inorganic salt solution containing nickel in a beaker, adding in surfactant with concentration being 5-10g / L, and performing magnetic stirring for 3h; dripping in ammonia water with the volume ratio of ammonia water to aqueous inorganic salt solution containing nickel being 0.01:1-0.015:1, and performing magnetic stirring for 3h; (2) placing the mixed solution obtained in step (1) in a stainless reaction kettle lined by polytetrafluoroethylene to be sealed, and heating for reaction in a muffle furnace for 12-20h with reaction temperature being 80-150 DEG C; (3) filtering, washing and drying the obtained nepheloid solution to obtain nickelhydroxide primer; (4) calcinating the nickelhydroxide primer obtained in step (3) at 350-500 DEG C for 2-4h to obtain porous structural nickel oxide nano flake. The inventive NiO nano flake has pore diameter of 30-40nm, diameter of 300-400nm, belongs to cubic system, high purity, and good quality.

Owner:BEIHANG UNIV

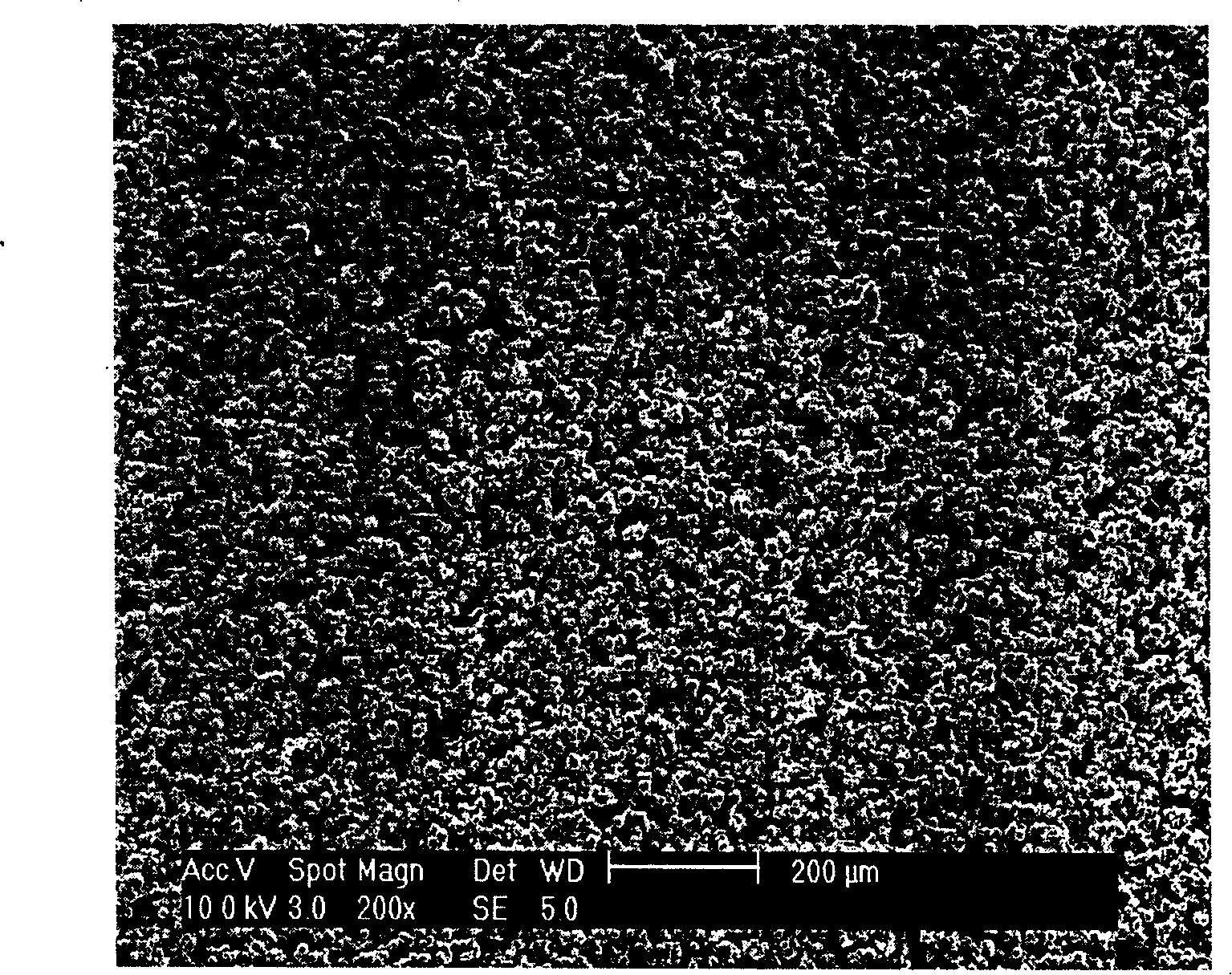

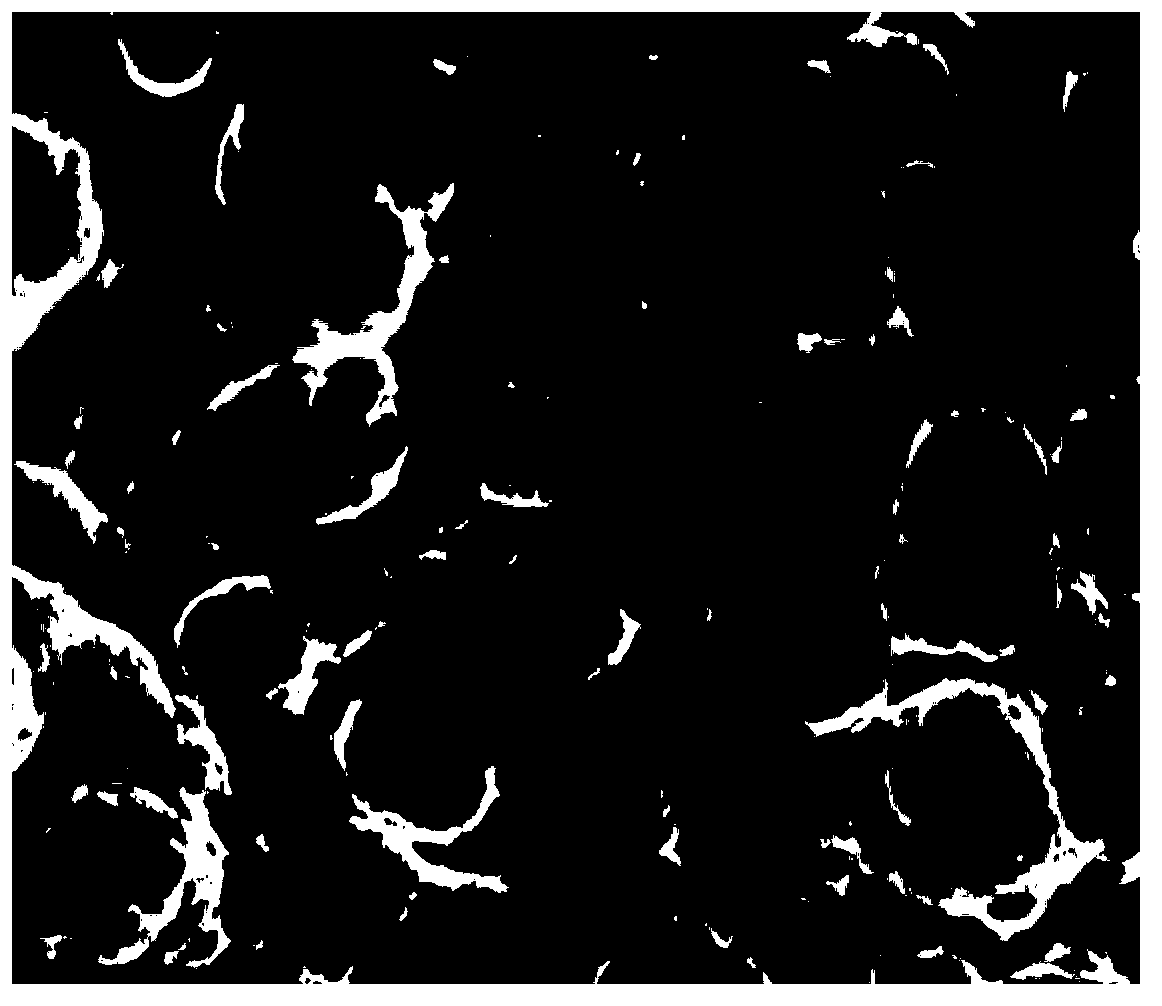

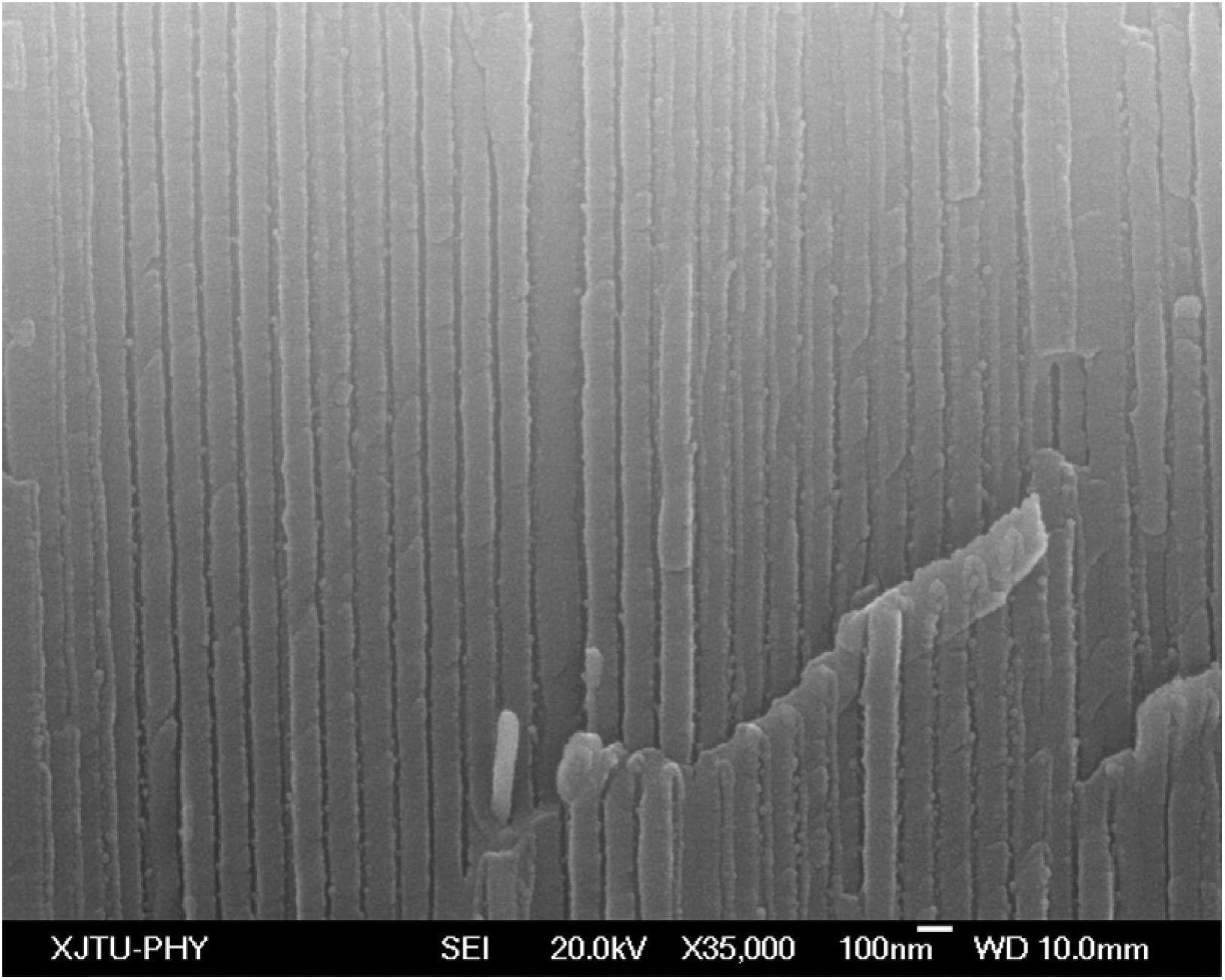

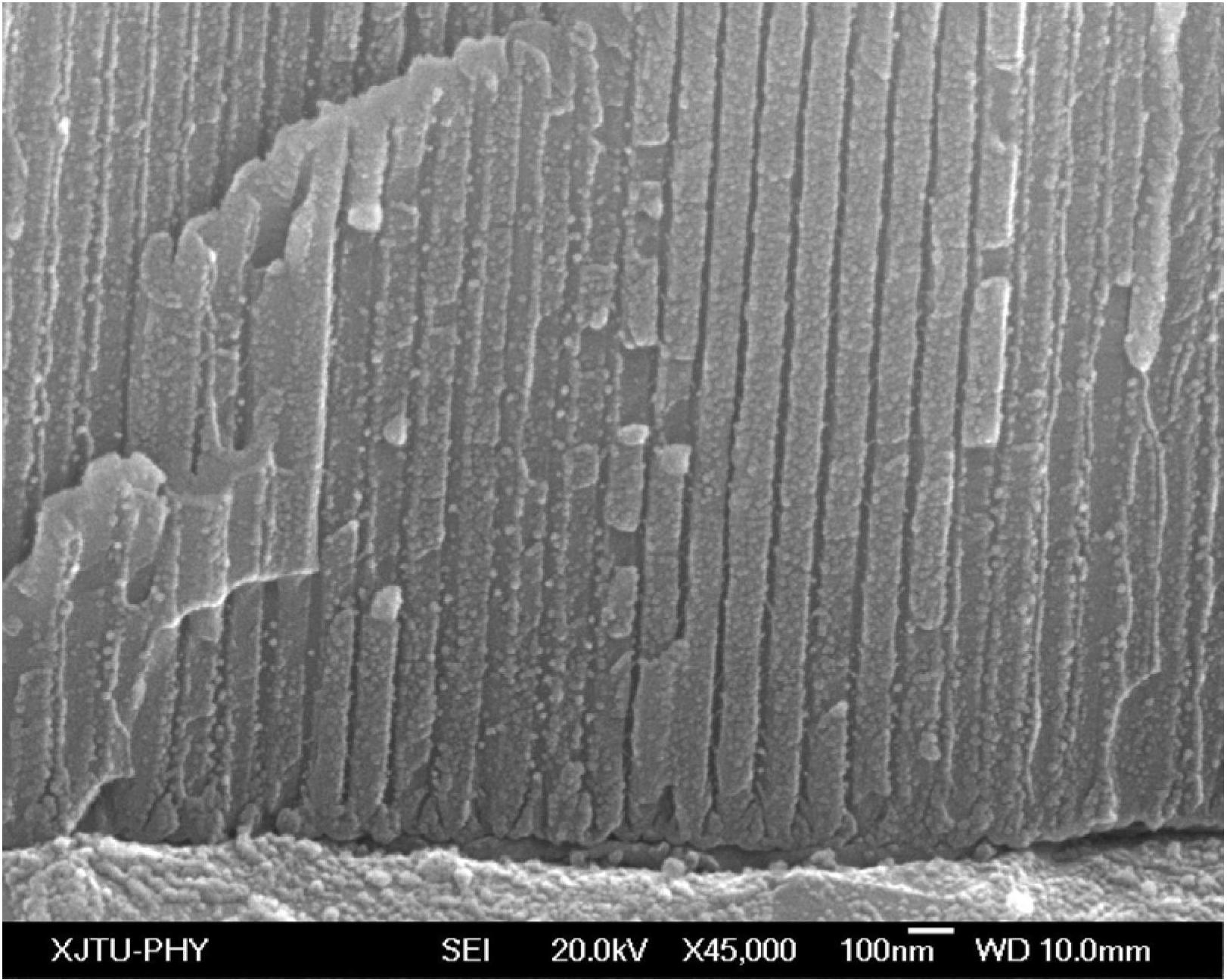

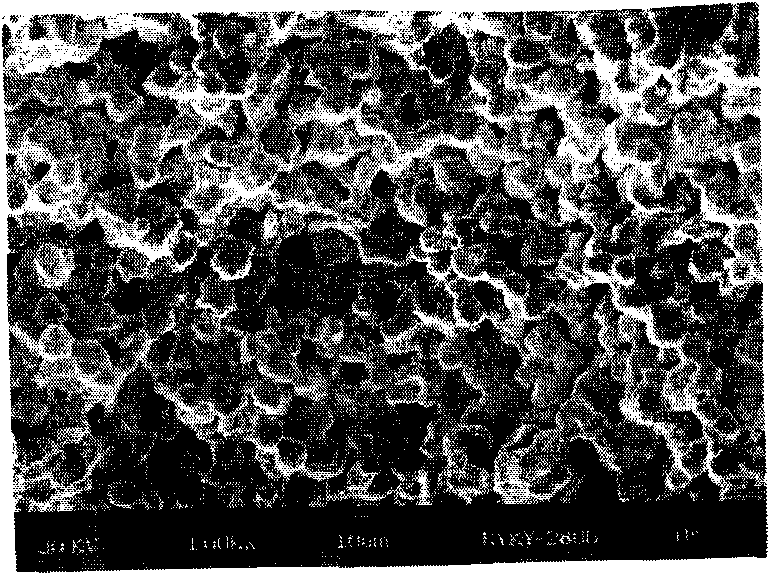

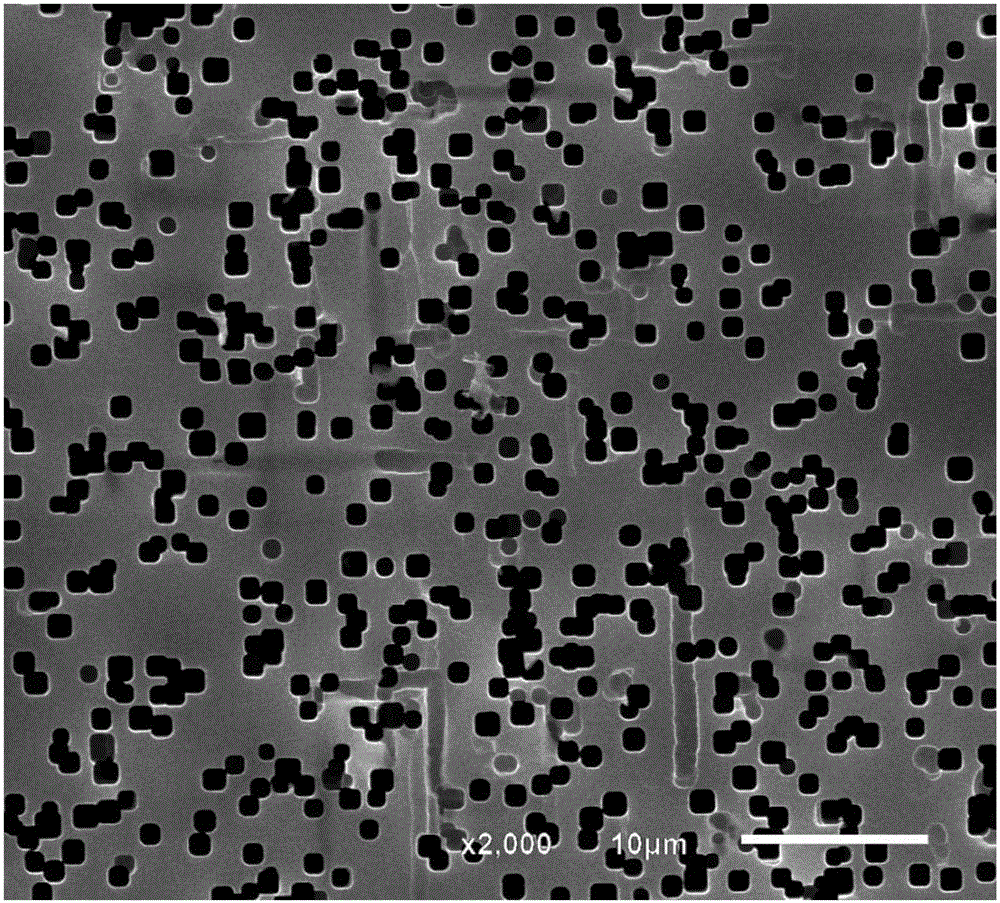

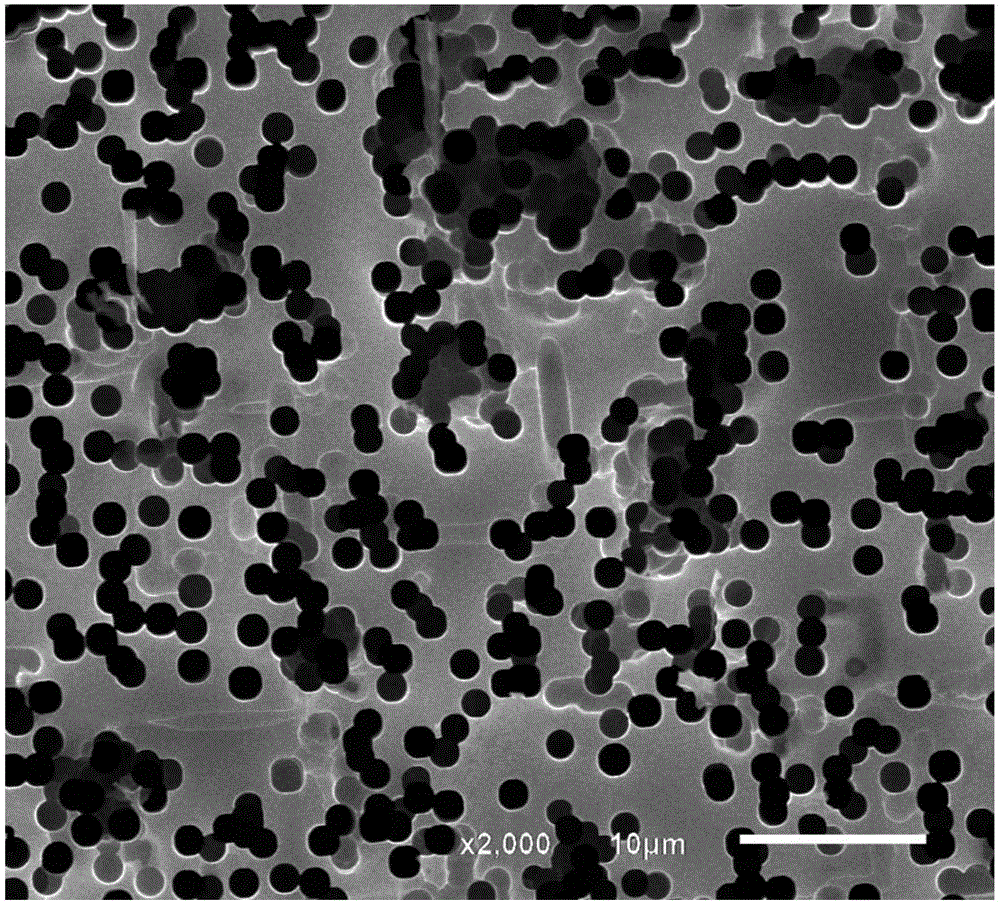

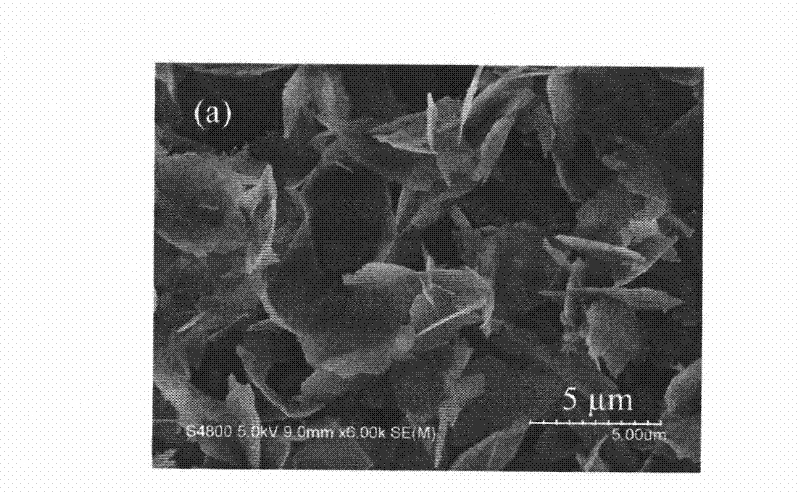

Micro-nano processing method for aluminum/aluminum alloy surface and aluminum/ aluminum alloy structure

InactiveCN103276435AWell distributed holesHigh bonding strengthMetal layered productsPhosphoric acidMicro nano

The invention discloses a micro-nano processing method for an aluminum / aluminum alloy surface. The method comprises the following steps of: placing the aluminum / aluminum alloy into electrolyte containing hydrochloric acid, sulfuric acid, phosphoric acid and a corrosion inhibitor to carry out direct current electrochemical corrosion, wherein the aluminum / aluminum alloy is used as an anode, the concentration of the hydrochloric acid is 1.5-3mol / L, the concentration of the sulfuric acid is 0.9-1.2mol / L, and the concentration of the phosphoric acid is 0.6-1mol / L. A method for integrating the aluminum / aluminum alloy and plastic comprises the following steps of processing a micro-nano porous structure on the aluminum / aluminum alloy surface by using the micro-nano processing method and tightly integrating the plastic and the aluminum / aluminum alloy surface by using the micro-nano porous structure. The micro-nano porous structure, which is formed by using the micro-nano processing method, is formed on the surface of an aluminum / aluminum alloy structure. The micro-nano processing method is high in micro-nanometer pore processing efficiency and good in micro-nanometer pore quality, and is very environment-friendly.

Owner:GUANGDONG JANUS SMART GRP CO LTD

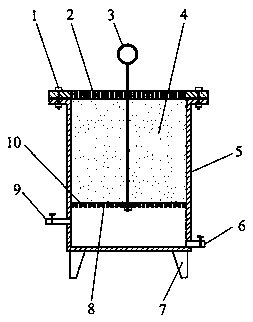

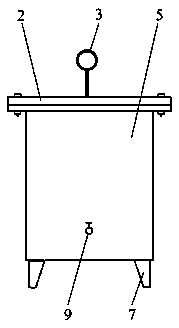

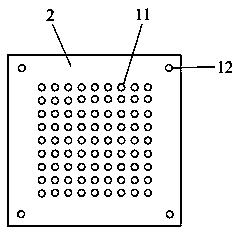

Preparation method and device for bottom blowing type photocatalytic porous permeable brick

The invention discloses a preparation method and device for a bottom blowing type photocatalytic porous permeable brick. The preparation device for the bottom blowing type photocatalytic porous permeable brick is characterized by comprising a forming die, a breathable end cover, a porous lining board, a draw bar, a nylon mesh, an air inlet pipe and a water draining pipe. The preparation method for the bottom blowing type photocatalytic porous permeable brick comprises the following steps: (1) smashing straw into particles with the length of 1-2cm; (2) putting the straw particles into a water glass solution to be soaked for 30 minutes, then taking out, and drying; (3) soaking in tung oil for 5 minutes, and then drying; (4) uniformly mixing the straw particles, cement, river sand, water glass, chopped fiber glass filaments, a cement foaming agent and water; (5) pouring mixed slurry into the forming die, and introducing CO2 gas at the temperature of 80 DEG C for curing; (6) drying for 5-7 days; (7) carrying out heat preservation on a porous brick for 1 hour at the temperature of 150 DEG C, slowly heating to 400 DEG C, carrying out heat preservation for 5 hours, and carrying out furnace cooling; and (8) impregnating and drawing a porous permeable brick in a photocatalytic plating solution for 5 minutes and then drying, and repeating for 3-4 times, so that the photocatalytic porous permeable brick is obtained.

Owner:HOHAI UNIV

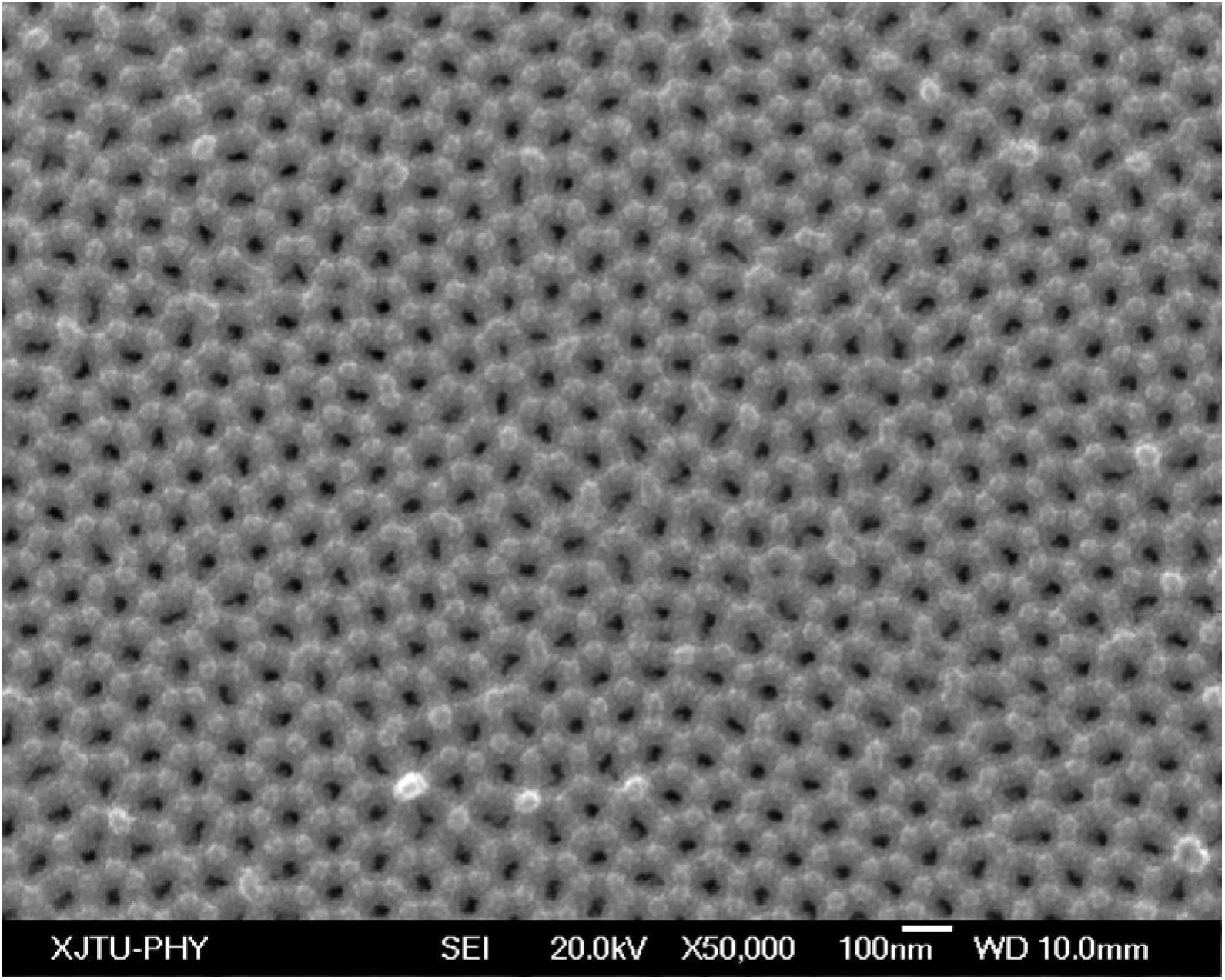

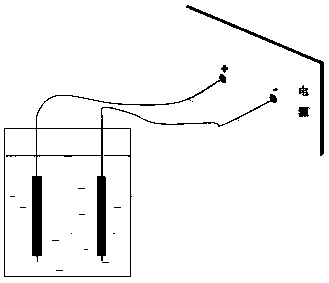

Method for preparing aluminum oxide template by step decompression reaming

InactiveCN102650066AEasy to synthesizeReduce thicknessSurface reaction electrolytic coatingPlatinumLayer thickness

The invention discloses a method for preparing an aluminum oxide template by step decompression reaming. The method comprises the steps as follows: 1) taking a polished aluminum foil as an anode and a platinum electrode as a cathode, placing the anode and the cathode into an acidic electrolytic solution, connecting a power supply, and carrying out anodic oxidation for 1-5 h for the first time; 2) after the anodic oxidation for the first time, removing an aluminum oxide film on the surface of the anode, and carrying out anodic oxidation for 1-5 h for the second time; 3) after the anodic oxidation for the second time, carrying out step decompression treatment by reducing the voltage between the anode and the cathode at a speed of 0.5-3 V / min and disconnecting the power supply until the voltage is reduced to be less than 16 V; and 4) after the step decompression treatment, cleaning the aluminum foil, placing into a reaming solution, and reaming for 10-60 min. According to the method, the baffle layer thickness of the aluminum oxide template and the length and diameter of template holes can be accurately controlled; and the needed equipment is simple, the operation process is convenient, and the parameters are easy to control.

Owner:XI AN JIAOTONG UNIV

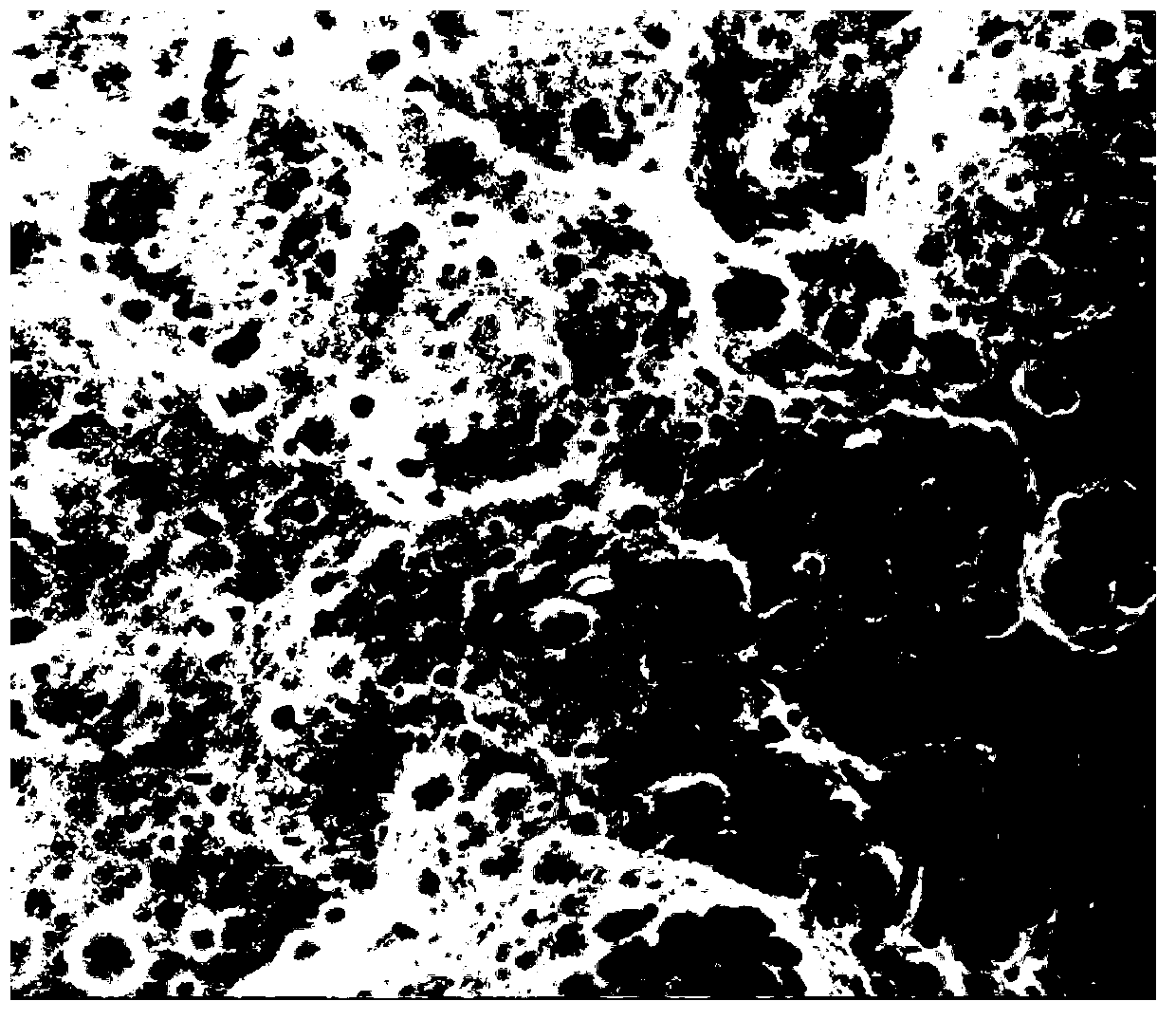

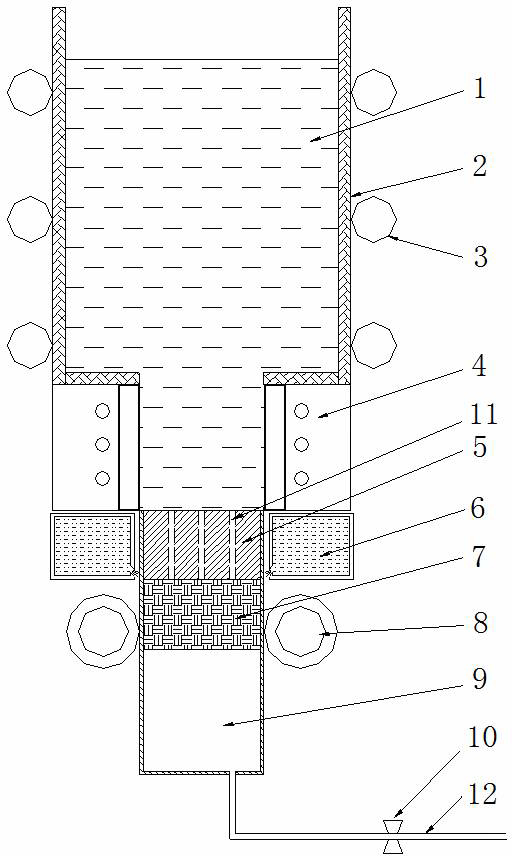

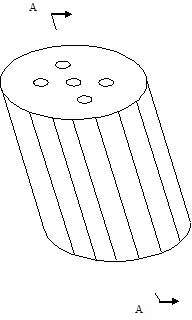

Method for preparing macroscopic through-type porous metal material and continuous casting device thereof

The invention discloses a method for preparing a macroscopic straight-through porous metal material and a continuous casting device thereof. The steps of the method are as follows: a. heating liquid metal in a crucible and keeping it warm; b. pouring the liquid metal downward into a heating type crystallizer, Keep the temperature of the liquid metal in the heating mold above the liquidus line; c. Blow gas to the liquid metal melt through the hole template, and at the same time establish a self-upper in the liquid metal melt near the dummy rod. d. Pull down the casting in the drawing direction of continuous casting through the backward displacement movement of the pulling down of the dummy bar and the upward movement of the mold, so that the liquid metal passing through the bottom of the heating mold is continuous from top to bottom Directional solidification to form a metal material casting with macroscopic straight-through porosity. The continuous casting device of the invention prepares the macroscopic straight-through directional porous metal through the method of direct blowing of the template and coupling the directional solidification of the metal melt. The equipment is simple, the operation is easy, it can be applied to a variety of metals, and the pore distribution is controllable.

Owner:SHANGHAI UNIV

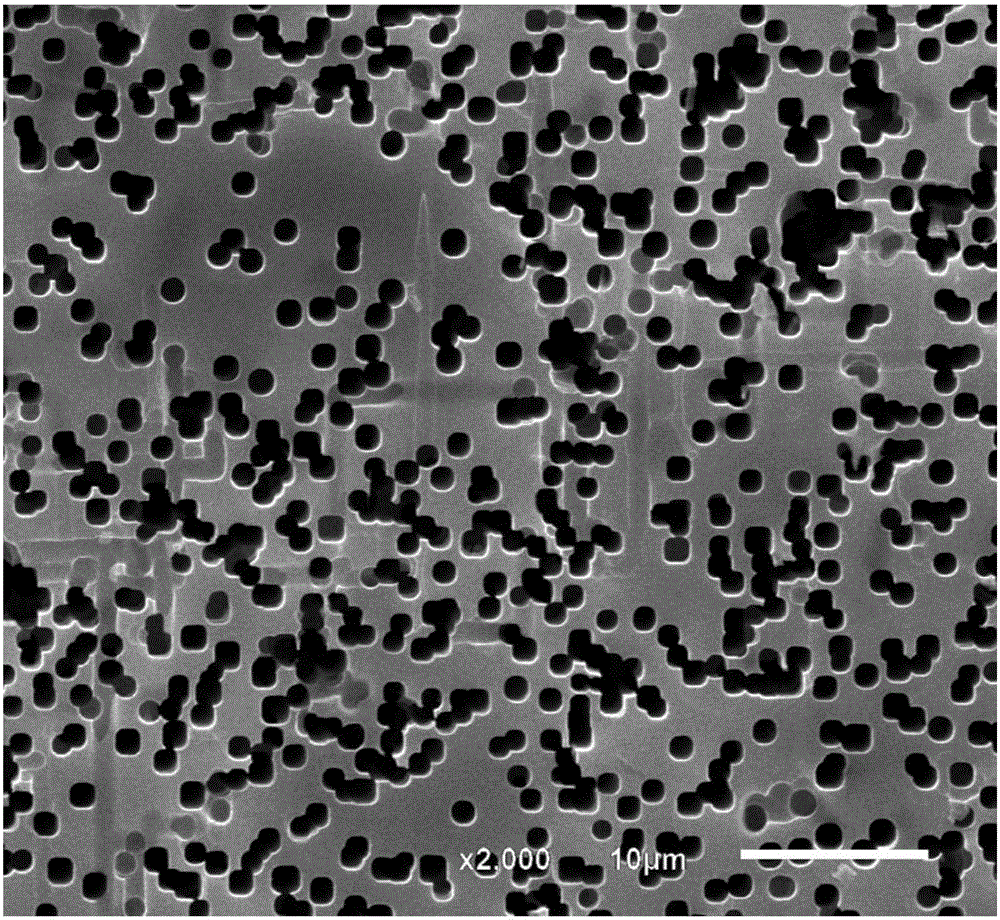

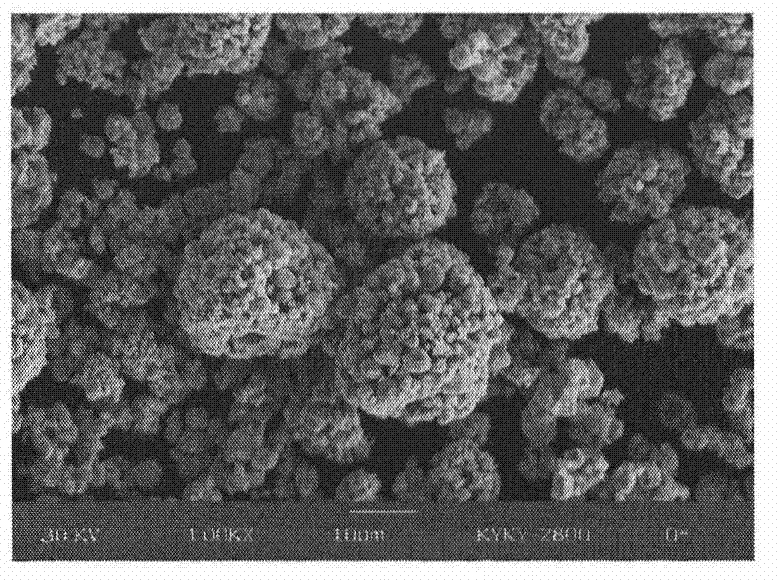

Method for preparing impregnated cathode matrix

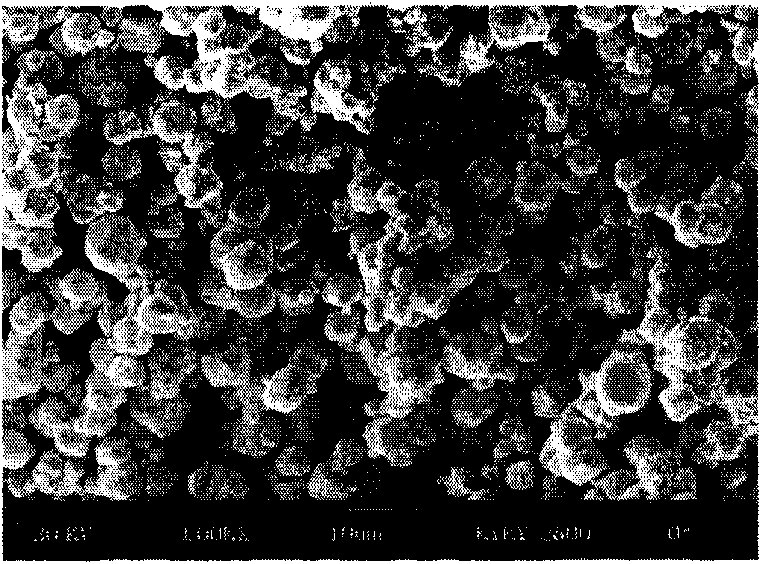

InactiveCN102024640AUniform hole sizeWell distributed holesThermionic cathode manufactureMicrowavePrill

The invention discloses a method for preparing an impregnated cathode matrix and relates to technology of microwave devices. The method is used for preparing a tungsten sponge matrix of an impregnated barium and tungsten cathode. Tungsten particles of different sizes are prepared into uniform spherical particles by particle spray drying powder treating technology, so that the flowability of tungsten powder is enhanced; and after being filled into a rubber sleeve, the treated tungsten powder can be beat, tamped or vibrated to form a close-packed structure, and then the close-packed structure is pressed and sintered to prepare the tungsten sponge matrix. The method is simple and practicable, the prepared impregnated cathode matrix has the advantages of uniform hole size, uniformly distributed holes, few closed holes and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

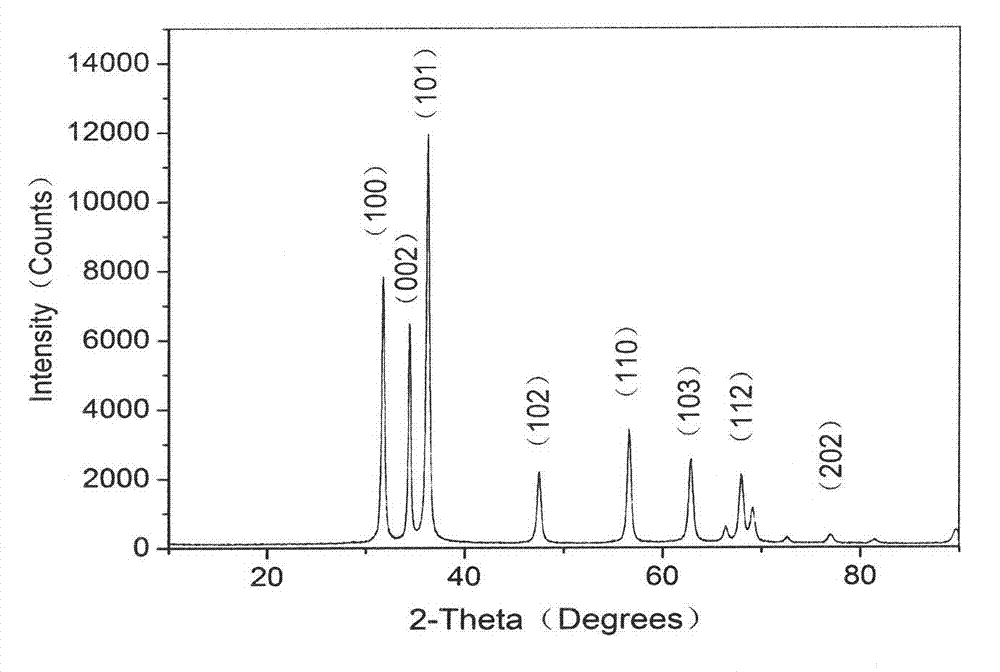

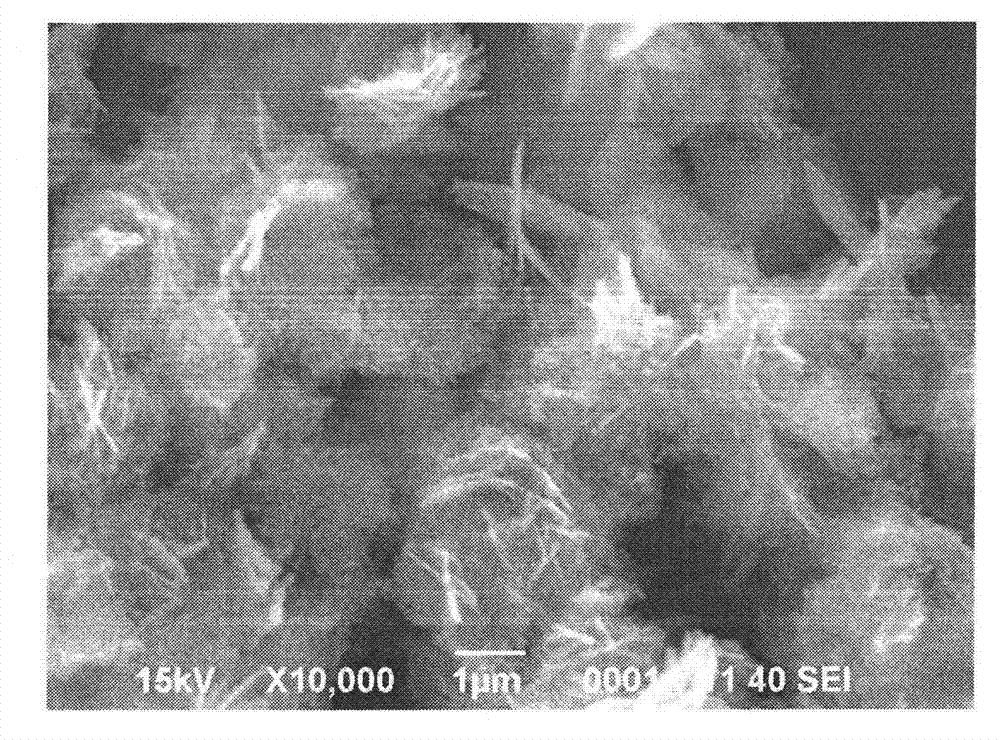

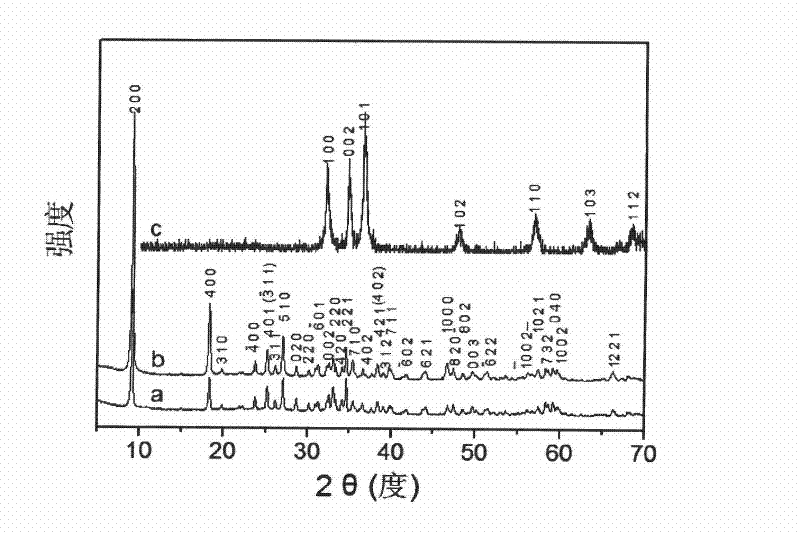

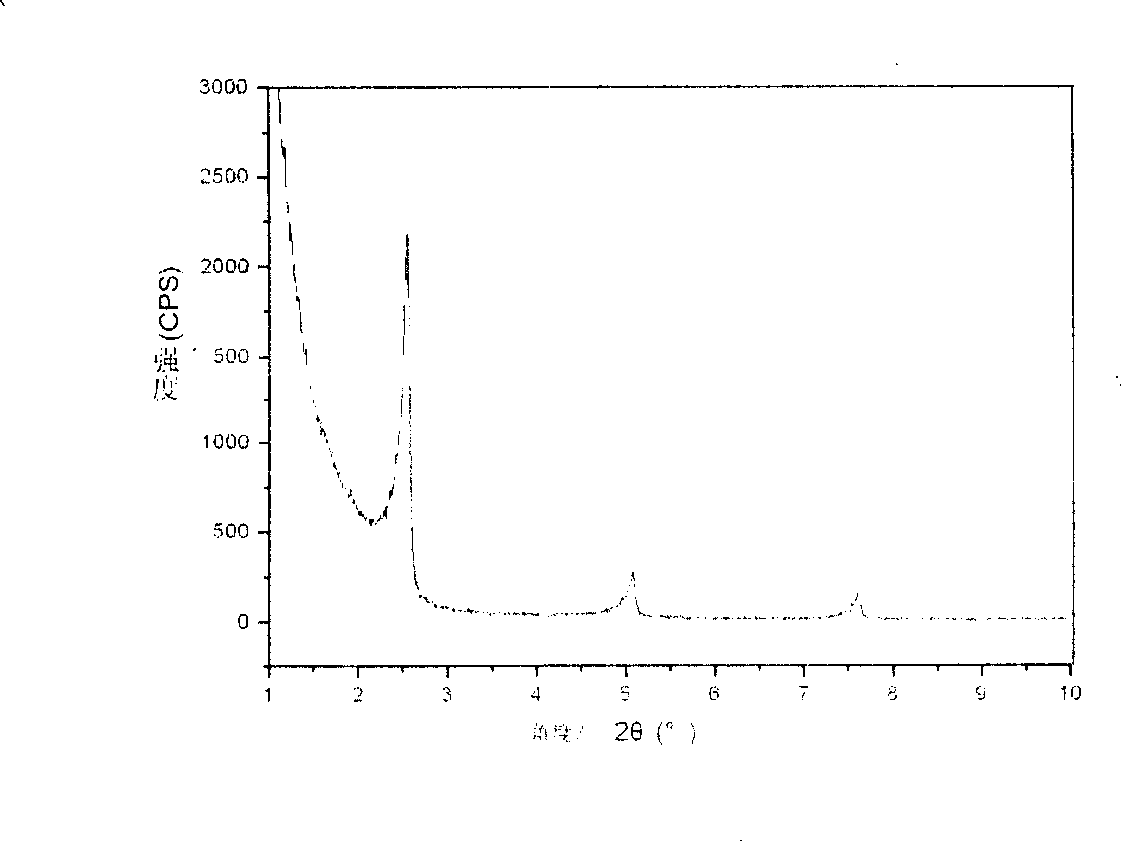

ZnO nano powder in sheet uniform porous structure as well as preparation method and applications thereof

InactiveCN102079539ALarge specific surface areaHigh purityZinc oxides/hydroxidesCell electrodesWater bathsReaction temperature

The invention discloses ZnO nano powder in a sheet uniform porous structure as well as a preparation method and applications thereof. The preparation method comprises the following steps of: adding a sodium carbonate solution to a reaction container in a thermostatic water bath, dripping a zinc nitrate solution in the sodium carbonate solution, continuously applying an external electric field of 50kv to the reaction container and stirring at a reaction temperature of 80-90 DEG C; and keeping the solution water bath temperature for 2h after dripping, separating, washing and drying the muddy solution obtained after the temperature preservation is finished to obtain a basic zinc carbonate precursor and roasting at 300-400 DEG C for 2-3h to obtain ZnO nano powder in the sheet uniform porous structure. The invention belongs to a hexagonal system, has the advantages of great specific surface area, high purity, good product quality without ZnO in other shapes, stable performance, constant performance when being arranged in air for a long time, simple process, low manufacture cost, low equipment requirement, rapidness of operation and mass production suitability.

Owner:SOUTH CHINA UNIV OF TECH

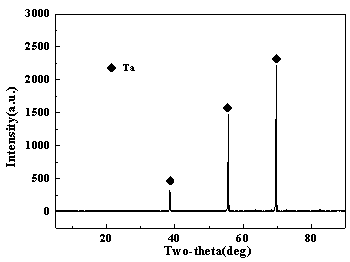

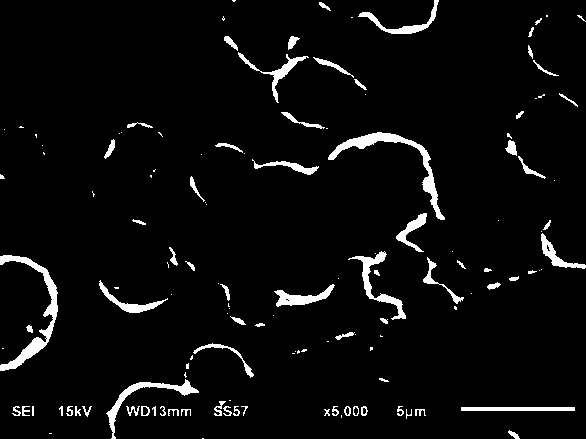

Preparation process of porous tantalum sheet

The invention belongs to the technical field of tantalum sheet preparation and discloses a preparation process of a porous tantalum sheet. An electrolytic corrosion mode is adopted for preparation. The preparation process comprises the steps of preparing a tantalum sheet as an anode electrode and platinum as a cathode electrode, and putting the anode electrode and the cathode electrode into an electrolytic cell; preparing an electrolyte solution with ethyl alcohol and a conductive agent, and putting the prepared electrolyte solution into the electrolytic cell, wherein the conductive agent is chloride which can be dissolved into the ethyl alcohol; after the distance between the anode electrode and the cathode electrode, fixing the anode electrode and the cathode electrode to the electrolytic cell; and connecting the anode electrode and the cathode electrode to a positive pole and a negative pole of a direct-current power source correspondingly, and starting electrolytic corrosion to prepare the porous tantalum sheet. The obtained porous tantalum sheet is large in number of holes; the holes are distributed relatively uniformly; the diameters of the holes are each at the micron level;and the tantalum sheet can be used as an excellent raw material in all relevant fields.

Owner:HUNAN UNIV OF TECH

Corrosion method for ultra-high-voltage and high-specific-capacity positive electrode corrosion foil

InactiveCN106409514AEvenly distributedLarge apertureElectrolytic capacitorsUltra high voltageAluminum electrolytic capacitor

The invention discloses a corrosion method for an ultra-high-voltage and high-specific-capacity positive electrode corrosion foil. The ultra-high-voltage positive electrode corrosion foil is a positive electrode foil used for an aluminium electrolytic capacitor, wherein Vt of the positive electrode foil is greater than or equal to 1,050V; and the corrosion method comprises the following steps of pre-treatment, first-stage corrosion, second-stage corrosion, third-stage corrosion and post-treatment. Through improvement of a corrosion process, corrosion mixed solution prescription and the like, the produced aluminum foil can satisfy the ultra-high-voltage formation requirement with Vt which is greater than or equal to 1,050V; in addition, the shortcoming of low specific capacity caused by high probability of blocking after formation due to small corrosion foil hole in the prior art is also overcome; higher mechanical strength and longer service life are achieved under the premise of obtaining higher pore diameter and static specific capacity; and meanwhile, the produced formation foil is high in stability, low in electric leakage, quick in voltage boosting time, and capable of filling up the blank in the field of the ultra-high-voltage corrosion foil in the prior art.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Low porosity closed cell foam aluminum alloy and its preparation method

The invention discloses a low porosity closed cell foam aluminum alloy preparation method comprising the steps of, (1) heating aluminium alloy to melting, (2) charging 0.5-5% thickener, stirring the aluminium alloy to increase thickness, (3) charging foaming agent 0.2-5.0 wt% of aluminium alloy, stirring homogeneously, (4) stirring 10s-180s again, (5) extracting the stirring paddle, (6) subjecting the thermal insulated foam aluminium alloy flux to simultaneous cooling. The invention also discloses a closed cell foam aluminium alloy with low factor of porosity.

Owner:SOUTHEAST UNIV

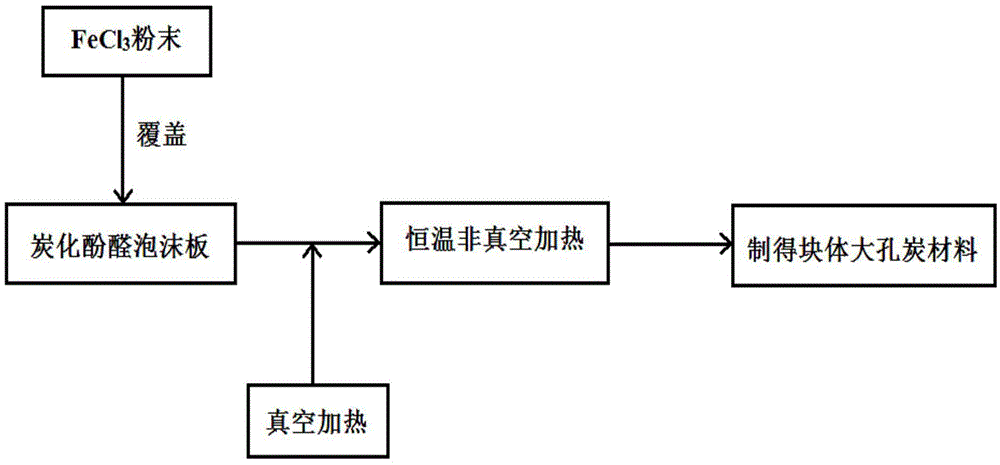

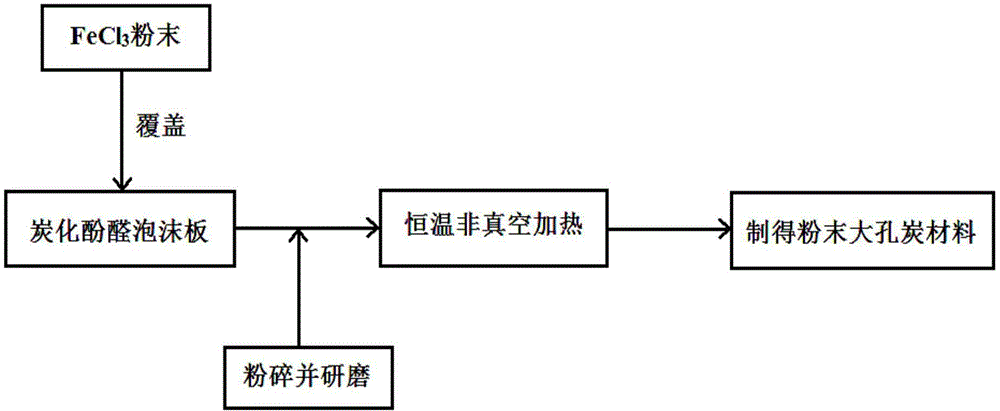

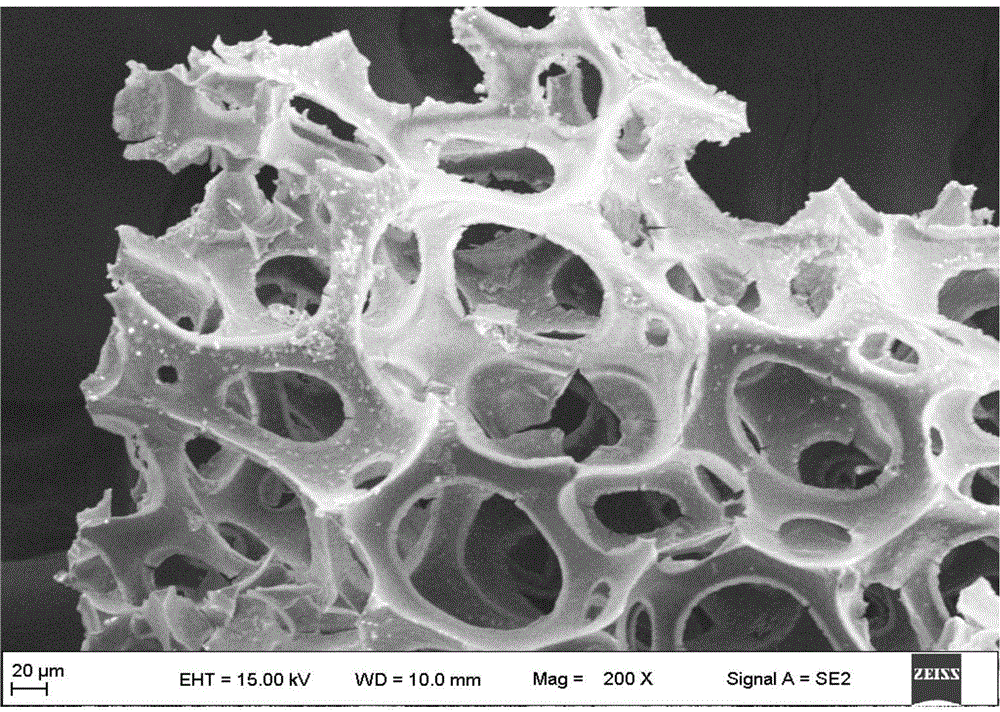

Preparation method and products of novel macroporous carbon material

The invention discloses a preparation method and products of a novel macroporous carbon material. According to the preparation method comprises the following steps of carbonizing and heating macroporous phenolic resin serving as a carbon source and FeCl3 serving as a catalyst to obtain the novel macroporous carbon material. By adopting the macroporous phenolic resin serving as the carbon source and FeCl3 serving as the catalyst, slow oxidation, catalysis and carbonization are simultaneously performed; by the structure-directing effect of the macroporous phenolic resin and the kirkendall diffusion effect of Fe element in FeCl3, the Fe element enters the phenolic resin plate to modify carbon pores, and the regular and hard macroporous carbon material having more smooth pore walls is finally prepared; and meanwhile, the distribution of pores in the prepared macroporous carbon material is more uniform.

Owner:NORTHEASTERN UNIV

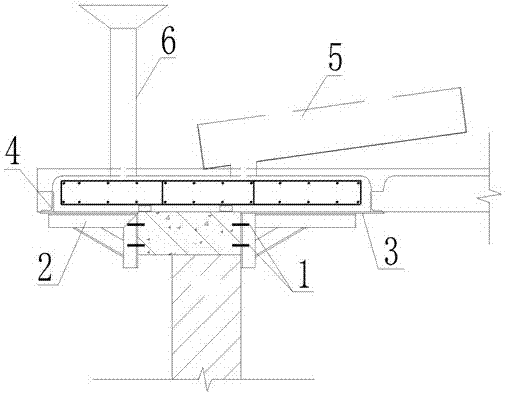

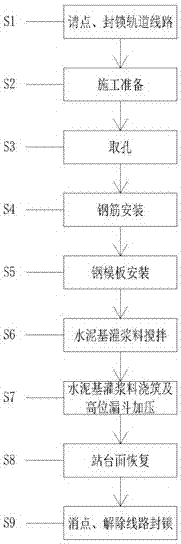

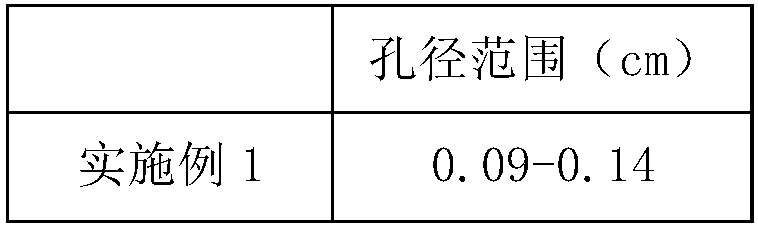

Reinforcing construction method for trough plate platform of operation subway station

InactiveCN108005402AGuarantee operational securityWell distributed holesBuilding repairsRebarSubway station

The invention discloses a reinforcing construction method for a trough plate platform of an operation subway station and belongs to the technical field of reinforcing construction of operation subwaystation structures. The reinforcing construction method comprises the following steps of S1, construction applying and blockage of a track line, S2, construction preparation, S3, hole forming, S4, mounting of steel bars, S5, mounting of steel formworks, S6, stirring of cement foundation grouting materials, S7, pouring of the cement foundation grouting materials and pressurizing of a high funnel, S8, platform surface recovering and S9, applying of construction completion and removing of line blockage. According to the reinforcing construction method for the trough plate platform of the operation subway station, the two holes with the diameter being 90 mm are formed in a trough plate and serve as the pouring hole and the pressurizing hole correspondingly, and not only can the integrity of the overall structure of the trough plate platform and the safety of the operation station be guaranteed, but also the reinforcing construction requirements can be met; the assembled steel formworks areutilized as a part of the reinforcing structure, and convenience and rapidness are achieved; and the reinforcing construction method has the advantages that safety is high, operation is convenient, applicability is high, and manual operation strength is reduced.

Owner:ELECTROMECHANICAL DEVICE INSTALLATION OF CTCE GROUP

A kind of permeable non-slip floor tile and its manufacturing method

ActiveCN103397767BFill technology gapsImprove the decorative effectLayered productsFlooringSurface layerPorous ceramics

The invention discloses a water permeating and anti-skidding floor tile. The water permeating and anti-skidding floor tile comprises a bottom layer, middle layers and a surface layer all of which are combined together. The bottom layer is a dense ceramic layer, and a water removing hole penetrating through the upper surface and the lower surface of the bottom layer is formed in the bottom layer. The middle layers are porous ceramic layers which are provided with a plurality of through holes, and the effective aperture of each through hole is not larger than that of the water removing hole. The surface layer is a decoration glaze layer, and a plurality of micropores are formed in the decoration glaze layer, and the effective aperture of each micropore is not larger than that of the through holes. Preferably, the middle layers comprise at least two layers, and the effective apertures of the through holes in each layer are reduced gradually from bottom to top. Compared with the prior art, the water permeating and anti-skidding floor tile has the advantages of being good in water permeating performance, anti-skidding effect, mold proofing effect, anti-pollution effect and decorative effect. The invention further provides a manufacturing method of the water permeating and anti-skidding floor tile.

Owner:江显异

Micro-nano processing method for aluminum/aluminum alloy surface and aluminum/ aluminum alloy structure

InactiveCN103276435BWell distributed holesHigh bonding strengthMetal layered productsMicro nanoO-Phosphoric Acid

A micro-nano processing method of an aluminum or aluminum alloy surface includes a step of placing aluminum or an aluminum alloy as an anode in an electrolyte containing hydrochloric acid, sulfuric acid, phosphoric acid, and an etching inhibitor for DC electrochemical etching, where the concentration of hydrochloric acid is 1.5 to 3 mol / L, the concentration of sulfuric acid is 0.9 to 1.2 mol / L, and the concentration of phosphoric acid is 0.6 to 1 mol / L. A method for integrating aluminum or an aluminum alloy and a plastic includes the following steps: forming a micro-nano porous structure on an aluminum or aluminum alloy surface by using the micro-nano processing method; and closely combining a plastic and the aluminum or aluminum alloy surface by means of the micro-nano porous structure. An aluminum or aluminum alloy structure has a micro-nano porous structure formed on the surface of the aluminum or aluminum alloy structure by using the micro-nano processing method. By using this method, the micro-nano hole processing efficiency is high, the quality is high, and the method is environmental friendly.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Method for continuously extracting beta-methylnaphthalene crude product from methylnaphthalene enrichment liquor

ActiveCN108440233AWell distributed holesUniform pore sizeDistillation purification/separationVapor condensationCarbon fibersOil phase

The invention provides a method for continuously extracting a beta-methylnaphthalene crude product from a methylnaphthalene enrichment liquor. The method comprises steps as follows: methylnaphthalenefractions are treated with an ammonium bisulfate water liquor and a heptane and ethanol amine mixed liquor sequentially, separation is performed, an upper-layer oil phase is taken, and alkyl methylnaphthalene subjected to secondary purification is obtained; an entrainer is added to alkyl methylnaphthalene subjected to secondary purification, indirect reduced pressure distillation operation is performed, the reduced pressure distillation is performed under the vacuum degree of minus 0.09 MPa and at the tower top temperature of 80 DEG C and the tower bottom temperature of 150 DEG C, a gas phasepasses through a porous alumina membrane / carbon fiber filler cold trap at the tower top, and the beta-methylnaphthalene crude product is obtained; the beta-methylnaphthalene crude product is put in afreezing microtome and frozen and crystalized at the temperature of subzero 25 DEG C to subzero 15 DEG C, separation is performed, then, redisliquor is performed at the temperature of 36-40 DEG C, andbeta-methylnaphthalene is obtained, wherein the porous alumina membrane / carbon fiber filler cold trap comprises alternate porous alumina layers and carbon fiber layers.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

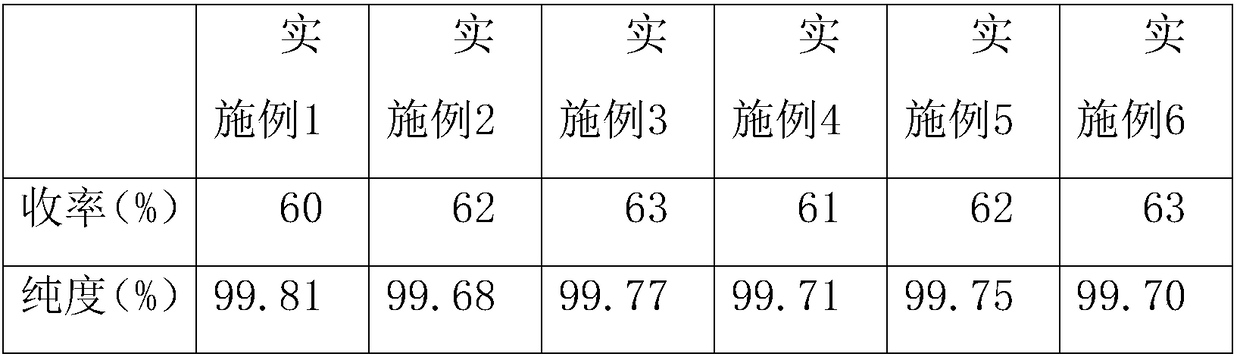

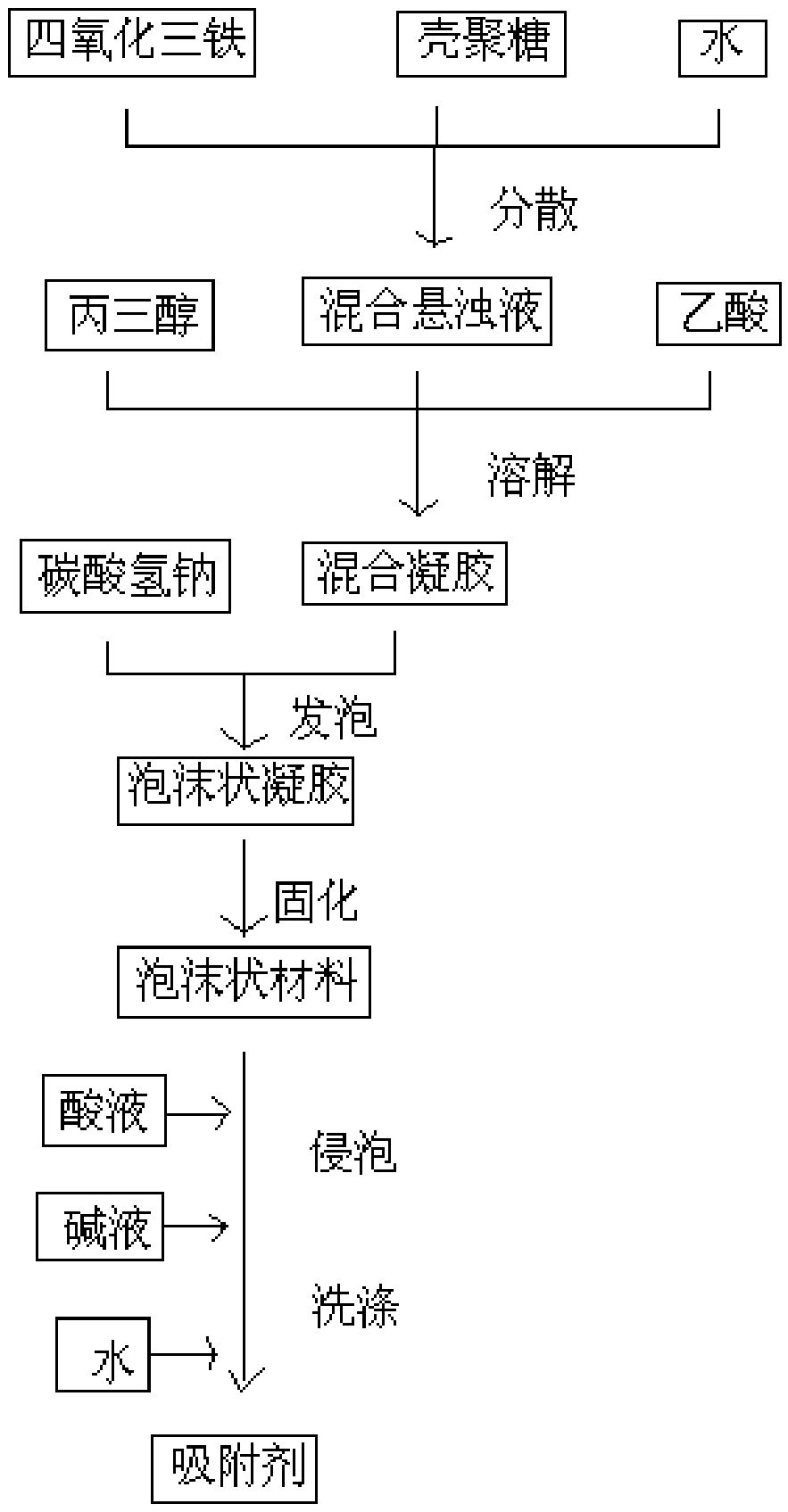

Foam-like magnetic chitosan adsorbent and preparation method thereof

ActiveCN108714414AImprove adsorption capacityEvenly distributedOther chemical processesWater contaminantsAcetic acidSodium bicarbonate

The invention discloses a foam-like magnetic chitosan adsorbent and a preparation method thereof. The foam adsorbent is foamed by carbon dioxide produced by the reaction of sodium bicarbonate and acetic acid, and is prepared under the aid and protection of glycerol, the size and distribution of pores in the foam adsorbent are uniform, and more active groups are retained on chitosan. Consequently,the foam-like magnetic chitosan adsorbent has the advantages of having adsorbability to metal ions, and being conducive to large-scale application of the foamed chitosan-based adsorbent in water treatment.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

ZnO nano powder in sheet uniform porous structure as well as preparation method and applications thereof

InactiveCN102079539BLarge specific surface areaHigh purityZinc oxides/hydroxidesCell electrodesWater bathsReaction temperature

The invention discloses ZnO nano powder in a sheet uniform porous structure as well as a preparation method and applications thereof. The preparation method comprises the following steps of: adding a sodium carbonate solution to a reaction container in a thermostatic water bath, dripping a zinc nitrate solution in the sodium carbonate solution, continuously applying an external electric field of 50kV to the reaction container and stirring at a reaction temperature of 80-90 DEG C; and keeping the solution water bath temperature for 2h after dripping, separating, washing and drying the muddy solution obtained after the temperature preservation is finished to obtain a basic zinc carbonate precursor and roasting at 300-400 DEG C for 2-3h to obtain ZnO nano powder in the sheet uniform porous structure. The invention belongs to a hexagonal system, has the advantages of great specific surface area, high purity, good product quality without ZnO in other shapes, stable performance, constant performance when being arranged in air for a long time, simple process, low manufacture cost, low equipment requirement, rapidness of operation and mass production suitability.

Owner:SOUTH CHINA UNIV OF TECH

Seedling raising soil for seedling raising of wheat stock seeds in greenhouse

InactiveCN107896910APrevent evaporationReduce penetrationAgriculture tools and machinesAnimal corpse fertilisersFiberMicrobial agent

The invention discloses seedling raising soil for seedling raising of wheat stock seeds in a greenhouse. The seedling raising soil comprises, by weight, 40-80 parts of sandy soil, 15-35 parts of rectorite compound, 15-20 parts of soil conditioner, 30-50 parts of wormcast, 15-35 parts of wheat bran, 15-25 parts of peanut shell powder, 2-8 parts of shrimp shell powder, 1-2 parts of EM microbial agent, 5-15 parts of ammonium nitrate, 10-16 parts of calcium magnesium phosphate fertilizer, 10-18 parts of potash magnesium sulphate fertilizer and 1-4 parts of sodium alginate. The rectorite compound is prepared in the steps that lignin fibers and sodium hydroxide are stirred, filtered and washed to be neutral, rectorite, hydroxyl silicone oil and dimethyl sulfoxide are added and continue to be stirred, filtered and washed to be neutral, hydrochloric acid is added and stirred, tetrabutyl titanate is added for ultrasonic dispersion, heating and standing are conducted, the product is filtered anddried, and the rectorite compound is obtained.

Owner:安徽绿雨种业股份有限公司

Manufacturing method of porous tasty bean curd based on microwave pretreatment

ActiveCN108576242AWell distributed holesMany holesCheese manufactureFood scienceThermal insulationFlavor

The invention provides a manufacturing method of porous tasty bean curd based on microwave pretreatment, comprising the following steps: (1) washing fresh soybeans and draining, adding distilled waterwhich is 6 times the weight of the soybeans, carrying out microwave treatment at the power of 200 W in a microwave oven for 3 min, taking the materials out of the microwave oven and cooling to room temperature to obtain pretreated soybeans; (2) immersing the pretreated soybeans in water until there is a planar concave in the center of the bean cotyledon, and taking out to obtain waterishlogged soybeans; (3) adding water to the waterishlogged soybeans and jordaning to obtain uncooked soya-bean milk, boiling the uncooked soya-bean milk for 1-3 min to obtain cooked soya-bean milk, immediately adding water and cooling to 63-67 DEG C within 10-15 seconds so as to obtain a serous fluid; (4) adding a coagulating agent into the serous fluid, carrying out thermal insulation for 10 min, and takingout to obtain bean curd pulp, and discharging water from the bean curd pulp through a flip self-pressing mode to obtain a semi-finished product; and (5) adding the semi-finished product into boiled cooking liquor and waiting for 3-5 min to obtain the porous tasty bean curd. The prepared bean curd has uniform aperture, good local flavor, and excellent yield and elasticity.

Owner:SUZHOU JINJI FOODS

Electrostatic spinning porous carbon material and preparation method thereof

InactiveCN112323262ALarge specific surface areaHigh porosityFilament/thread formingHeating/cooling textile fabricsPolymer scienceSpinning

The invention discloses an electrostatic spinning porous carbon material and a preparation method thereof. The preparation method of the electrostatic spinning porous carbon material comprises the following steps that silk fibroin, polyoxyethylene, potassium chloride and anhydrous formic acid are taken for being uniformly mixed to obtain a spinning solution; the spinning solution is subjected to electrostatic spinning to obtain an electrostatic spinning membrane, and the spinning voltage is 14-18kV; and high-temperature carbonization is carried out on the electrostatic spinning membrane in a nitrogen atmosphere to obtain the electrostatic spinning porous carbon material. The electrostatic spinning porous carbon material is prepared from a nitrogen element, and the content of the nitrogen element is 6-22 wt%. The preparation method of the electrostatic spinning porous carbon material is convenient to operate, the preparation process is easy to control, the technological process is short, and the obtained electrostatic spinning porous carbon material has good hydrophilic performance and pore structure.

Owner:SUZHOU UNIV

A method for continuously extracting β-methylnaphthalene crude product from methylnaphthalene enriched liquid

ActiveCN108440233BWell distributed holesUniform pore sizeDistillation purification/separationVapor condensationFiberCarbon fibers

The invention provides a method for continuously extracting a beta-methylnaphthalene crude product from a methylnaphthalene enrichment liquor. The method comprises steps as follows: methylnaphthalenefractions are treated with an ammonium bisulfate water liquor and a heptane and ethanol amine mixed liquor sequentially, separation is performed, an upper-layer oil phase is taken, and alkyl methylnaphthalene subjected to secondary purification is obtained; an entrainer is added to alkyl methylnaphthalene subjected to secondary purification, indirect reduced pressure distillation operation is performed, the reduced pressure distillation is performed under the vacuum degree of minus 0.09 MPa and at the tower top temperature of 80 DEG C and the tower bottom temperature of 150 DEG C, a gas phasepasses through a porous alumina membrane / carbon fiber filler cold trap at the tower top, and the beta-methylnaphthalene crude product is obtained; the beta-methylnaphthalene crude product is put in afreezing microtome and frozen and crystalized at the temperature of subzero 25 DEG C to subzero 15 DEG C, separation is performed, then, redisliquor is performed at the temperature of 36-40 DEG C, andbeta-methylnaphthalene is obtained, wherein the porous alumina membrane / carbon fiber filler cold trap comprises alternate porous alumina layers and carbon fiber layers.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Method for preparing impregnated cathode matrix

InactiveCN102024640BUniform hole sizeWell distributed holesThermionic cathode manufacturePrillMicrowave

The invention discloses a method for preparing an impregnated cathode matrix and relates to technology of microwave devices. The method is used for preparing a tungsten sponge matrix of an impregnated barium and tungsten cathode. Tungsten particles of different sizes are prepared into uniform spherical particles by particle spray drying powder treating technology, so that the flowability of tungsten powder is enhanced; and after being filled into a rubber sleeve, the treated tungsten powder can be beat, tamped or vibrated to form a close-packed structure, and then the close-packed structure is pressed and sintered to prepare the tungsten sponge matrix. The method is simple and practicable, the prepared impregnated cathode matrix has the advantages of uniform hole size, uniformly distributed holes, few closed holes and the like.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

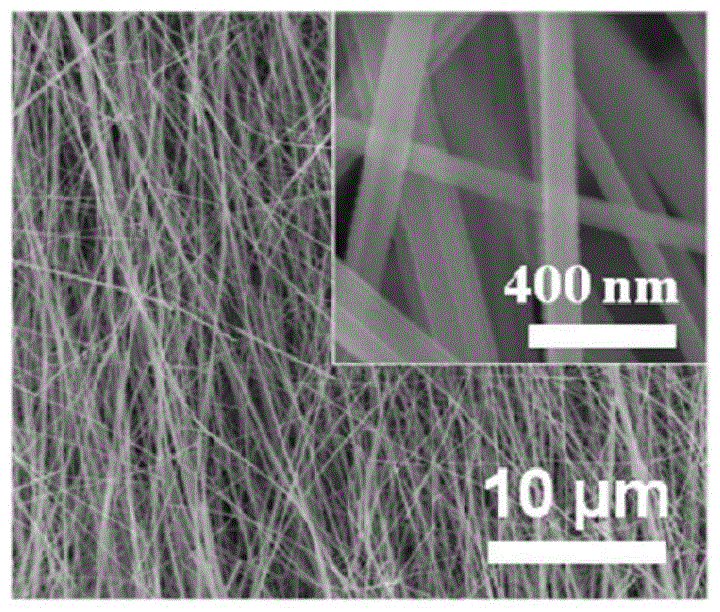

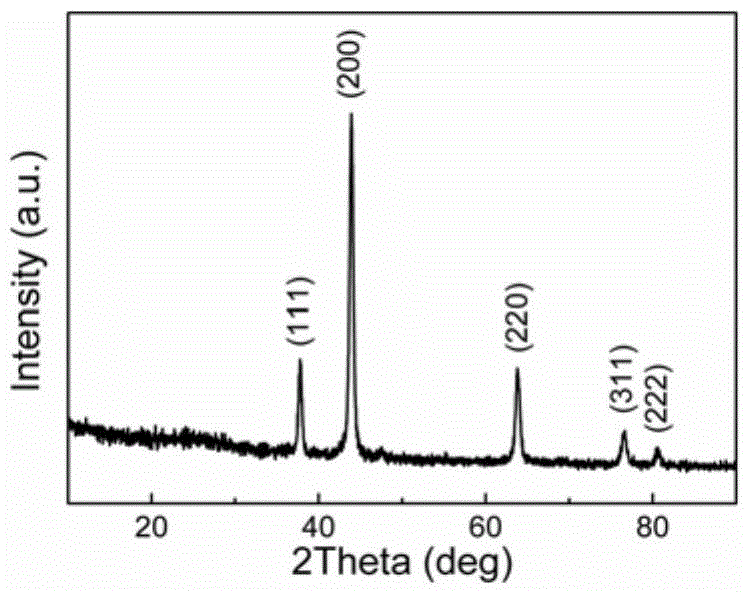

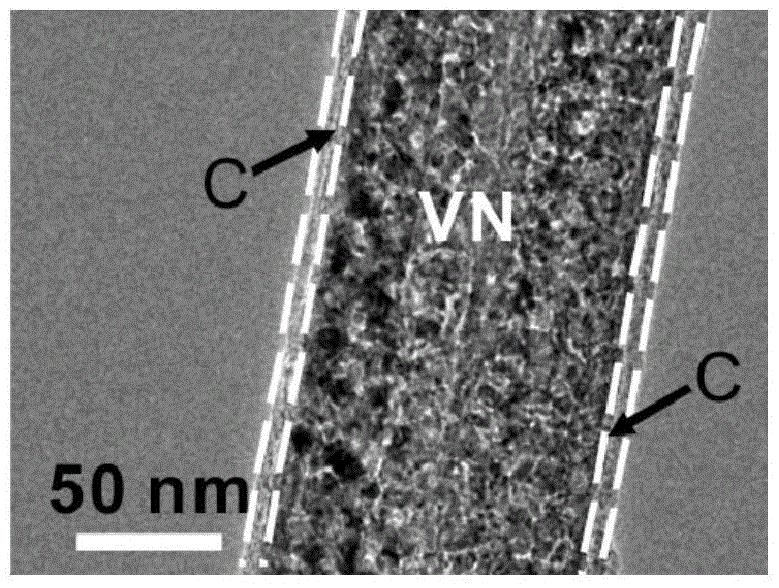

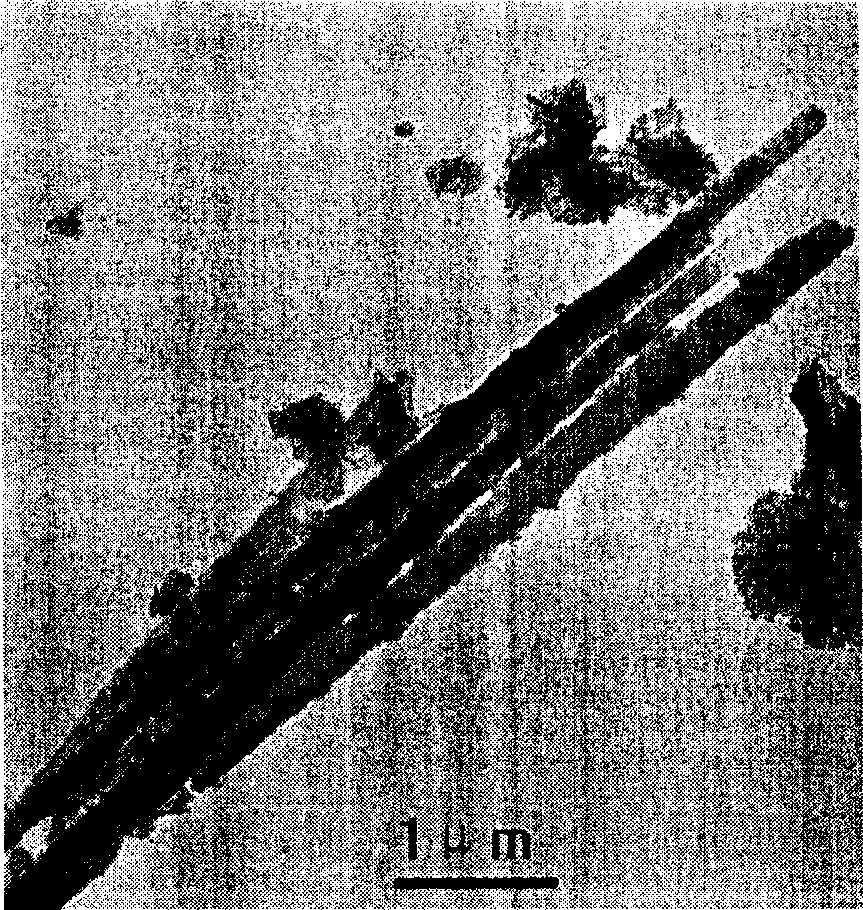

A carbon-coated porous vanadium nitride nanowire film and its preparation method

InactiveCN104505509BUniform size distributionLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesNanowireElectrochemistry

The invention specifically relates to a carbon-coated porous vanadium nitride nanowire film and a preparation method thereof. The preparation method comprises the following steps: 1) preparing vanadium pentoxide nanowires, and diluting the vanadium pentoxide nanowires by water to obtain a dispersion liquid with a concentration of 0.3mg / mL; 2) taking 100mL of the dispersion and uniformly stirring, adding trishydroxymethyl aminomethane buffering liquid and then stirring, then adding 10-200mg of dopamine hydrochloride, stirring for 0.5-4h until the solution is dark green, cleaning the polymerized sample by deionized water, and drying in a drying box to obtain a polydopamine-coated vanadium pentoxide nanowire film; 3) placing the dried-formed sample film in a tubular furnace and carrying out a heat treatment, insulating for 3h at 300-1000 DEG C under an NH3 condition, and naturally cooling to a room temperature with the furnace, so as to obtain the carbon-coated porous vanadium nitride nanowire film. The method disclosed by the invention is reliable in preparation process, low in energy consumption and high in yield; the prepared carbon-coated porous vanadium nitride nanowires are uniform in distribution, obvious in pore structure, controllable in length, and suitable for the field of electrochemistry.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing sheet porous structural ZnO nano powder

InactiveCN100560504CWell distributed holesHigh purityNanostructure manufactureZinc oxides/hydroxidesMicrowaveReaction temperature

Owner:SHANDONG UNIV

Method for preparing flake porous ZnO nano powder

The invention relates to a method for preparing flake porous ZnO nano powder, which comprises the following steps: adding ammonia into solution of zinc nitrate dropwise, and adjusting the pH of the solution to between 6 and 8; under the condition of stirring by magnetic force at the rotating speed of 0 to 180r / m, performing reaction at the temperature of between 0 and 80DEG C for 0.5 to 3 hours; separating, washing and drying the obtained cloudy solution to obtain a crosslinked flake and dispersed flake basic zinc nitrate precursor; and calcinating the basic zinc nitrate precursor with the two appearances at the temperature of between 220 and 500DEG C for 0.5 and 3 hours to obtain the flake porous ZnO nano powder. The nano ZnO product prepared by the method is white powder, belongs to a hexagonal system, has large specific surface area, high purity and good product quality, and responds to gas such as ethanol and acetone sensitively.

Owner:ANHUI NORMAL UNIV

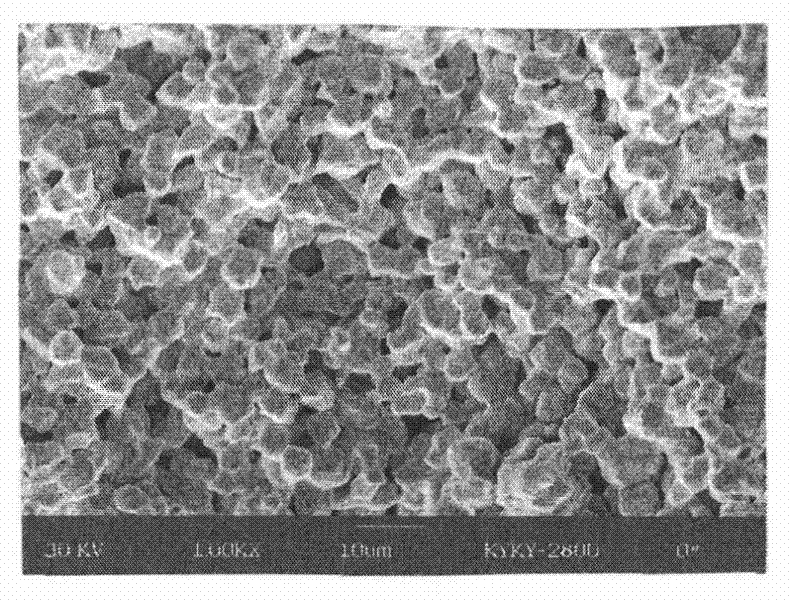

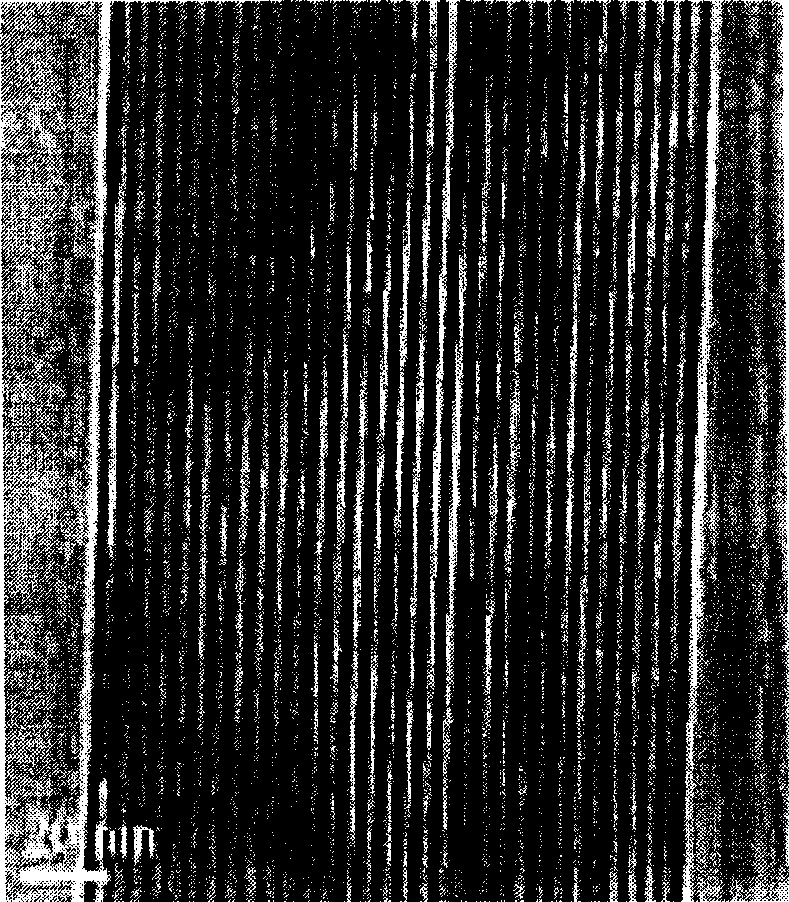

Meso-porous nanometer particle of calcium phosphate, preparation method and application thereof

InactiveCN100460016CBiocompatible Inorganic NanocarriersDegradable Inorganic NanocarriersInorganic non-active ingredientsPhosphorus compoundsBand shapeBiocompatibility Testing

The invention dis closes a nanomater granule of mesoporous calcium phosphate which is used as medicine carrier. It comprises Ca10(PO4)6(OH)2, the crystalline is nanometer banded shape, the width of band is 40-150 nm, length is 5-10 um, specific surface area is 160-280 m2.g-1 and the acverage bore diameter is 3-8 nm. The said prepartion process comprises following steps: adding phosphate radical solution, calcium ion solution in order into solution containing surface active agent and cosurfactant, getting mixing solution; dripping alkaline liquor slowly and stirring at the same into mixing solution to regulate pH to 8-11; stirring for reaction for 1-48 hours and getting reaction product of white deposition; washing white deposition with organic dissolvent and water and getting nanomater granule of mesoporous calcium phosphate. The product is characterized by no toxicity, good biocompatibility, high medicine carrying amount and a certain degradability.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com