Patents

Literature

278results about How to "Non-deterministic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

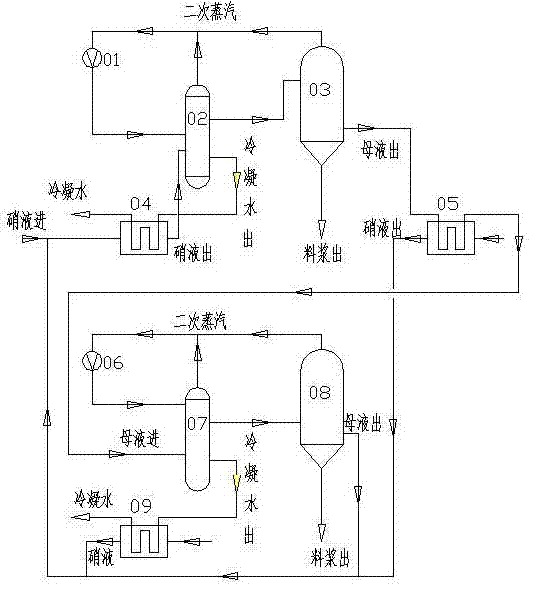

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

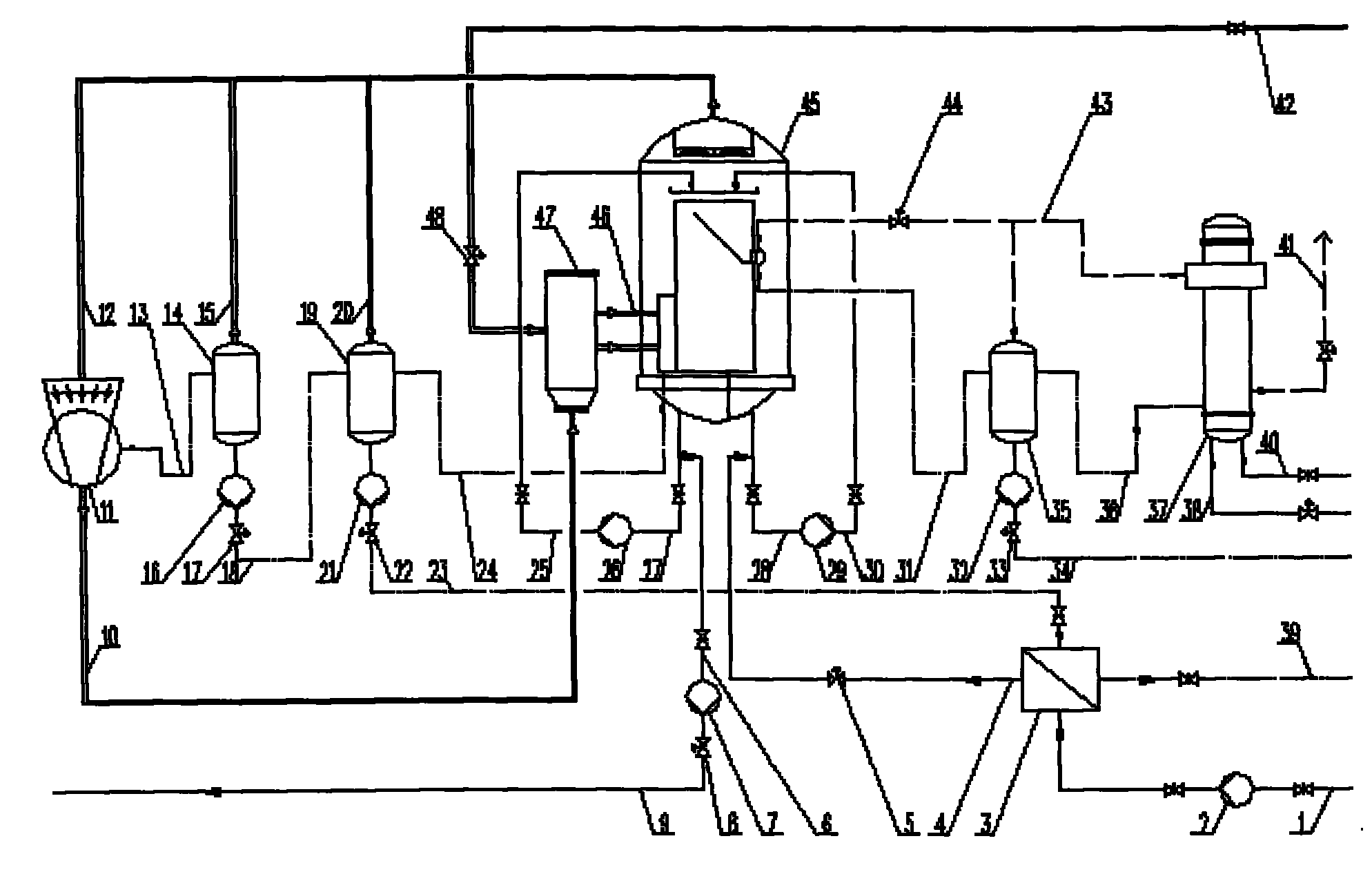

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

Apergillus niger strain and application thereof

InactiveCN1924000ANon-deterministicMild reaction conditionsFungiMicroorganism based processesMicrobiologyAspergillus niger

The invention discloses Aspergillus niger ML-0016 strain and application, which is characterized by the following: the reserving number is CCTCC.NO.M206034; the soy isoflavone glycoside is converted by strain to manufacture soy isoflavone glycosyl and aglycone.

Owner:JIANGSU ACAD OF AGRI SCI

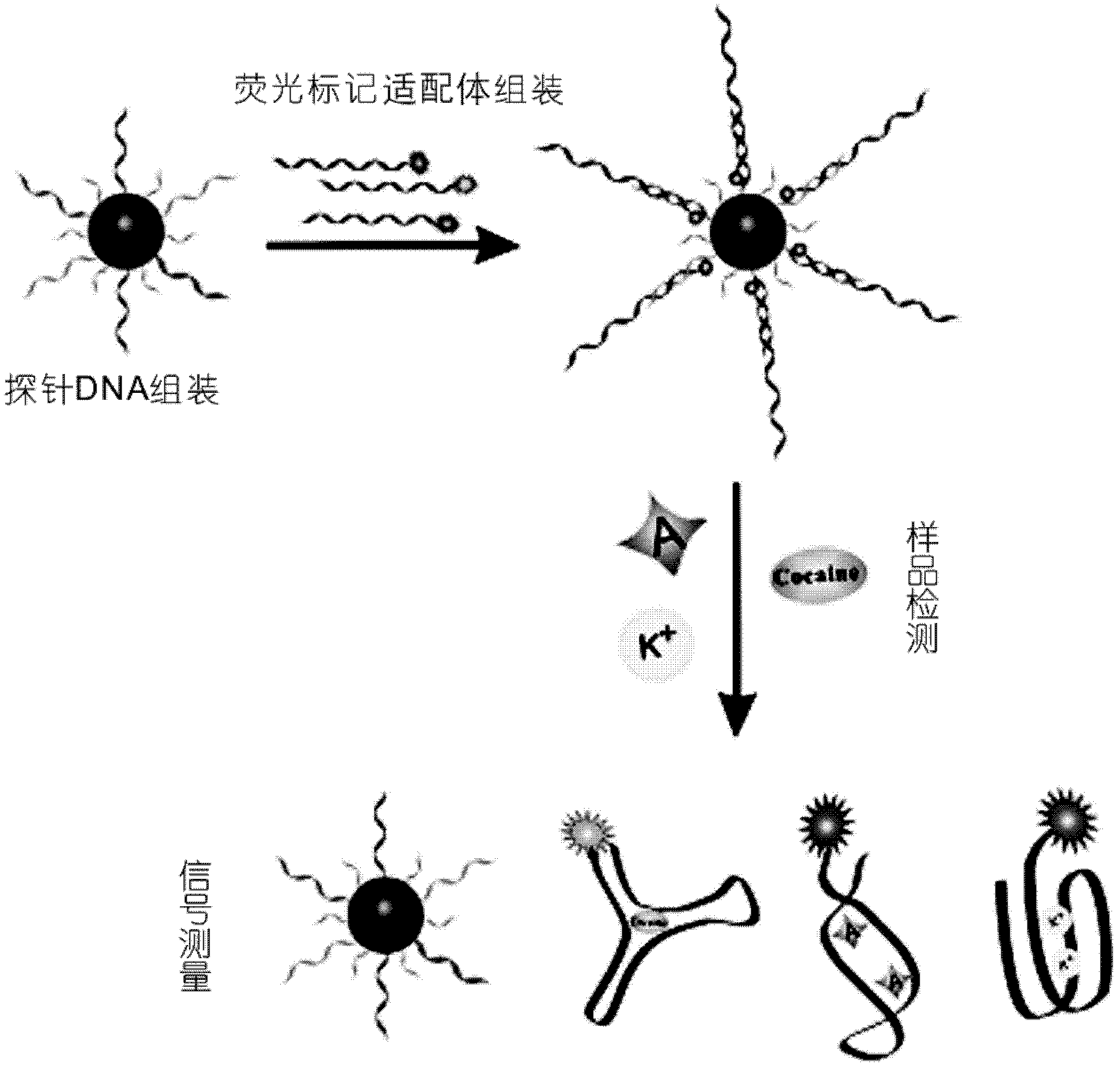

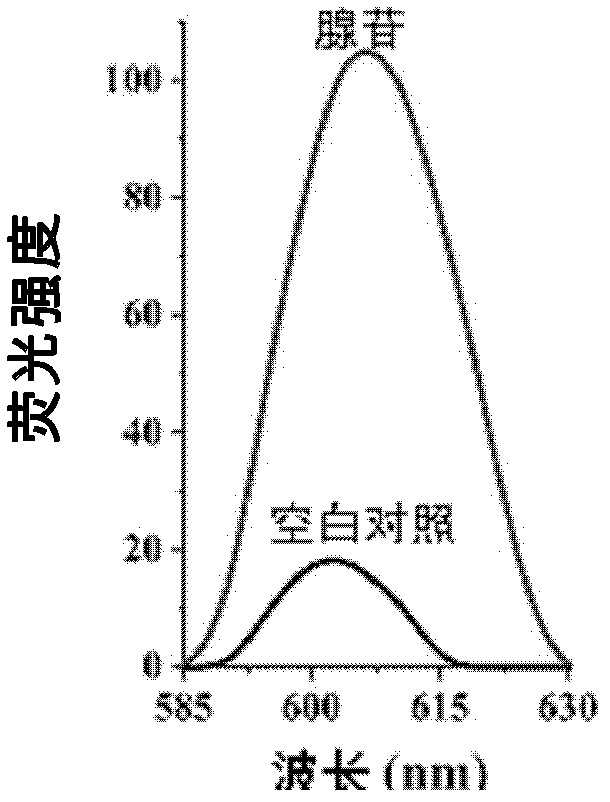

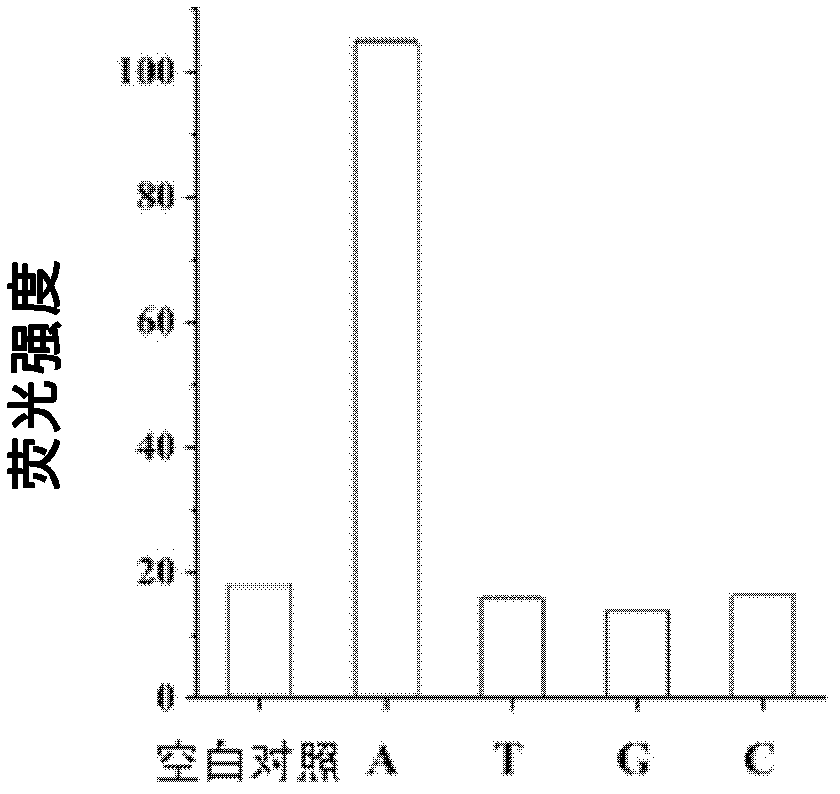

Small molecule probe based on nano-gold and aptamer and preparation method of small molecule probe

InactiveCN102676508AHigh detection sensitivityHigh quenching capacityMicrobiological testing/measurementFluorescence/phosphorescenceAptamerGold particles

The invention discloses a small molecule probe based on nano-gold and aptamer and a preparation method of the small molecule probe. The small molecule probe comprises nano-gold particles, more than one type of sulfydryl modifying deoxyribonucleic acid (DNA) fragment assembled on the nano-gold particles and more than one type of aptamer which is marked by fluorescent groups, and at least a part of fragments of the more than one type of the aptamer are complemented and hybridized with the more than one type of sulfydryl modifying DNA group. The small molecule probe is short in detecting time, simple in operation, high in specificity, good in repeatability, high in accuracy, and the false positive result is effectively reduced. By means of the aptamer technology, a high detection sensibility is achieved, and various molecules can be simultaneously detected.

Owner:华森新科(苏州)纳米技术有限公司

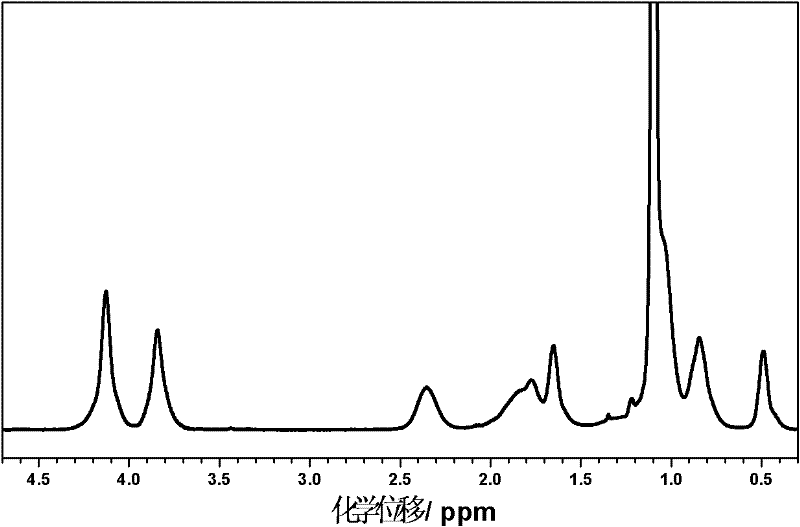

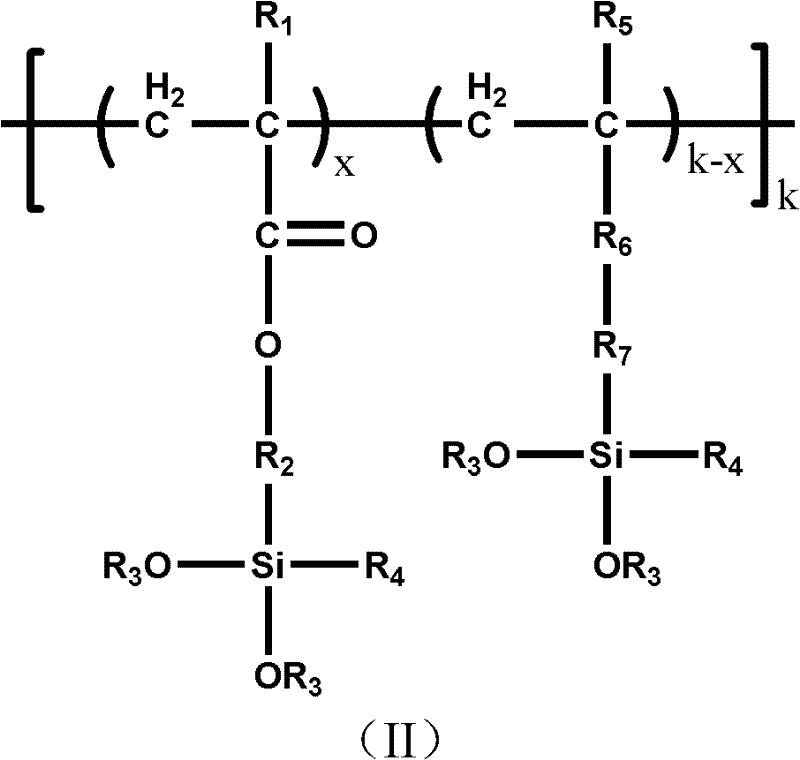

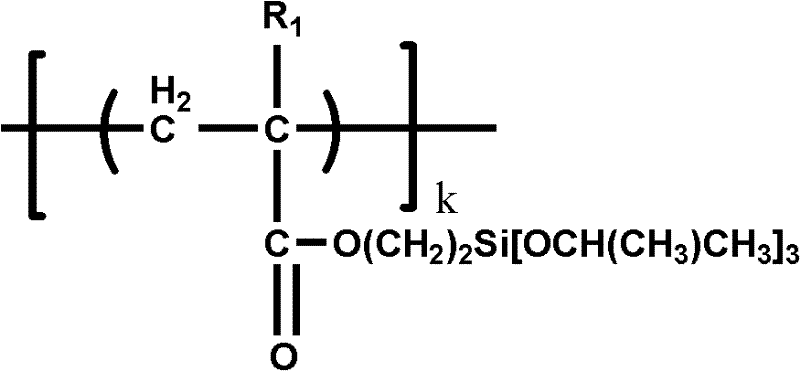

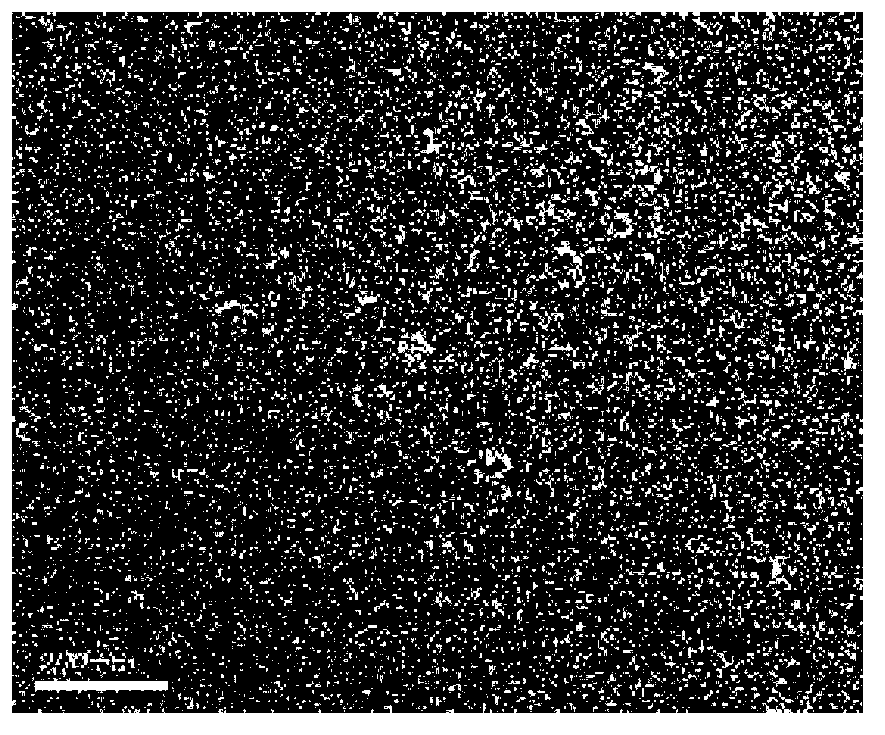

Amphiphobic fluoro-containing crosslinkable block copolymer and preparation method and application thereof

InactiveCN102199263AGood superhydrophobic and oleophobic propertiesPrecise structurePaper coatingCoatingsNano siliconPolymer science

The invention discloses amphiphobic fluoro-containing crosslinkable block copolymer and a preparation method and application thereof. The block copolymer can be used for preparing a super-amphiphobic coating on the surface of glass or printing paper, and the super-amphiphobic coating is prepared by the following steps of: (1) putting silica nano spheres into benzotrifluoride to obtain solution ofsilica nano spheres; (2) adding solution of amphiphobic fluoro-containing crosslinkable block copolymer, tetrahydrofuran, hydochloric acid solution and water into the solution of silica nano spheres,and reacting for 7 to 12 hours to obtain a crude product of modified silica nano spheres; (3) washing the crude product of modified silica nano spheres to obtain modified silica nano spheres; and (4)dispersing the modified silica nano spheres into the benzotrifluoride to obtain solution, dripping the solution onto a glass sheet, and after the solvent is volatilized, forming the super-amphiphobiccoating on the surface of the glass sheet, or soaking the printing paper in the solution, taking the paper out, and drying the paper to obtain the super-amphiphobic coating on the surface of the paper. The amphiphobic fluoro-containing crosslinkable block copolymer can endow a material with good superhydrophobic and oleophobic properties; and the coating has high stability and hardly falls off and denatures.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

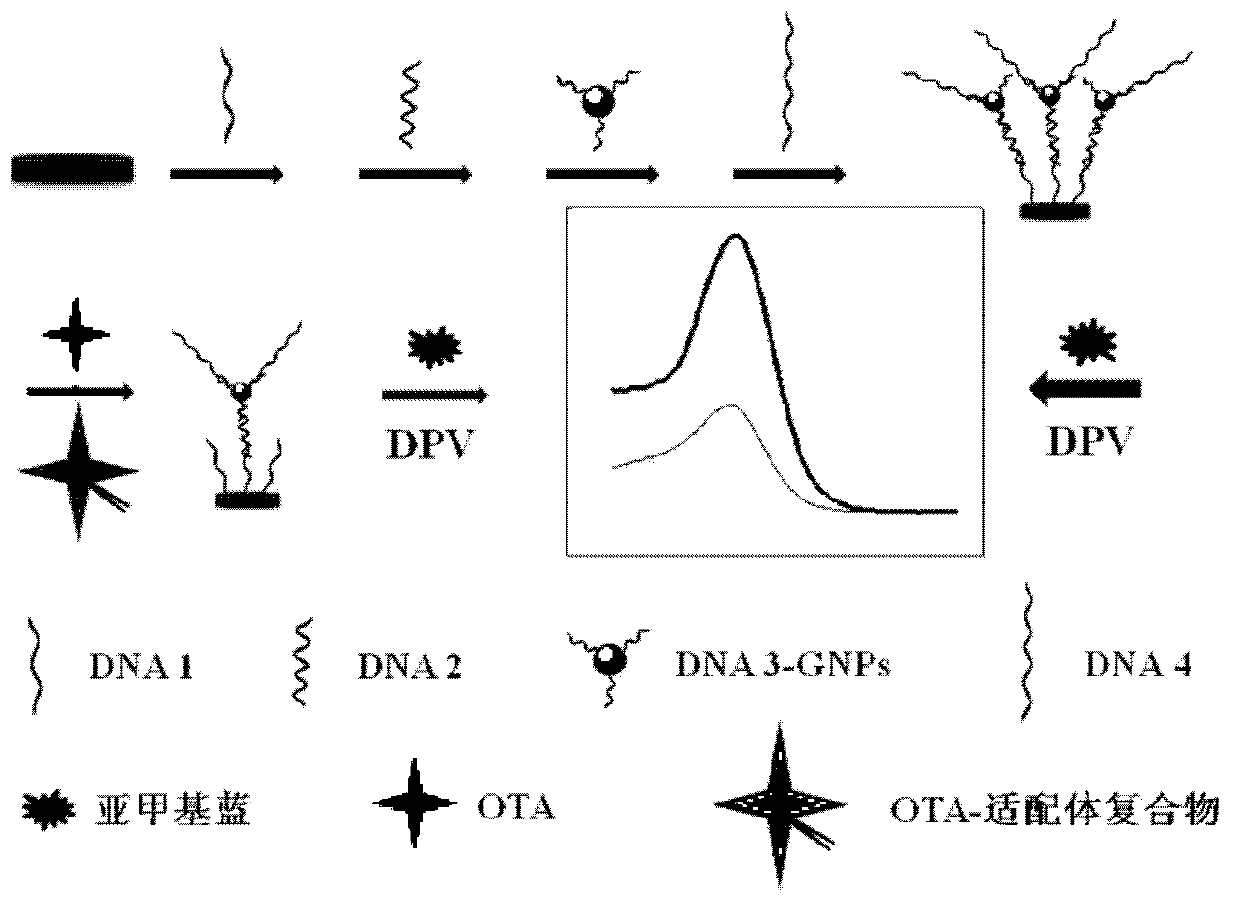

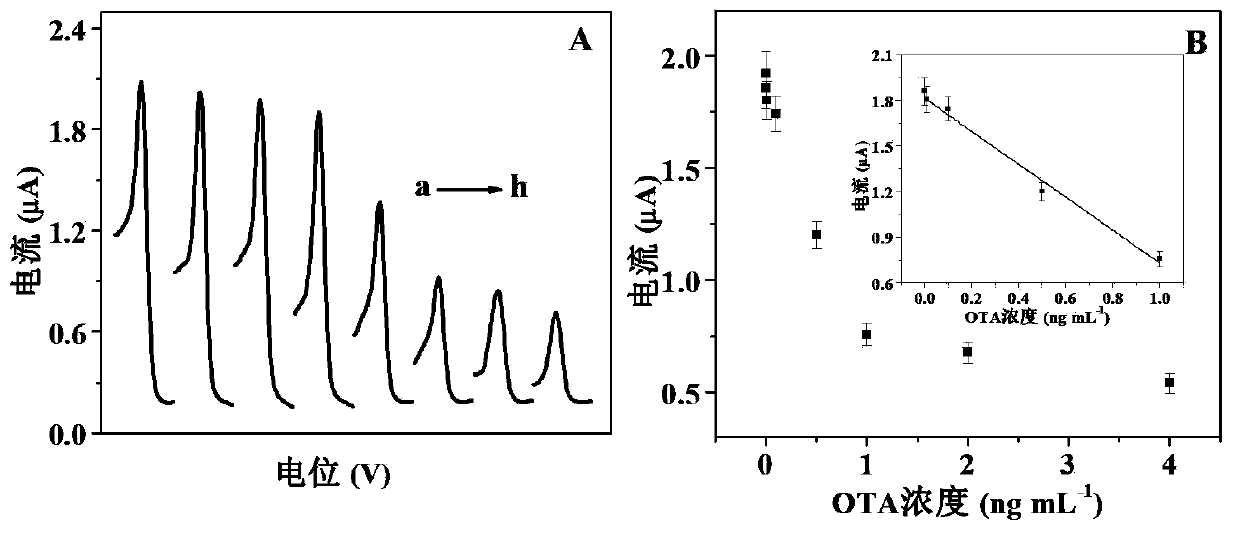

Method for detecting trace ochratoxin A (OTA) by adopting electrochemical aptamer sensor

InactiveCN103424448AHigh specificityNon-deterministicMaterial analysis by electric/magnetic meansOchratoxin AStandard curve

The invention relates to a method for detecting trace ochratoxin A by adopting an electrochemical aptamer sensor, and belongs to the technical field of electrochemical sensors. The method comprises the following steps: firstly, the DNA modification is performed on a gold electrode; then an aptamer is assembled through the complementary base pairing effect so as to capture labeled DNA of gold nanoparticles; the DNA rich in G is assembled on the surfaces of the gold nanoparticles so as to capture a great quantity of methylene blue (MB) to build a signal amplification strategy; finally, a series of OTA standard solutions is detected by taking differential pulse voltammetry scanning as the detection means so as to obtain the response relation between the reductive peak current of MB and the concentration of OTA, and a standard curve is drawn. The invention aims to provide a preparation method of an aptamer sensor, which is simple in operation, high in sensitivity and strong in specificity and is used for sensitivity detection of trace OTA.

Owner:JIANGSU UNIV

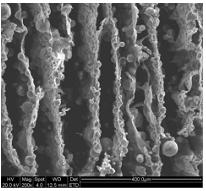

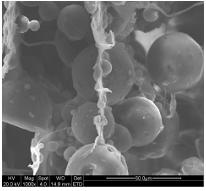

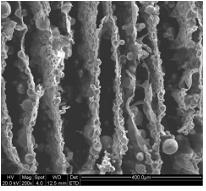

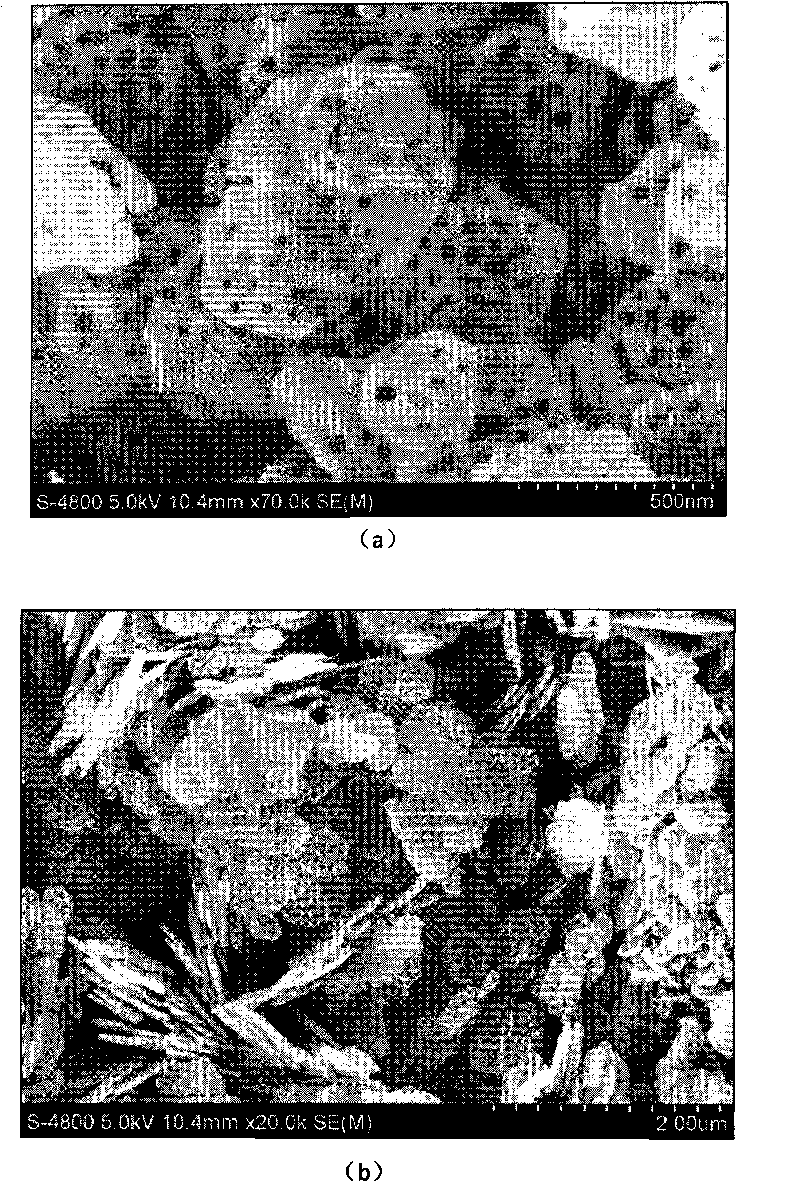

Method for preparing bionic composite material with lamellar multilevel structure

The invention discloses a method for preparing a bionic composite material with lamellar multilevel structure, belonging to the field of biomedical materials. Combining icy template method with composite microsphere method, the method prepares the bionic composite material with lamellar multilevel structure. The method not only includes economical advantage and environmental friendliness simultaneously, but can also be conducted under lasting low-temperature conditions, thus the denaturation of bioactive materials is hardly caused and the prepared composite material, having fine structure, high strength, light weight and good selectivity, is better advantageous for cell adhesion, furthermore, the composite material has excellent biocompatibility, regular array of laminas, good inter-lamina communication and bridging of similar mineral bridges. The microspheres in regular shape on the laminas are evenly embedded in lamellar organic matters, or partial microspheres are stringed around the laminas by taking threadlike organic matters as axis to form sugarcoated haws-like shape; concaves and convexes as well as extremely large surface area provided by the microspheres on the laminas of the material can create good adhesion and proliferation conditions for the growth of histiocyte and blood vessel.

Owner:HUAZHONG UNIV OF SCI & TECH

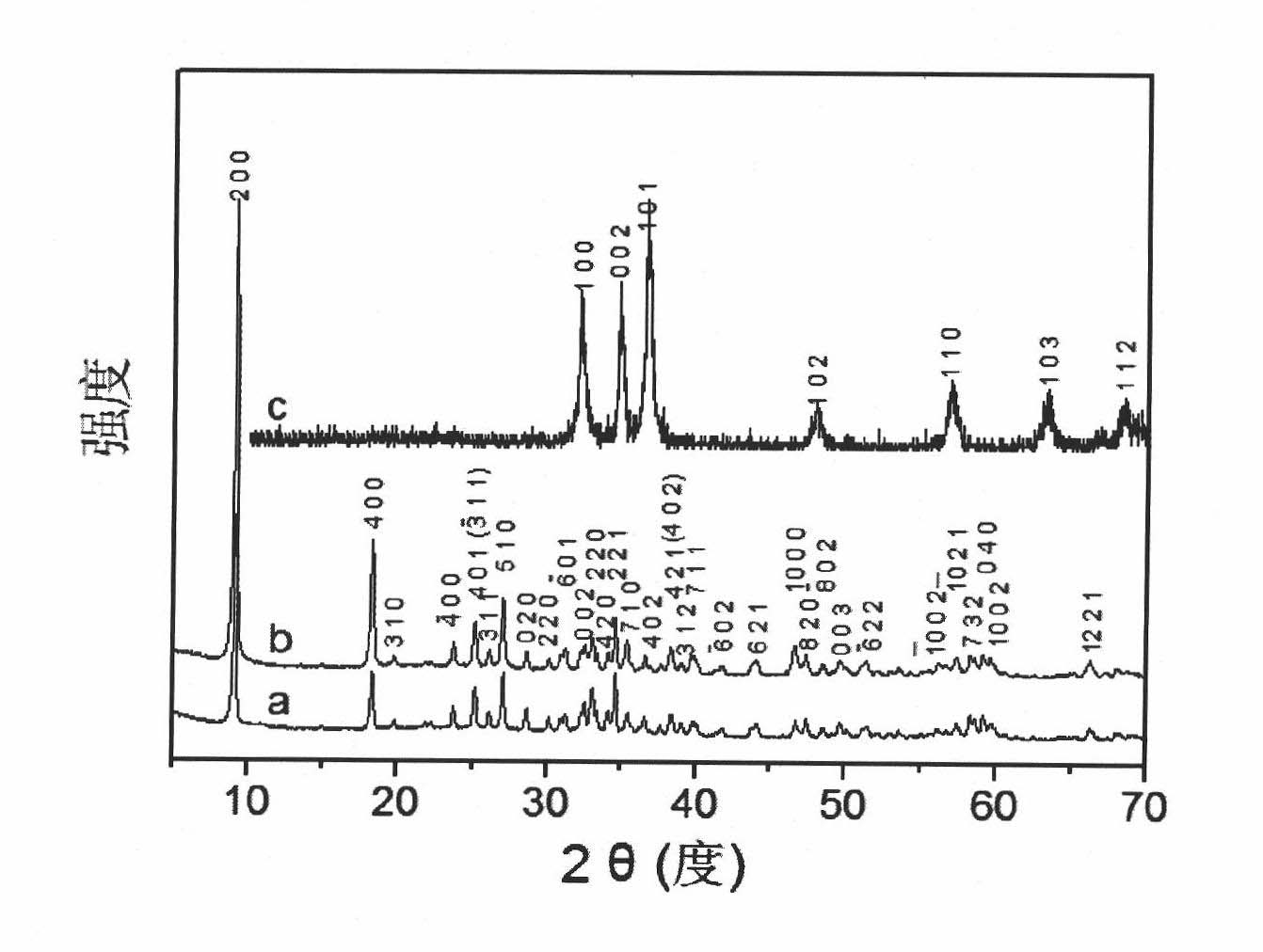

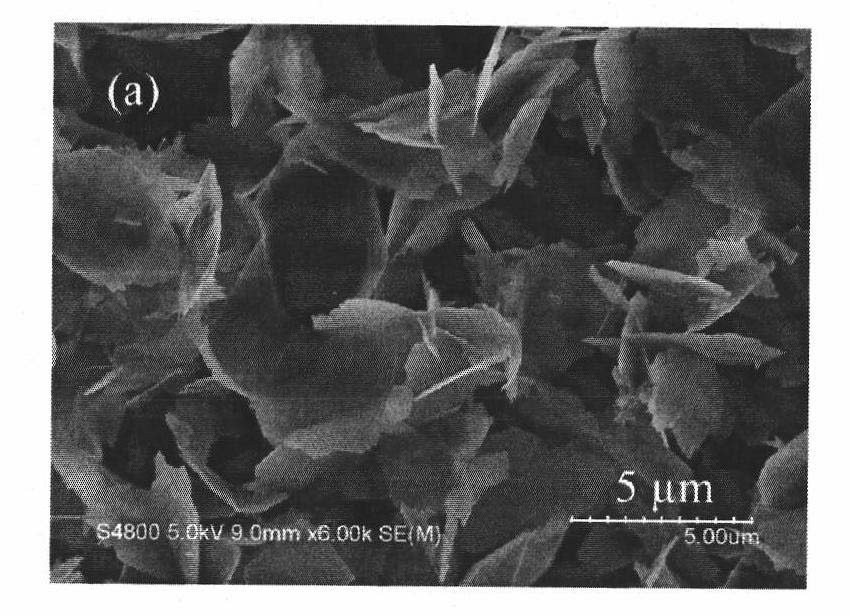

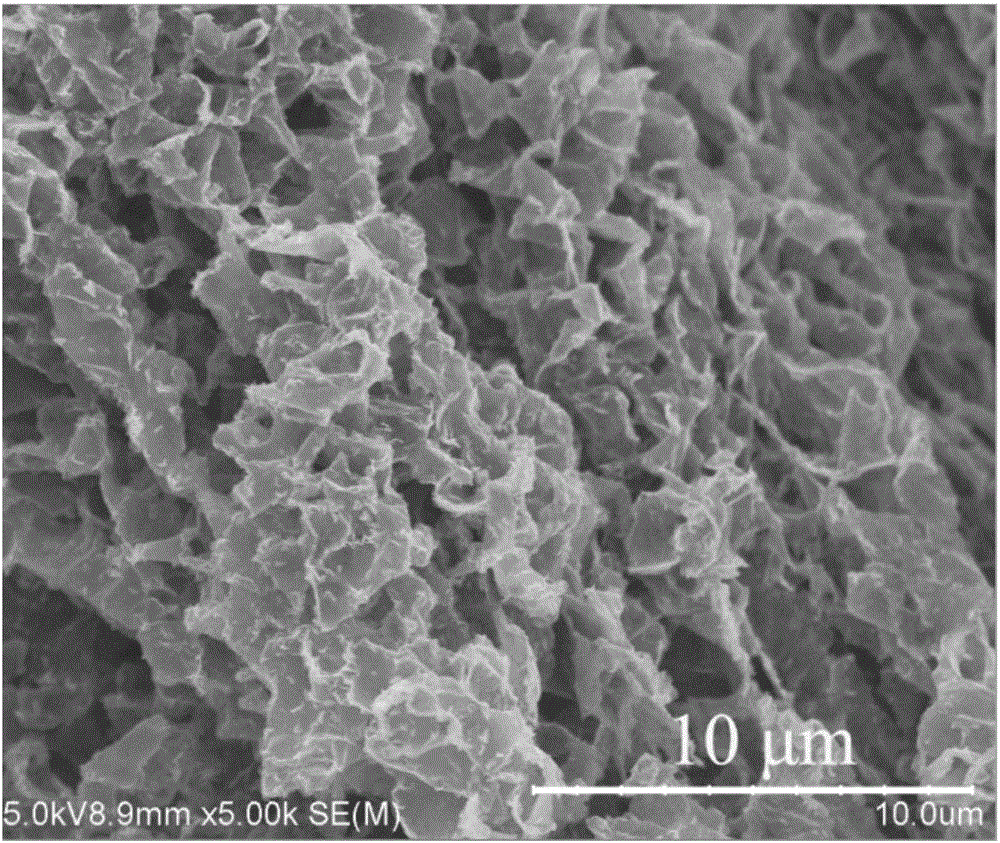

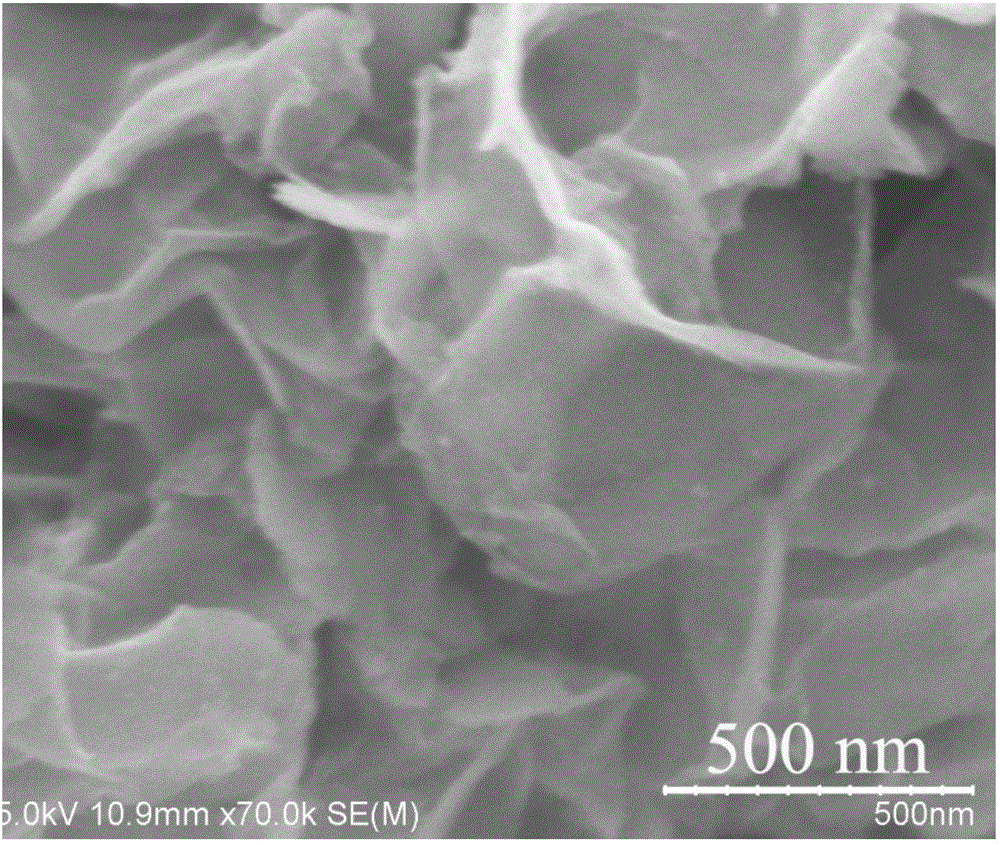

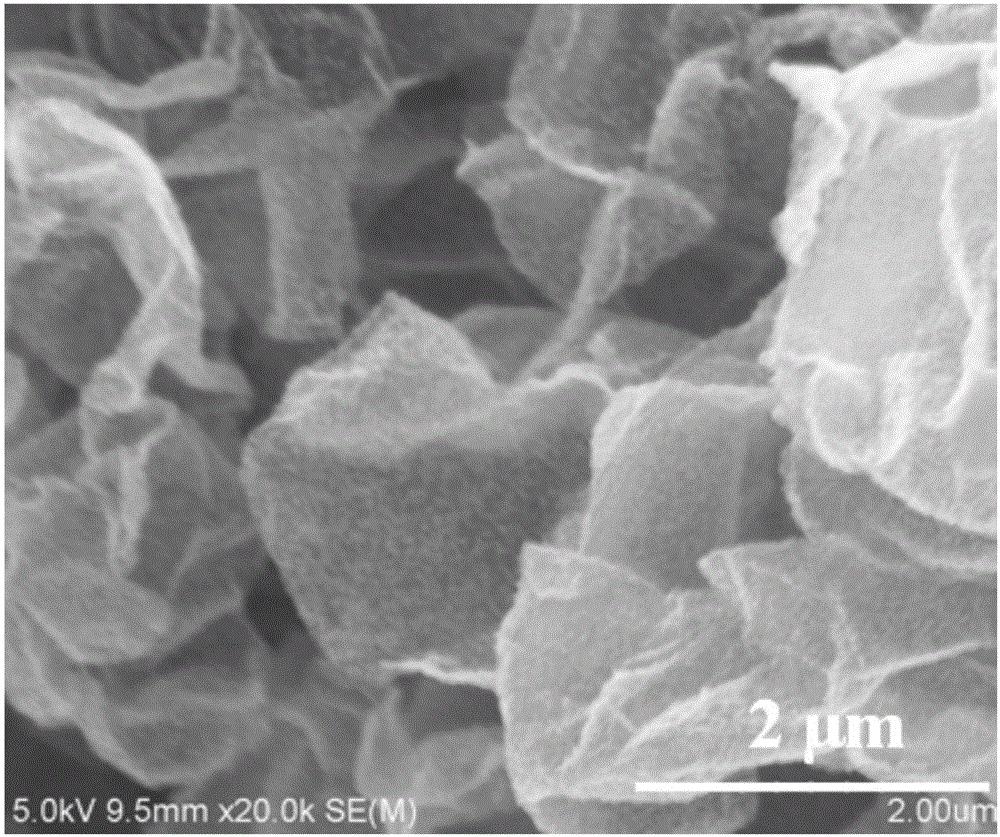

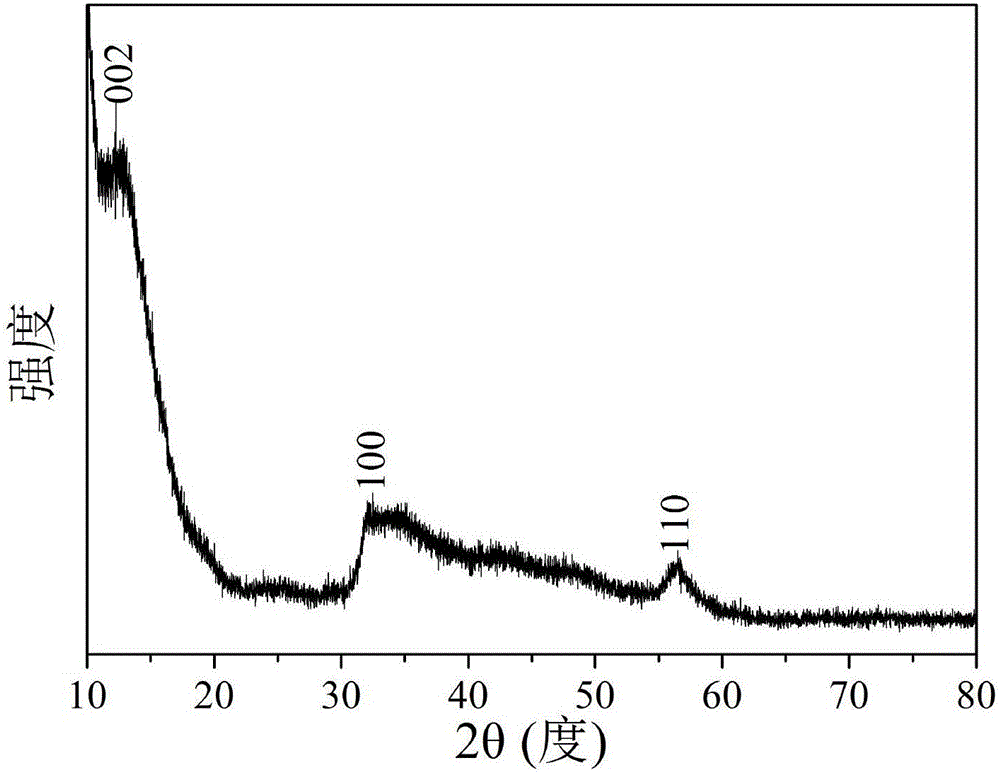

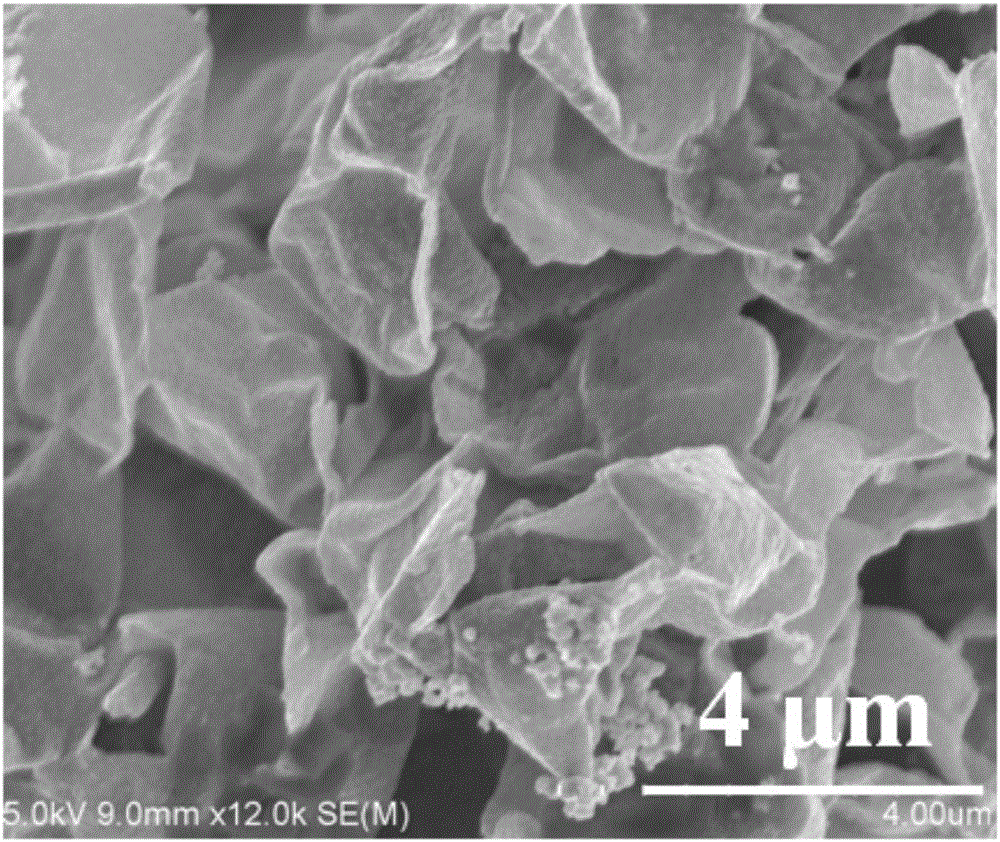

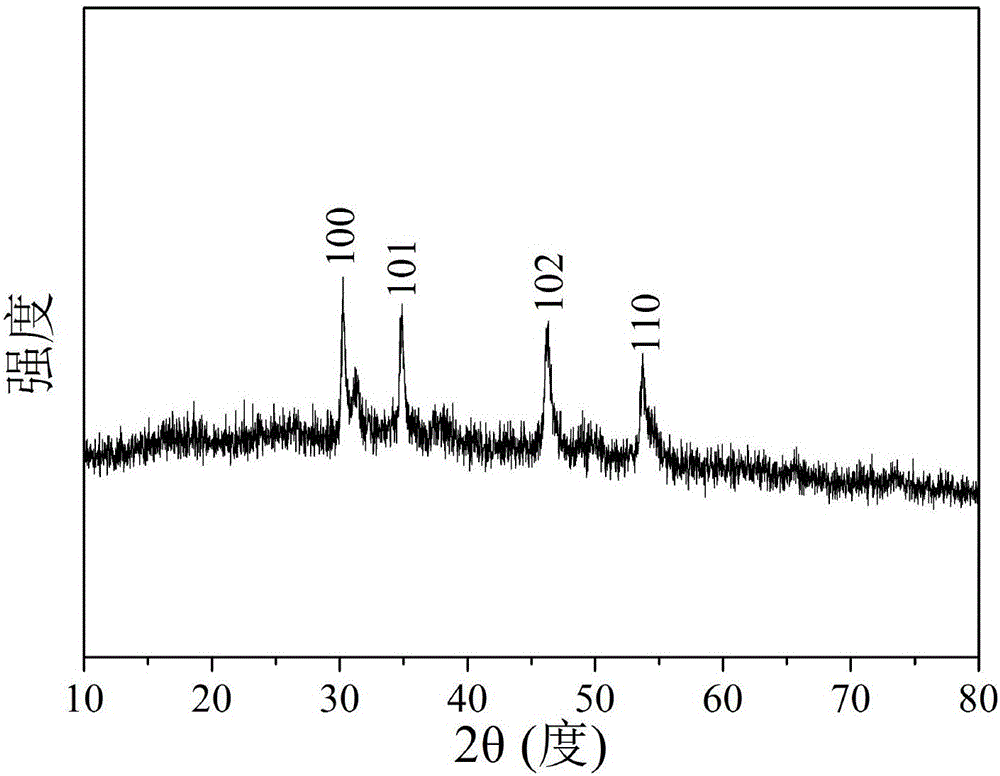

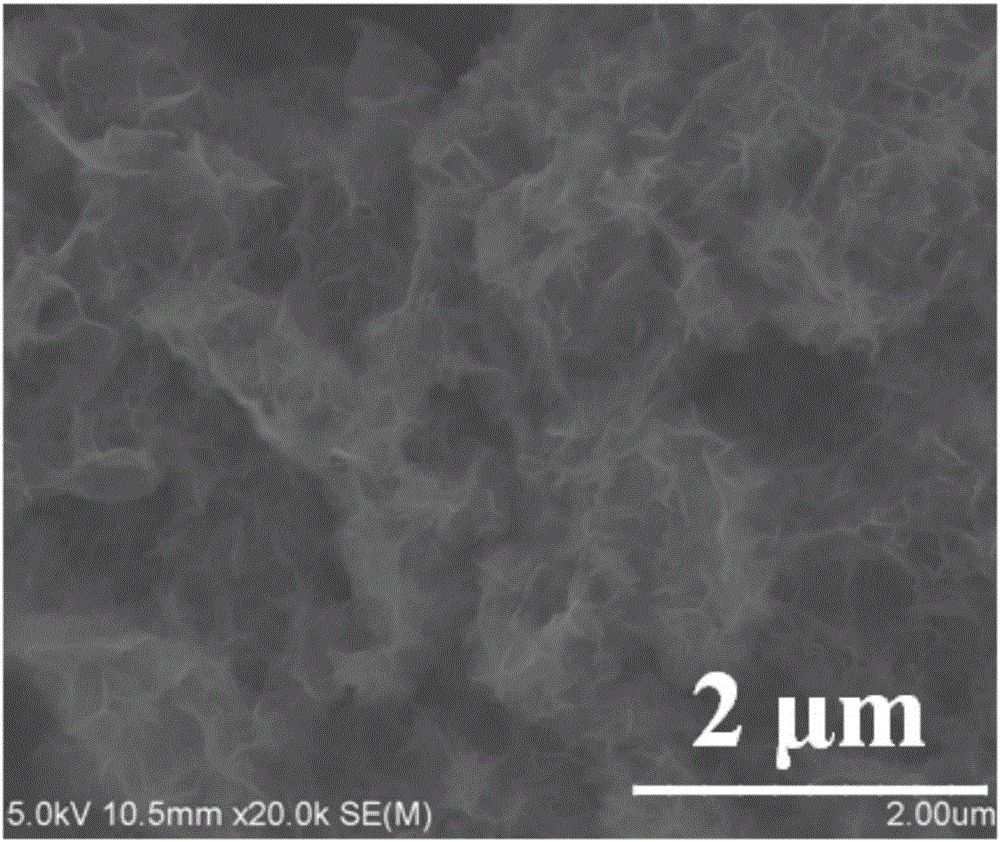

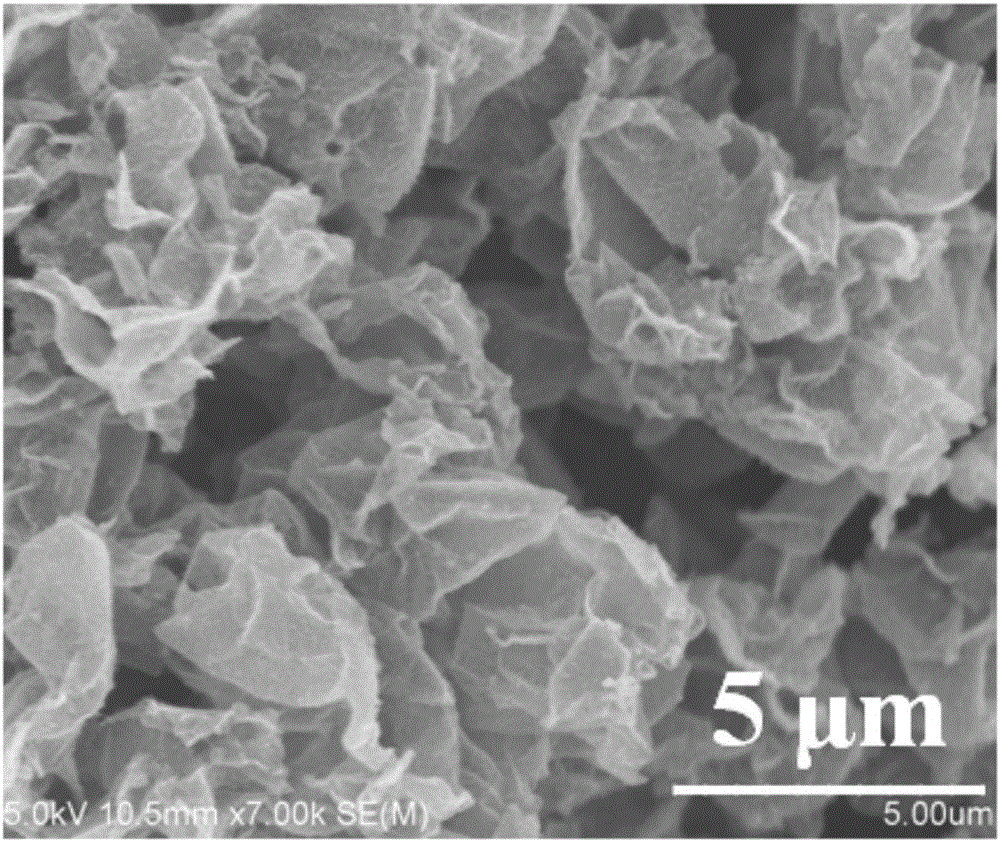

Method for preparing flake porous ZnO nano powder

InactiveCN101786651AHigh crystallinityImprove product qualityZinc oxides/hydroxidesWhite powderZinc nitrate

The invention relates to a method for preparing flake porous ZnO nano powder, which comprises the following steps: adding ammonia into solution of zinc nitrate dropwise, and adjusting the pH of the solution to between 6 and 8; under the condition of stirring by magnetic force at the rotating speed of 0 to 180r / m, performing reaction at the temperature of between 0 and 80DEG C for 0.5 to 3 hours; separating, washing and drying the obtained cloudy solution to obtain a crosslinked flake and dispersed flake basic zinc nitrate precursor; and calcinating the basic zinc nitrate precursor with the two appearances at the temperature of between 220 and 500DEG C for 0.5 and 3 hours to obtain the flake porous ZnO nano powder. The nano ZnO product prepared by the method is white powder, belongs to a hexagonal system, has large specific surface area, high purity and good product quality, and responds to gas such as ethanol and acetone sensitively.

Owner:ANHUI NORMAL UNIV

Circulation evaporator

InactiveCN101811743ANon-deterministicLower evaporation temperatureWater/sewage treatment by heatingPapermakingSewage

The invention discloses an evaporator for performing innocent treatment on sewage in industries of papermaking and the like. In an existing device, a secondary steam pipe is connected to an inlet of a compressor; an outlet of the compressor is connected with a steam inlet of a steady head tank; the other steam inlet pipe of the steady head tank is connected with a fresh steam pipe of a boiler; a steam outlet of the steady head tank is connected with a falling-film evaporator which is at least provided with one circulating pipe connected with a circulating pump; an outlet of a stripper plant of the falling-film evaporator is communicated with a non-condensable air pipe and a heavily-polluted condensate water outlet pipe which is communicated with a water inlet of a heavily-polluted condensate water tank; a water outlet of the heavily-polluted condensate water tank is communicated with a heavily-polluted condensate water delivery pipe; and a condensation water outlet pipe of a condenser is communicated with the water inlet of the heavily-polluted condensate water tank.

Owner:兰州节能环保工程有限责任公司 +1

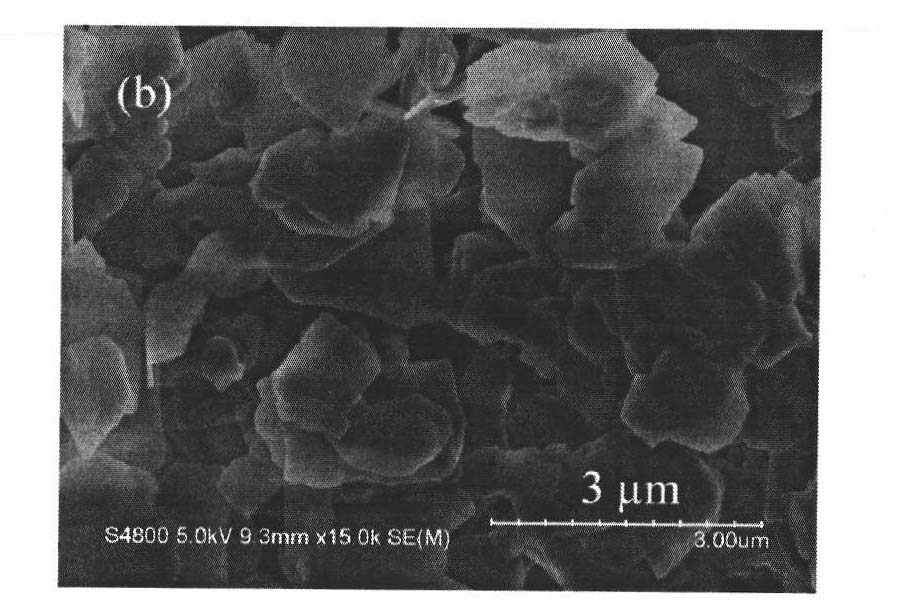

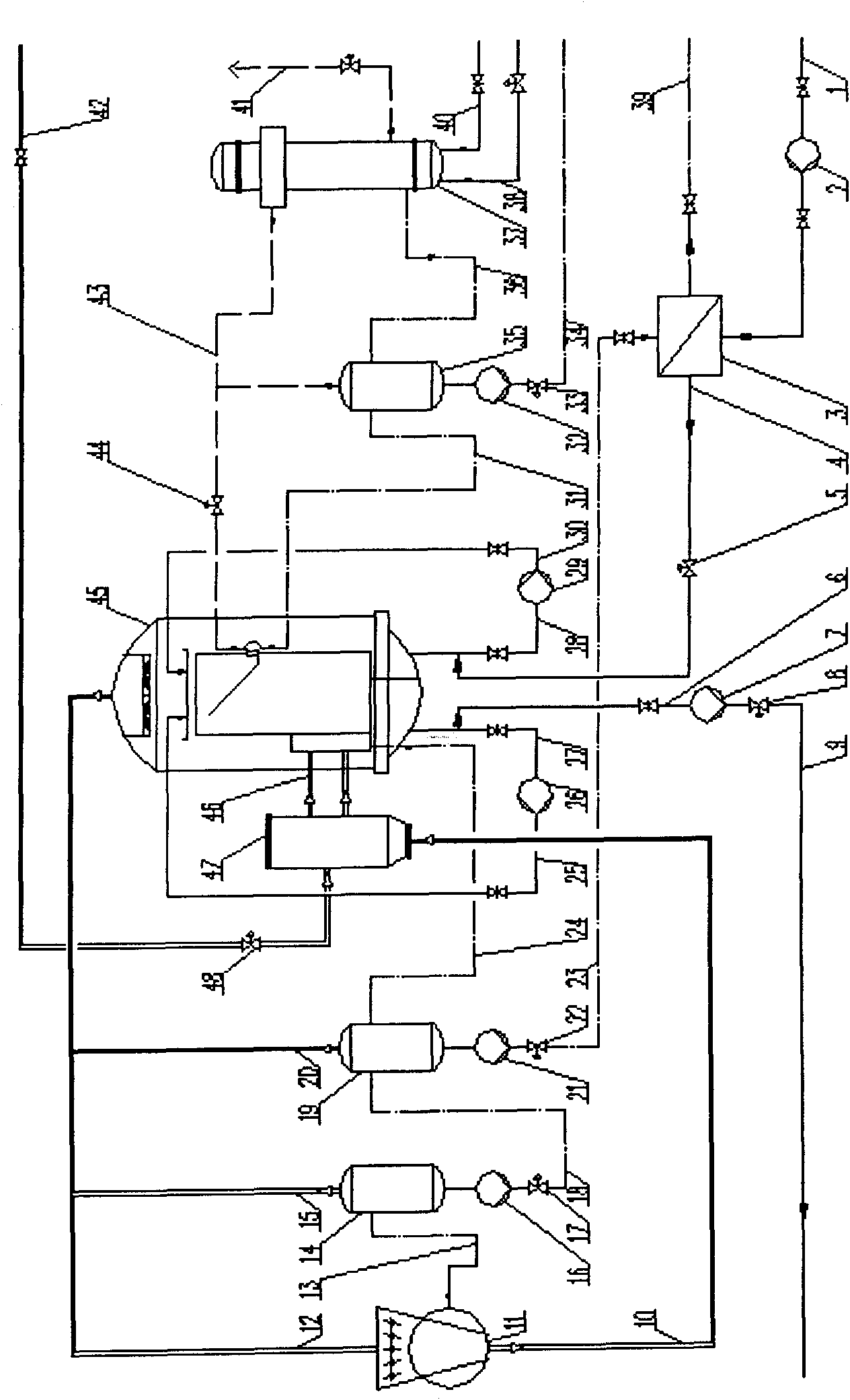

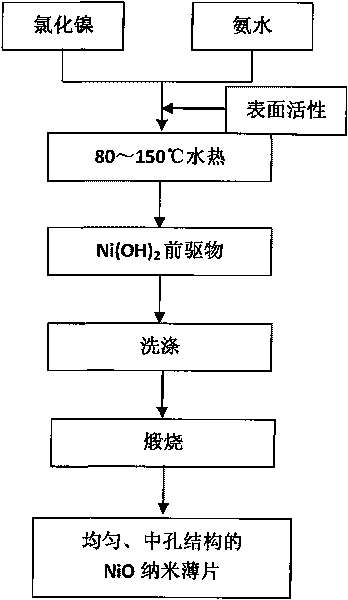

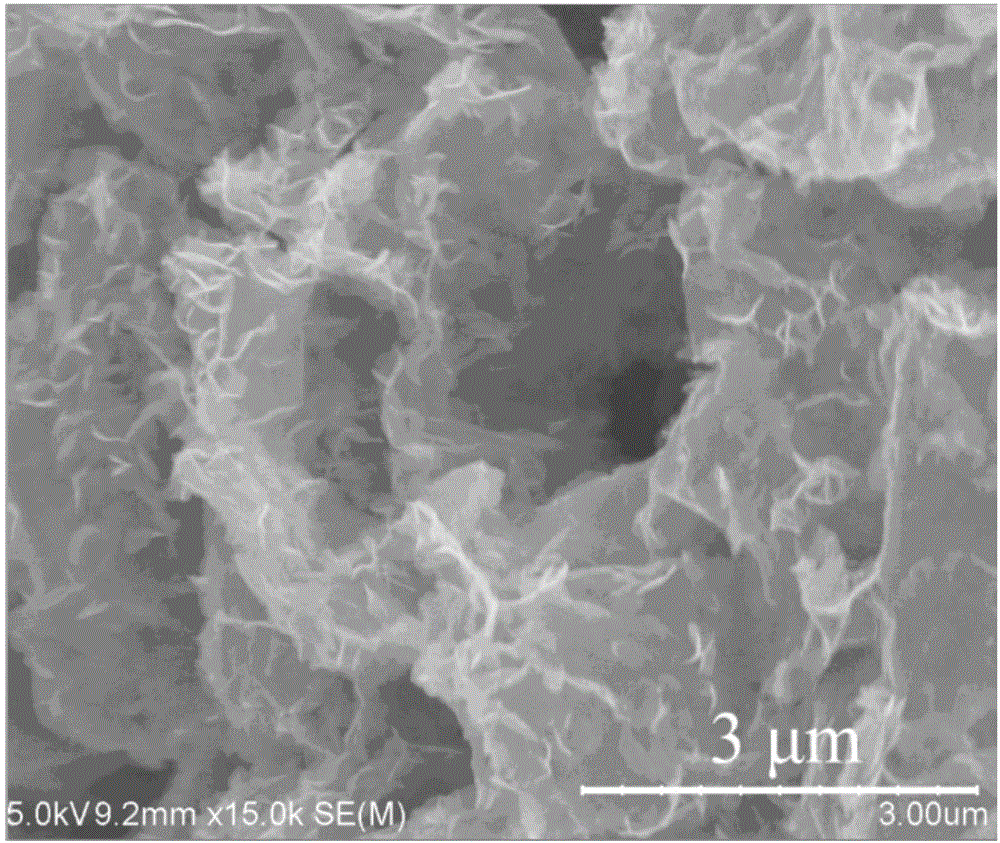

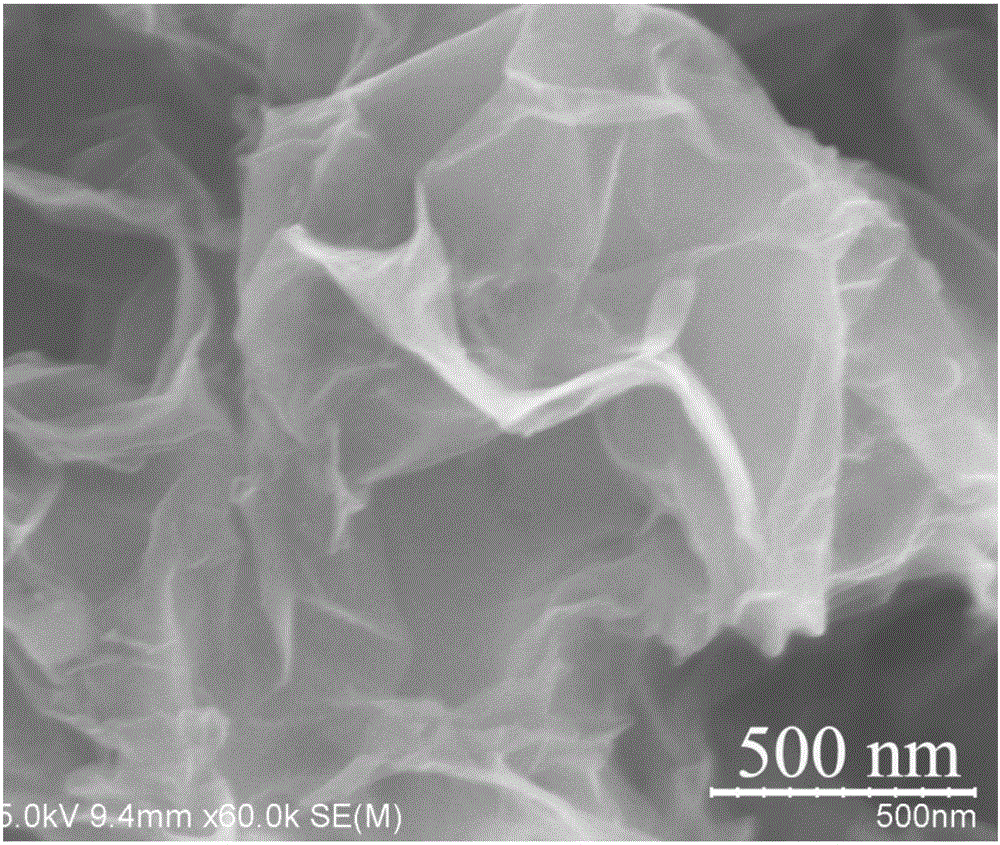

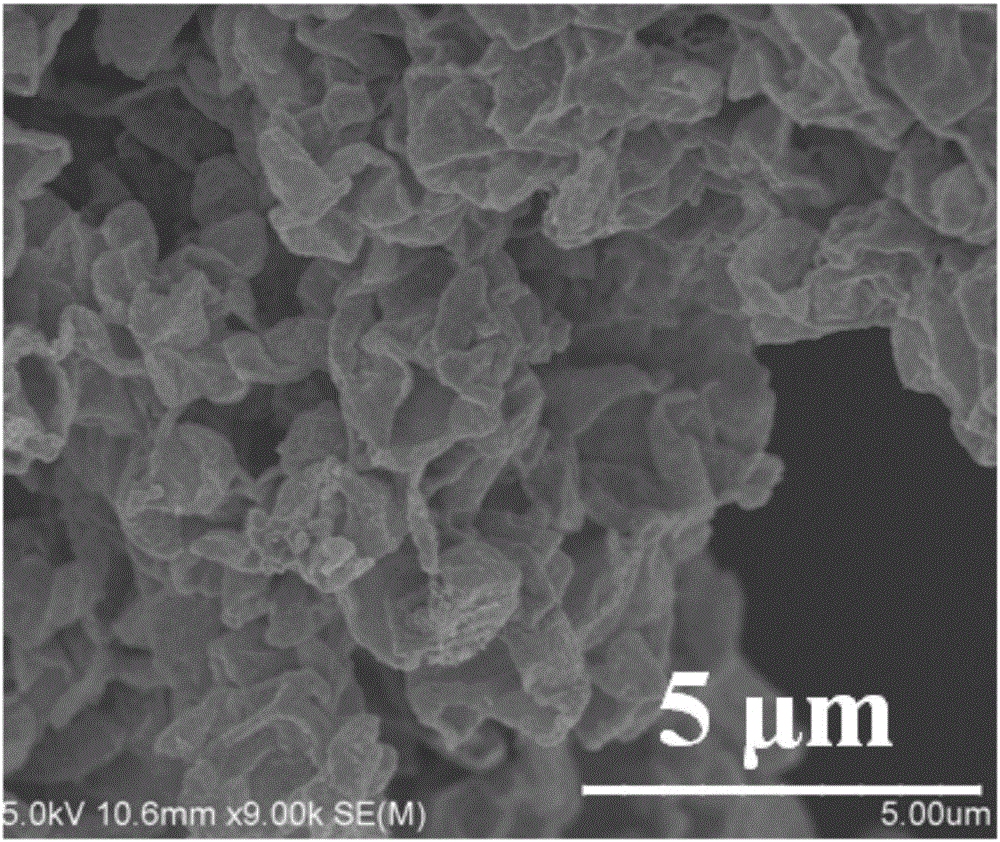

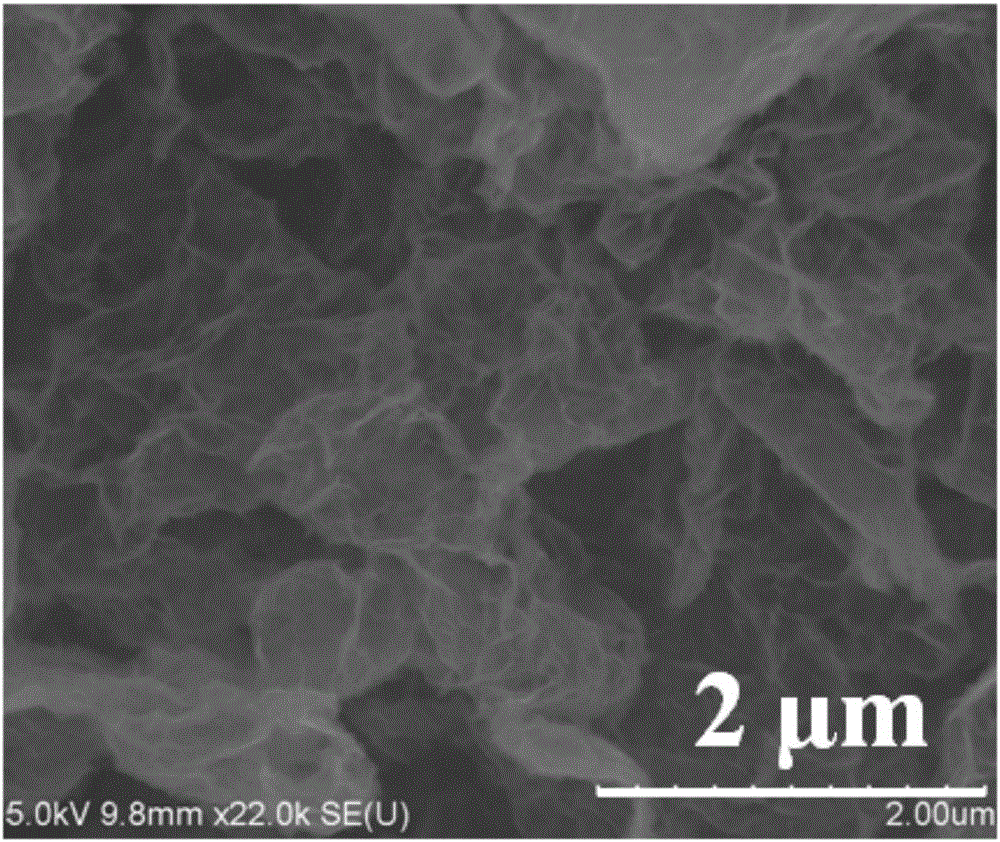

Preparation method of nickel oxide nano flake with uniform and mesoporous structure

InactiveCN101704558AWell distributed holesHigh purityNanostructure manufactureNickel oxides/hydroxidesInorganic saltsNickel oxide hydroxide

The invention provides a preparation method of nickel oxide nano flake with uniform and mesoporous structure, which is implemented by (1) putting 0.05-0.15mol / L of aqueous inorganic salt solution containing nickel in a beaker, adding in surfactant with concentration being 5-10g / L, and performing magnetic stirring for 3h; dripping in ammonia water with the volume ratio of ammonia water to aqueous inorganic salt solution containing nickel being 0.01:1-0.015:1, and performing magnetic stirring for 3h; (2) placing the mixed solution obtained in step (1) in a stainless reaction kettle lined by polytetrafluoroethylene to be sealed, and heating for reaction in a muffle furnace for 12-20h with reaction temperature being 80-150 DEG C; (3) filtering, washing and drying the obtained nepheloid solution to obtain nickelhydroxide primer; (4) calcinating the nickelhydroxide primer obtained in step (3) at 350-500 DEG C for 2-4h to obtain porous structural nickel oxide nano flake. The inventive NiO nano flake has pore diameter of 30-40nm, diameter of 300-400nm, belongs to cubic system, high purity, and good quality.

Owner:BEIHANG UNIV

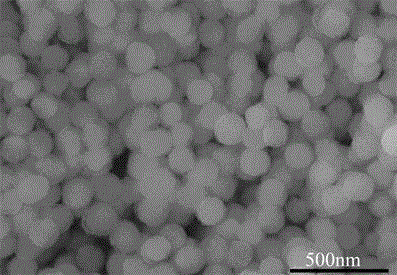

Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

InactiveCN102680539AHigh purity powderPorous pore size distribution is uniformMaterial resistanceTin dioxideMicro nano

The invention discloses a preparation method of porous nickel oxide / tin dioxide micro / nano spheres, which comprises the following steps: stirring tin tetrachloride pentahydrate, nickel sulfate hexahydrate, sodium hydroxide and ammonia water which are used as raw materials, heating, separating, washing, drying and the like to obtain micro / nano spherical hydroxy nickel stannate; and roasting a micro / nano spherical NiSn(OH)6 precursor at high temperature, and cooling to respectively obtain porous micro / nano spherical NiO / SnO2 powder. The micro / nano spherical NiO / SnO2 product prepared by the method disclosed by the invention is light green powder, and has the advantages of large specific area and good product quality. The impedance gas sensing element prepared from the micro / nano spherical NiO / SnO2 powder has high sensitivity, and the sensitivity S value for 100ppm methylbenzene and formaldehyde gases is respectively up to 19.8 and 27.6.

Owner:ANHUI NORMAL UNIV

Process for preparing human serum albumin

ActiveCN103394076ANon-deterministicHigh yieldPeptide/protein ingredientsSerum albuminUltrafiltrationFiltration

The invention discloses a process for preparing human serum albumin. According to the process, a low-temperature ethanol separation method is adopted, and the human serum albumin is prepared from human plasma. The process comprises the steps of dissolving plasma; preparing an ingredient I; preparing an ingredient II and an ingredient III; preparing an ingredient IV; preparing an ingredient V; refining the ingredient V; carrying out ultrafiltration; diluting; carrying out pasteurization; sterilizing and packaging albumen; incubating products; and packaging finished products. The process has the advantages that solid-liquid separation is carried out by adopting a pressure filtration technology, so that the albumin yield which is higher than 29 g / L plasma is increased remarkably, the purity is higher than 98%, and the stability of the products is improved remarkably; Zetaplus deep filter-core filtration is combined with the prolongation of pasteurization time, so that the PKA (Protein Kinase A) level of the products is effectively controlled to be lower than 20IU / ml, and the risks of excessive heat source and virus infection in the products are reduced; and during the process, sodium chloride solutions of two gradient concentrations are used for carrying out ultrafiltration, so that not only can the ethanol residual quantity of the products be controlled to be lower than 0.025%, but also the aluminum residual quantity can be effectively minimized to be lower than 50 micrograms / L.

Owner:华润博雅生物制药集团股份有限公司

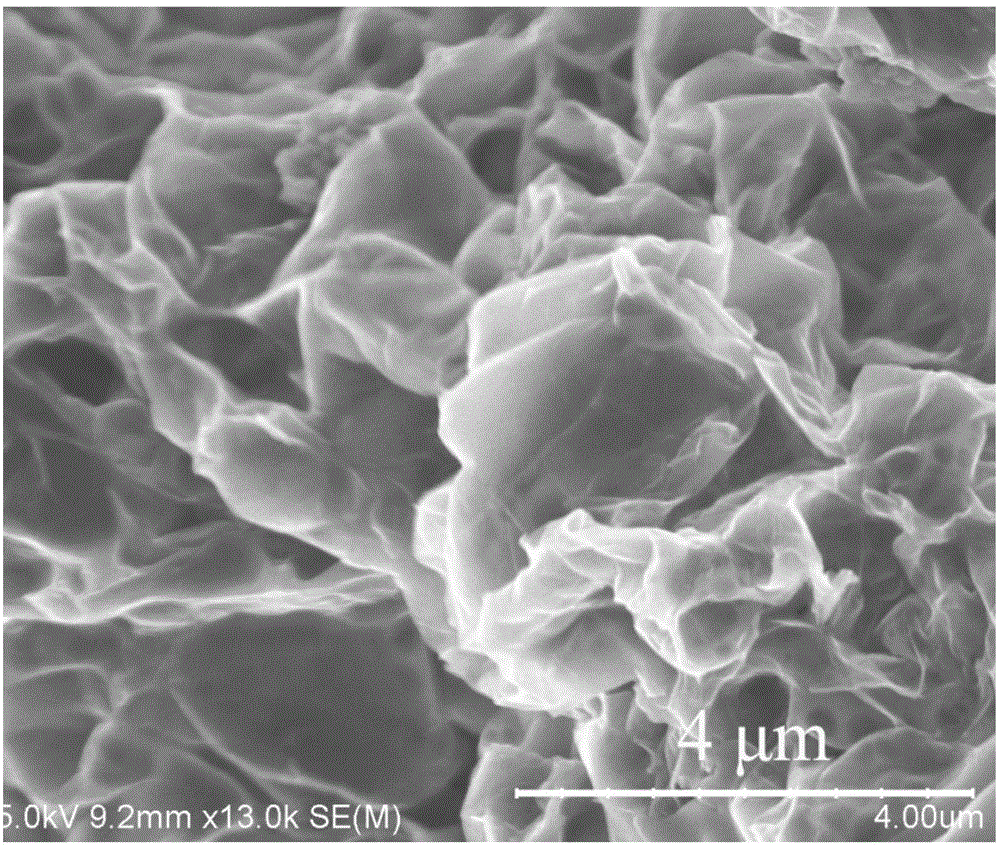

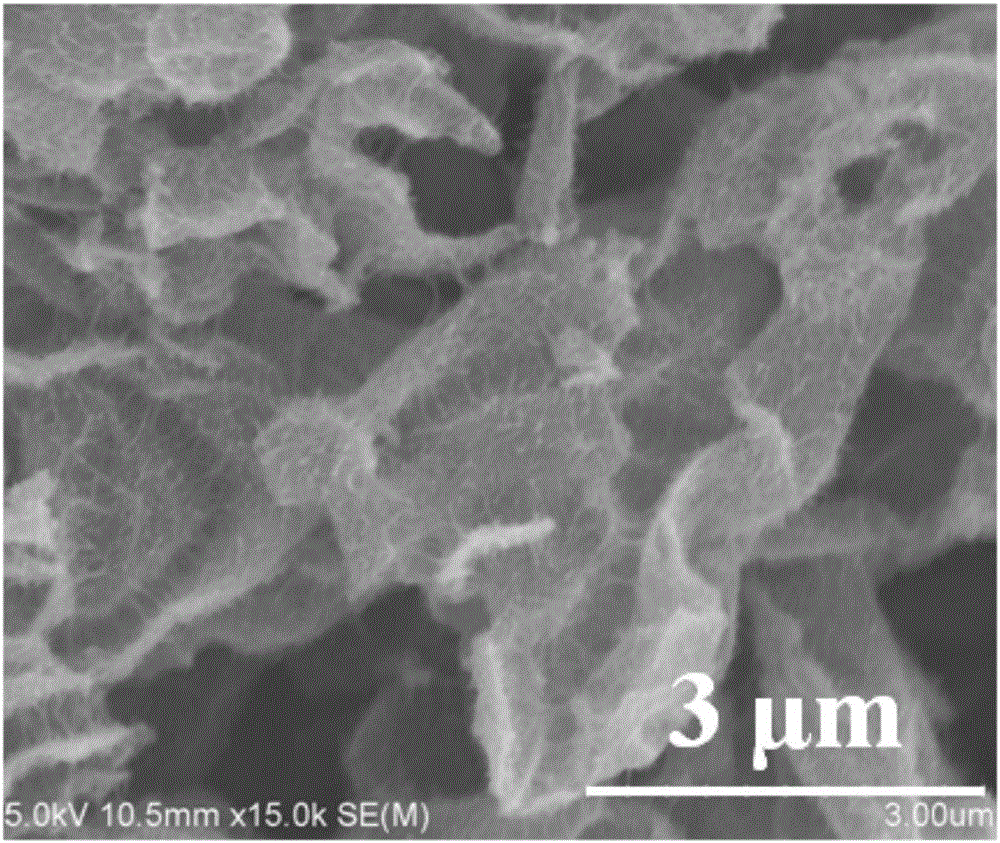

Preparation method for stannic disulfide/graphene nanocomposite, negative electrode of lithium ion battery, and lithium ion battery

InactiveCN106129378AEvenly distributedImprove performanceCell electrodesSecondary cellsGraphene nanocompositesCvd graphene

The invention discloses a preparation method for a stannic disulfide / graphene nanocomposite, a negative electrode of a lithium ion battery, and the lithium ion battery. The preparation method comprises the following steps of performing a hydrothermal process and a compounding process. By adoption of the preparation method, the stannic disulfide is subjected to direct in-situ growth on the surface of graphene; then the obtained stannic disulfide is washed and dried to obtain the sheet-shaped stannic disulfide / graphene nanocomposite; the material is applied to the negative electrode material of the lithium ion battery; the stability and the conductivity of the material are effectively improved; the performance of the battery is improved; and the stannic disulfide / graphene nanocomposite has the advantages of high cycling stability, high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

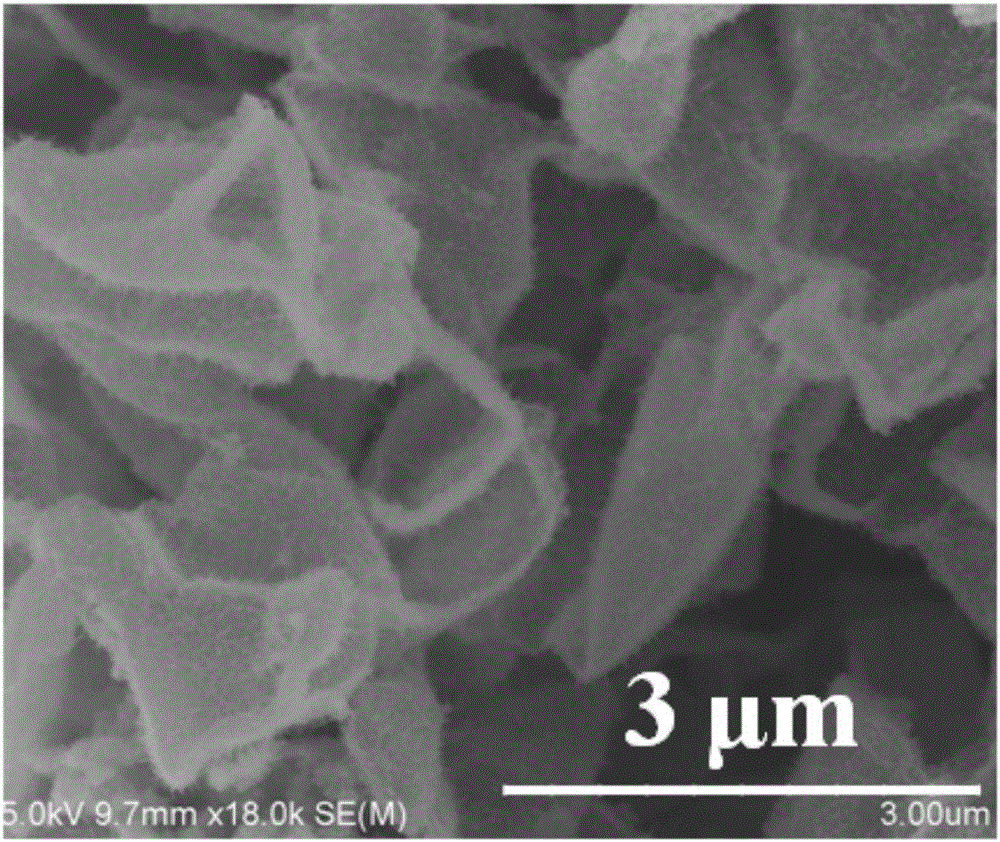

Preparation method of manganese sulfide/graphene nano composite material, negative electrode of lithium ion battery and lithium ion battery

ActiveCN106159239AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

The invention discloses a preparation method of a manganese sulfide / graphene nano composite material, a negative electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the steps of a hydrothermal procedure and a compounding procedure. By virtue of the preparation method, in-situ growth of manganese sulfide is directly carried out on the surface of graphene; after washing and drying steps are carried out, the manganese sulfide / graphene nano composite material is obtained; the disadvantages such as poor stability caused by volume change are overcome through compounding of the manganese sulfide and three-dimensional reduced graphene oxide are overcome and the conductivity is enhanced, so that the properties of the lithium ion battery are improved; the material is applied to a negative electrode material of the lithium ion battery and has the advantages of good circulating stability, high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

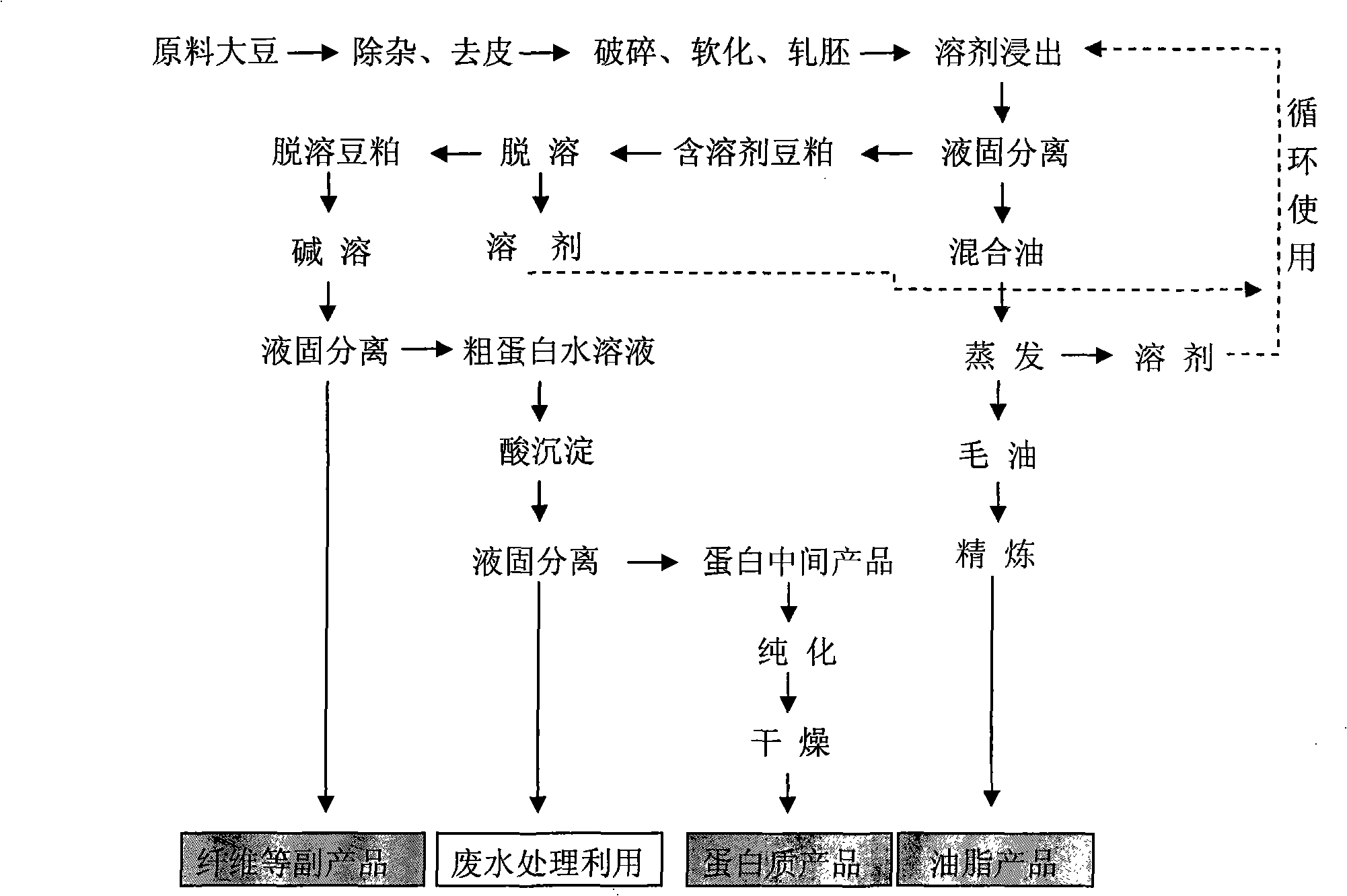

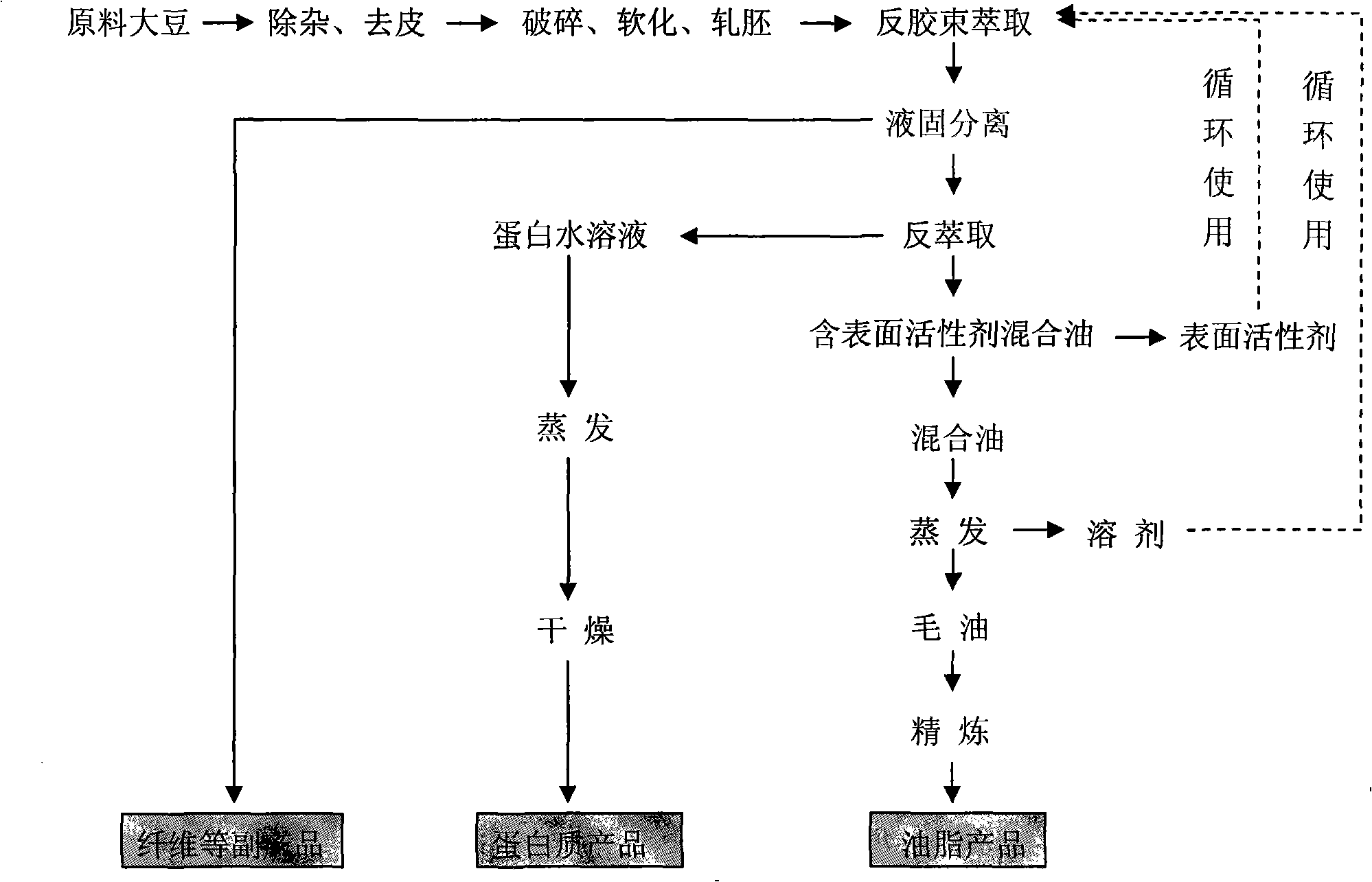

Method for simultaneously separating soy protein and oil fat with inverse micelle abstraction technique

ActiveCN101343309AThe production process is simpleReduce production costs and fixed asset investmentPeptide preparation methodsFermentationSolventChemistry

Disclosed is a method for separating soybean protein and fat by the reversed micellar extraction, which comprises the following procedures: (1) reversed micellar solution is prepared; (2)a pretreated raw material of soybean is added into the reversed micellar solution to extract protein and fat; (3) electrolyte solution is added so that the protein is transferred into the aqueous phase from the reversed micellar solution to be separated, thereby realizing back extraction of the protein, and protein aqueous solution and mixed oil are obtained; (4) the obtained protein product and the fat product are processed. The method has the following main advantages: the fat and the protein are separated at the same time in the reversed micellar extraction system, so the production process is greatly simplified, and the production cost and the investment on the fixed assets are reduced; the method has the advantages of solvent extraction; in the process of extraction, the protein is surrounded by the water environment in the reversed micellar, and the environment is close to the environment in the cells with mild condition, so the protein is not denatured and can keep the biological activity of the protein, and the purity of the product is high; and no acid and alkali wastewater is discharged without pollution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

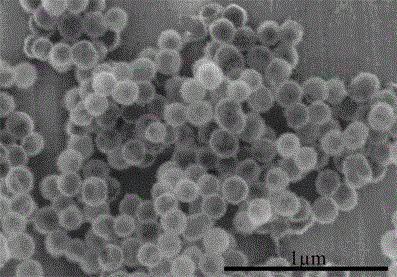

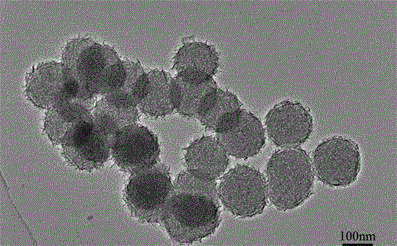

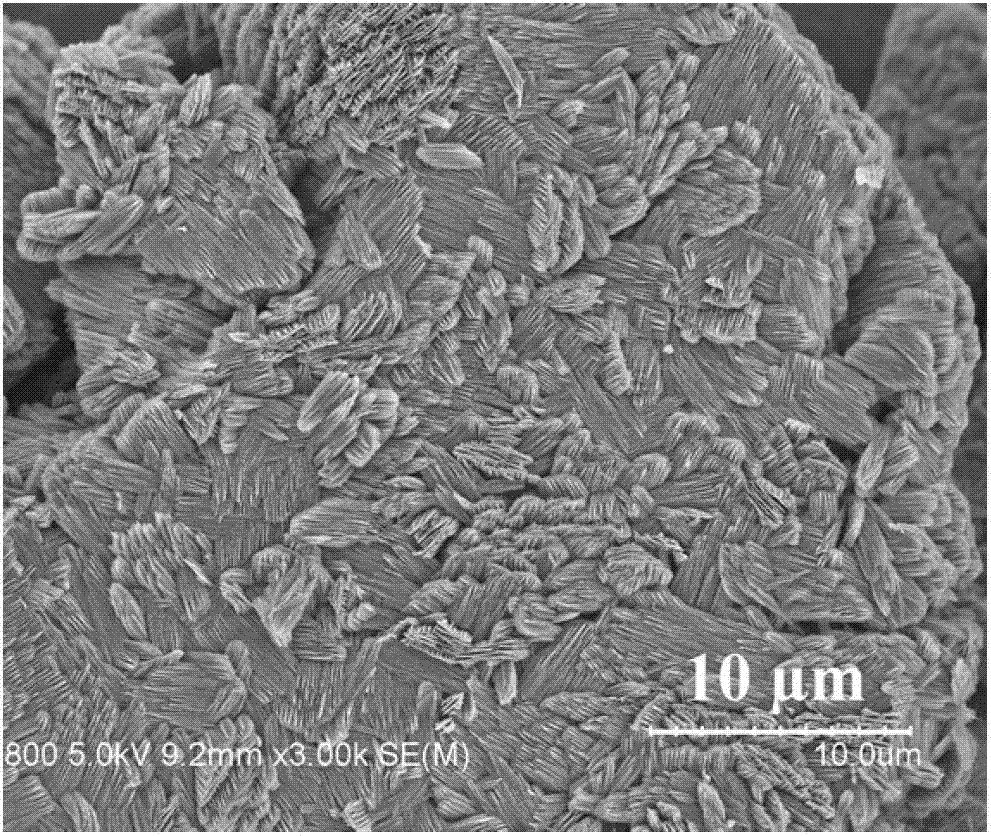

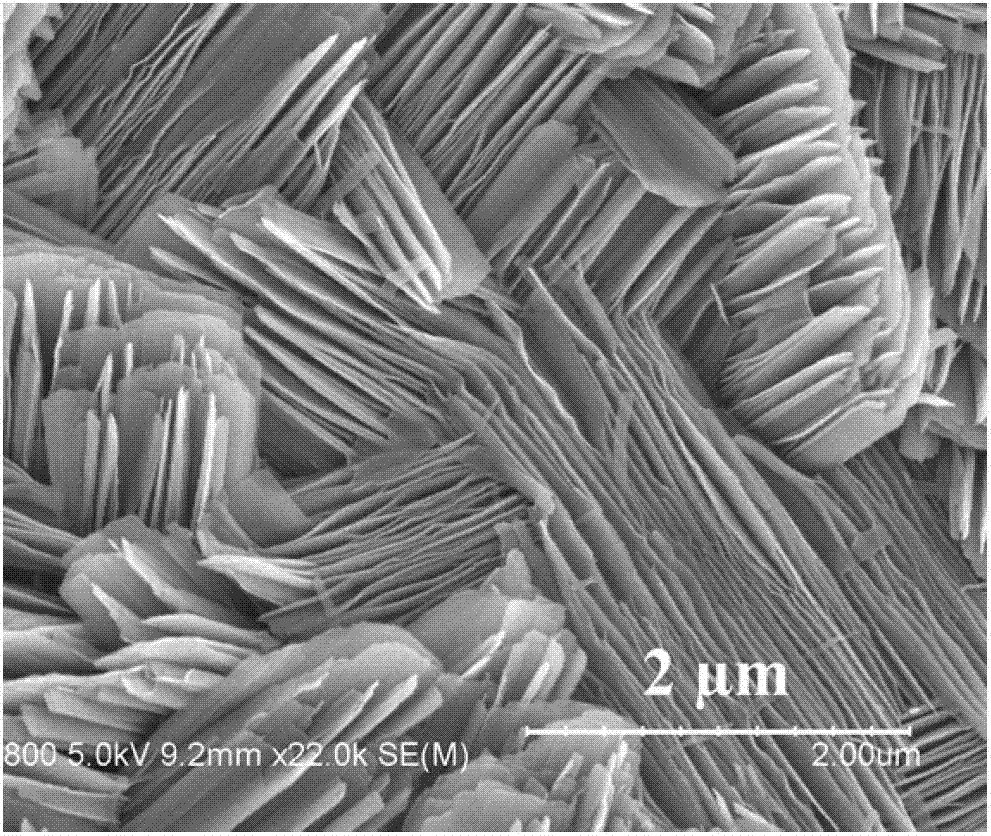

Sea-urchin-shaped nanometer nickel silicate hollow sphere and preparation method thereof

InactiveCN105129809APerfect control of size and shapeArbitrary control of morphologyMaterial nanotechnologySilicon compoundsNickel saltSilicic acid

The invention discloses a sea-urchin-shaped nanometer nickel silicate hollow sphere and a preparation method thereof. An appropriate quantity of silicon dioxide spherules and an appropriate amount of urea, soluble nickel salt and deionized water are added into a hydrothermal reaction kettle core, react for certain time inside a drying oven at the constant temperature of 80-150 DEG C and then are naturally cooled to indoor temperature; the prepared product is subjected to centrifugal washing and drying, an appropriate quantity of NaOH solutions and the product are together added into a hydrothermal reaction kettle and placed at the constant temperature of 100-200 DEG C to be subjected to hydrothermal reaction for certain time, and the product is subjected to centrifugal washing and drying and then calcined at certain temperature to prepare the sea-urchin-shaped nanometer nickel silicate hollow sphere. The prepared nickel silicate hollow sphere is tested by an X-ray diffractometer, a scanning electron microscope and a transmission electron microscope and is in a sea urchin shape, the wall of the sphere is quite thin, the specific surface area is large, particle size distribution is even, and the nickel silicate hollow sphere can serve as a material for manufacturing an electrochromic device and an electrode material for manufacturing a super capacitor.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

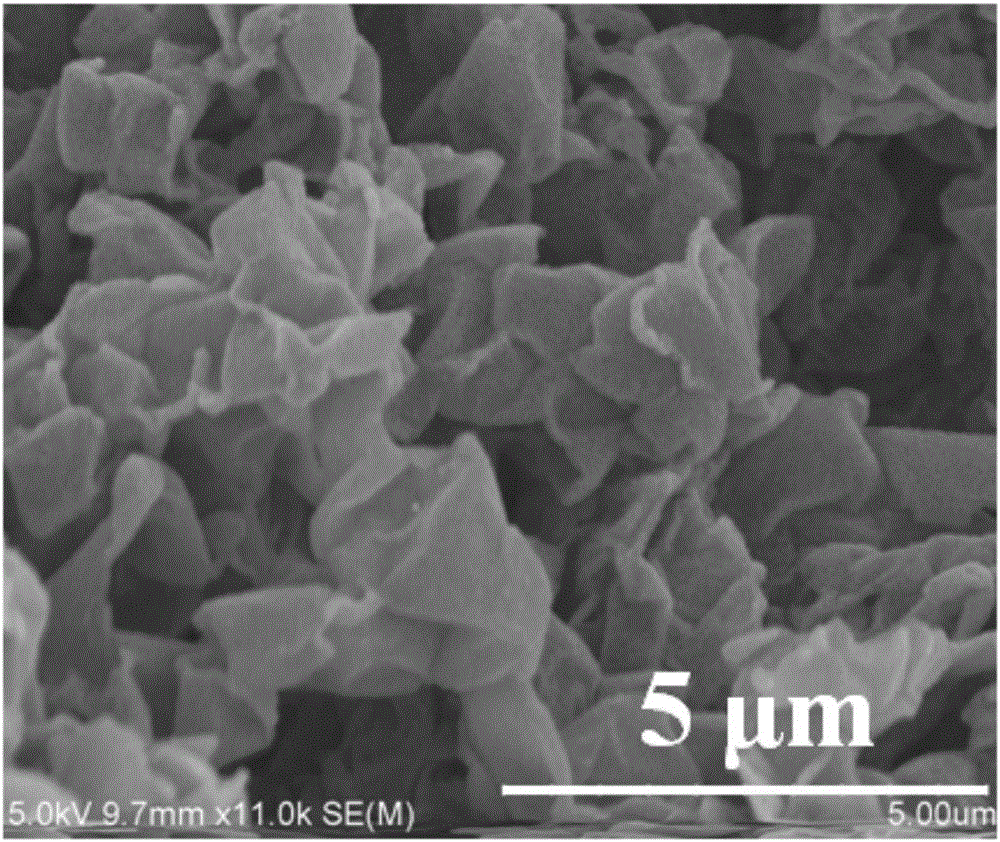

Method for preparing molybdenum disulfide/graphene nanometer composite materials, lithium ion battery and cathode thereof

ActiveCN106207171AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesNano compositesGraphene nanocomposites

The invention discloses a method for preparing molybdenum disulfide / graphene nanometer composite materials, a lithium ion battery and a cathode thereof. The method includes a hydrothermal working procedure and a composite working procedure. The method, the lithium ion battery and the cathode have the advantages that lamellar molybdenum disulfide can directly grow on the surfaces of graphene in an in-situ manner, and accordingly the molybdenum disulfide / graphene nanometer composite materials are unique in morphology and have large specific surface areas, and the problem of graphene and molybdenum disulfide agglomeration can be solved; the molybdenum disulfide / graphene nanometer composite materials applied to cathode materials for the lithium ion battery are good in cycle stability and high in specific energy density, and the like.

Owner:ANHUI NORMAL UNIV

Method for highly efficiently extracting protein from walnut dreg

InactiveCN102936610ALow costHigh extraction ratePeptide preparation methodsFermentationChromatography columnElectrolyte

The invention provides a method for highly efficiently extracting protein from walnut dreg. The method comprises the steps that: a, walnut dreg is crushed into walnut dreg powder; b, according to a ratio that n-hexane:succinic diisooctyl sodium sulfonate=1mL:0.04-0.10g, n-hexane is dissolved in succinic diisooctyl sodium sulfonate, such that a mixed solution is obtained; the mixed solution is mixed with an electrolyte buffering solution, such that a reverse micelle solution is obtained; c, the walnut dreg powder in the step a and the reverse micelle solution obtained in the step b are mixed according to a ratio that reverse micelle solution:walnut dreg powder=1mL:0.02-0.10g; the mixture is subjected to stirring or microwave and enzyme method assisted extraction; centrifugation is carried out, and a supernatant is a protein pre-extraction liquid; d, the protein pre-extraction liquid obtained in the step c and the electrolyte buffering solution is mixed according to a volume ratio that protein pre-extraction liquid:electrolyte buffering solution=1:0.5-1:2; the mixture is subjected to stirring or microwave-assisted extraction; centrifugation is carried out, and lower-layer clear liquid is protein post-extraction liquid; and e, the protein post-extraction liquid obtained in the step d is subjected to chromatography column desalting, such that a product is obtained.

Owner:新疆林科院经济林研究所 +1

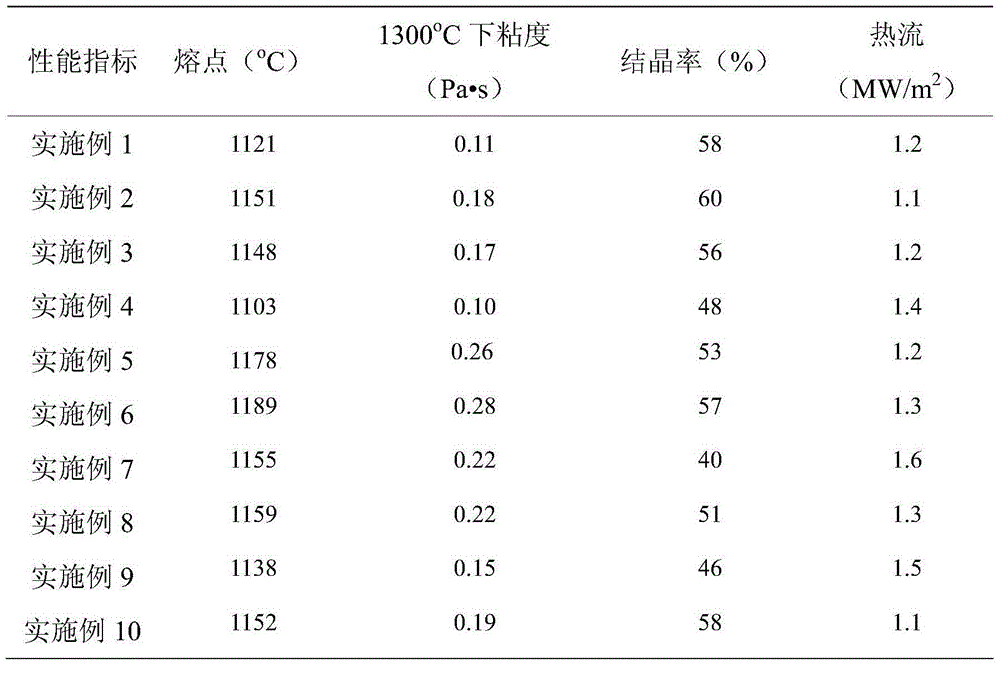

Novel medium manganese steel casting powder for automobile and application thereof

The invention relates to a novel medium manganese steel casting powder for an automobile and application of the novel medium manganese steel casting powder and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises, by mass, CaO 29%-37%, Al2O3 16%-25%, SiO2 11%-15%, MgO 2%-7%, Na2O 10%-14%, Li2O 1%-5%, MnO 1%-7% and F- 9%-13%. The melting point of the casting powder is 1,100-1,200 DEG C; at 1,300 DEG C, the viscosity of the casting powder is 0.10-0.30 Pa*s, and the crystallizing rate is 40%-70%; the heat flow is 1.1-1.6 MW / m<2> in the continuous casting process. The designed casting powder can be well used in the medium manganese steel continuous casting process for the automobile with the mass percentage of Mn being 3.0%-15.0%.

Owner:CENT SOUTH UNIV

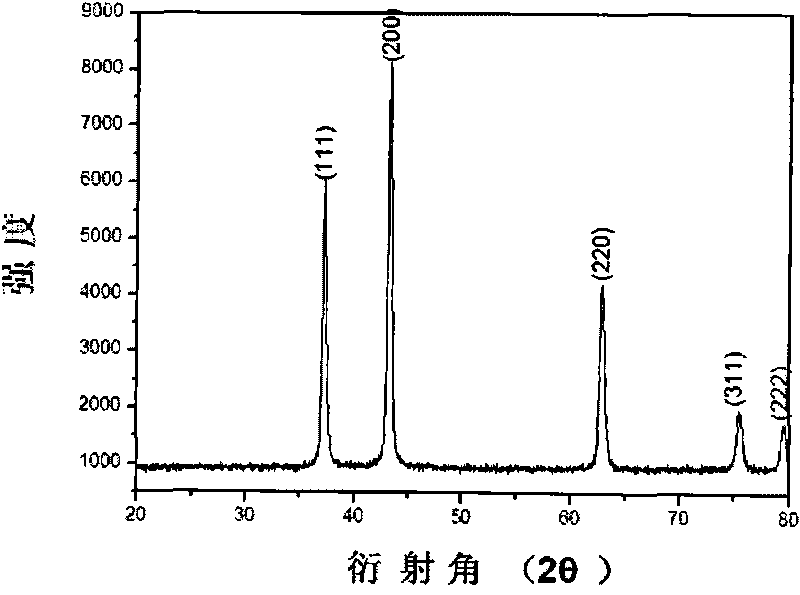

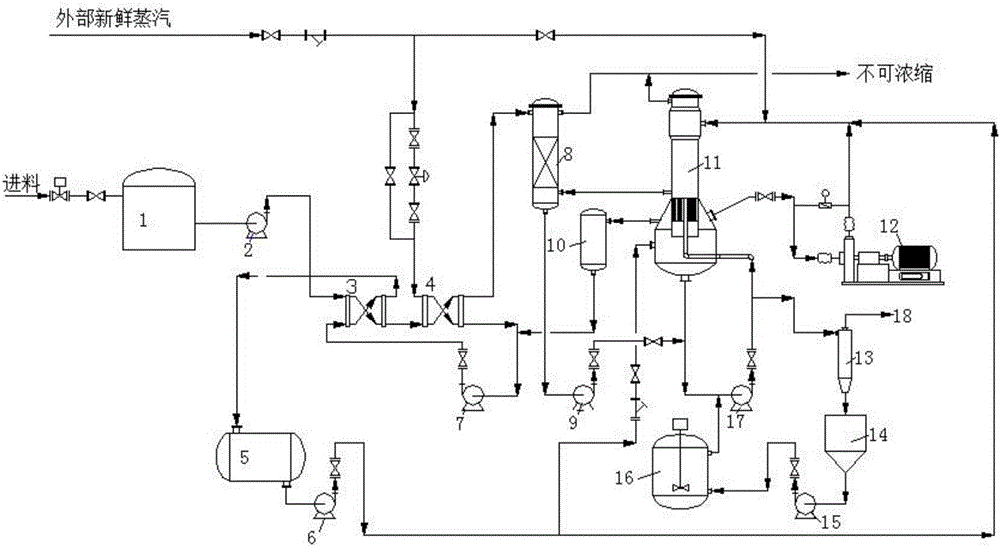

Mechanical steam recompression falling film evaporation process method and system

ActiveCN104986910AImprove thermal efficiencySave energyMultistage water/sewage treatmentSteam pressureSteam condensation

The invention provides a mechanical steam recompression falling film evaporation process method comprising the following specific steps: (1) high-salt wastewater pretreatment is carried out, wherein a material is delivered into a preheater through a feeding pump; condensate water of falling film evaporator secondary steam condensation is adopted as a heat source of the preheater, and the material is preheated; the preheated material is delivered into a liquid mixing device, and is mixed with liquid from an evaporation chamber of the falling film evaporator; and the mixture is delivered into the falling film evaporator; (2) a falling film evaporation system is established, wherein after the material enters the falling film evaporator, with indirect heating of evaporator shell-side steam, the material absorbs heat and the temperature is increased; the material enters the evaporation chamber; with the negative pressure in the evaporation chamber, the material is instantly evaporated, and most of water is converted into secondary steam and is discharged from a secondary steam outlet; and (3) a steam compression recycling system is established, wherein secondary steam from the evaporation chamber enters a steam compressor; with the compression of the steam compressor, steam pressure and temperature are both increased; and the steam is returned to the shell-side of the falling film evaporator again and is reused.

Owner:JIANGSU DUBLE ENG

Method for preparing nickel sulfide/graphene nanocomposite, lithium ion battery cathode and lithium ion battery

ActiveCN106207127AStable performanceEasy to storeMaterial nanotechnologyCell electrodesCvd grapheneNanometre

The invention discloses a method for preparing a nickel sulfide / graphene nanocomposite, a lithium ion battery cathode and a lithium ion battery. The preparation method comprises a hydrothermal process and a compounding process. According to the preparation method, nickel sulfide is compounded on graphene, and a black nickel sulfide and graphene composite is obtained through washing and drying. The composite has a very large specific surface area, and the dropping between nickel sulfide and graphene is effectively avoided in the lithiation process; what is most important, the agglomeration problem of graphene and nickel sulfide nano particles is solved to a large extent, the shortcomings of poor stability and poor electrical conductivity and the like are overcome well, and thus the goal of improving battery performances is achieved. The nanocomposite is applied to a lithium ion battery cathode material and has the advantages of good cycle stability and high specific energy density and the like.

Owner:ANHUI NORMAL UNIV

Preparation method for nickel oxide/graphene nanocomposite, negative electrode of lithium ion battery and lithium ion battery

ActiveCN106229503AEvenly distributedImprove performanceMaterial nanotechnologyCell electrodesGraphene nanocompositesOxide composite

The invention discloses a preparation method for a nickel oxide / graphene nanocomposite, a negative electrode of a lithium ion battery and the lithium ion battery. The preparation method comprises the following steps of a hydrothermal process, a compound process and a roasting process. According to the preparation method, nickel hydroxide directly carries out in-situ growth on the surface of graphene, so that a three-dimensional reduced graphene oxide composite with the specific morphology is formed and has a large specific surface area, a black flaky nickel oxide and graphene composite is obtained through washing, drying and roasting, a problem of aggregation of the graphene and the nickel oxide is solved, and the defects of poor stability, poor electrical conductivity and the like of the negative electrode material are well solved, and thus a purpose of improving the performance of the lithium ion battery is realized; the material is applied to the negative electrode material of the lithium ion battery and has the advantages of good cycling stability, high specific energy density and the like.

Owner:中森联合科技有限公司

Preparation method of manganese oxide/graphene nano-composite material, lithium ion battery negative electrode and lithium ion battery

ActiveCN106252628AEvenly distributedImprove performanceCell electrodesSecondary cellsNano compositesGraphene nanocomposites

The invention discloses a preparation method of a manganese oxide / graphene nano-composite material, a lithium ion battery negative electrode and a lithium ion battery. The preparation method comprises the steps of: a hydrothermal process, a compounding process and a roasting process. The preparation method provided by the invention enables direct in-situ growth of hydroxyl manganese oxide on a graphene surface, hydroxyl manganese oxide is compounded on graphene to form a three-dimensional reduced graphene oxide composite material with unique appearance and large specific surface area, and after washing, drying and roasting, a colorless linear manganese oxide and three-dimensional reduced graphene oxide composite material can be obtained. The material solves the agglomeration problem of three-dimensional reduced graphene oxide and manganese oxide nanowire, and well solves the poor stability, poor electrical conductivity and other shortcomings in itself, thus reaching the purpose of enhancing battery performance. The material can be applied to a lithium ion battery negative electrode material, and has the advantages of good cyclic stability and high specific energy density, etc.

Owner:ANHUI NORMAL UNIV

Method for preparing soybean isoflavone aglycone

InactiveCN101063158AIncrease added valueMild reaction conditionsFermentationAlgluceraseBoiling point

The invention discloses a preparing method of soybean isoflavone aglycone, which comprises the following steps: (1) adding acetone boiling point reflux into soybean molasses; filtering; evaporating the filtering liquid to dryness; getting solid; (2) adding acetic ester boiling point into the solid; filtering; adding acetone boiling point reflux into filtering liquid; filtering; drying the solid material; getting soybean isoflavone glycoside; (3) diluting the soybean isoflavone glycoside with distilled water; adding into beta-glucosidase; hydrolyzing; getting soybean isoflavone aglycone. This invention increase the added value of soybean molasses, which possesses high stability and little byproduct.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Protein powder for fodder, and preparing method and use thereof

InactiveCN1507790AReduce energy consumptionLow costEgg immunoglobulinsProtein composition from eggsEscherichia coliAnimal science

The present invention relates to a preparation method of feed protein powder containing colibacillus yolk antibody whose active valence is greater than or equal to 1:64 and its application. Its preparation method includes the following steps: preparing serotype colibacillus immunogen, using said immunogen to immunize health egg-laying hen, immunogen injection dose is 0.5-3.0 ml / every hen, collecting the egg laid by hen after which is immunized for 7-10 days, remaining the egg containing colibacillus yolk antibody whose active valence is greater than 1:64 for stand-by, using whole egg liquor to make pasteurization and spray-drying.

Owner:北京同力兴科农业科技有限公司

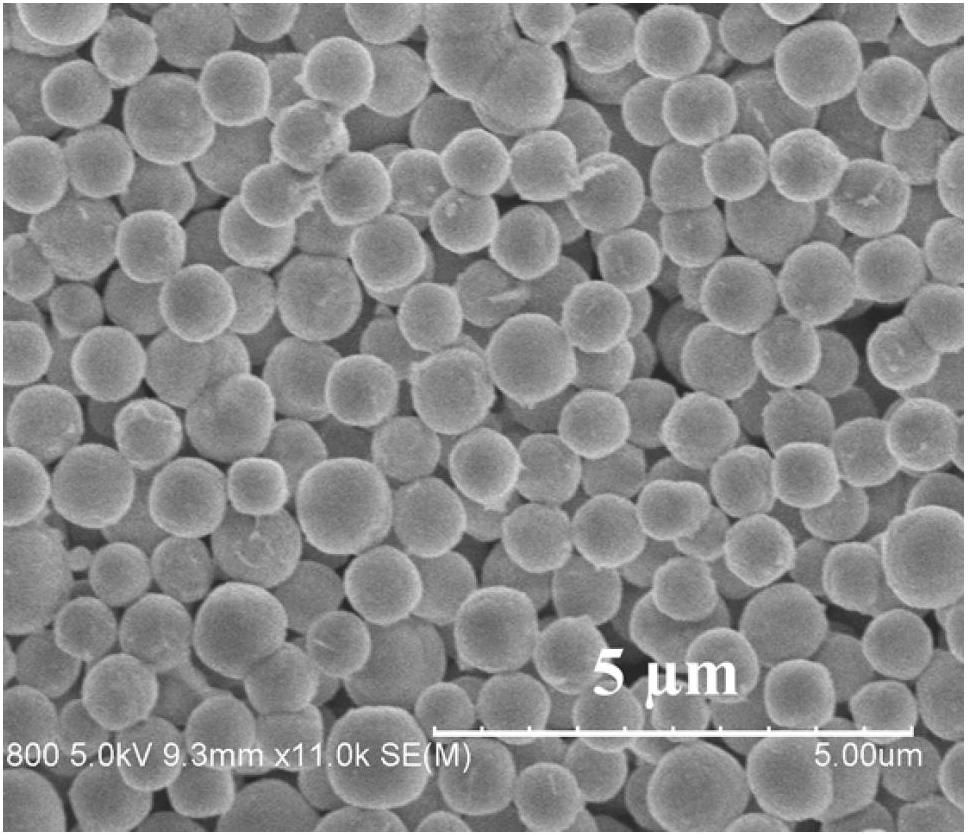

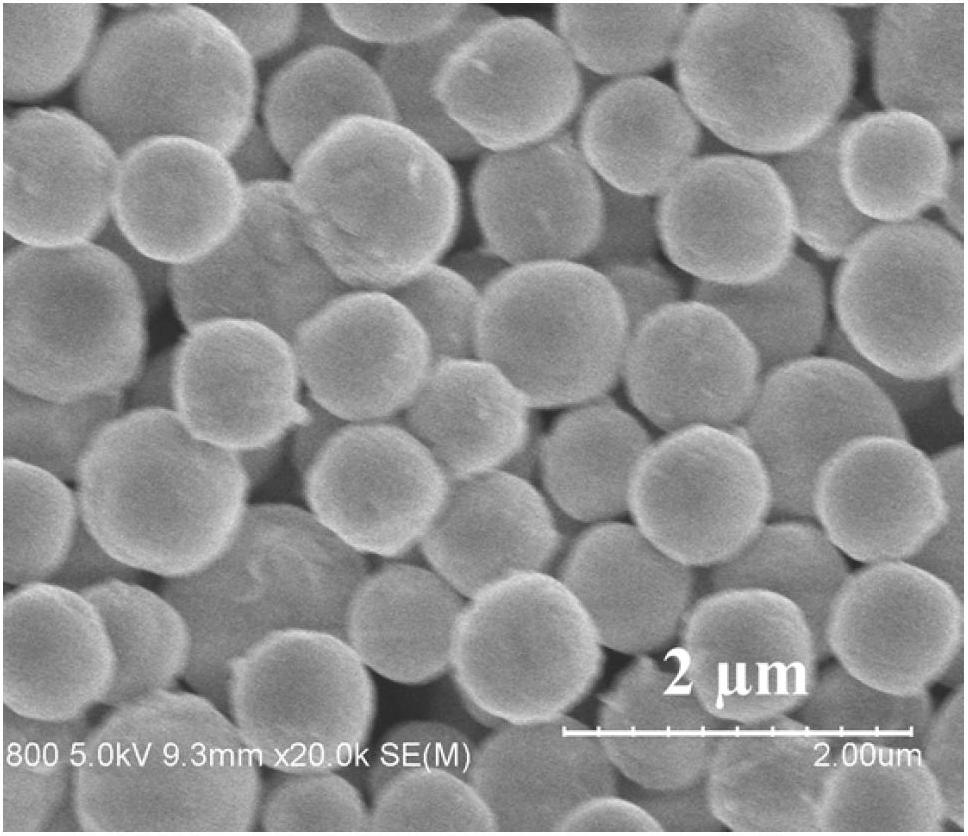

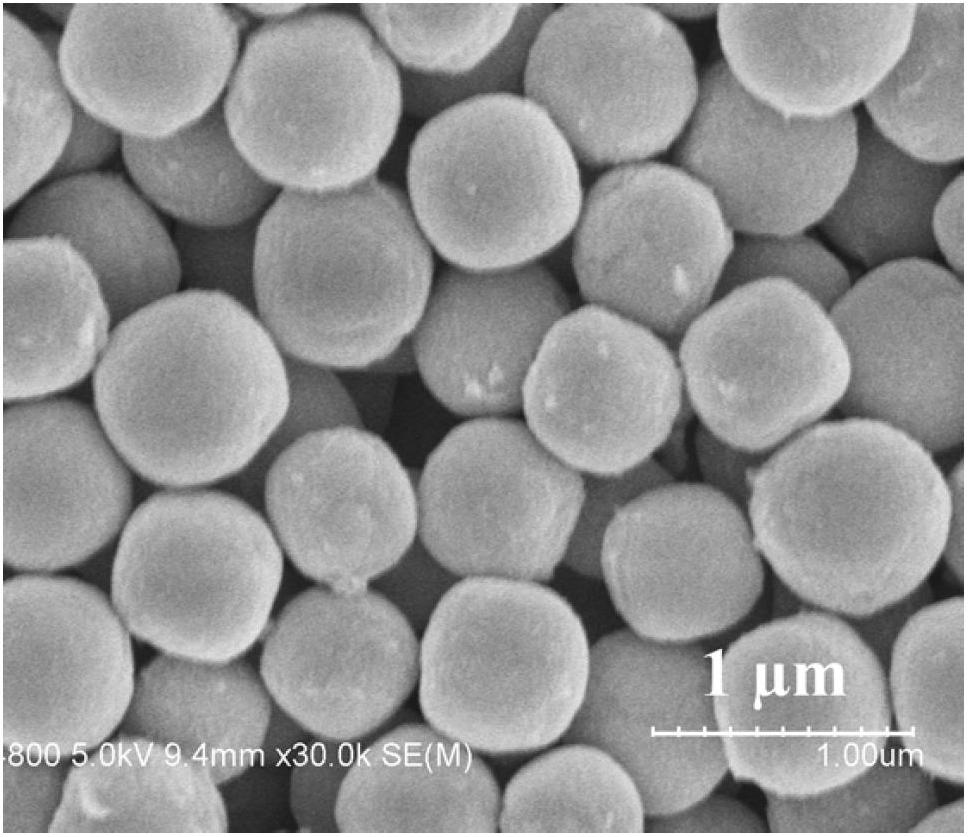

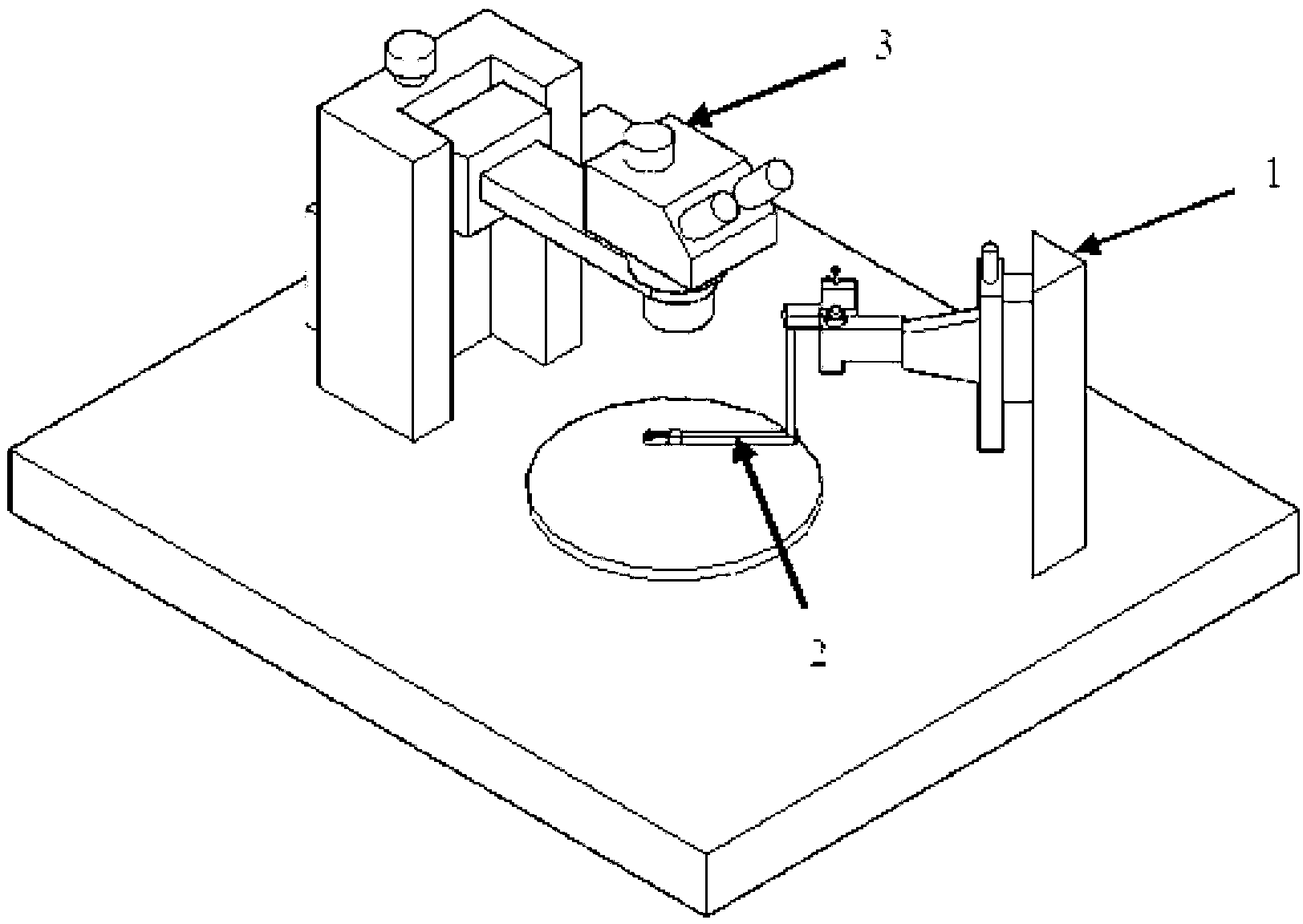

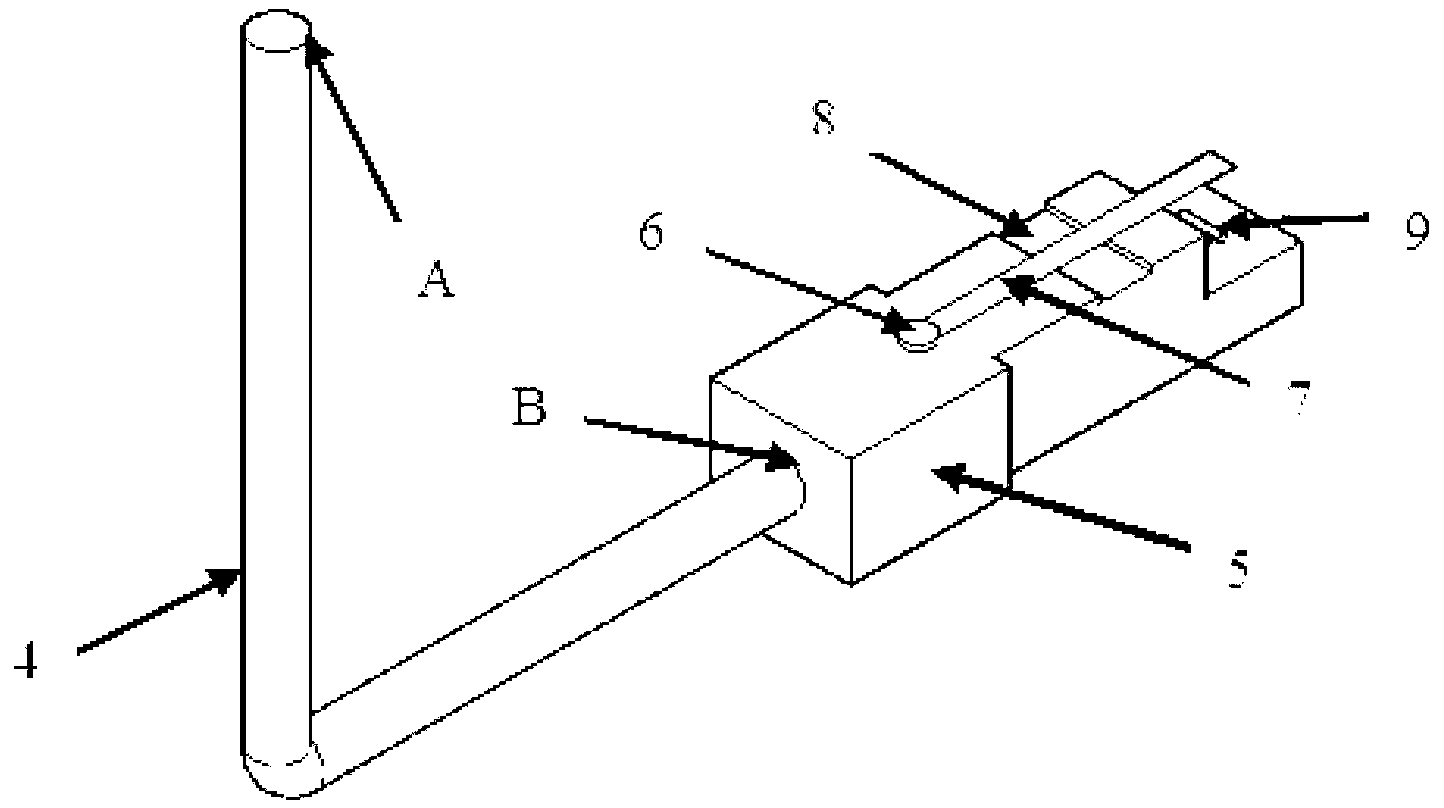

Device and method for preparing PVDF (polyvinylidene fluoride) micro-particle probe by physical adhesion method

ActiveCN103018492AEasy to operatePracticalScanning probe microscopyMedicineQuantitative determination

The invention discloses a device and a method for preparing a PVDF (polyvinylidene fluoride) micro-particle probe by a physical adhesion method. The device comprises a micro-operator and a microscope which are arranged on a foundation table, wherein an L-shaped probe clamp is arranged at the end of the micro-operator, and the lens of the microscope and the L-shaped probe clamp are oppositely arranged. The method comprises the following steps of: preparing PVDF microparticles having the particle size of 5-20 mum; and adhering the obtained PVDF microparticles at the free end of the micro-suspension arm of an AFM (atomic force microscope) tipless probe by virtue of an adhesive, drying and curing, and then obtaining the PVDF micro-particle probe. The device and the method disclosed by the invention are suitable for preparation for various micro-particle probes, simple and practicable, and strong in practicability; and the obtained PVDF microparticle probe is low in cost, wide in source, and capable of being used for the quantitative measurement for a micro-force between membrane-pollutants and pollutants under different water quality conditions, so as to analyse a membrane pollution mechanism.

Owner:陕西省膜分离技术研究院有限公司

Preparation method of composite preservative film

The invention provides a preparation method of a composite nylon material. The preparation method comprises the following steps: I. adding natural polysaccharide into an acetic acid water solution, heating to be completely gelatinized, to obtain a mixture I; II, adding an emulsifier and a plasticizer into the mixture I, heating and stirring, to obtain a mixture II; III, then adding natural functional materials into water, stirring to be completely dissolved, to prepare a natural functional material water solution; IV. cooling the mixture II to 50DEG C, adding protein, performing water bath heating and stirring, to obtain a mixture III; V, mixing the mixture III with the natural functional material water solution, to obtain a mixture IV; VI, pouring the mixture IV into a mould, drying and forming a film; and VII, cooling the film obtained in the step VI to be at normal temperature. The preparation method is simple, the production cost is low, the formed preservative film has the characteristics of being non-toxic and harmless, and good in moisture barrier property, so that the preservation effect of food can be effectively enhanced.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

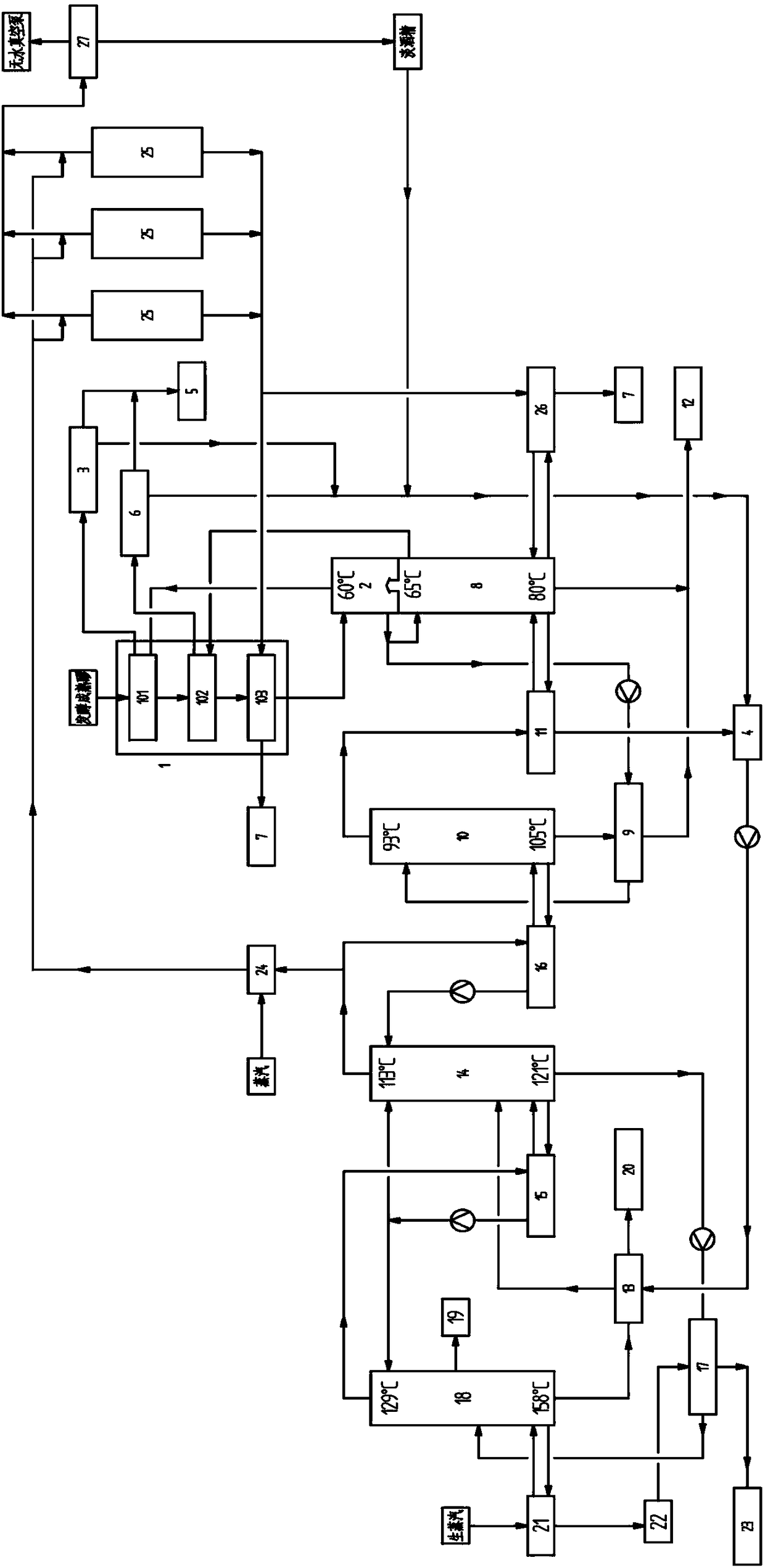

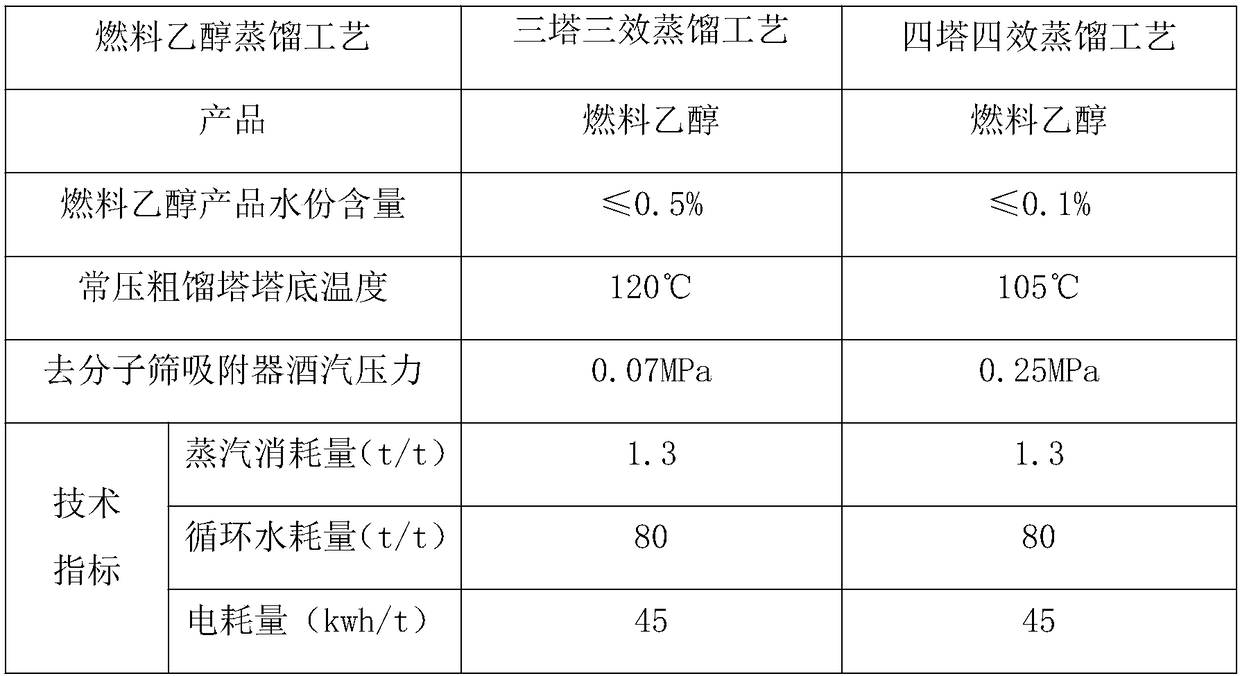

Double-coarseness, double-rectification, four-tower and four-effect energy saving distillation fuel ethanol production system and using method thereof

PendingCN108558602AReduce contentNon-deterministicFermented solutions distillation/rectificationOrganic compound preparationMolecular sieveAlcohol

The invention discloses a double-coarseness, double-rectification, four-tower and four-effect energy saving distillation fuel ethanol production system and a using method thereof, and relates to the technical field of ethanol energy-saving production. The system mainly comprises a negative pressure vinasse tower / a degassing section, a normal pressure vinasse tower, a medium pressure rectificationtower and a high-pressure rectification tower, and the heating modes of all above towers are as follows: the high-pressure rectification tower is indirectly heated by a rectification tower reboiler through adopting fresh steam, alcohol steam from the top of the high-pressure rectification tower supplies heat to a medium-pressure rectification tower through a medium-pressure rectification tower reboiler, alcohol steam from the top of the medium-pressure rectification tower supplies heat to the normal pressure vinasse tower through a normal pressure vinasse tower reboiler, alcohol steam from thetop of the normal pressure vinasse tower supplies heat to the negative pressure vinasse tower through a negative pressure vinasse tower reboiler, and the alcohol steam of fuel ethanol also supplies heat to the negative pressure vinasse tower. The system has the following advantages: the steam enters one tower, and four towers work, so the consumption in the distillation process is maximally reduced; proteins in vinasse are not prone to be denatured, so the feed color is good, and devices are not coked and obstructed, and do not need to shut down and to be cleaned; and a molecular sieve has agood dehydration effect, so low water content, small molecular sieve loading capacity and small device investment are achieved.

Owner:肥城金塔机械科技有限公司

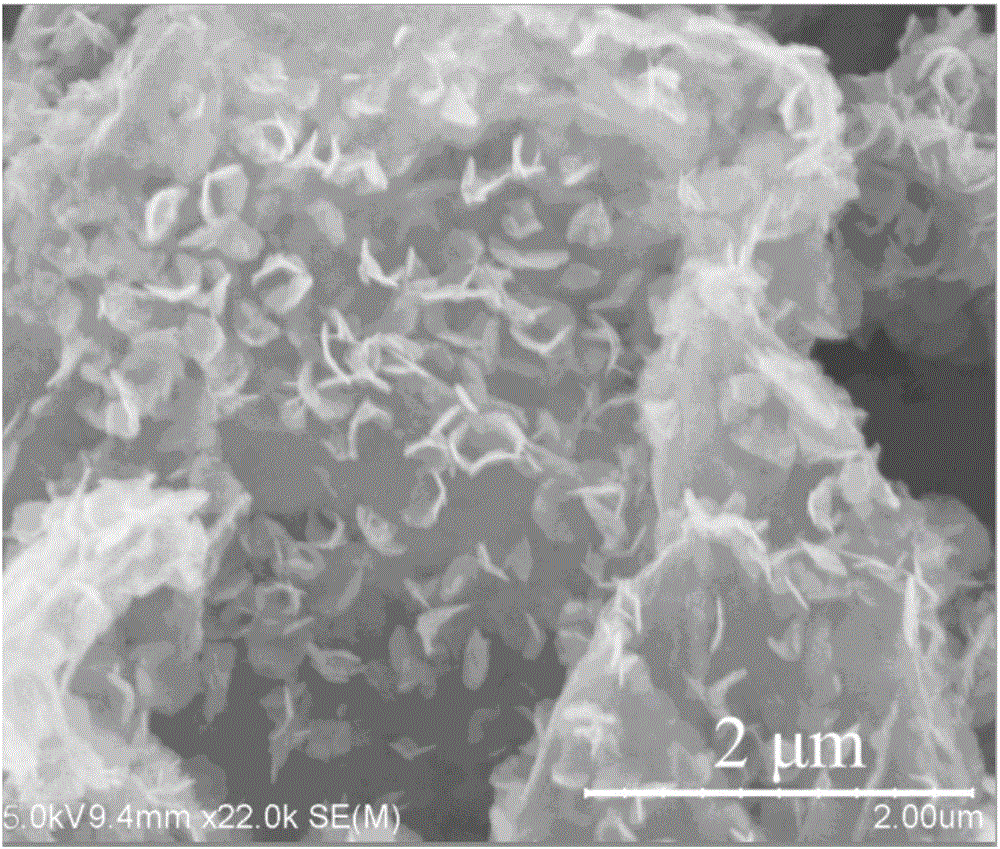

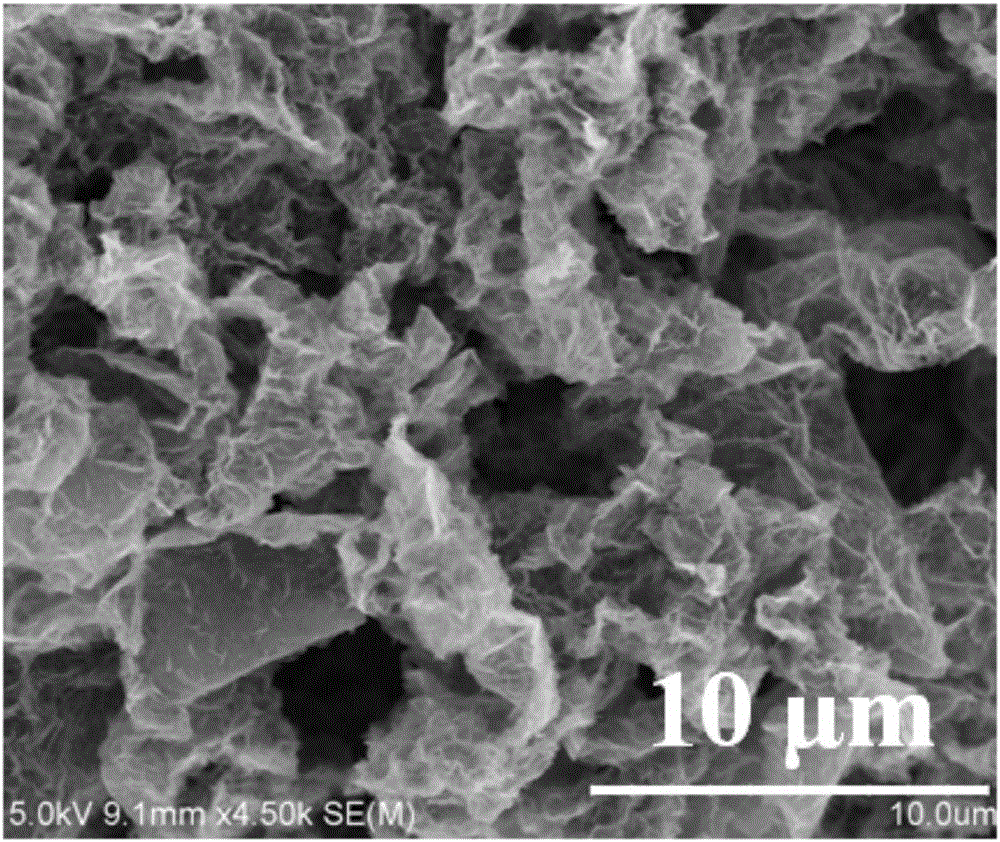

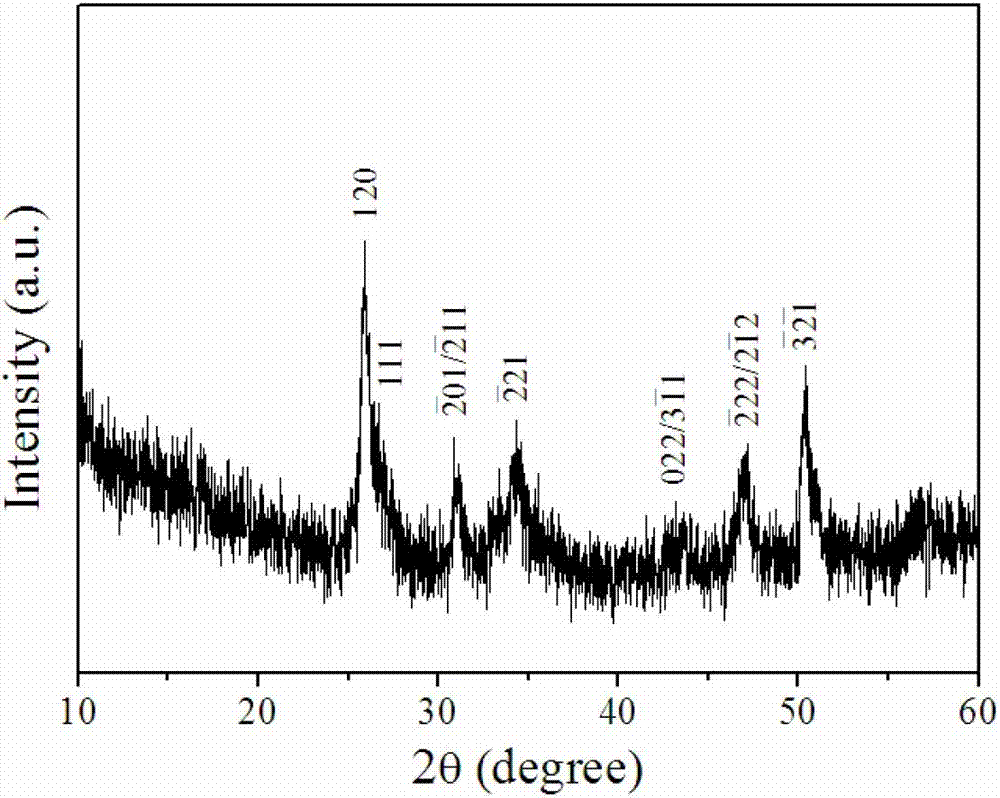

Preparation method for three-dimensional layered CoV2O6 micro-nano powder

InactiveCN102730769AHigh purityPorous pore size distribution is uniformOther chemical processesCobalt compoundsMicro nanoCOBALTOUS NITRATE HEXAHYDRATE

The present invention discloses a preparation method for three-dimensional layered CoV2O6 micro-nano powder. According to the present invention, cobaltous nitrate hexahydrate or cobalt chloride hexahydrate, sodium hydroxide or hydrochloric acid, and vanadium pentoxide as raw materials; and steps of mixing, hydrothermal reaction, separation, washing, drying and the like are performed to obtain the three-dimensional layered CoV2O6 micro-nano powder. The three-dimensional layered CoV2O6 product prepared by the method of the present invention is black powder, wherein the three-dimensional layered CoV2O6 product belongs to a triclinic crystal system, and has advantages of large specific surface area (86.8 m<2> / g), high purity and good product quality. In addition, the three-dimensional layered CoV2O6 micro-nano powder prepared by the method of the present invention provides characteristics of fast adsorption rate and large saturated adsorption capacity for methylene blue trihydrate in solutions, wherein the saturated adsorption capacity is up to165.6 mg / g when the pH value of the solution is 1.0.

Owner:ANHUI NORMAL UNIV

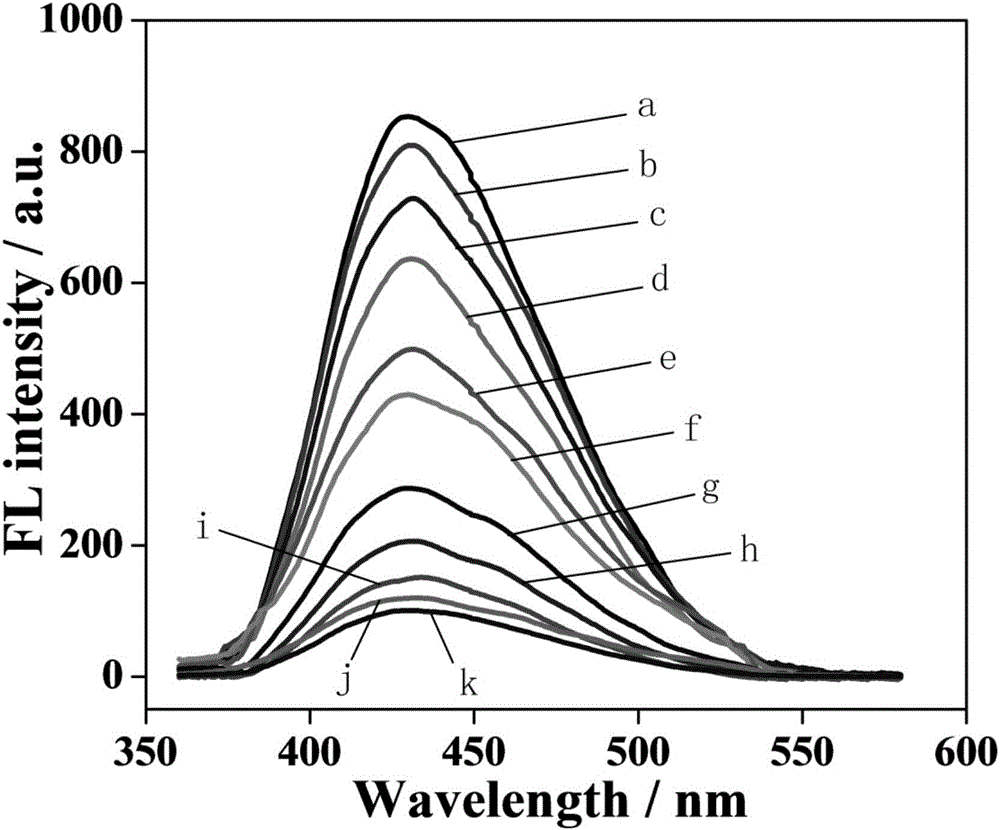

Method for producing fluorescence resonance energy transfer sensor and rapidly detecting CaMV35S

InactiveCN106092978AClear design ideasThe synthesis method is simpleFluorescence/phosphorescenceComplementary pairNitrogen doped graphene

The invention provides a method for producing a fluorescence resonance energy transfer sensor and rapidly detecting CaMV35S. The method comprises the following steps: 1, preparing a nitrogen-doped graphene quantum dot (NGQDs) solution; 2, preparing a silver nanoparticle (AgNPs) dispersion; 3, preparing a nitrogen-doped graphene quantum dot-probe1 (NGQDs-probe1) dispersion; 4, preparing a silver nanoparticle-probe2 (AgNPs-probe2) dispersion; 5, constructing the fluorescence resonance energy transfer sensor; and 6, detecting the target DNA of CaMV35S, and establishing a standard curve. The sensor is produced based on the DNA complementary pairing hybridization specification, so compared with sensors produced based on immunoreaction, the method provided by the invention has the characteristics of strong binding force with target molecules, high specificity, difficult degeneration after long-time exposure, and low requirements for surrounding environment.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com