Lithium ion battery positive pole material, preparation method thereof, lithium ion battery positive pole and all-solid-state lithium battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of interface element diffusion and limited interface performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment is used to illustrate the lithium-ion battery cathode material and all-solid-state lithium battery of the present disclosure, as well as their preparation methods.

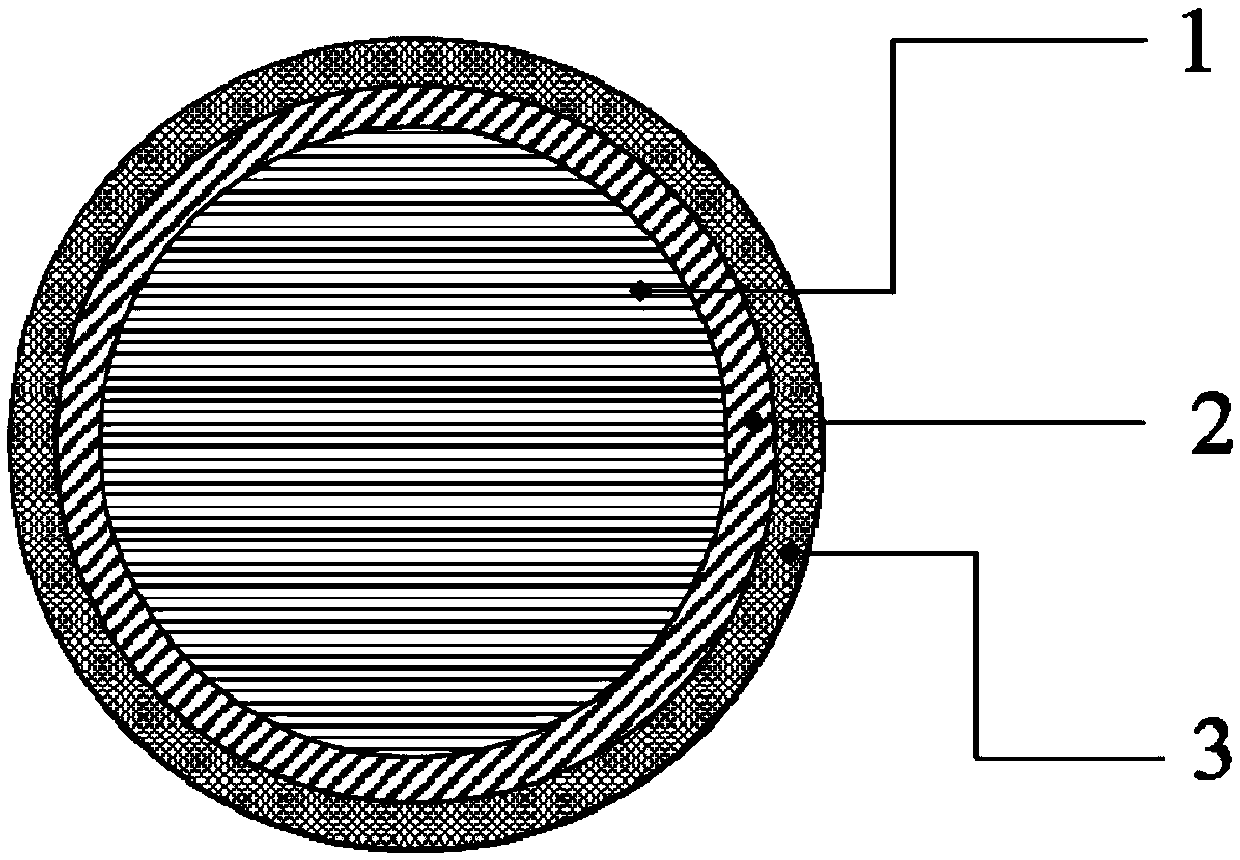

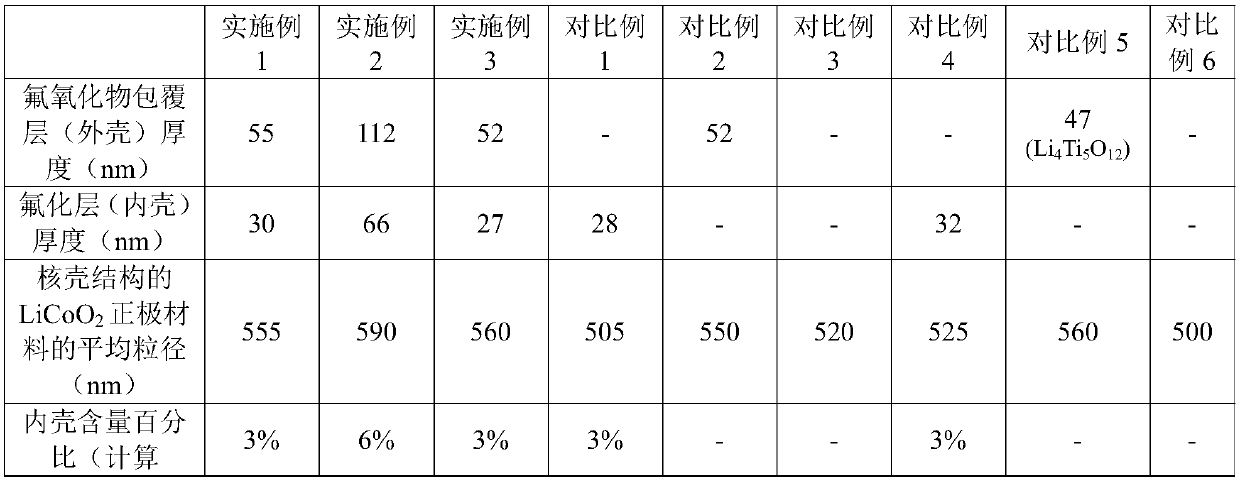

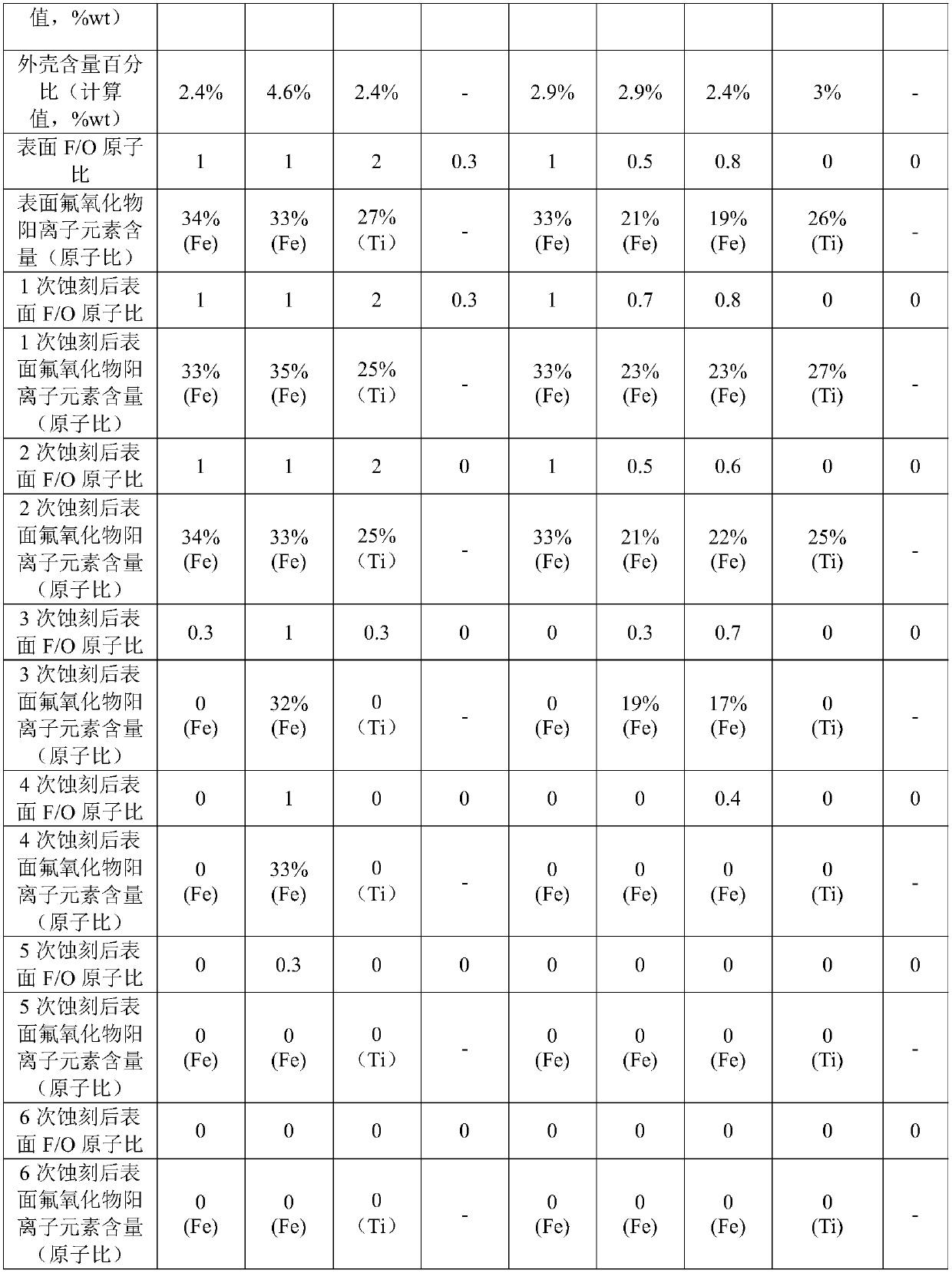

[0063] (1) Preparation of positive electrode C

[0064] First, a positive electrode material with a core-shell structure with a fluorinated inner shell and an oxyfluoride outer shell is prepared, and the positive active material as the core material is LiCoO 2 material, the specific preparation method is, 1000gLiCoO 2 with 30gFeF 3 Put it into a semi-closed reaction vessel with a volume of 5L, add 100mL of deionized water, 100mL of diluted HF solution (anhydrous HF: deionized water = 11.1mL: 88.9mL) and 800mL of ethanol, start stirring, seal and heat to 170°C for reaction until the pressure in the reaction vessel reaches 8×10 6 After Pa (that is, 80 atmospheres), open the pressure reducing valve to ensure that the pressure in the container is 8×10 6 Pa, until the reaction is completed, t...

Embodiment 2

[0073] The same steps as in Example 1 were used to prepare the coated positive electrode material and lithium ion battery of this example, the difference being that:

[0074] In step (1), FeF 3 The dosage is not 30g, but 60g. The 100mL diluted HF solution used has an anhydrous HF: deionized water ratio of 22.2mL: 77.85L. Other steps and operations are the same.

Embodiment 3

[0076] The same steps as in Example 1 were used to prepare the coated positive electrode material and lithium ion battery of this example, the difference being that:

[0077] In step (1), the simultaneous fluorination and TiOF 2 Coated LiCoO 2 Positive electrode material, its preparation method is, with 1000gLiCoO 2 with 30gTiF 4 Put it into a semi-closed reaction vessel with a volume of 5L, add 100mL of deionized water, 100mL of diluted HF solution (anhydrous HF: deionized water = 11.1mL: 88.9mL) and 800mL of ethanol, start stirring, seal and heat to 200°C for reaction until the pressure in the reaction vessel reaches 1×10 7 After Pa (that is, 100 atmospheres), open the pressure reducing valve to ensure that the pressure in the container is 1×10 7 Pa, until the reaction is complete, the simultaneous fluorination and TiOF 2 Coated LiCoO 2 positive electrode material, and then directly use the positive electrode material to assemble a solid-state lithium battery, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com