Novel medium manganese steel casting powder for automobile and application thereof

A technology of mold slag and medium manganese steel, which is applied in the field of continuous casting of iron and steel, can solve problems such as unstable heat flow and poor quality of billet, and achieve the effects of inhibiting interface reaction, strengthening control, and better controlling heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

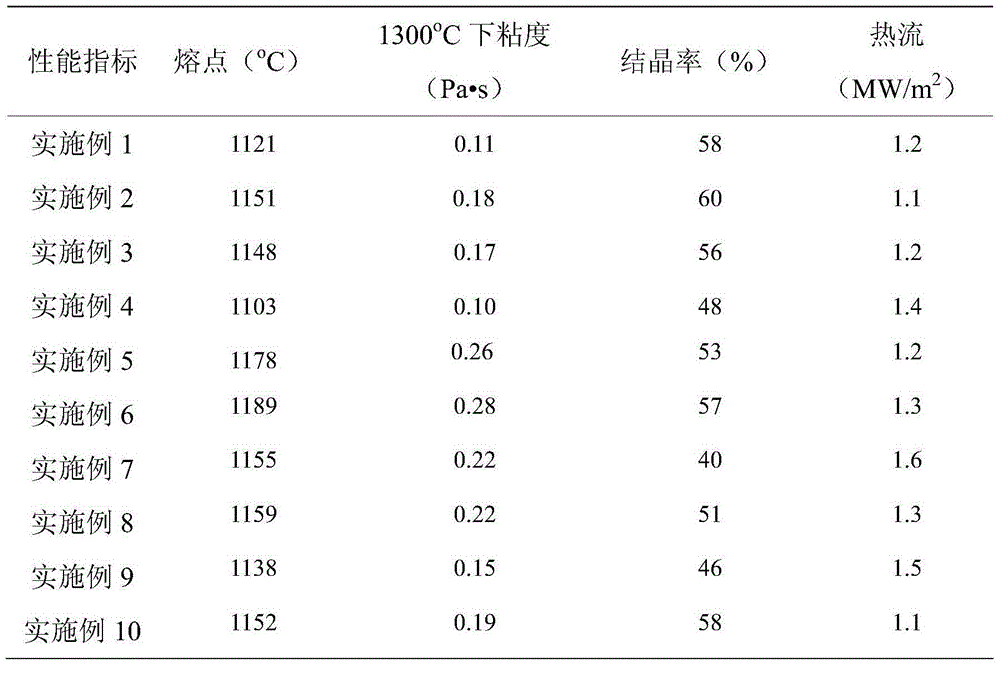

Embodiment 1

[0037] A medium and high manganese steel continuous casting mold mold powder for automobiles, its composition mass percentage is: CaO 32.1%, Al 2 o 3 21.3%, SiO 2 11.8%, MgO 3.8%, Na 2 O 12.7%, Li 2 O 1.4%, MnO 4.8%, F - 12.1%. The mold flux CaO / Al 2 o 3 is 1.5. The main physical properties of the mold flux measured by the above method are shown in Table 1. The mold powder designed in this embodiment is used in the continuous casting process of medium-manganese steel for automobile steel with a mass percentage content of 0.5% C, 6.5% Mn and 3.5% Al; the equiaxed crystal ratio of the obtained slab is 88%, and the Longitudinal cracks and inclusions occur less than 0.55% of the time.

Embodiment 2

[0039] A medium and high manganese steel continuous casting mold mold powder for automobiles, its composition mass percentage is: CaO 35.8%, Al 2 o 3 18.1%, SiO 2 11.5%, MgO 4.8%, Na 2 O 11.5%, Li 2 O 1.5%, MnO 5.0%, F - 11.8%. The mold flux CaO / Al 2 o 3 is 2.0. The main physical properties of the mold flux measured by the above method are shown in Table 1. The mold powder designed in this embodiment is used in the continuous casting process of medium-manganese steel for automobile steel with a mass percentage content of 0.6% C, 7.3% Mn, and 5.5% Al; the equiaxed crystal ratio of the obtained slab is 90%, and the slab The probability of occurrence of longitudinal cracks and inclusions is less than 0.34%.

Embodiment 3

[0041] A medium and high manganese steel continuous casting mold mold powder for automobiles, its composition mass percentage is: CaO 32.7%, Al 2 o 3 16.8%, SiO 2 13.5%, MgO 5.0%, Na 2 O 13.1%, Li 2 O 1.9%, MnO 5.5%, F - 11.5%. The mold flux CaO / Al 2 o 3 is 1.9. The main physical properties of the mold flux measured by the above method are shown in Table 1. The mold flux designed in this embodiment is used in the continuous casting process of medium-manganese steel for automobile steel with a mass percentage content of C 1.0%, Mn 10.0%, and Al 2.5%; the equiaxed crystal ratio of the obtained slab is 91%, and the slab The probability of occurrence of longitudinal cracks and inclusions is less than 0.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com