Method for preparing bionic composite material with lamellar multilevel structure

A biomimetic composite material and layered technology, which is applied in the field of biomedical materials, can solve the problems of insufficient structural design and single material selection, and achieve the effects of non-degeneration, good interlayer connectivity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

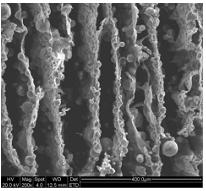

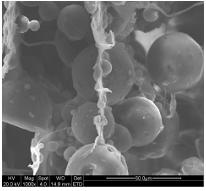

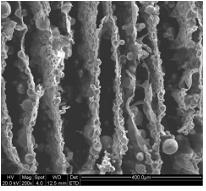

[0028] Take 0.8g of PLA with a molecular weight of 10,000 and dissolve it in 12ml of acetone with a concentration of 0.067g / ml. After fully dissolving, this is solution A; take 0.2g of nano-hydroxyapatite and disperse it in 6ml of water, and ultrasonically disperse it in the form of an emulsion It is solution B; pour solution B into solution A, and stir quickly until it is uniformly dispersed to form solution C; dissolve 0.4g polyvinyl alcohol (PVA) in 200ml water, place it on a stirrer and stir at a speed of 400rpm, and wait until it is fully dissolved , this solution is D; pour C solution into the stirring D solution at a constant speed to obtain solution E; solution E continues to stir for 6 hours to volatilize the organic solvent; then use dialysis to wash away PVA and collect HA / PLA microsphere powder Put it into an Erlenmeyer flask, ultrasonically disperse it, and put it into -20°C for 12 hours to pre-freeze; after pre-freezing, put it into a freeze dryer at -50°C and fre...

Embodiment 2

[0032] Take 10g PLA with a molecular weight of 60,000 and dissolve it in 100ml of dichloromethane with a concentration of 0.1g / ml. After fully dissolving, this is solution A; take 5gn-HA and disperse it in 20ml of dichloromethane, and disperse it ultrasonically. Solution B; pour solution B into solution A, and stir quickly until it is evenly dispersed to form solution C; dissolve 0.5% PVA in 1000ml water, place it on a stirrer and stir at a speed of 400rpm, and wait until it is fully dissolved. A beaker, this solution is D; slowly and uniformly add the C solution dropwise to the stirring D solution to obtain the solution E; continue to stir the solution E for 8 hours to evaporate the organic solvent; then use suction filtration to wash away the PVA and collect HA / PLA microsphere powder is placed in a conical flask, ultrasonically dispersed, and pre-frozen at -80°C for 12 hours; after pre-freezing, put it into a freeze dryer and freeze-dry it at -50°C, less than 20Pa for 24 hou...

Embodiment 3

[0036] Take 1.5g of PCL with a molecular weight of 100,000 and dissolve it in 22.5ml of dichloromethane with a concentration of 6.67g / ml until it is fully dissolved. This is solution A; take 1g of β-TCP and disperse it in 20ml of ethanol, and disperse it ultrasonically to form a solution in the form of an emulsion B; Pour solution B into solution A, and stir quickly until it is uniformly dispersed to form solution C; dissolve 0.5% PVA in 400ml water, place it on a stirrer and stir at a speed of 400rpm, until it is fully dissolved, divide it into four beaker, this solution is D; slowly and uniformly add solution C to the stirring solution D to obtain solution E; continue to stir solution E for 8 hours to evaporate the organic solvent; then use suction filtration to wash away PVA and collect HA / Put the PCL microsphere powder into the Erlenmeyer flask, ultrasonically disperse it, put it into -80 ℃ pre-freeze for 12 hours; after pre-freezing, put it into the freeze dryer and freez...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com