A carbon-coated porous vanadium nitride nanowire film and its preparation method

A vanadium nitride nanometer and vanadium pentoxide nanometer technology, which is applied in the field of carbon-coated porous vanadium nitride nanowire films and their preparation, can solve problems such as the inability to form electrode films, and achieves alleviation of volume changes and uniform size distribution. , the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

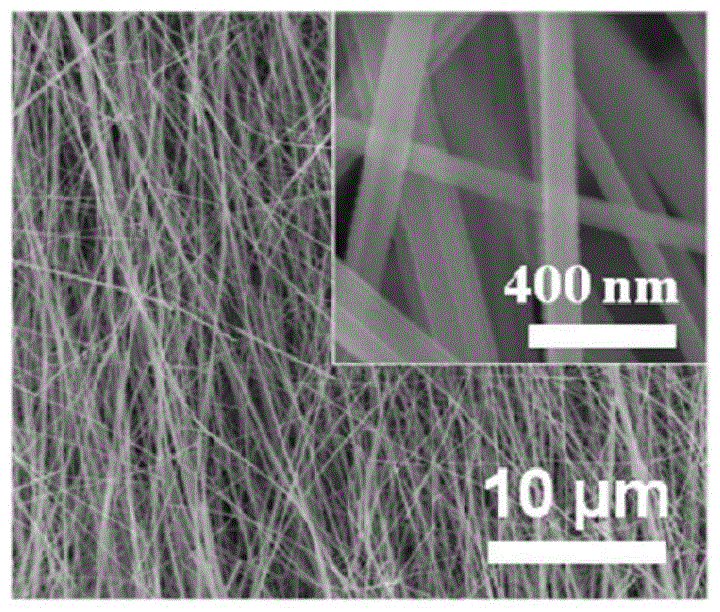

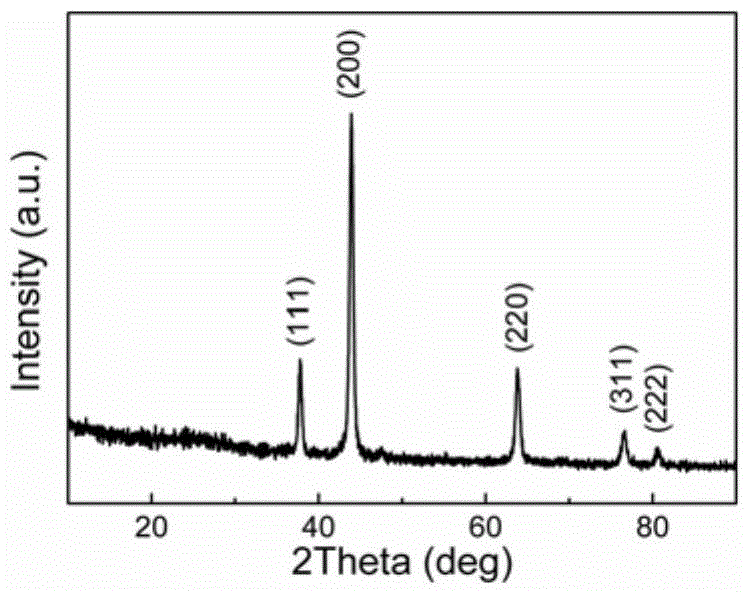

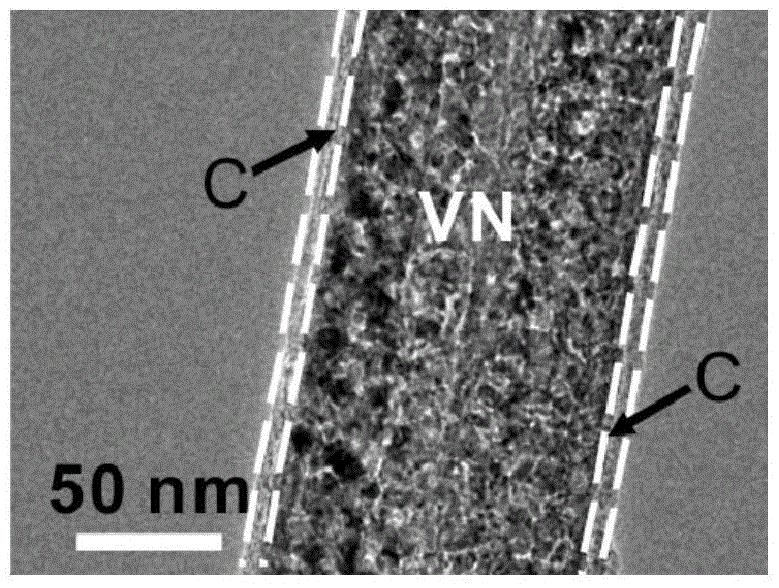

[0034] A method for preparing a carbon-coated porous vanadium nitride nanowire film. First, dissolve 2.73g of vanadium pentoxide in 25ml of hydrogen peroxide, then add distilled water until the solution volume is 300ml, and stir for 0.5h to form an orange-red transparent solution. Pour the transparent liquid into a hydrothermal kettle and place it in a drying oven at 180°C Under the condition of water heat for 96h, finally, wash out the obtained vanadium pentoxide nanowire; dilute the cleaned sample to a certain concentration with deionized water, take 100mL of the dispersion and stir evenly, add Tris (trishydroxymethylaminomethane) After stirring for 2 minutes, add 10-30 mg of dopamine hydrochloride, and stir for 0.5-1 hour until the solution is dark green. Wash the polymerized sample with deionized water, place it in a drying oven, and dry it at 60 degrees for 12 hours to obtain PDA-coated dioxypentoxide Vanadium nanowire film; the dried sample film was placed in a tube furn...

Embodiment 2

[0041] A method for preparing a carbon-coated porous vanadium nitride nanowire film. First, dissolve 2.73g of vanadium pentoxide in 25ml of hydrogen peroxide, then add distilled water until the solution volume is 300ml, and stir for 0.5h to form an orange-red transparent solution. Pour the transparent liquid into a hydrothermal kettle and place it in a drying oven at 180°C Under the condition of water heat for 96h, finally, wash out the obtained vanadium pentoxide nanowire; dilute the cleaned sample to a certain concentration with deionized water, take 100mL of the dispersion and stir evenly, add Tris (trishydroxymethylaminomethane) After stirring for 2 minutes, add 10-30 mg of dopamine hydrochloride, stirring for 1-2 hours until the solution is dark green, wash the polymerized sample with deionized water, put it in a drying oven, and dry at 60 degrees for 12 hours to obtain PDA-coated vanadium pentoxide Nanowire thin film; the dried sample film was placed in a tube furnace fo...

Embodiment 3

[0044] A method for preparing a carbon-coated porous vanadium nitride nanowire film. First, dissolve 2.73g of vanadium pentoxide in 25ml of hydrogen peroxide, then add distilled water until the solution volume is 300ml, and stir for 0.5h to form an orange-red transparent solution. Pour the transparent liquid into a hydrothermal kettle and place it in a drying oven at 180°C Under the condition of water heat for 96h, finally, wash out the obtained vanadium pentoxide nanowire; dilute the cleaned sample to a certain concentration with deionized water, take 100mL of the dispersion and stir evenly, add Tris (trishydroxymethylaminomethane) After stirring for 2 minutes, add 30-50 mg of dopamine hydrochloride, stirring for 2-4 hours until the solution is dark green, wash the polymerized sample with deionized water, put it in a drying oven, and dry at 60 degrees for 12 hours to obtain PDA-coated vanadium pentoxide Nanowire thin film; the dried sample film was placed in a tube furnace fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com