Preparation method for three-dimensional layered CoV2O6 micro-nano powder

A micro-nano powder and layered technology is applied in the field of preparation of functional micro-nano materials, which can solve the problems of unsolved problems of decolorization, complex composition of printing and dyeing wastewater, and high cost of activated carbon preparation. The effect of uniform pore size distribution and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve the cobalt nitrate hexahydrate raw material in 40 ml of water to prepare a 0.5M cobalt nitrate solution, add vanadium pentoxide (0.02mol) and vitamin C (0.06mol) under magnetic stirring at a speed of 50 rpm, and then The pH of the solution was adjusted to 3.0 with 0.5M dilute hydrochloric acid to obtain a cloudy mixed solution.

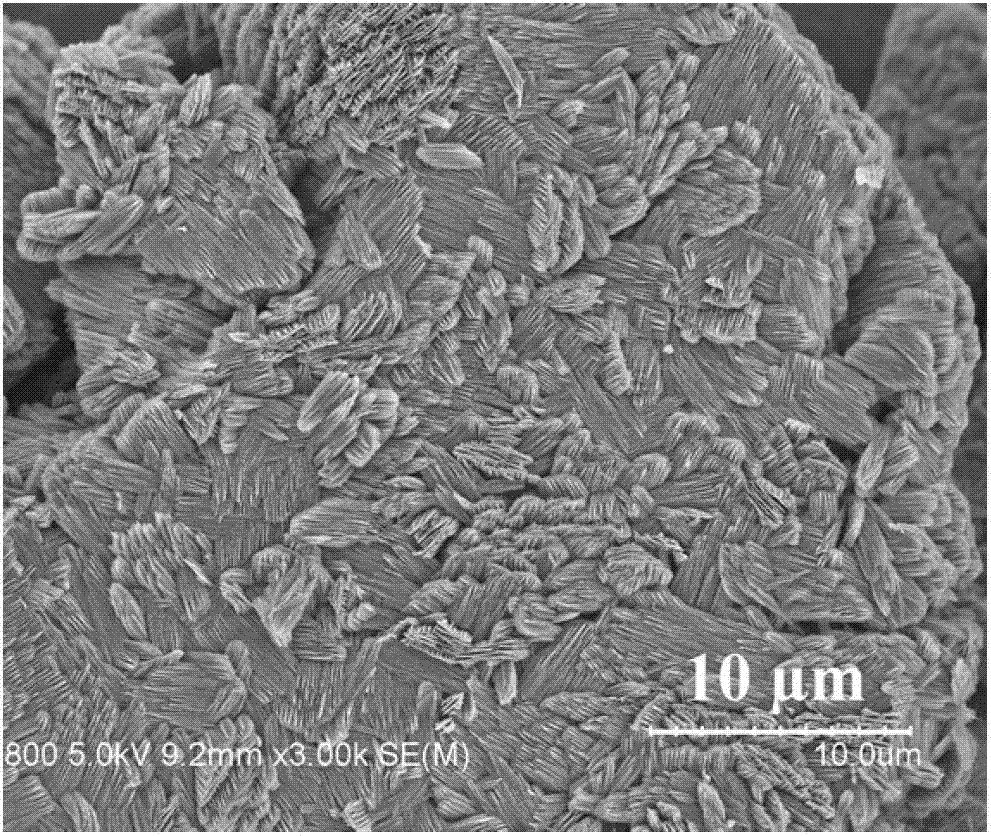

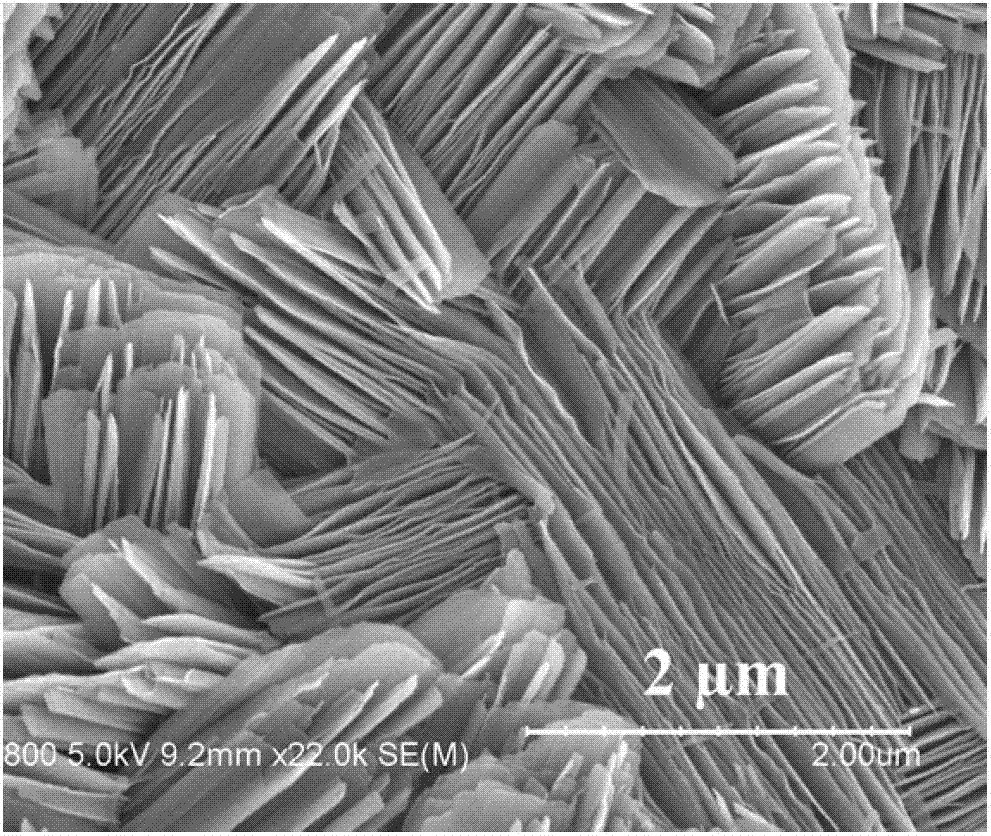

[0033] The obtained turbid mixed solution was transferred into a hydrothermal reaction kettle, and hydrothermally reacted at 160 °C for 10 h, and then the precipitate was filtered, washed, and dried to obtain a black solid powder product. The product characterization results are shown in the appendix figure 1 And attached figure 2 shown.

Embodiment 2

[0035] Dissolve the cobalt nitrate hexahydrate raw material in 40 ml of water to prepare a 0.5M cobalt nitrate solution, add vanadium pentoxide (0.02mol) and vitamin C (0.20mol) under magnetic stirring at a speed of 80 rpm, and then The pH of the solution was adjusted to 8.0 with 0.5M sodium hydroxide solution to obtain a cloudy mixed solution.

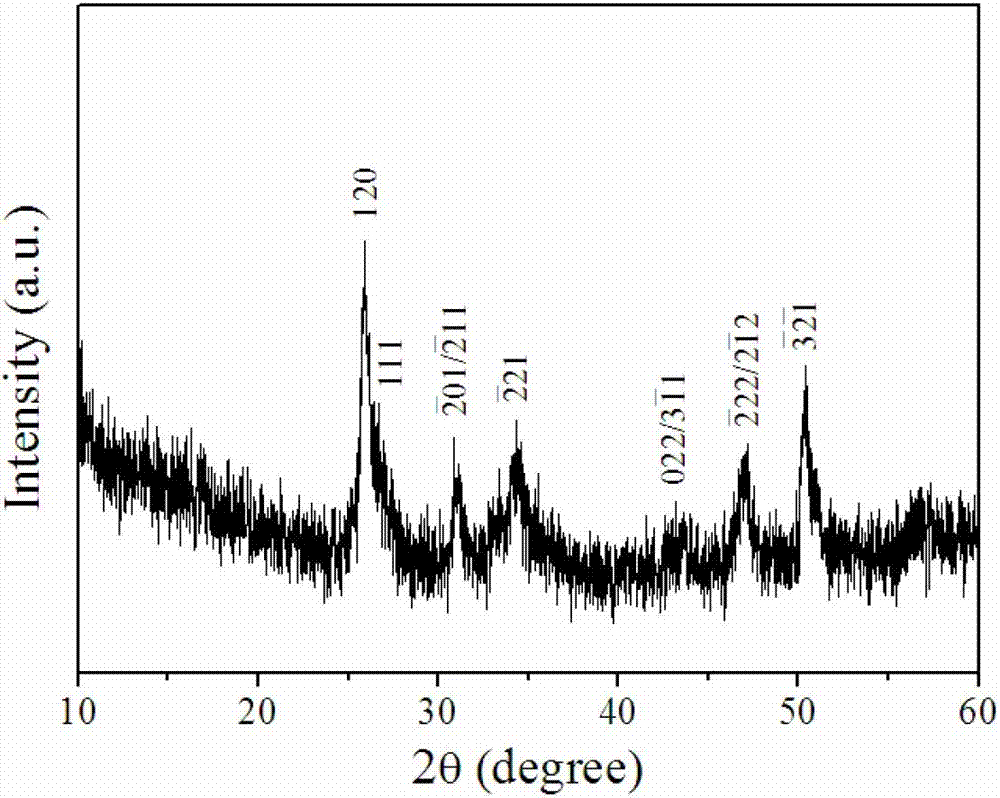

[0036] Transfer the obtained turbid mixed solution into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 180°C for 3 hours, then filter, wash, and dry the precipitate to obtain a black solid powder product. The characterization results of the product are shown in the attached image 3 shown.

Embodiment 3

[0038] Dissolve the cobalt nitrate hexahydrate raw material in 40 ml of water to prepare a 0.5M cobalt nitrate solution, add vanadium pentoxide (0.02mol) and vitamin C (0.30mol) under magnetic stirring at a speed of 100 rpm, and then The pH of the solution was adjusted to 10.0 with 0.5M sodium hydroxide solution to obtain a cloudy mixed solution. The obtained turbid mixed solution was transferred into a hydrothermal reaction kettle for hydrothermal reaction at 240° C. for 8 h, and then the precipitate was filtered, washed and dried to obtain a black solid powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com