Sea-urchin-shaped nanometer nickel silicate hollow sphere and preparation method thereof

A nano-silicic acid and sea urchin-like technology, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve complex and changeable factors affecting synthesis conditions, difficult control of sample shape and particle size, and relatively high requirements for fine operation. Advanced problems, to achieve the effect of low price, non-denaturation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

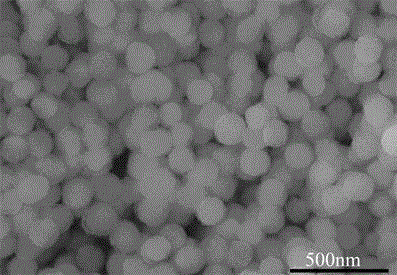

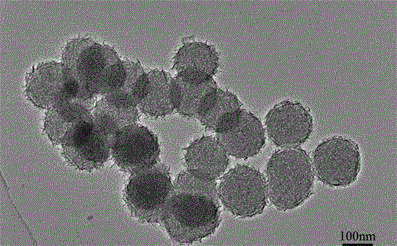

[0029] 1) Ultrasonic disperse 0.5g of silica balls (particle size about 120nm), 1.3g of urea and 0.2g of nickel nitrate hexahydrate in 40mL of deionized water, pour it into the core of a polytetrafluoroethylene reactor and place it in a 105°C Heated in an oven for 12 hours, cooled naturally to room temperature, centrifuged and washed the obtained product with deionized water and absolute ethanol, and dried at 70°C for 10 hours to obtain a nickel salt / SiO2 core-shell structure. The SEM picture is as follows: figure 1 shown;

[0030] 2) Weigh 0.05g of the product prepared in step 1) and disperse it in 40ml of NaOH solution with a pH of 12, pour it into the hydrothermal reaction

[0031] In the kettle, heat at a constant temperature of 160°C for 12 hours, cool naturally to room temperature, wash the obtained product by centrifugation with deionized water and absolute ethanol, and dry at 60°C for 12 hours;

[0032] 3) The product obtained in step 2) was calcined in air at 200° C....

Embodiment 2

[0034] 1) Ultrasonic disperse 1.2g of silica balls, 1.7g of urea and 0.1g of nickel nitrate hexahydrate in 40mL of deionized water.

[0035] The obtained solution was poured into the polytetrafluoroethylene reactor core, and heated in an oven at 120°C for 10 hours, cooled to room temperature naturally, and the obtained product was centrifugally washed with deionized water and absolute ethanol, and then heated at 80°C Dry for 7 hours;

[0036] 2) Weigh 0.05g of the product obtained in step 1) and disperse it in 40ml of Na with a pH of 12 2 CO 3 / NaOH solution, pour water

[0037] In a thermal reaction kettle, heat at a constant temperature of 200°C for 10 hours, cool naturally to room temperature, wash the prepared product with deionized water and absolute ethanol, and dry it at 80°C for 7 hours;

[0038] 3) The product obtained in step 2) was calcined in air at 400° C. for 1.5 h to prepare sea urchin-shaped nano-nickel silicate hollow spheres.

Embodiment 3

[0040] 1) Ultrasonic disperse 1.5g of silica balls, 1.3g of urea and 0.07g of nickel nitrate hexahydrate in 35mL of deionized water.

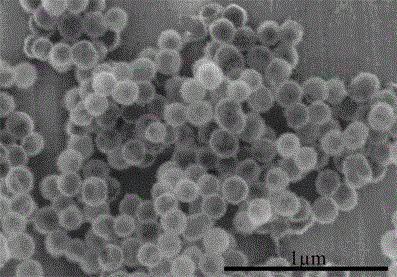

[0041] Pour the obtained solution into the core of a polytetrafluoroethylene reactor and place it in an oven for 8 hours at 150°C, cool it down to room temperature naturally, wash the obtained product centrifugally with deionized water and absolute ethanol, and dry it at 160°C for 5 hours ,, the nickel salt / SiO2 core-shell structure is obtained, and its SEM picture is as follows figure 2 shown;

[0042] 2) Weigh 0.10g of the product prepared in step 1) and disperse it in 40ml of KOH solution with a pH of 13, and pour it into a hydrothermal reaction kettle

[0043] , 100°C constant temperature hydrothermal reaction for 12h, naturally cooled to room temperature, the prepared product was washed with deionized water and absolute ethanol, and dried at 100°C for 6h;

[0044] 3) The product obtained in step 2) was calcined in air at 350° C. for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com