Device and method for preparing PVDF (polyvinylidene fluoride) micro-particle probe by physical adhesion method

A technology of microparticle and adhesion method, applied in the field of atomic force microscope (AFM) probe preparation, can solve the problems of affecting microscopic force measurement, complex preparation method, narrow source range, etc. Simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

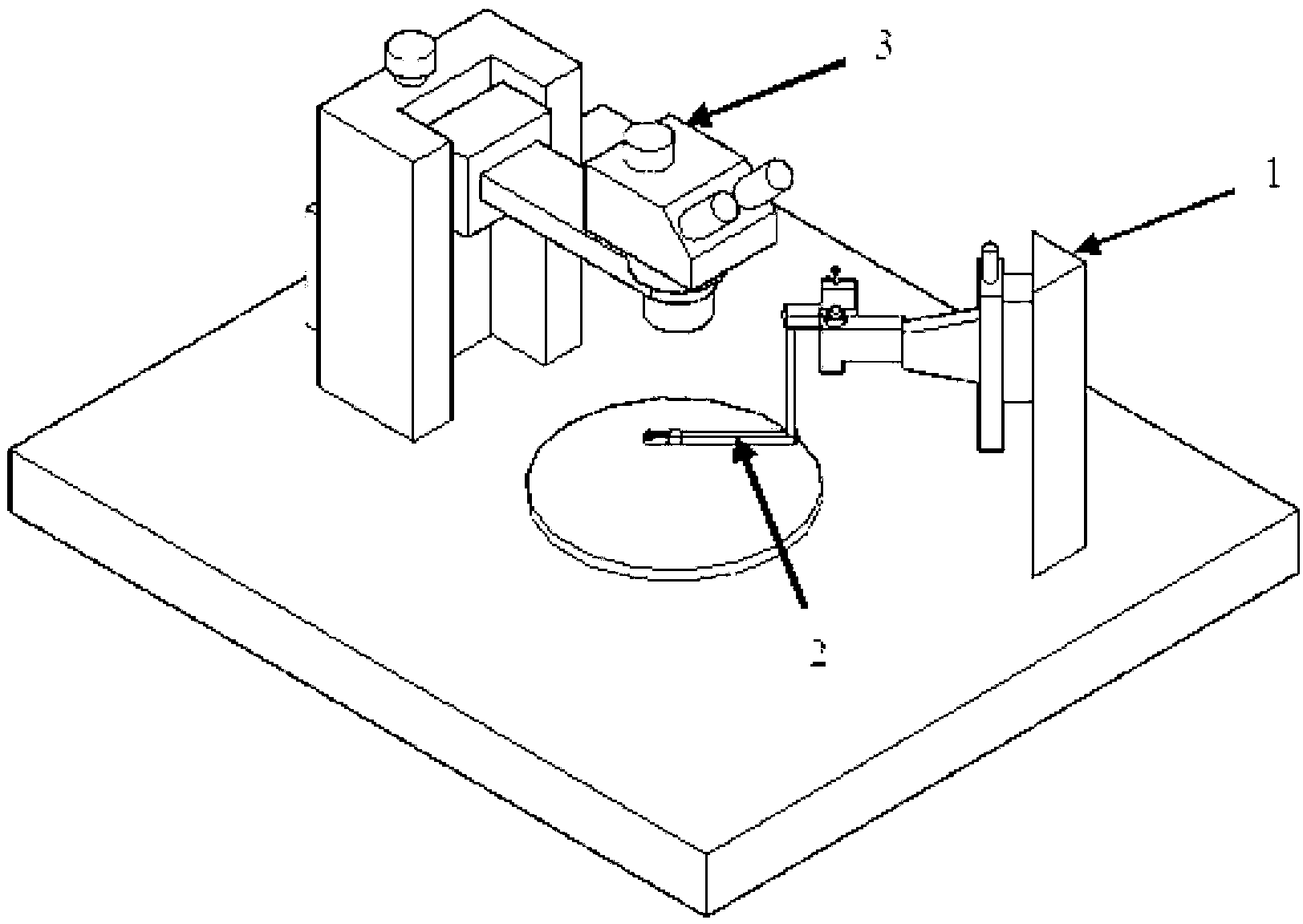

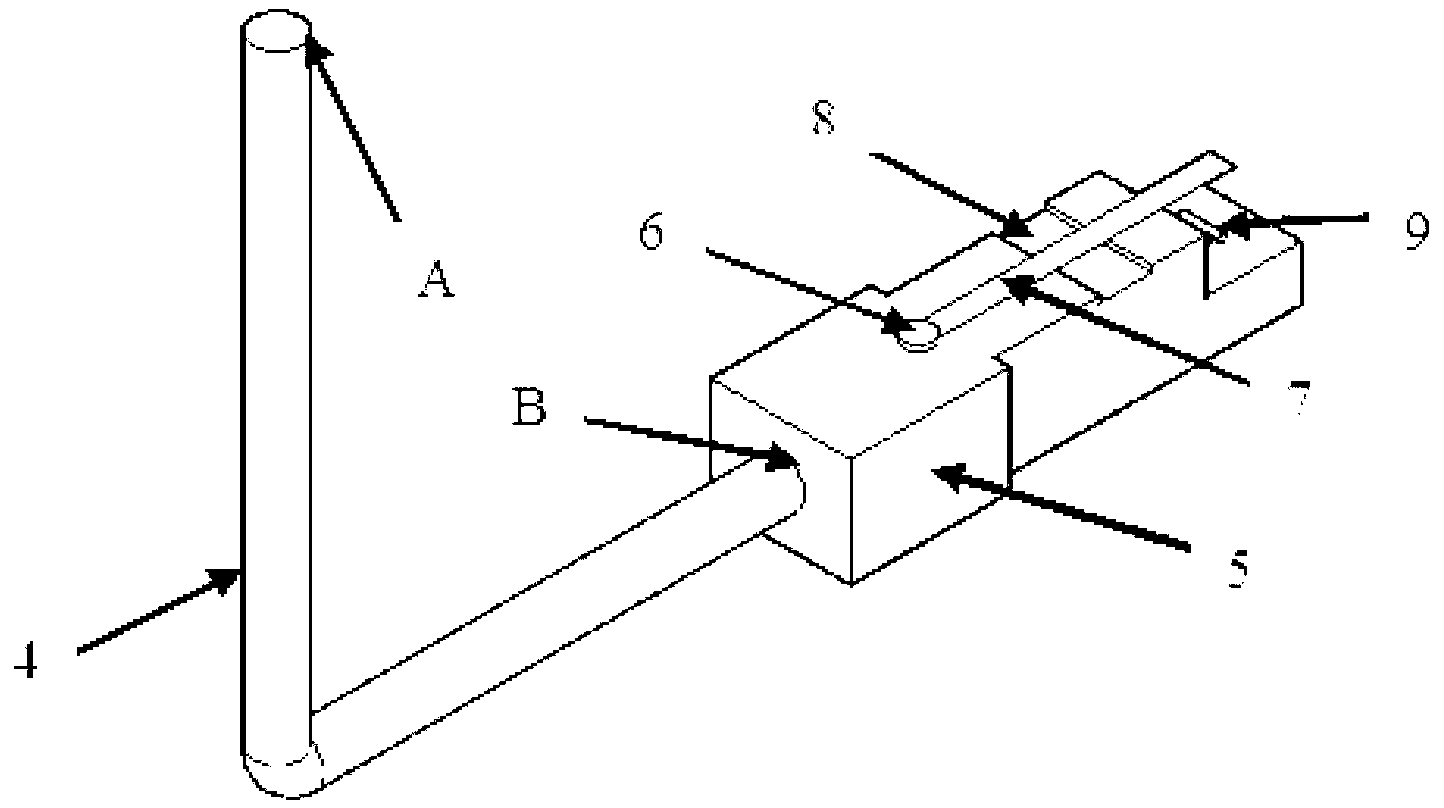

Method used

Image

Examples

Embodiment 1

[0037] 1) Place the commercially purchased PVDF microparticles in an aqueous solution with a N,N-dimethylacetamide content of 20wt%, stir and dissolve at 60°C for 1.5h, stop heating the aqueous solution, continue stirring and pour into the aqueous solution continuously Add ice cubes until the temperature of the mixture reaches 0°C;

[0038] The main mechanism of this method is that the organic solvent is a PVDF solvent, and water is a PVDF non-solvent. During the process of stirring and dissolving PVDF at high temperature, the organic solvent is continuously volatilized while the PVDF particles are continuously dissolving, and the particle size is also continuously decreasing. When the organic solvent is completely volatilized, the temperature is rapidly lowered and cooled, so that the PVDF microparticles are quickly gelled and solidified in the aqueous solution, and PVDF microparticles with small particle sizes are obtained.

[0039] 2) Ultrasonic disperse the aqueous solutio...

Embodiment 2、 Embodiment 3、 Embodiment 4

[0048] Embodiment 2,3,4 preparation steps and equipment technological process are the same as embodiment 1, and concrete preparation conditions are as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com