Double-coarseness, double-rectification, four-tower and four-effect energy saving distillation fuel ethanol production system and using method thereof

A fuel ethanol and four-effect technology is applied in the field of double-coarse, double-refined, four-column, four-effect, energy-saving distillation to produce fuel ethanol systems, and can solve the problems of no application examples, blackening of feed color, and low pressure at the top of combined towers, and achieve dehydration. The effect of good effect, good feed color and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

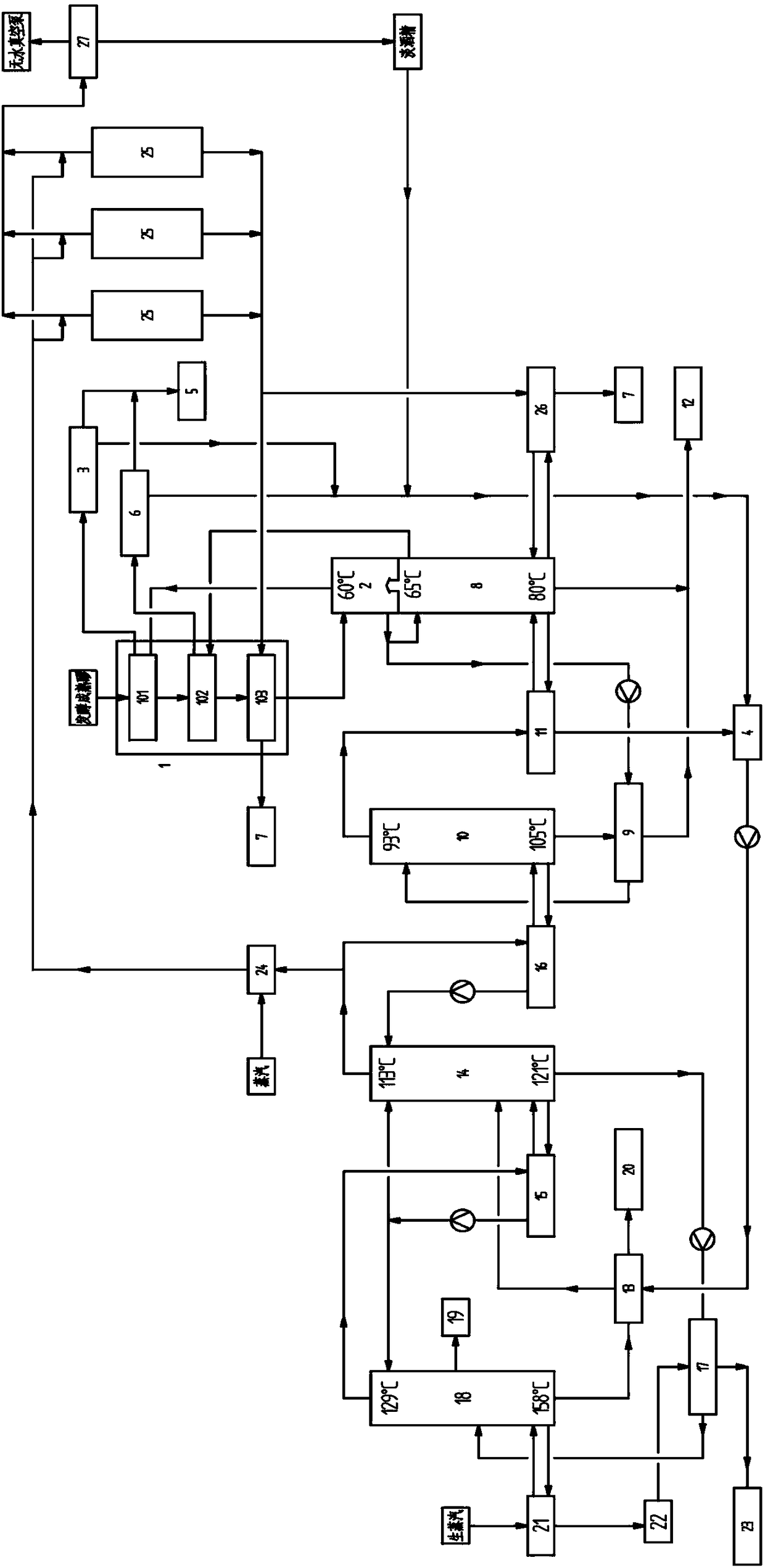

[0025] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

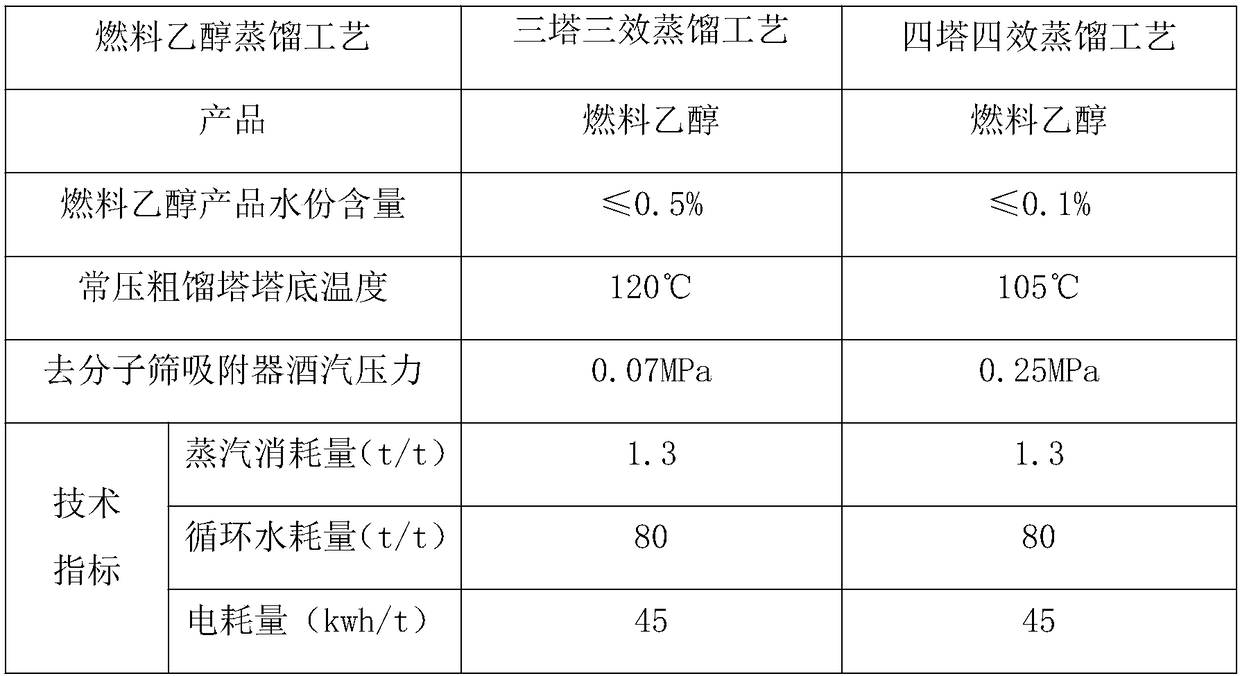

[0026] The dual-coarse, double-finishing, four-tower, four-effect energy-saving distillation system for producing fuel ethanol and its application method are mainly equipped with a negative-pressure beer tower 8 / degassing section 2, an atmospheric pressure beer tower 10, a medium-pressure finishing tower 14, and a high-pressure finishing tower 18 , the heating mode of each tower is as follows: the high-pressure finishing tower 18 adopts raw steam to be indirectly heated through the finishing tower reboiler 21, and the wine vapor at the top of the high-pressure finishing tower 18 passes through the medium-pressure finishing tower reboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com