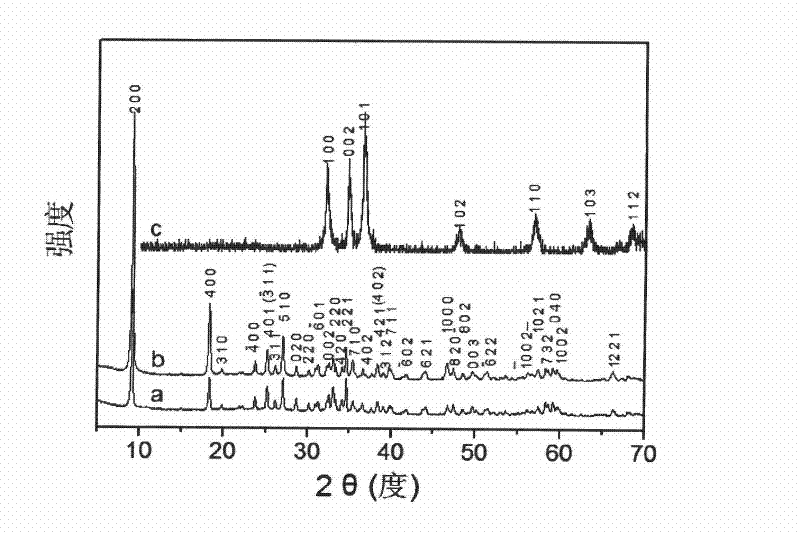

Method for preparing flake porous ZnO nano powder

A nano-powder and flake technology, applied in the field of preparation of ZnO nano-powder, can solve the problems of difficulty in realizing industrialized large-scale production of products, low yield and high cost, and achieve stable sensitive performance, high crystallinity and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

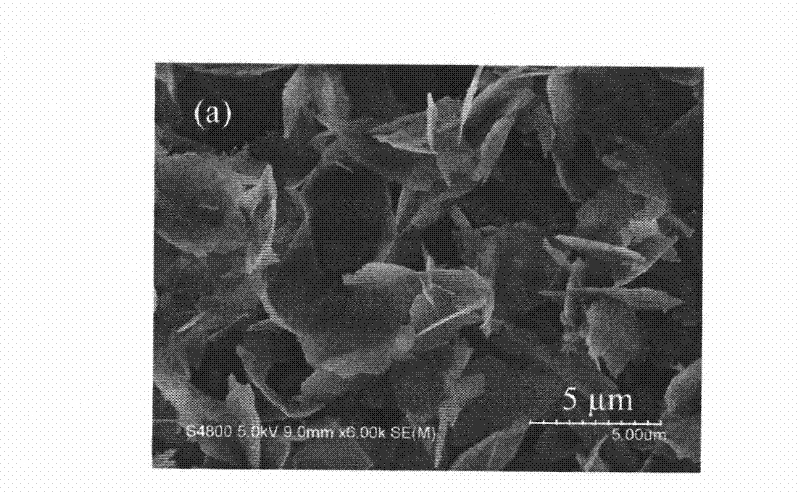

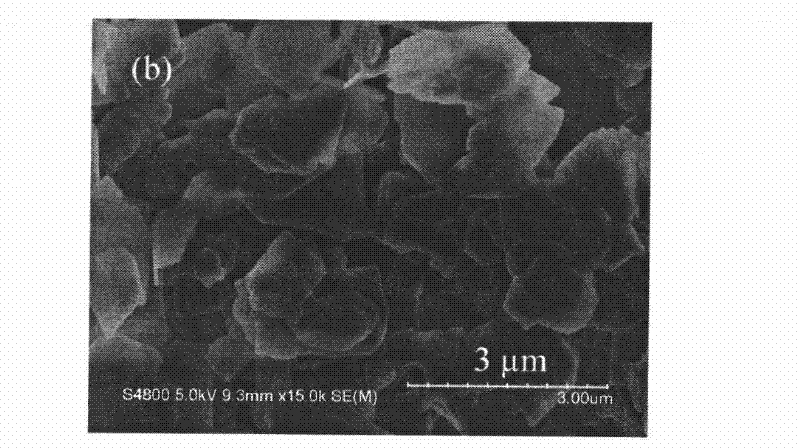

Embodiment 1

[0037] (1) Zinc nitrate hexahydrate raw material is dissolved in water, the zinc nitrate solution of preparation 0.1M, get this zinc nitrate solution 50ml in the flask, under magnetic stirring, drip ammoniacal liquor (concentration is 25wt%), adjust the pH of solution It is about 6.5, and the mixture is obtained.

[0038] (2) Put the turbid liquid flask obtained in step (1) at a temperature of 10° C., and let it stand for reaction for 2 hours to obtain a turbid liquid.

[0039] (3) Filter, wash and dry the turbid solution obtained in step (2) to obtain a basic zinc nitrate precursor.

[0040] (4) The basic zinc nitrate precursor obtained in the step (3) is placed in a muffle furnace at 450° C. for 2 h and roasted to obtain a porous ZnO nanopowder.

Embodiment 2

[0042] (1) Dissolve the zinc nitrate hexahydrate raw material in water, prepare the zinc nitrate solution of 0.3M, get the zinc nitrate solution 50ml in the flask, under magnetic stirring, add ammoniacal liquor (concentration is 25wt%) dropwise, adjust the pH of the solution It is about 7.0, and a mixed solution is obtained.

[0043] (2) The flask of the cloudy solution obtained in step (1) was reacted for 3 hours under magnetic stirring at a temperature of 25° C. and a rotation speed of 50 rpm to obtain a cloudy solution.

[0044] (3) Filter, wash and dry the turbid solution obtained in step (2) to obtain a basic zinc nitrate precursor.

[0045] (4) The basic zinc nitrate precursor obtained in the step (3) is placed in a muffle furnace at 400° C. for 2 h and calcined to obtain a porous ZnO nanometer powder.

Embodiment 3

[0047] (1) Dissolve the zinc nitrate hexahydrate raw material in water, prepare the zinc nitrate solution of 0.5M, get the zinc nitrate solution 50ml in the flask, under magnetic stirring, add ammoniacal liquor (concentration is 25wt%) dropwise, adjust the pH of the solution It is about 7.0, and a mixed solution is obtained.

[0048] (2) The flask of the cloudy solution obtained in step (1) was reacted for 1 hour under magnetic stirring at a temperature of 50° C. and a rotation speed of 80 rpm to obtain a cloudy solution.

[0049] (3) Filter, wash and dry the turbid solution obtained in step (2) to obtain a basic zinc nitrate precursor.

[0050] (4) The basic zinc nitrate precursor obtained in the step (3) is placed in a muffle furnace at 400° C. for 2 h and calcined to obtain a porous ZnO nanometer powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com