Method for preparing nickel sulfide/graphene nanocomposite, lithium ion battery cathode and lithium ion battery

A technology of nanocomposite materials and lithium-ion batteries, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of lithium-ion battery performance degradation, easy overlapping of sheet structures, poor electrochemical performance, etc., and achieve experimental equipment Low requirements, good cycle performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of graphite oxide: weigh 5.0g graphite and 3.75g NaNO respectively 3 Put it into a 1L beaker, stir vigorously, slowly add 150mL of concentrated sulfuric acid, stir for 0.5 hours, then slowly add 20g of KMnO 4 , Added in 0.5 hours, and continued to stir for 20 hours, because the viscosity of the reactant increased, the stirring was stopped, and a paste-like purple-red substance was obtained. After standing for 5 days, slowly add 500mL deionized water and 30mLH 2 o 2 At this time, the color of the solution becomes more obvious bright yellow. After the solution is fully reacted, it is centrifuged and washed to obtain graphite oxide.

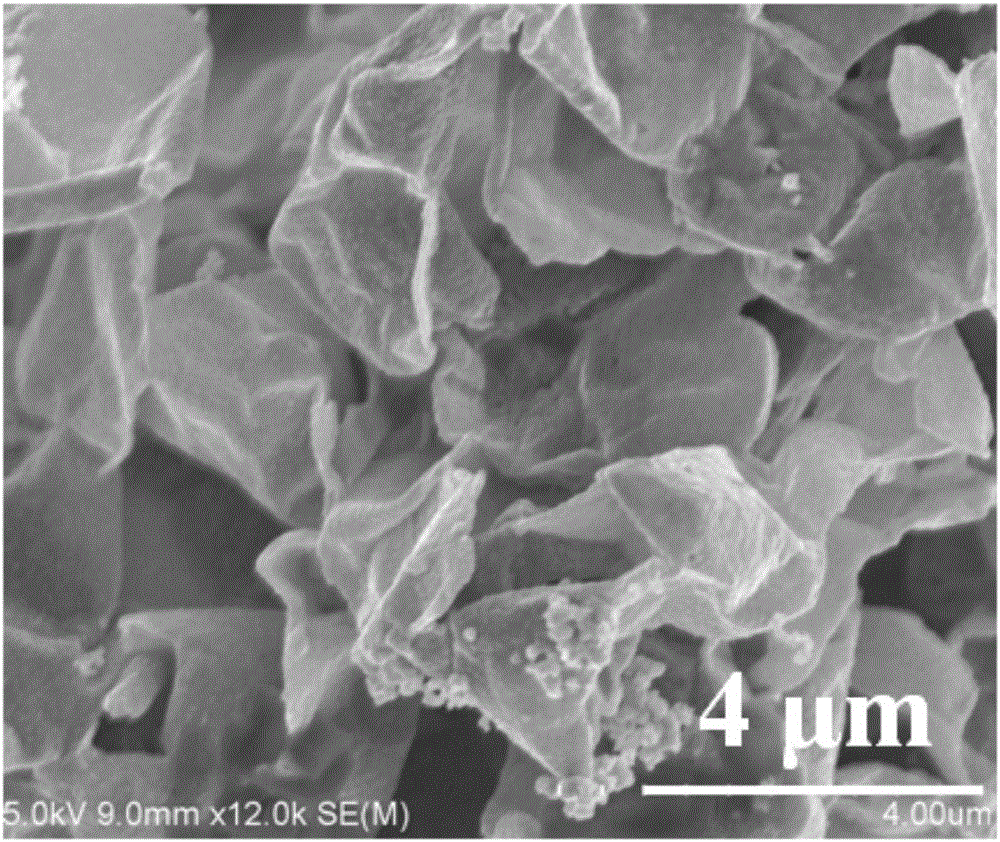

[0040] Hydrothermal process: Dissolve 70mg graphene oxide in 80mL deionized water, add 10mL concentrated sulfuric acid (ρ=1.84g / cm 3 ), ultrasonically dispersed for 3 hours, and then transferred to a reaction kettle, and reacted at a constant temperature of 160 ° C for 24 hours to obtain three-dimensional columnar reduced graph...

Embodiment 2

[0043] The preparation method of graphite oxide is with embodiment 1.

[0044] Hydrothermal process: Dissolve 110mg graphene oxide in 80mL deionized water, add 8mL concentrated sulfuric acid (ρ=1.84g / cm 3 ), ultrasonically disperse for 2 hours, then transfer it to a reactor, and react at a constant temperature of 190°C for 20 hours to obtain three-dimensional columnar reduced graphene oxide, which is washed and collected.

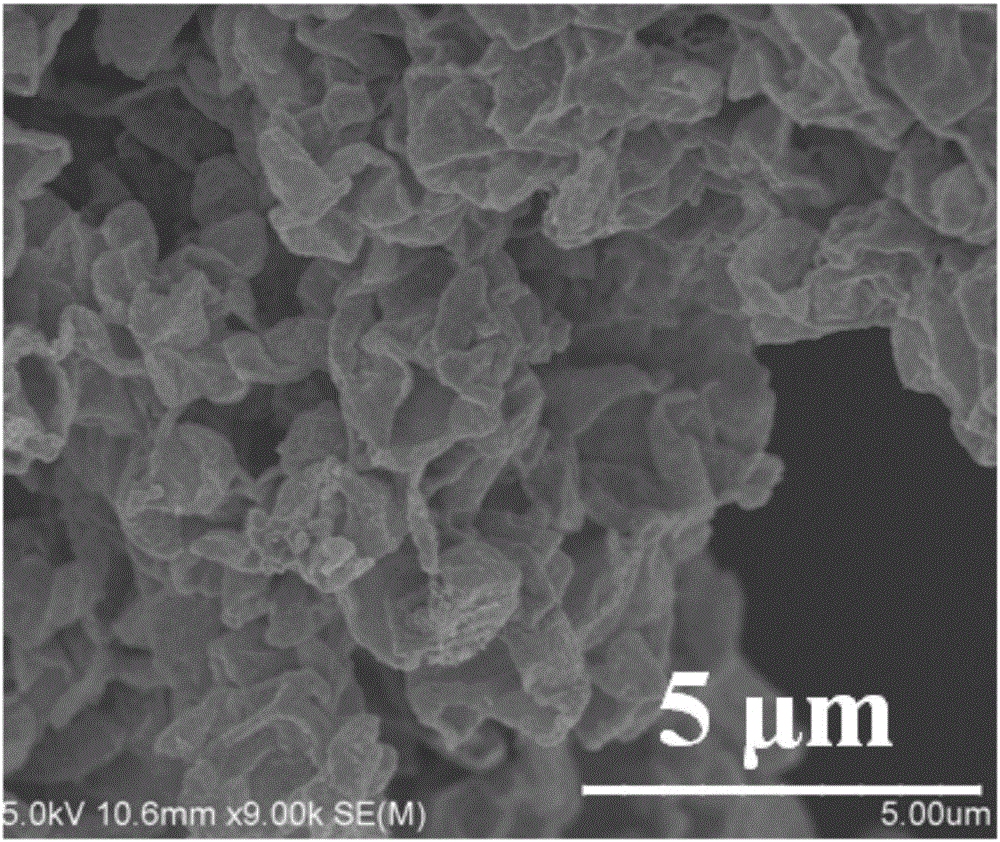

[0045] Composite process: Dissolve 1.2g of nickel nitrate, 0.6g of thiourea, and 0.6g of urea into a mixed solvent (12mL of water and 4mL of ethanol), add 22mg of three-dimensional columnar reduced graphene oxide into the above mixed solution, soak at 20°C for 2 Then transfer it to a reactor, react at a constant temperature of 220°C for 22 hours, wash the product, dry it in vacuum at 40°C for 12 hours, and collect the nickel sulfide / graphene nanocomposite material.

Embodiment 3

[0047] The preparation method of graphite oxide is with embodiment 1.

[0048] Hydrothermal process: Dissolve 90mg graphene oxide in 80mL deionized water, add 9mL concentrated sulfuric acid (ρ=1.84g / cm 3 ), ultrasonically disperse for 4 hours, then transfer it to a reactor, and react at a constant temperature of 260°C for 18 hours to obtain three-dimensional columnar reduced graphene oxide, which is washed and collected.

[0049] Composite process: 0.6g nickel chloride, 0.3g thioacetamide, and 0.2g urea were dissolved in a mixed solvent (4mL water and 12mL DMF), and 18mg three-dimensional columnar reduced graphene oxide was added to the above mixed solution, 30 ℃ soaking for 3 days, then transferred to the reactor, 240 ℃ constant temperature reaction for 20 hours, the product was washed, 70 ℃ vacuum drying for 6 hours, and the nickel sulfide / graphene nanocomposite material was collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com