Micro-nano processing method for aluminum/aluminum alloy surface and aluminum/ aluminum alloy structure

A technology of micro-nano processing and aluminum alloy surface, which is applied in the field of aluminum or aluminum alloy and plastic integration method and aluminum or aluminum alloy structure, can solve the problems of organic matter environmental pollution, etc., and achieve high bonding strength, high-efficiency integrated composite preparation, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

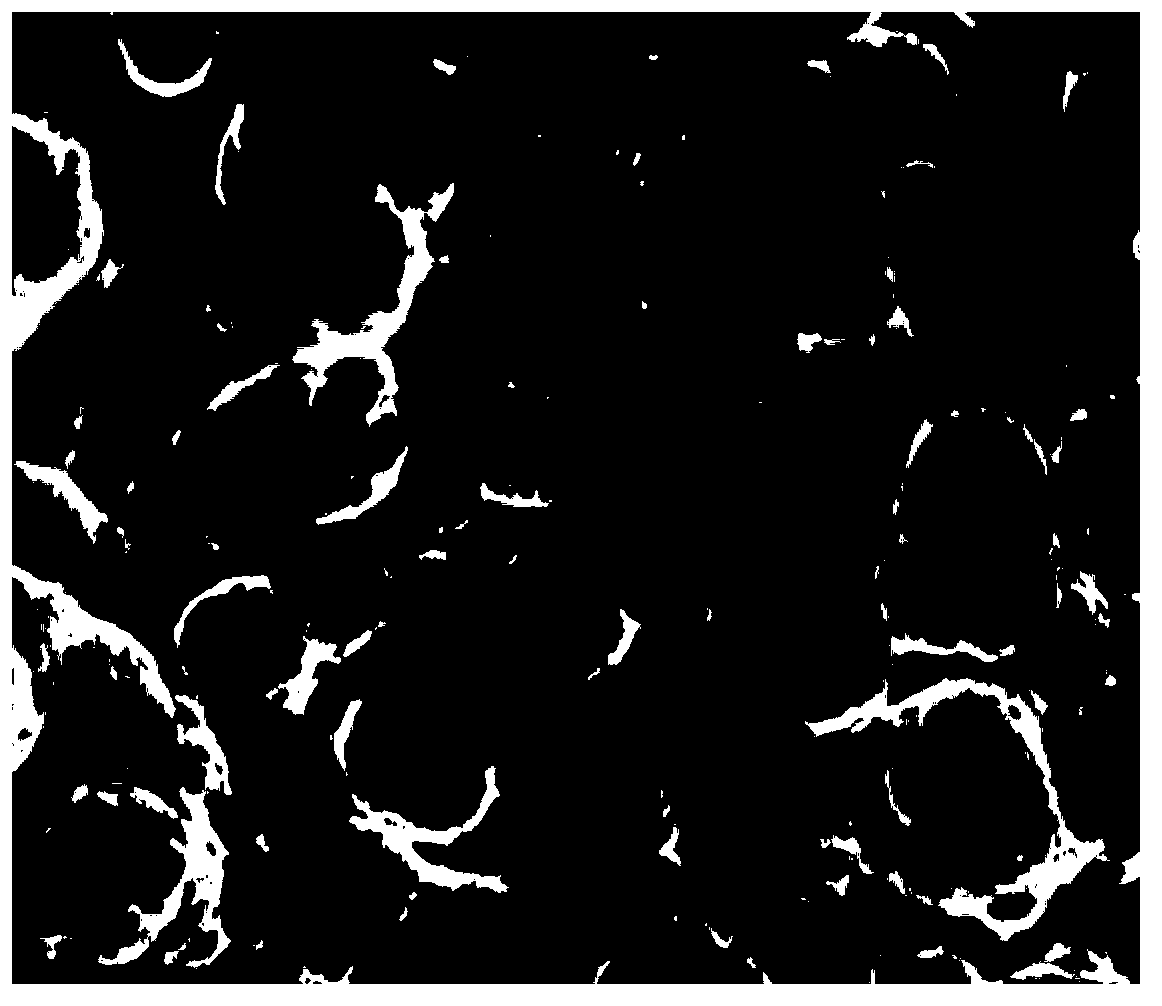

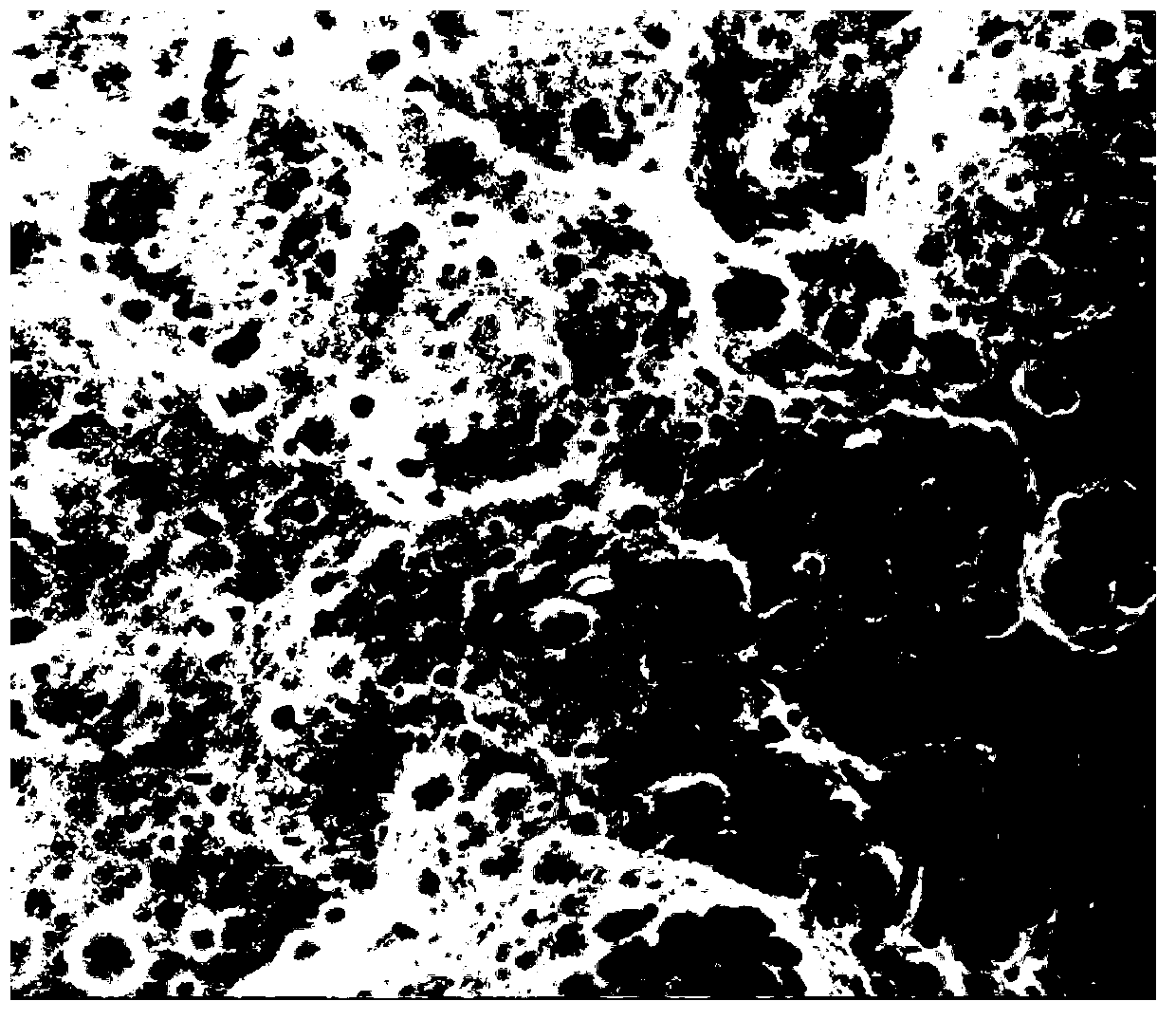

Image

Examples

example 1

[0055]A commercially available 2mm thick A5052 aluminum alloy plate was purchased, and the aluminum alloy was uniformly cut into 20mm×10mm aluminum sheets by wire cutting. Select iron sandpaper of models 360#, 600#, and 800# in order for grinding. When grinding, the sample must be rotated 900 every time the sandpaper is changed to ensure that all the scratches left by the previous process are removed, so that the thickness of the sample reaches about 5um, and then use ethanol solution to clean in ultrasonic for 10 minutes to remove Surface oil stains were cleaned with deionized water and dried in a drying oven at 120°C.

[0056] Prepare 100ml of NaOH solution with a mass concentration of 2% with ion-exchanged water, heat it to 40°C in a water bath, dip the aforementioned aluminum alloy sheet in this solution for 2 minutes in a hanging manner, and then wash the aluminum alloy sheet with deionized water clean.

[0057] Then dilute 100ml of HNO3 solution with a mass concentrati...

example 2

[0060] A commercially available 2 mm thick A6063 aluminum alloy plate was purchased, and the aluminum alloy was uniformly cut into aluminum sheets of 20 mm×10 mm by wire cutting. A small hole is opened on each aluminum alloy sheet, and the surface is polished with iron sandpaper of models 360#, 600#, and 800# in sequence. When grinding, every time a sandpaper is changed, the sample is rotated 900 to ensure that all the scratches left by the previous process are removed, so that the thickness of the surface of the sample is removed to a level of about 5um, and then the ethanol solution is used to clean it in ultrasonic waves for 10 minutes. Remove the surface oil, then rinse it with deionized water, and dry it in a drying oven at 120°C

[0061] Prepare 100ml of NaOH solution with a mass concentration of 2% with ion-exchanged water, heat it to 40°C in a water bath, dip the aforementioned aluminum alloy sheet in this solution for 2 minutes in a hanging manner, and then clean the ...

example 3

[0065] Commercially available aluminum foil was purchased and cut into thin slices of 20mm×10mm. A small hole is opened on each sheet, and the surface is directly polished with 800# iron sandpaper, and then cleaned with ethanol solution in ultrasonic for 10 minutes to remove surface oil, then cleaned with deionized water, and placed in a 120°C drying oven dry

[0066] Prepare 100ml of NaOH solution with a mass concentration of 1.5% in ion-exchanged water, heat it in a water bath to 40°C, immerse the aforementioned aluminum foil in the solution for 2 minutes in a hanging manner, and then clean the aluminum foil with deionized water.

[0067] Next, prepare 100ml of HNO3 solution with a mass concentration of 1% in ion-exchanged water, heat it to 40°C in a water bath, and immerse the above-mentioned alkali-washed aluminum foil in this solution for 1 minute in a hanging manner. Then the aluminum foil was cleaned with deionized water.

[0068] Then use the aluminum foil as the ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com