Patents

Literature

59results about How to "Fine fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

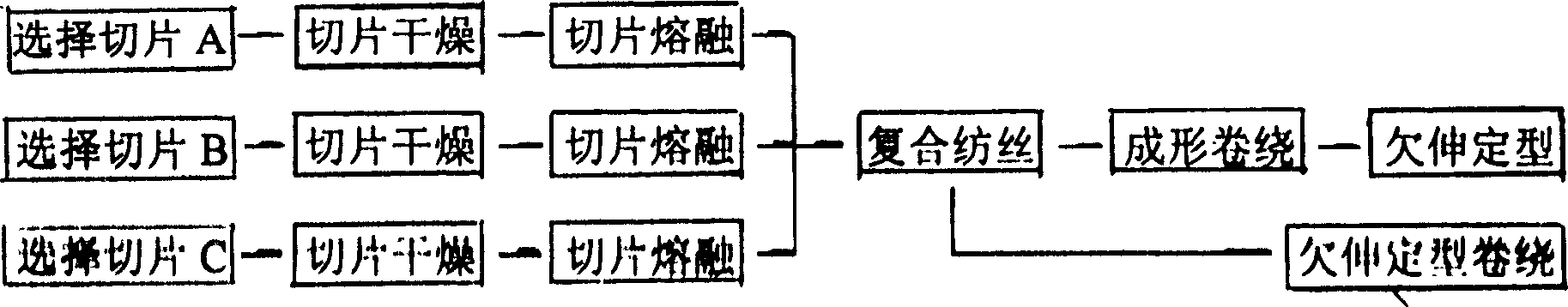

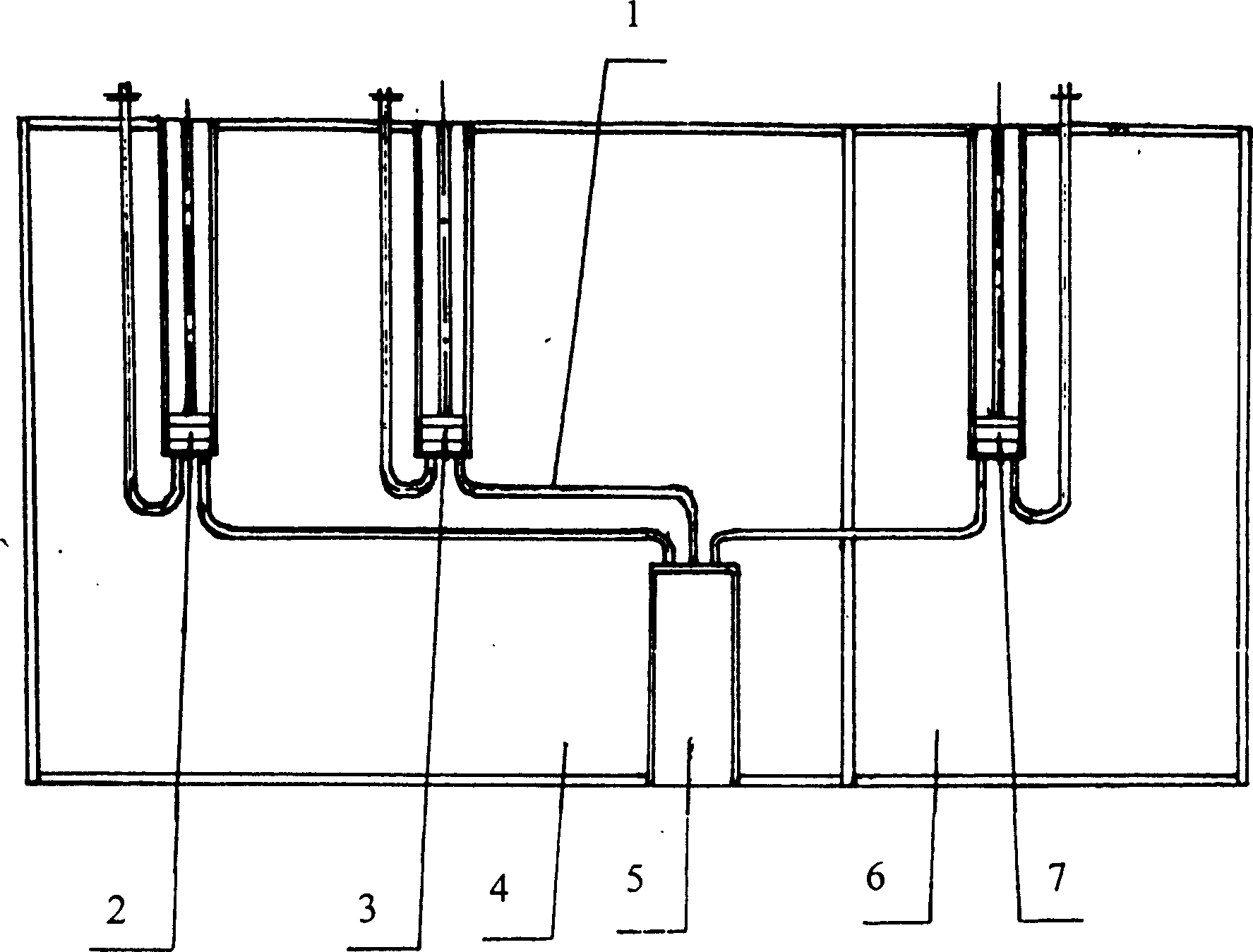

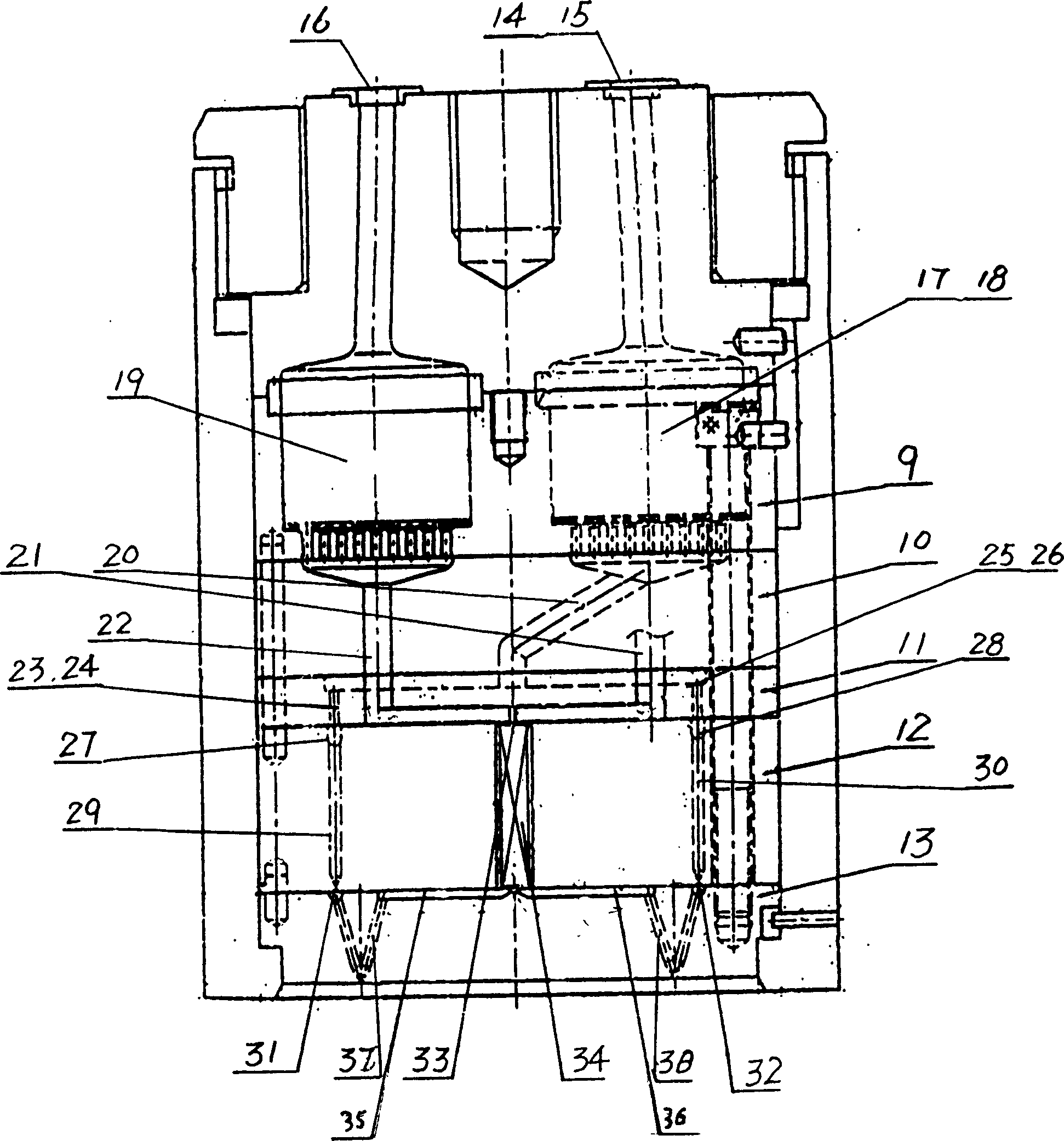

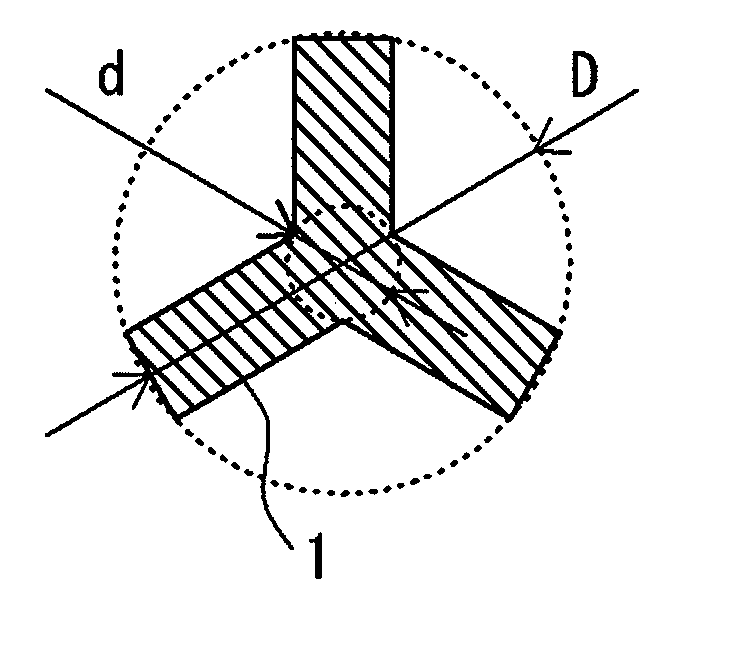

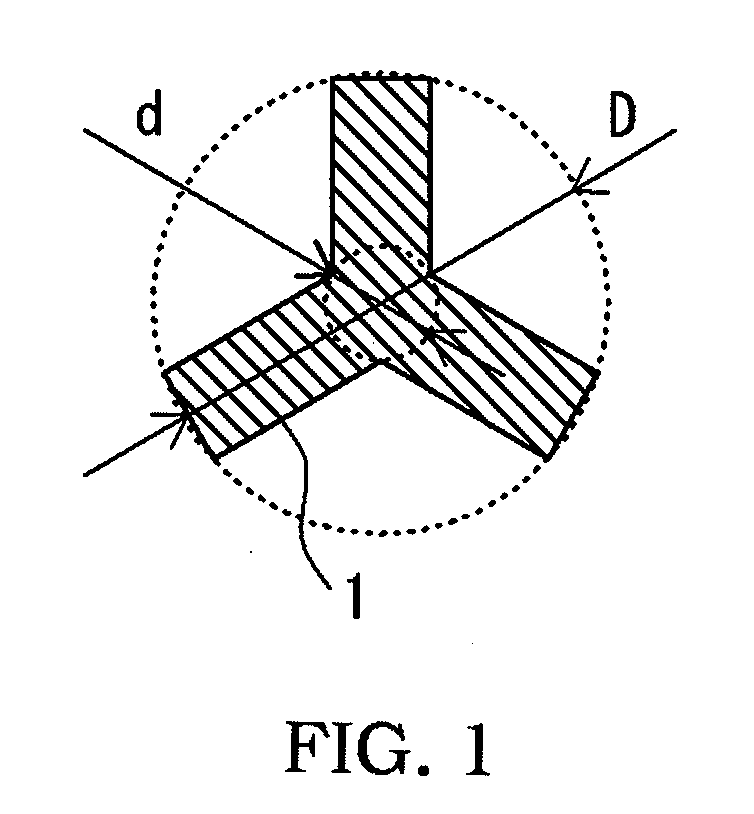

Method for producing three-component self-crimped filament yarn

InactiveCN1676685AFine fiberLow modulusFilament/thread formingConjugated synthetic polymer artificial filamentsEllipseSkin core

This invention is about a kind of producing method of self-curling long filament with superthin structure, with the method of three groups fusing composite spinning. The fibers of the 3 groups are the long fibers with the titer of single fiber 1-6 dtex and the number of pores (12-72)*2. The fibers have at least 7% curling and shrinking percentage after hotly forming and at least 20% curling and shrinking percentage after alkali process. The cross-section of one single fiber is paralleling or eccentric skin-core structural circle, ellipse or snowman. One side of the cross section has fortuitous laminated structure, and the outside fiber ratio is 0.3-0.8 dtex. The producing steps of the self curling long fibers are slice choosing - slice drying - slice fusing - combined spinning - forming curling - drafting to form the shape. By mixing the spinning units and combining the units of big heat shrinking percentage in the paralleling or eccentric skin-core structural way, we can solute the soluble units during the after operation, and separate the outboard fibers of the self curling filaments, making the fibers more slender and modulus smaller. In a word, the curling and shrinking ratio, feeling and amenity have been largely improved.

Owner:SHAOXING GLOBAL CHEM FIBER

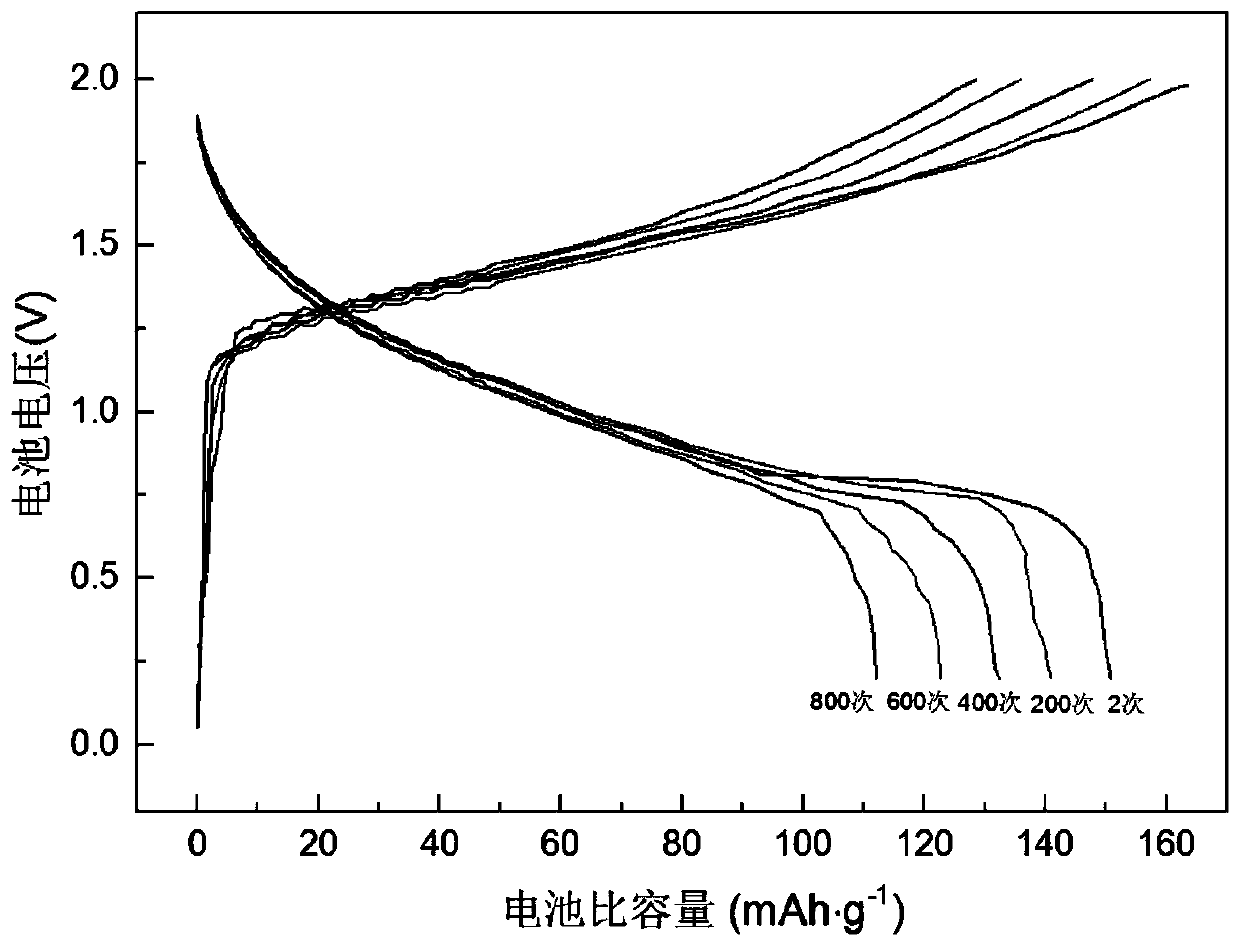

Flexible water system zinc ion battery

ActiveCN110190344AAvoid safety hazardsNot easy to decomposeFinal product manufactureSecondary cellsElectrical batteryDynamic balance

The invention discloses a flexible water system zinc ion battery. The flexible water system zinc ion battery comprises a cathode layer, an anode layer, a current collection layer, a diaphragm and an aqueous electrolyte. The current collection layer comprises a breathable layer and a substrate layer, the substrate layer is provided with at least one opening holes. The perforated structure of the breathable layer and the substrate layer solves the problems of gas generation and electrolyte drying in the battery circulation process, so that the internal and external gaseous water of the battery reaches the states of circulation exchange and dynamic balance, and the circulation performance of the battery is greatly improved; and the assembled flexible water system zinc ion battery has the advantages of light weight, thin thickness, low cost, environmental friendliness, high safety, good rate capability, high power density and the like, and the excellent bending performance and flexibilityof the flexible water system zinc ion battery can meet the bending requirements of different angles, so that the flexible water system zinc ion battery is suitable for large-scale application and industrial production in the field of wearable electronic equipment.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Filter medium, fluid filter, and engine oil filter

InactiveUS20080314821A1Good dispersionImprove filtration efficiencyMembrane filtersMachines/enginesFilter mediaFiber diameter

A filter medium comprises a modified cross-section fiber (A) having a fiber diameter between 40 and 70 μm, an extremely fine fiber (B) having a fiber diameter of more than 5 μm and no more than 10 μm and a modified cross-section fiber (C) having a fiber diameter between 15 and 30 μm, the content of the extremely fine fiber (B) is between 3 and 10% by mass, and the content of the modified cross-section fiber (C) is between 5 and 15% by mass based on 100% by mass of total the fibers in the filter medium.

Owner:TOYOTA BOSHOKU KK +1

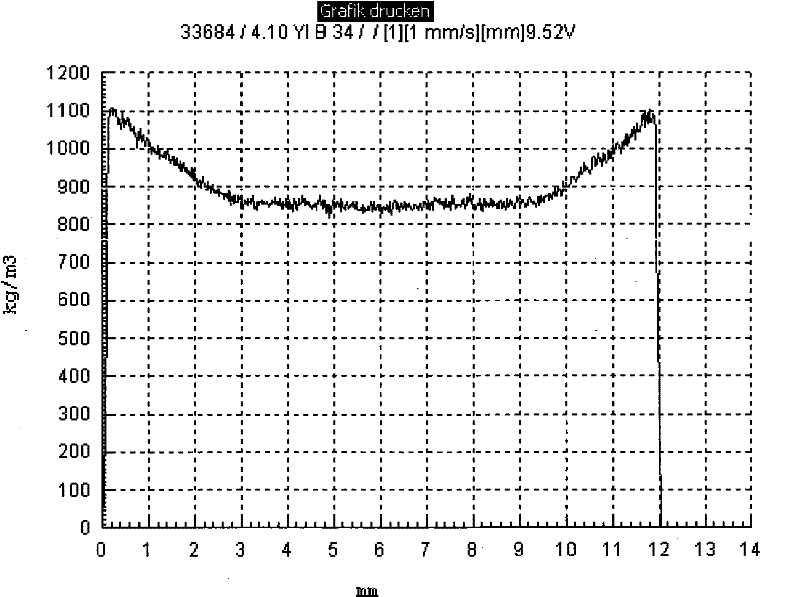

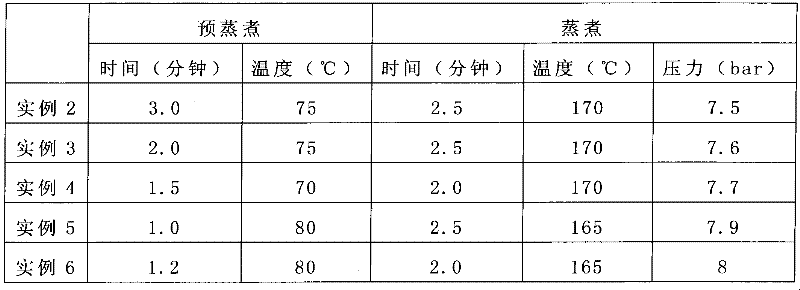

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

Polypropylene resin, fiber, and nonwoven fabric

ActiveUS20090098786A1Improve productivityNovel propertyRotary stirring mixersPaper coatingNonwoven fabricPolypropylene

A polypropylene resin having: (1) a melt flow rate (MFR) of 6 to 100 g / 10 minutes, (2) a molecular weight distribution (Mw / Mn), measured by gel permeation chromatography, of 3 to 6, and (3) a 116° C. non-eluted component content (100-W116(%)) of 50% or more and a content of components eluted at 90° C. or less (W90) of 10 to 30%, measured by temperature-rising fractional chromatography (TREF).

Owner:IDEMITSU KOSAN CO LTD

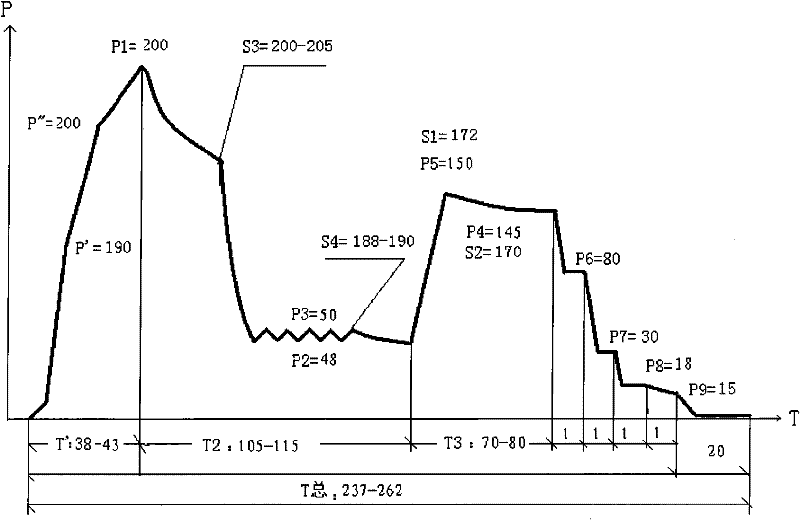

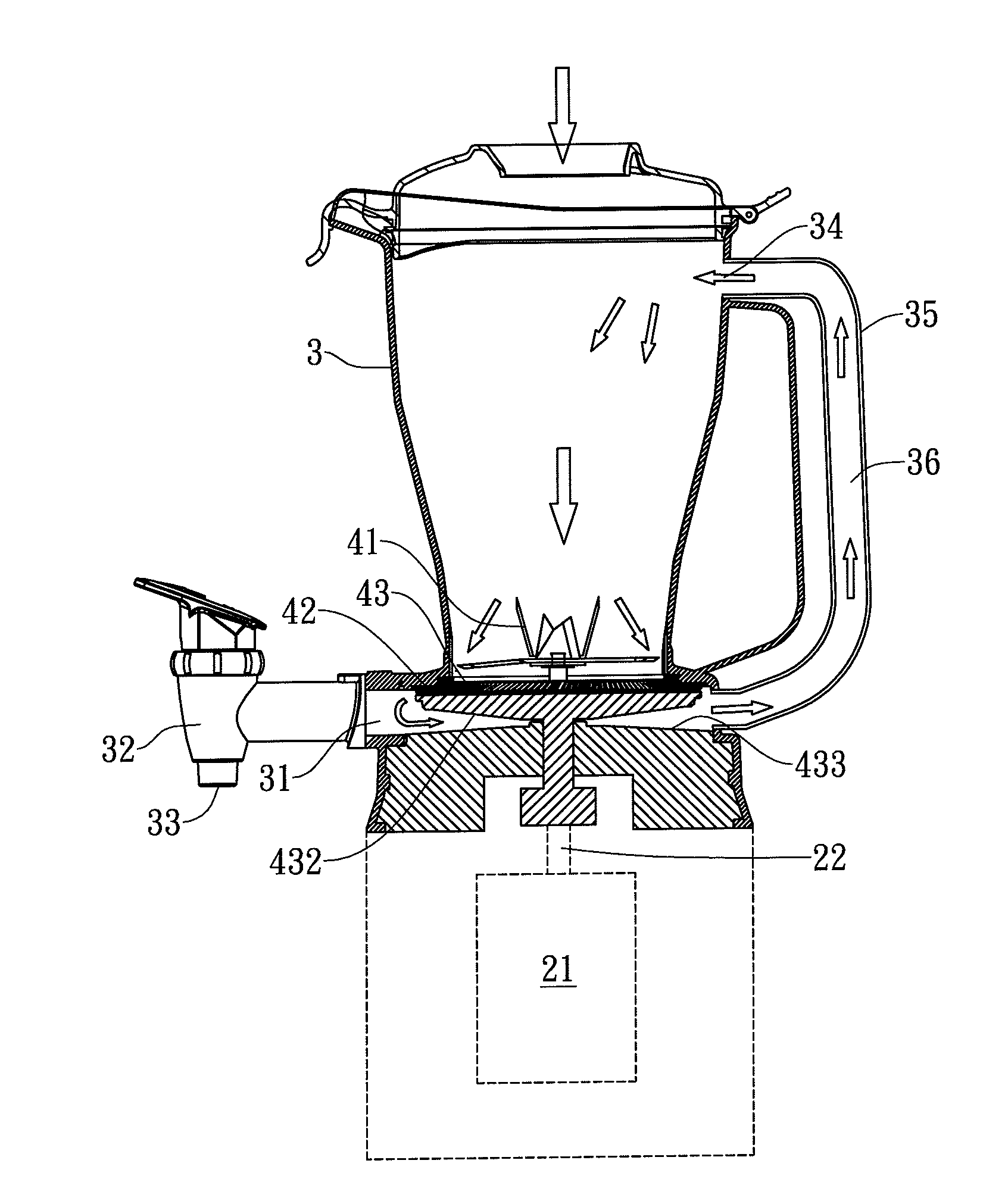

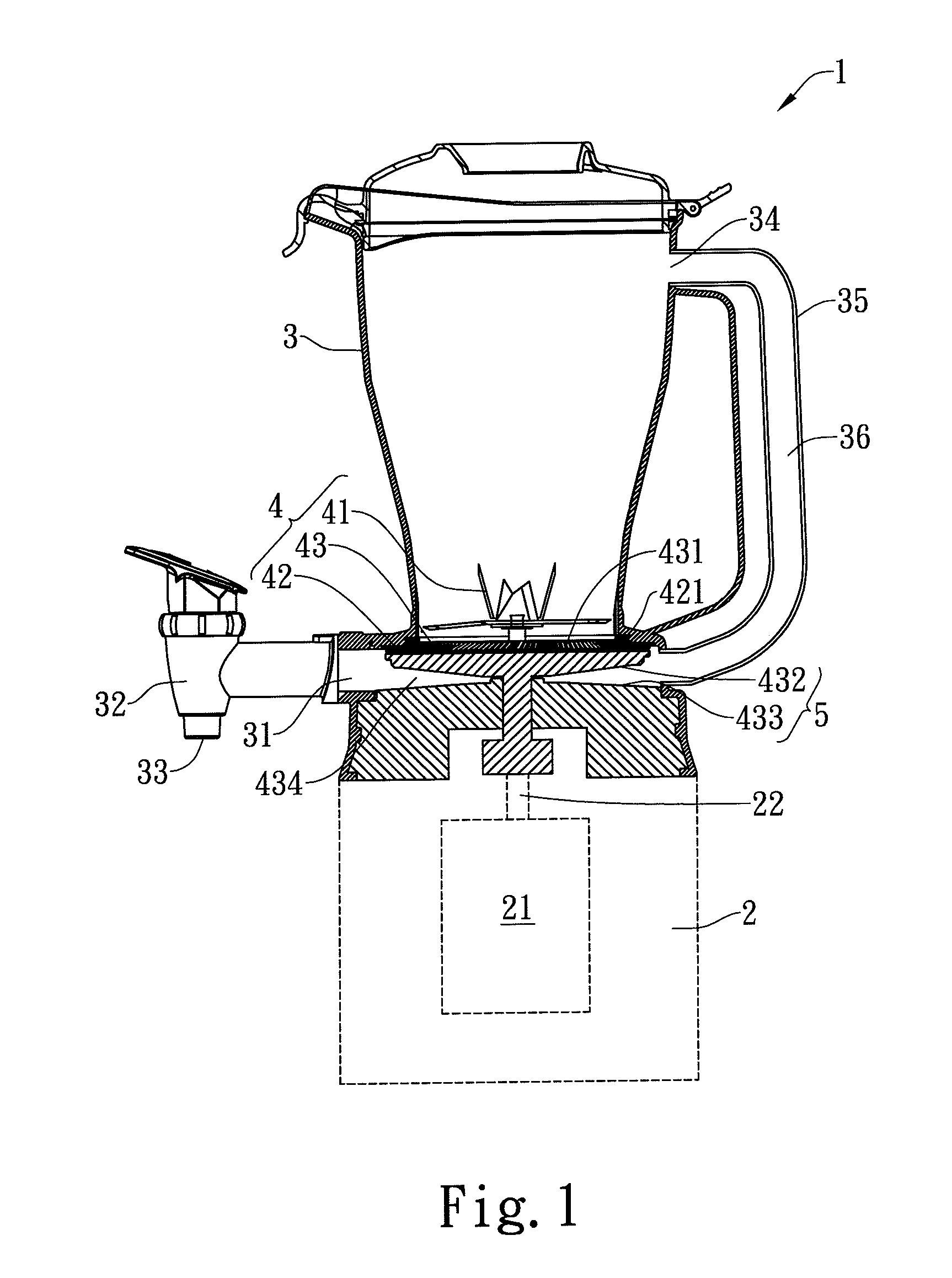

Circulating processor

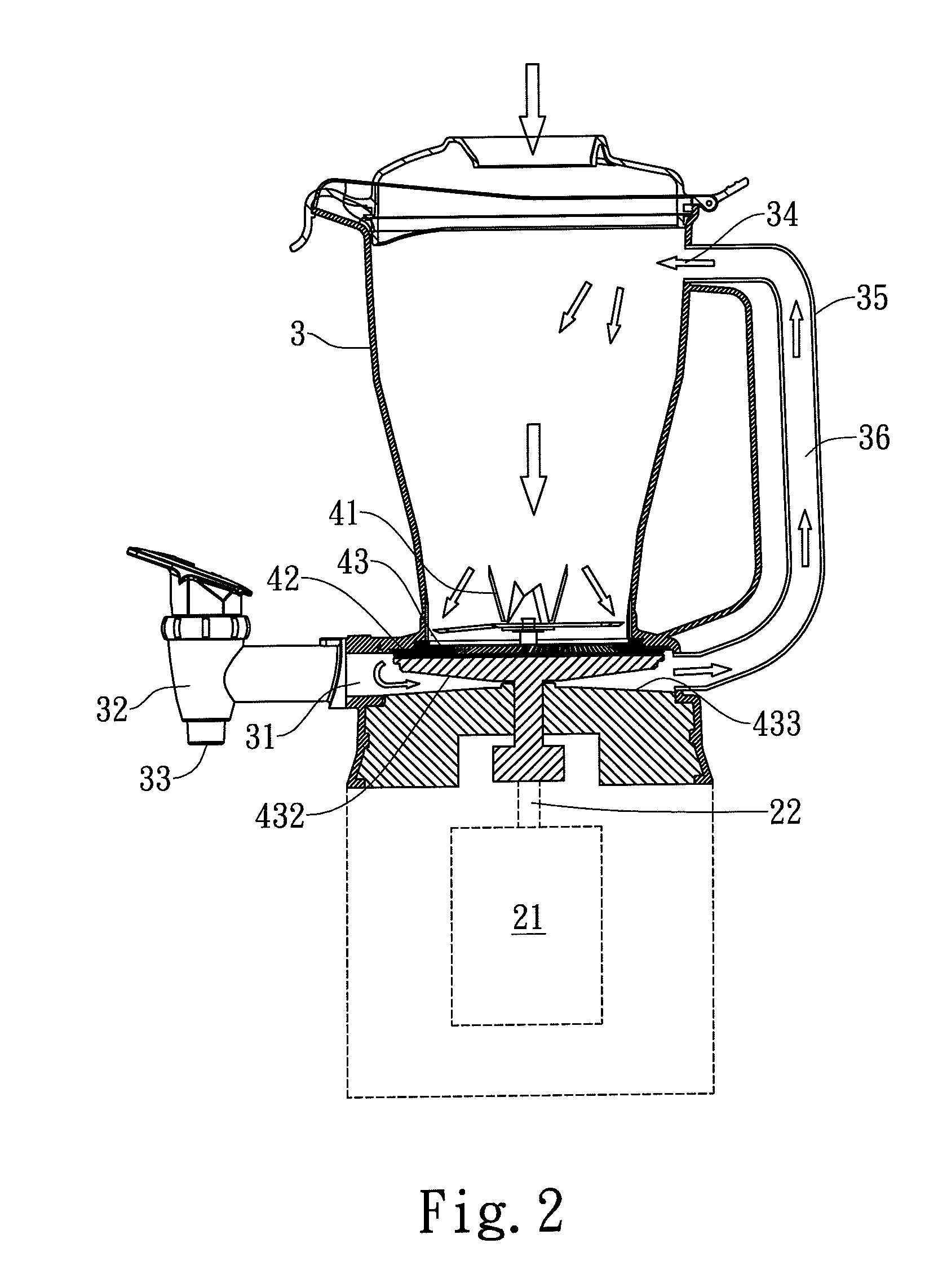

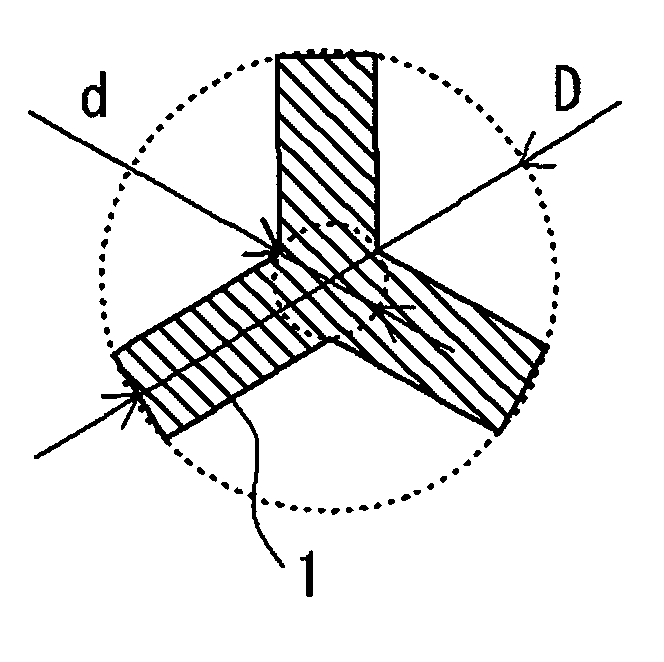

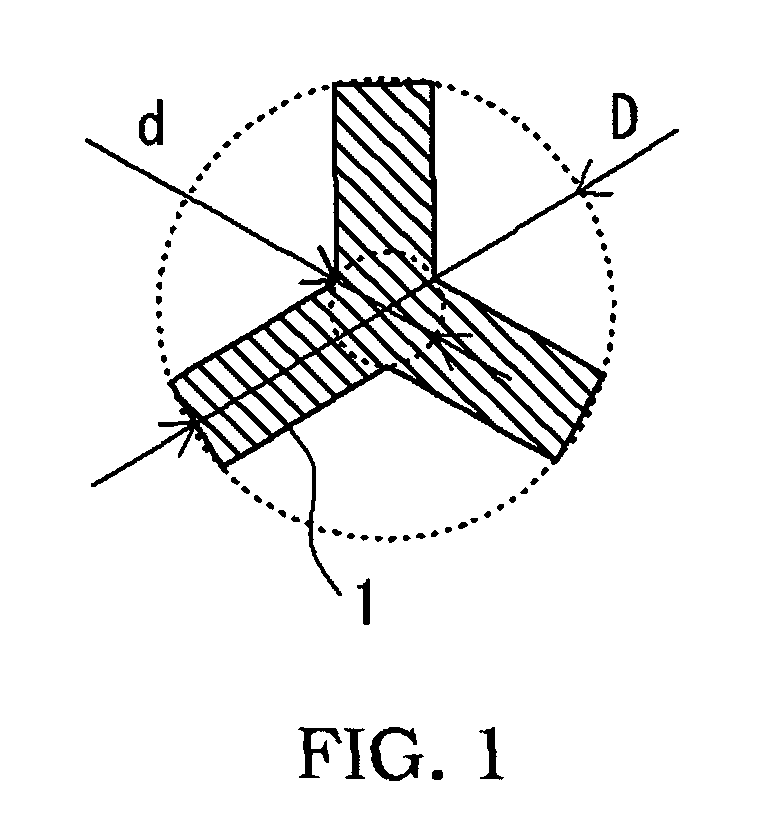

InactiveUS20130256437A1Improve saccharification efficiencyPromote absorptionGrain treatmentsStrainersRefluxEngineering

A circulating processor includes a base, a container, a cutlery and a pressurizing mechanism. An operating motor is disposed in the base and is disposed with a mandrel therein. The container is disposed above the base, where a space is formed on its bottom part, and a reflux opening is formed on its upper half part and in communication with the space. The cutlery is positioned on the container's bottom part and connected to the mandrel. Thereby, when the operating motor operates, the mandrel and the cutlery are enabled to rotate synchronously, to mash food, vegetables and fruits in the container. The pressurizing mechanism is in communication with the space of the container. Through the pressurizing effect of the pressurizing mechanism, the mashed food, vegetables and fruits can be transferred into the container via the reflux opening, so as to perform circulating mashing treatment.

Owner:LIN WEI CHIH

Filter medium, fluid filter, and engine oil filter

InactiveUS7987996B2Improve efficiencyProlong lifeMembrane filtersLoose filtering material filtersFiberFilter media

A filter medium comprises a modified cross-section fiber (A) having a fiber diameter between 40 and 70 μm, an extremely fine fiber (B) having a fiber diameter of more than 5 μm and no more than 10 μm and a modified cross-section fiber (C) having a fiber diameter between 15 and 30 μm, the content of the extremely fine fiber (B) is between 3 and 10% by mass, and the content of the modified cross-section fiber (C) is between 5 and 15% by mass based on 100% by mass of total the fibers in the filter medium.

Owner:TOYOTA BOSHOKU KK +1

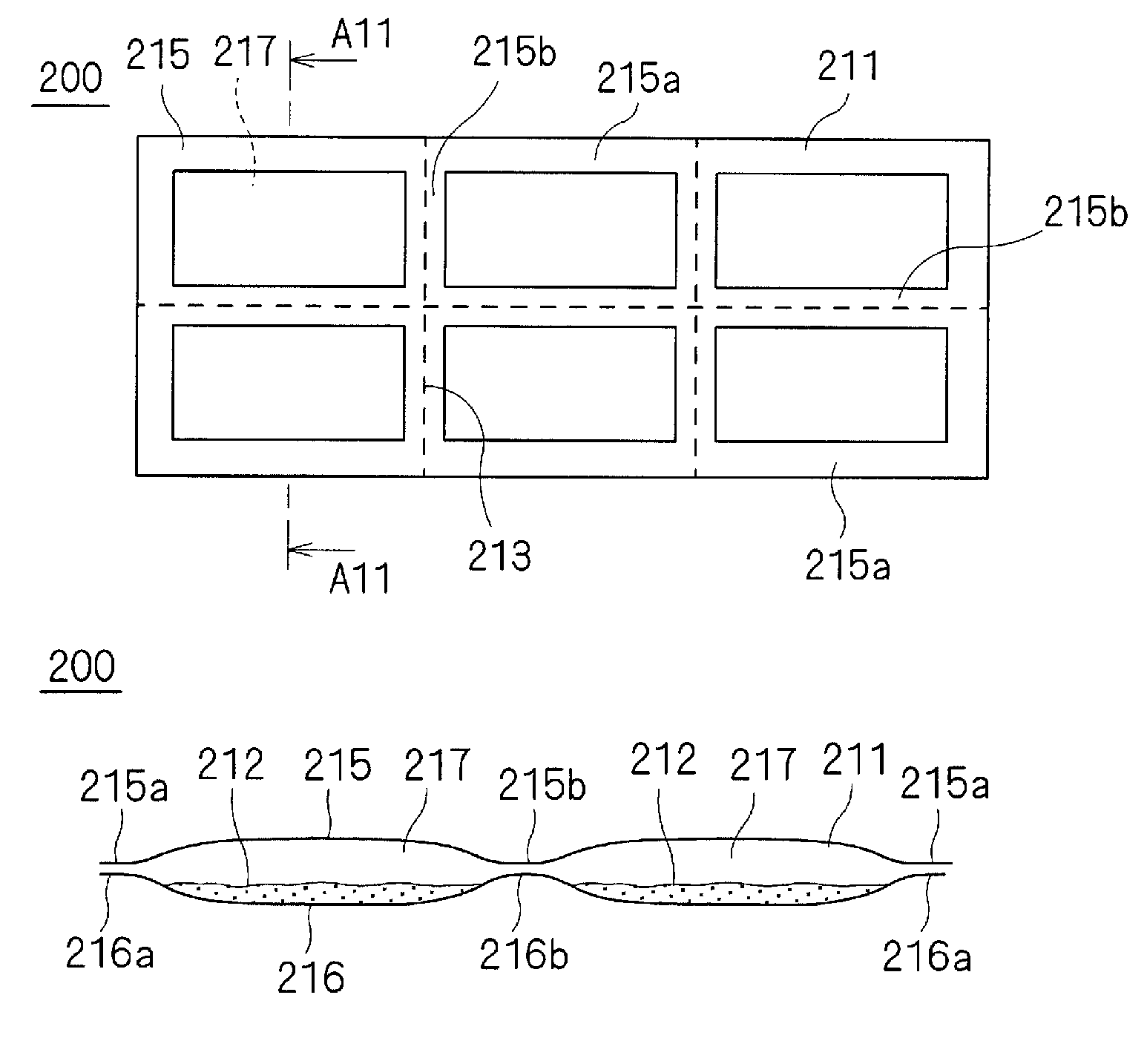

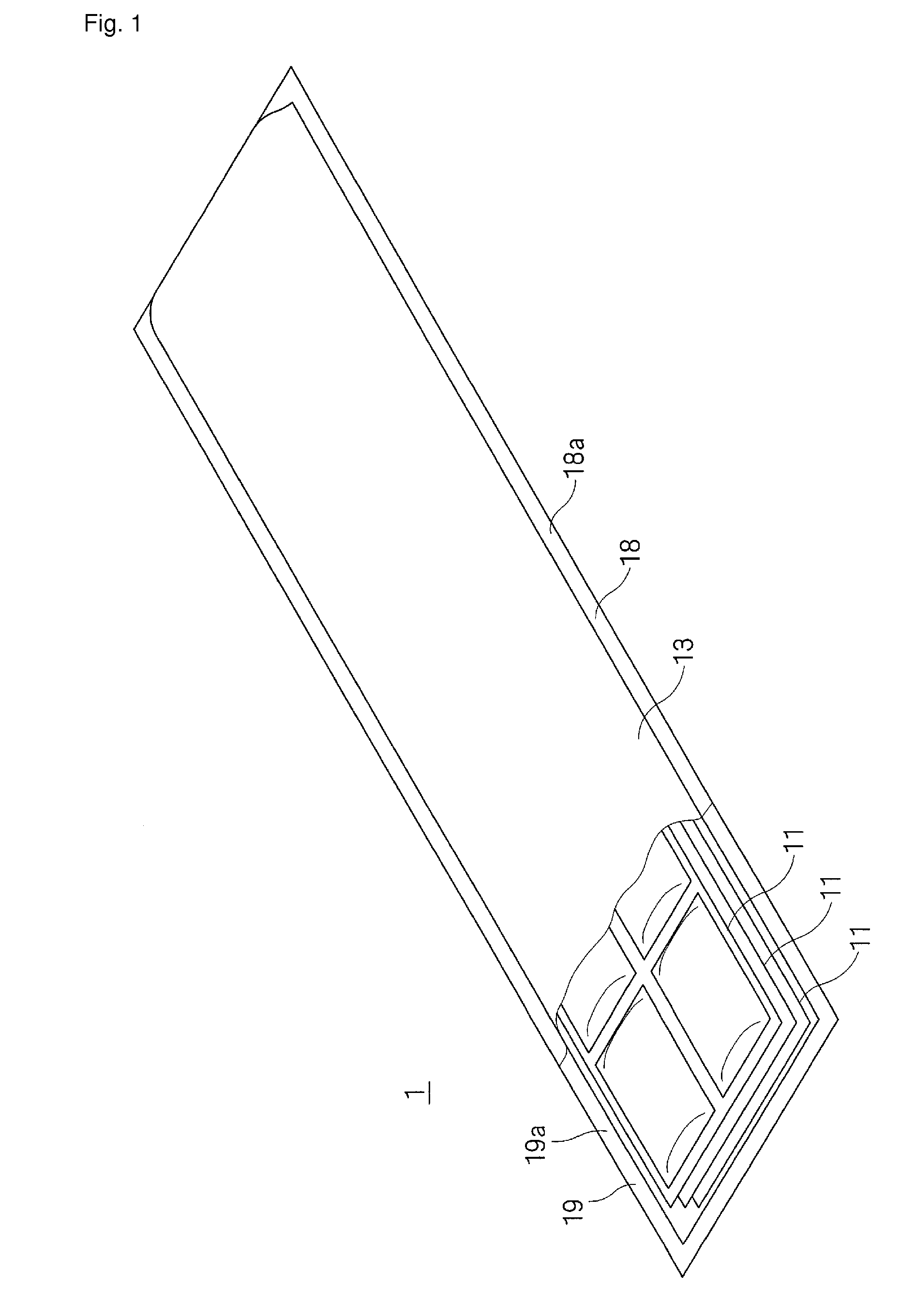

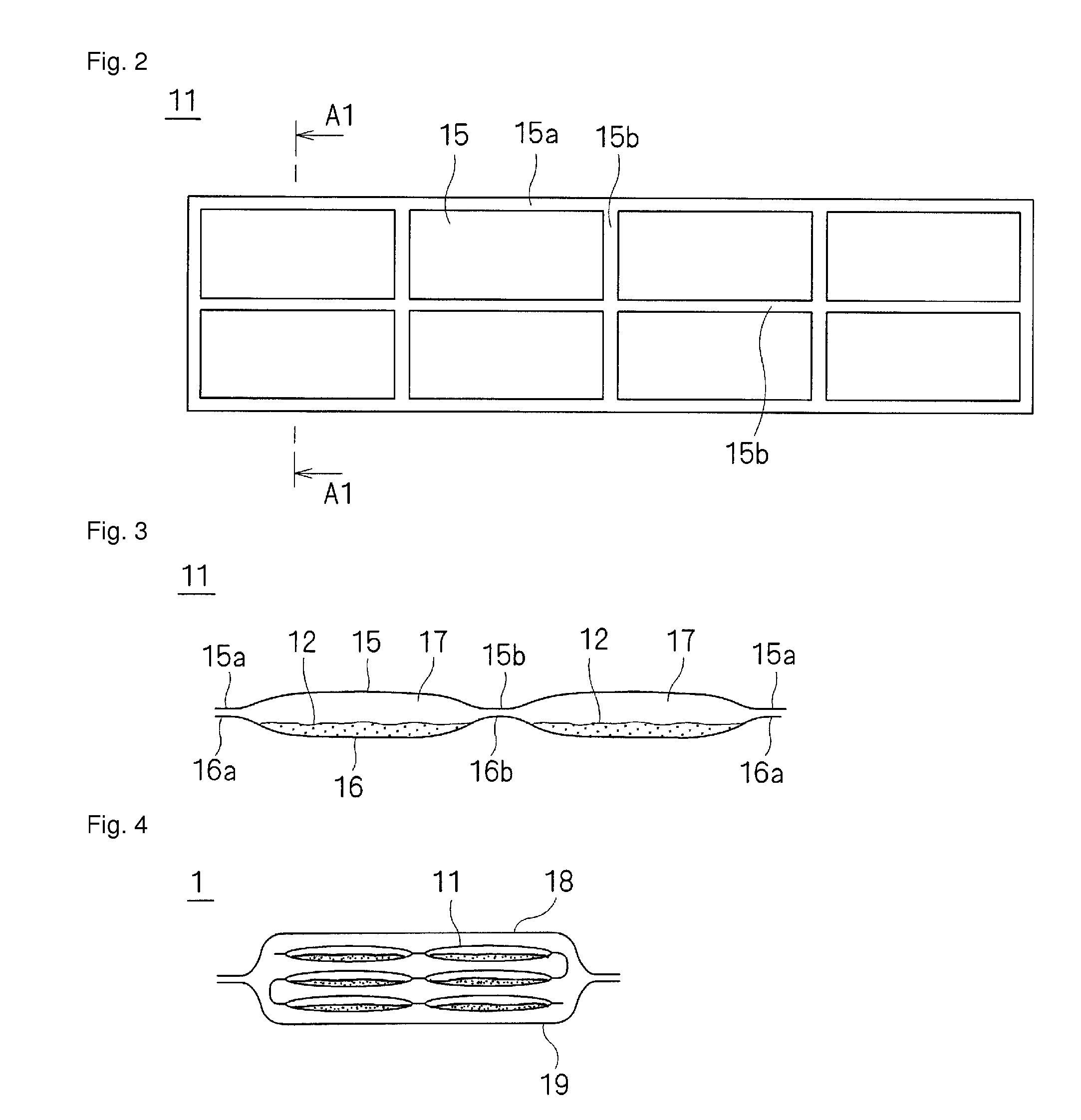

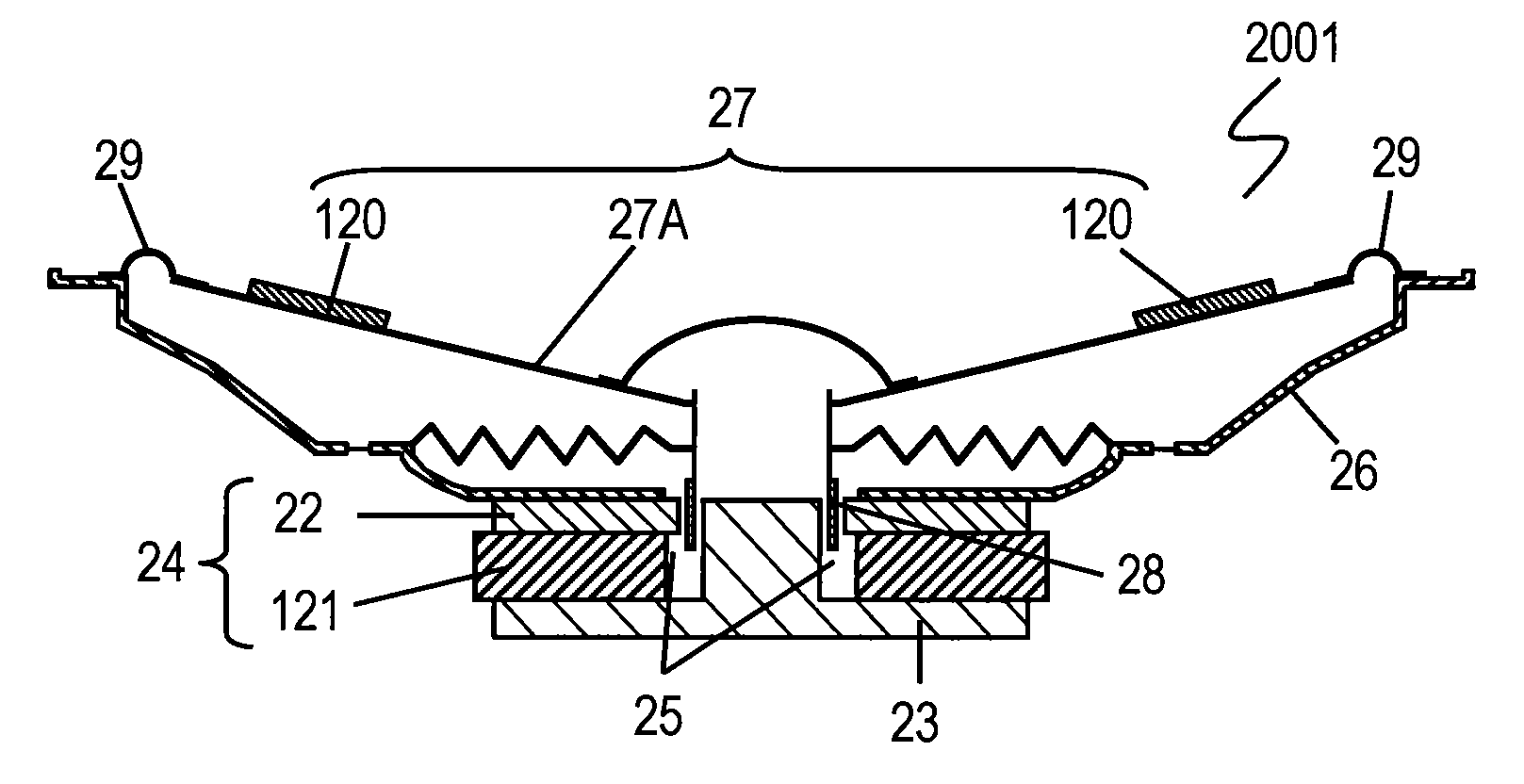

Absorbent article

The present invention provides an absorbent article that allows full use of the absorption performance of an absorbent polymer without inhibiting the swelling of the absorbent polymer due to the absorption of excreted body fluids, and that can be biodegraded with efficiency when it is disposed after use by burial in the soil or the like. The absorbent article includes at least one inner bag-like member, an absorbent polymer, and an outer bag-like member. The inner bag-like member is formed into a thin and substantially sheet-like form of a sheet having biodegradability and fluid permeability, and includes multiple accommodation spaces that are detached from the outside and separated from one another. The absorbent polymer has biodegradability and a substantially granular or powder form and is contained in each of the accommodation spaces in the inner bag-like member so as to be freely movable within the accommodation spaces.

Owner:LIVEDO CORP

Compound meat tendering salt and meat tendering method

InactiveCN106262763AReduce implicative effectPrevent oxidationFood ingredient as antioxidantMeat/fish preservationFiberIodised salt

The invention provides compound meat tendering salt and a meat tendering method. The compound meat tendering salt is prepared from, by weight, 0.2-2 parts of papain, 0.5-2 parts of calcium gluconate, 2-5 parts of sodium malate, 75-85 parts of starch and 15-25 parts of iodized salt. According to the method, the compound meat tendering salt is prepared into a compound meat tendering salt water solution with the mass concentration of 10-30%, and meat and the compound meat tendering salt water solution are mixed according to the mass-volume ratio of 1 g to 3-5 ml and are salted at the temperature of 40-70 DEG C for 10-20 minutes. Meat tendering treatment is conducted on meat by adopting the compound meat tendering salt, the protein in the meat can be moderately degraded, the implication effect of fiber texture is reduced, the meat density and toughness can be reduced, the salted meat can be easy to shear, elasticity is not lost, and the meat has a good taste.

Owner:重庆合川盐化工业有限公司

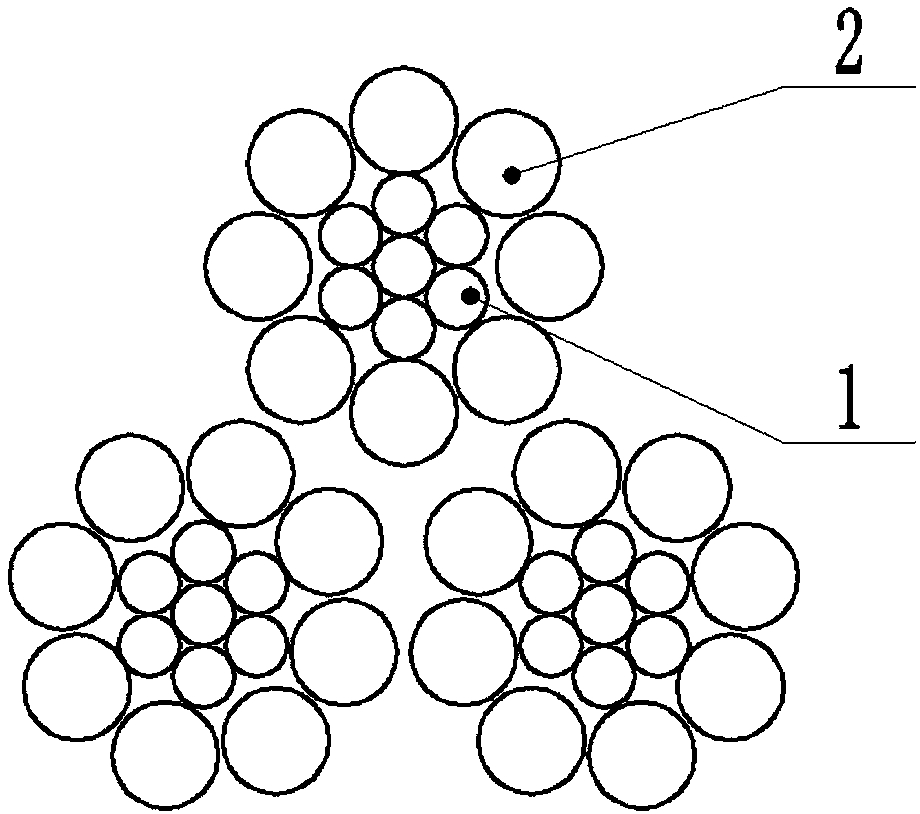

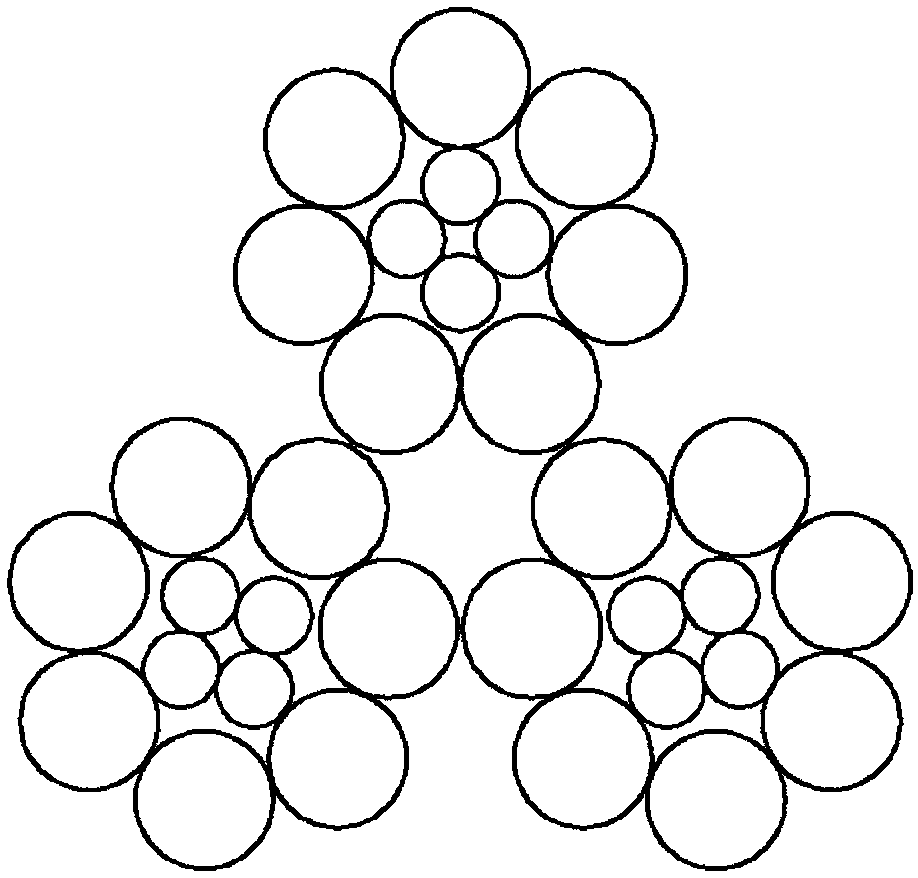

Wire rope composite fiber core and production method and application thereof

The invention relates to a wire rope composite fiber core and a production method and application thereof. The wire rope composite fiber core is formed by singly twisting multiple composite fiber cores; the single strand of each composite fiber core includes a jute main core and a polypropylene outer core; multiple polypropylene yarns form the polypropylene outer core evenly covering the outer side of the jute main core. The jute yarn is used to replace sisal yarn to produce the wire rope core, and the problem of high core diameter fluctuations is avoided; the jute core has uniform diameter and good oil absorption, and operational vibration and noise of an elevator are effectively relieved; yarn fracture rate of a whole rope is better than that of a rope with a sisal core; by using the composite structure of the polypropylene yarn outer core twisted to the jute main core, the defect that the jute fiber is less than sisal fiber in fiber strength, and the strength of the composite fibercore is better than that of the sisal core.

Owner:海城正昌工业有限公司

Preparation method of SiC continuous fiber reinforced titanium-based composite, and product

The invention discloses a preparation method of a SiC continuous fiber reinforced titanium-based composite, and a product. The preparation method comprises the following steps that a SiC continuous fiber with the diameter being 10-15 [mu]m is placed in the air environment to be subjected to heat treatment, then, with the SiC continuous fiber as a base material, Al2O3 is sputtered on the surface ofthe SiC continuous fiber through magnetron sputtering, and thus the SiC continuous fiber covered with an Al2O3 coating is obtained; a titanium or titanium alloy base body is heated to be melted, andthus a melted titanium or titanium alloy solution is obtained; the SiC continuous fiber covered with the Al2O3 coating is placed in a mould, preheating is conducted, and the mould is vacuumized; and the melted titanium or titanium alloy solution is pressed into the mould, heat preservation and cooling are conducted, and thus the SiC continuous fiber reinforced titanium-based composite is obtained.The filament SiC continuous fiber is adopted as the reinforcing base material, and the magnetron sputtering technology and a vacuum pressure impregnation method are combined, so that the prepared SiCcontinuous fiber reinforced titanium-based composite has the advantages that the structure is compact, the mechanical property is high, the interface stable property is good, and the service life islong.

Owner:CENT SOUTH UNIV

Method for preparing cotton stalk skin fiber through steam explosion and laccase combined treatment

InactiveCN104047062AFine fiberEasy to processMechanical fibre separationFibre treatment to obtain bast fibreFiberEngineering

The invention relates to a method for preparing a cotton stalk skin fiber through steam explosion and laccase combined treatment. The method comprises the steps of firstly adopting the steam explosion method for separating cotton stalk skin, then using laccase generated by white-rot fungi for treating the fiber obtained after explosion, and finally using amino silicon oil for softening the cotton stalk skin fiber. The technological process comprises the steps of mechanical cotton stalk skin cutting, soaking, steam explosion, hot water cleaning, laccase treatment, high temperature inactivation, washing, lubricating treatment, washing, airing, combing and cotton stalk skin fiber obtaining. The explosion time of a steam explosion test stand is quite short and is 0.0875 s, and the acting force on fiber separation during the explosion moment is large. Due to the fact that the steam explosion is mainly used for removing hemicellulose and pectin, the lignin content is still high, the laccase generated by the white-rot fungi is selected for further degrading lignin in the cotton stalk skin fiber, and the method for preparing the cotton stalk skin fiber through steam explosion and laccase combined treatment has the advantages of being mild in action condition, high in specificity, free of environment pollution and the like compared with a traditional alkali treatment method.

Owner:JIANGNAN UNIV

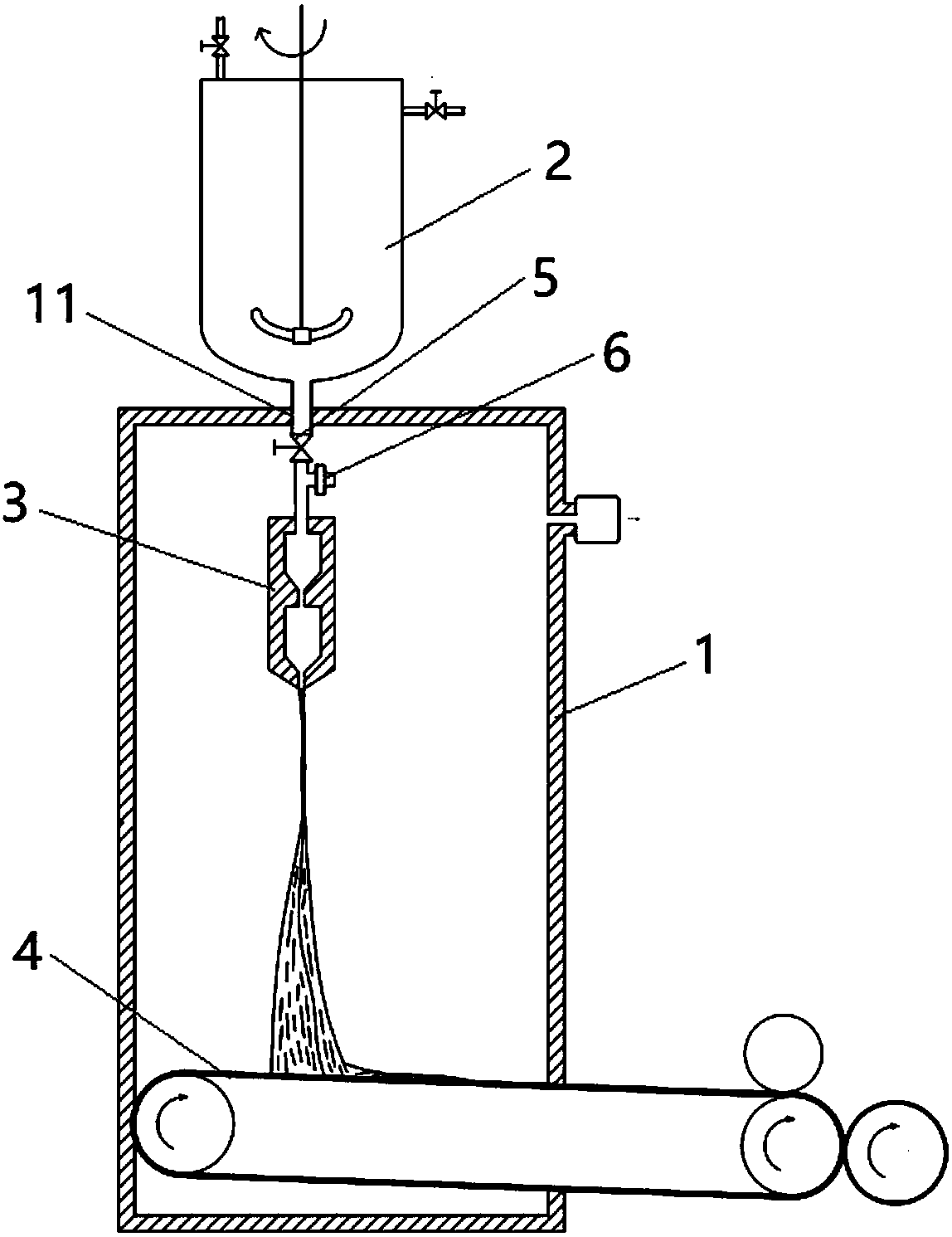

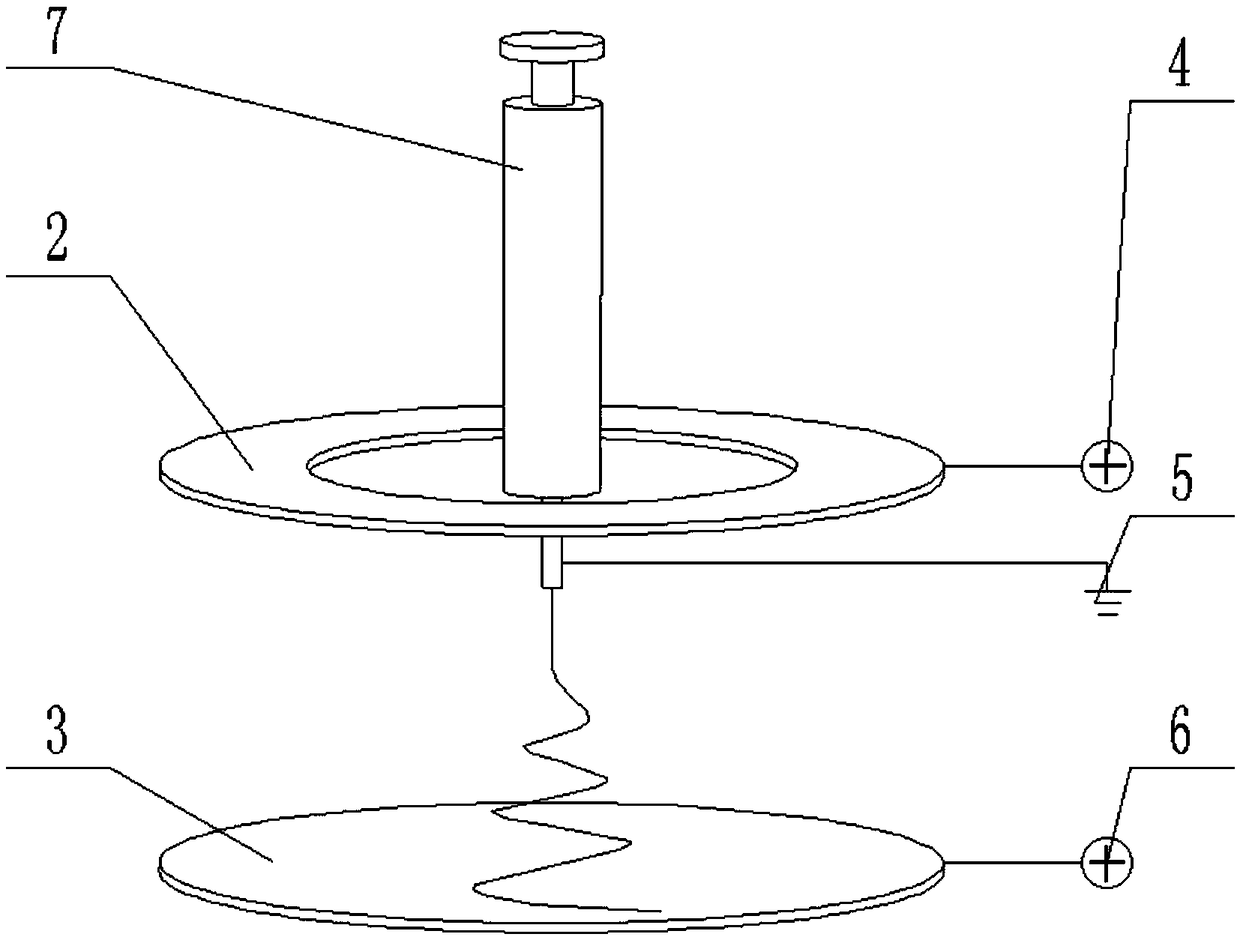

PPS (polyphenylene sulfide) flashing equipment and spinning method thereof

ActiveCN110129907AFine fiberHigh strengthArtificial thread manufacturing machinesNon-woven fabricsFiberProcess engineering

The invention discloses PPS (polyphenylene sulfide) flashing equipment. The equipment comprises a box, a spinning nozzle, a high-pressure reactor and a conveying device, wherein a spinning solution inlet is formed in the box, the spinning nozzle is arranged in the box, the bottom end of the high-pressure reactor is connected with the spinning nozzle through the spinning solution, and the conveyingdevice is arranged at the bottom of the box. The equipment also comprises an adjusting valve and an interceptor which are sequentially arranged above the spinning nozzle. Besides, the invention discloses a flash spinning method of PPS. A PPS polymer and a flash spinning process are combined for the first time to produce PPS flashed non-woven fabric, and fine-fiber and high-strength PPS non-wovenfabric is formed.

Owner:XIAMEN DANGSHENG NEW MATERIAL CO LTD

Method for producing protein feed by utilizing bagasse

The invention discloses a method for producing a protein feed by utilizing bagasse. The protein feed is prepared from bagasse, molasses, corn flour, soybean meal, bran, rice bran, Chinese medicinal materials and a composite fermentation bacterial agent. The domestication bacteria used in the method for producing the protein feed by utilizing bagasse are from nature and obtained through enrichment,screening and domestication, have super strong cellulose decomposition capability. The prepared composite fermentation bacterial agent has high fermentation efficiency and good stability, can effectively reduce the crude fiber content of raw materials such as bagasse, rice bran and the like, so the high molecular carbohydrate which is difficult to be fully digested and absorbed by animals such ascrude fiber, lignin and the like is converted into low molecular substances which can be absorbed and utilized, the digestion and utilization rate of the animals is improved, the prepared fermented feed is more comprehensive in nutrition and higher in feed conversion rate, meanwhile, the content of crude protein in the fermented feed is improved, the nutrition and palatability of the feed are improved, the use of antibiotics can be avoided in the fermentation process, and the feed is safe and environment-friendly.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

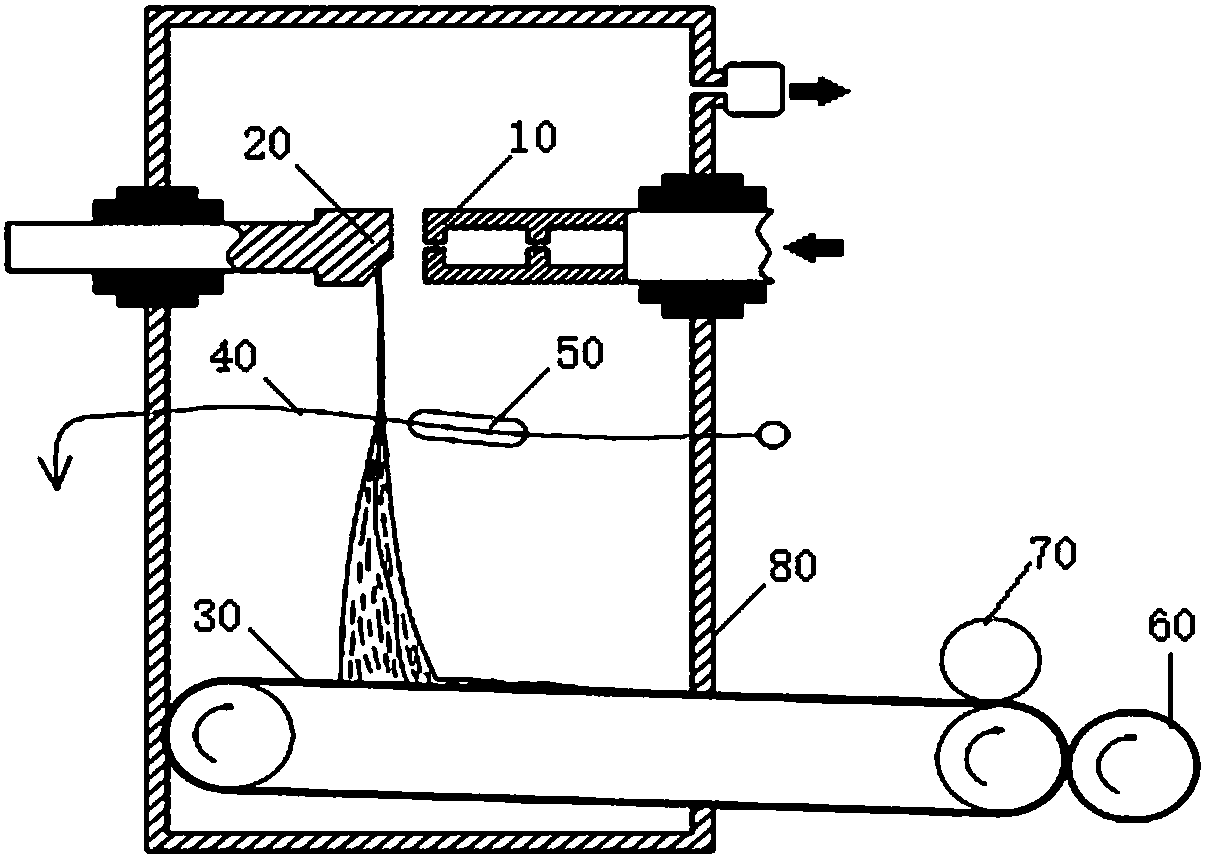

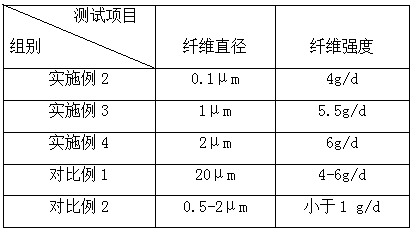

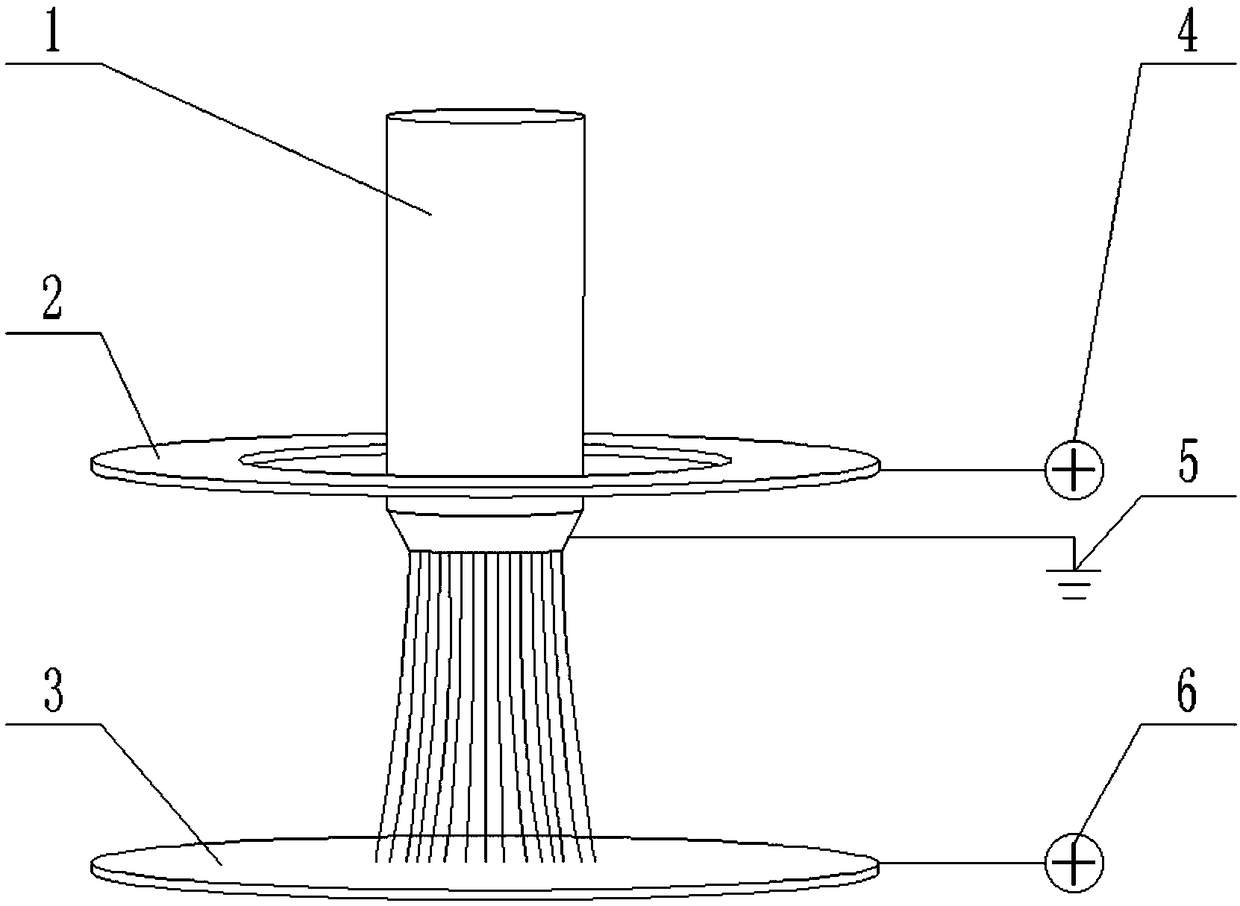

Induction field intensity enhancement device and method for tip of electrostatic spinning spray head

ActiveCN109487348AReduced risk of breakdownImprove equipment safety and operational continuityFilament/thread formingElectrospinningElectric field

The invention discloses an induction field intensity enhancement device and method for the tip of an electrostatic spinning spray head, and belongs to the field of electrostatic spinning. The induction field intensity enhancement device mainly comprises a spinning spray head, a first electrode plate, a second electrode plate, a first high-voltage electrode, a grounding electrode and a second high-voltage electrode, wherein the first electrode plate is perforated and penetrates through the spinning spray head, and is flush with the tip of the spinning spray head or is arranged at the same sideat a certain distance from the tip, the second electrode plate is arranged at the opposite side at a certain distance from the tip of the spinning spray head, the spinning spray head is connected withthe grounding electrode, the first electrode plate is connected with the first high-voltage electrode, the second electrode plate is connected with the second high-voltage electrode, two electrifiedelectrode plates make the spray head electrified through induction, formed electric fields are superposed, so that the induction field intensity of the tip of the electrostatic spinning spray head isenhanced, and it can be achieved that two weaker applied voltages are utilized, the induction field intensity of the tip of the spray head is increased while the breakdown risk is reduced, thereby achieving the purposes of further reducing the fiber diameter and increasing the jet flow number of the spinning spray head.

Owner:QINGDAO UNIV OF SCI & TECH

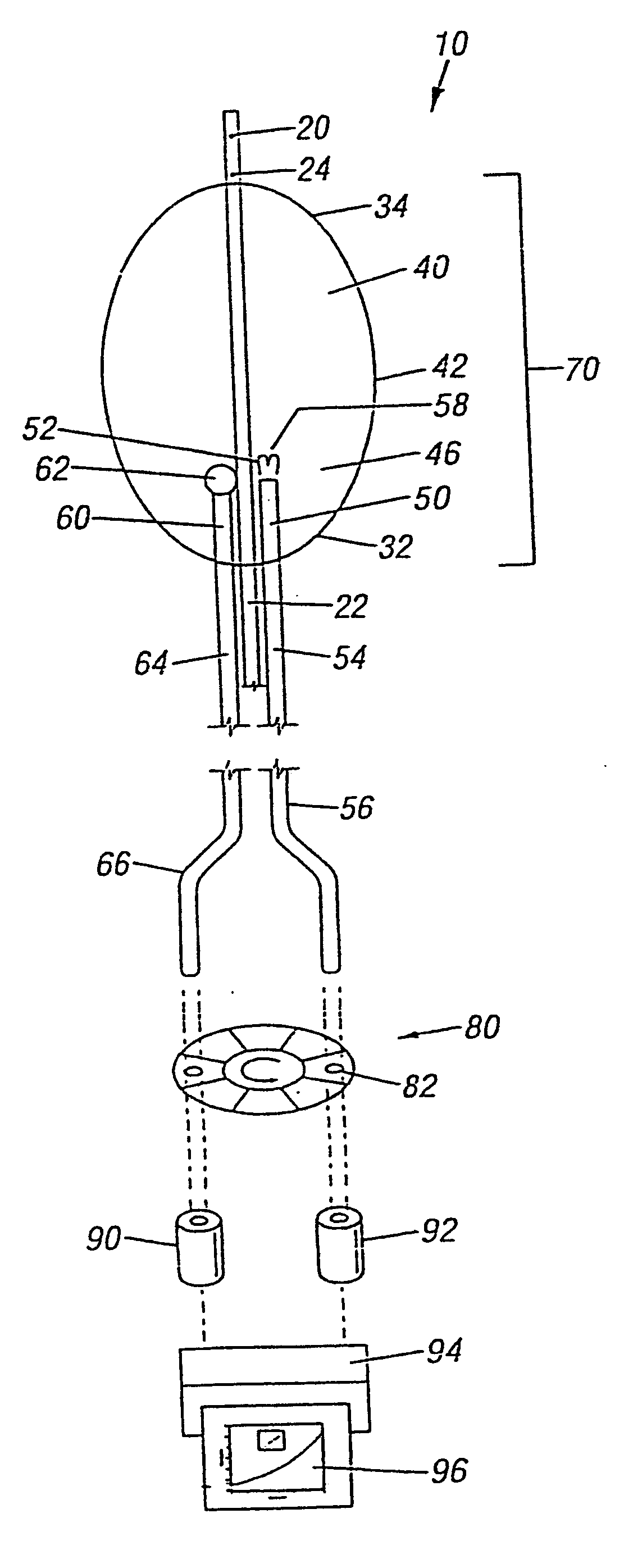

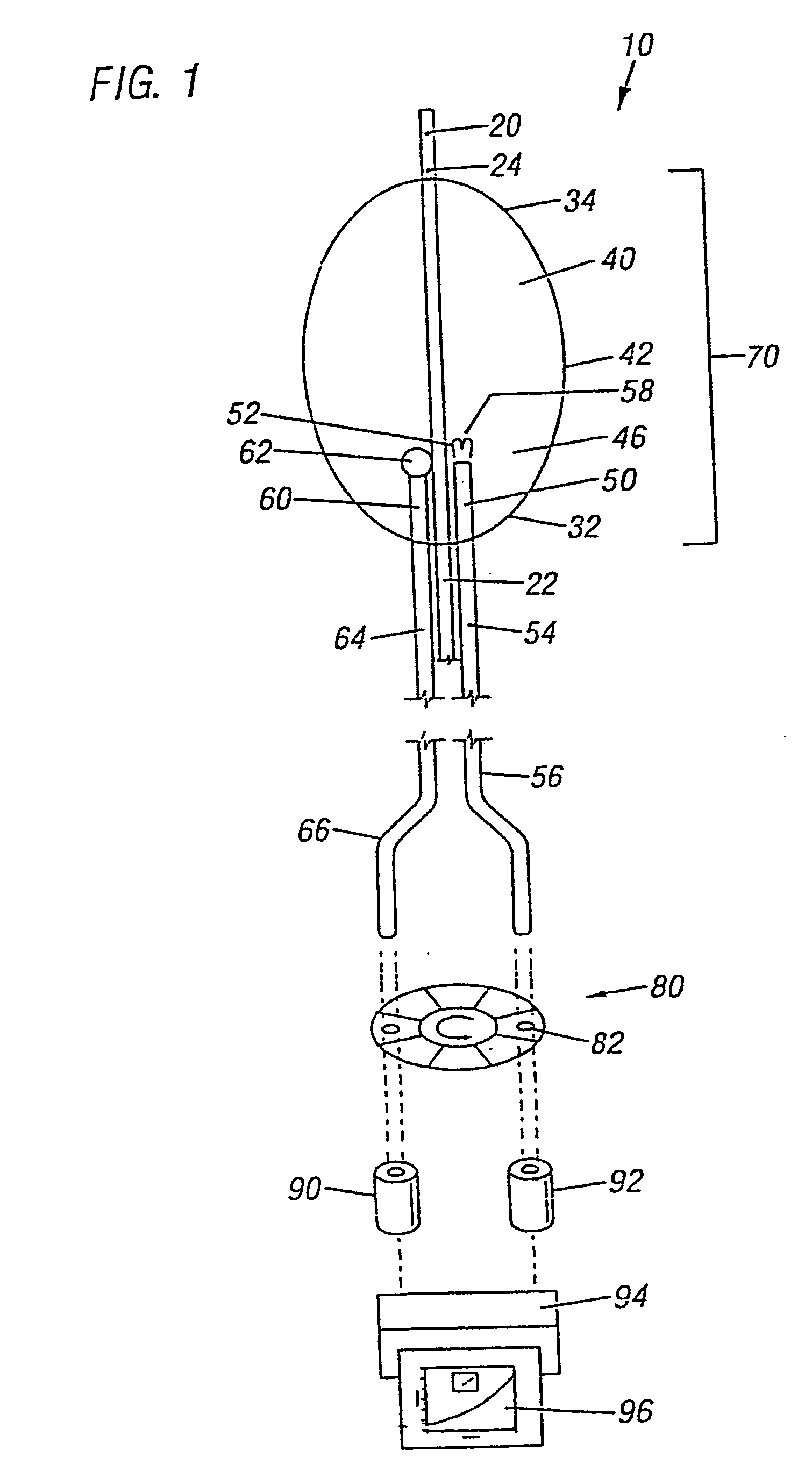

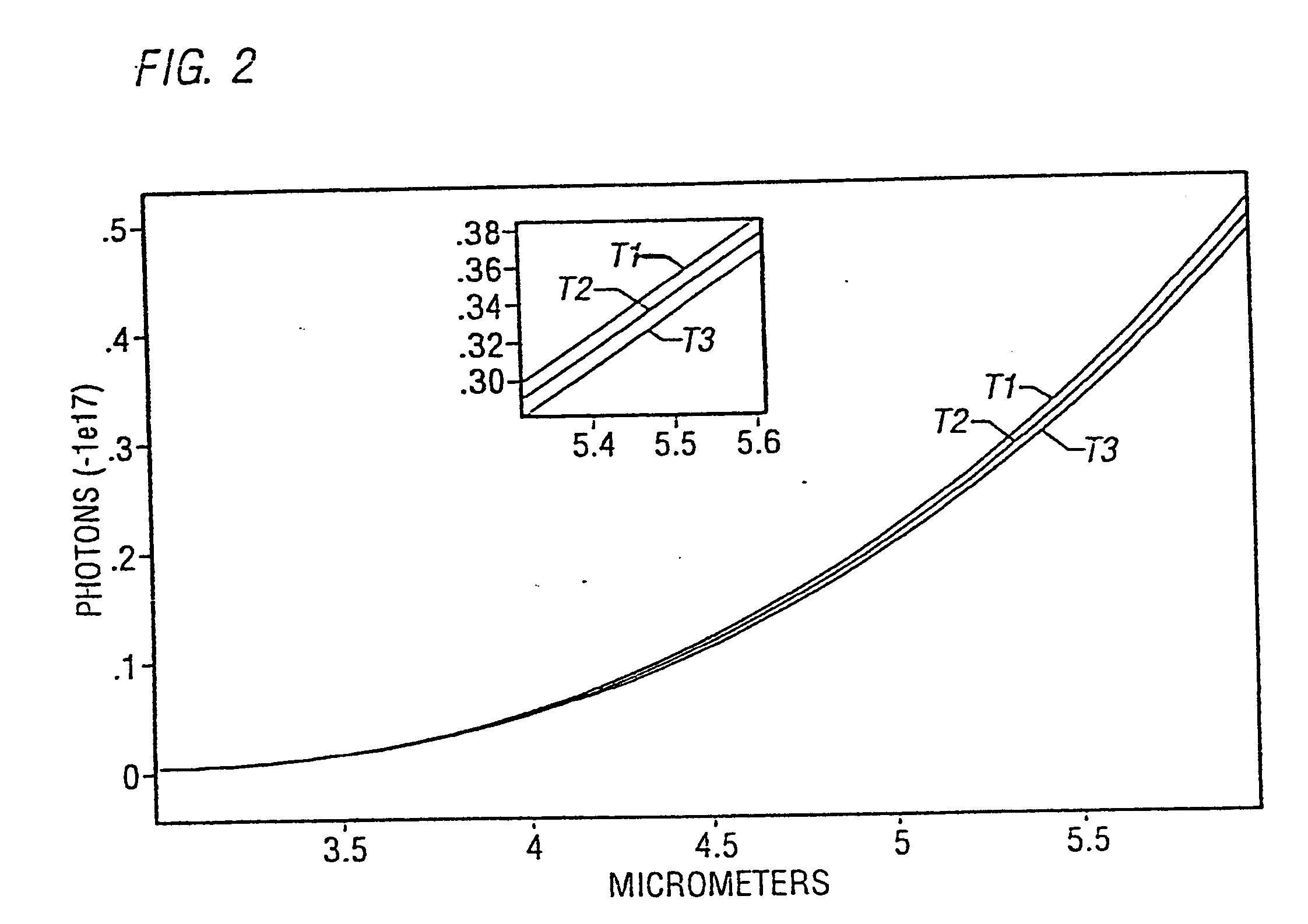

Detecting thermal discrepancies in vessel walls

InactiveUS20060094980A1High riskOvercome failureSurgeryDiagnostics using spectroscopyCholesterolThrombus

An infrared, heat-sensing catheter particularly useful for identifying potentially fatal arterial plaques in patients with disease of the coronary or other arteries and its use are detailed. In one embodiment, an infrared fiberoptic system (with or without ultrasound) is employed at the tip of the catheter to locate inflamed, heat-producing, atherosclerotic plaque, which is at greater risk for rupture, fissure, or ulceration, and consequent thrombosis and occlusion of the artery. In another embodiment, a catheter with an infrared detector (with or without ultrasound) employed at its tip will likewise locate inflamed heat-producing atherosclerotic plaque. The devices and methods of the invention may be used to detect abscesses, infection, and cancerous regions by the heat such regions differentially display over the ambient temperature of immediately adjacent tissues. The methods and devices of the invention may also be used to detect regions of cooler than ambient tissue in a vessel or organ which indicate cell death, thrombosis, cell death, hemorrhage, calcium or cholesterol accumulations, or foreign materials.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

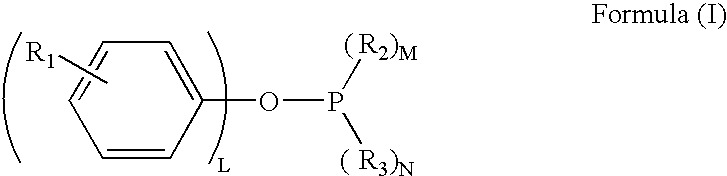

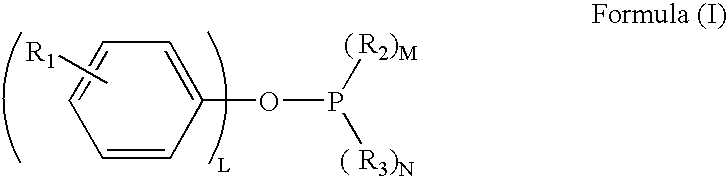

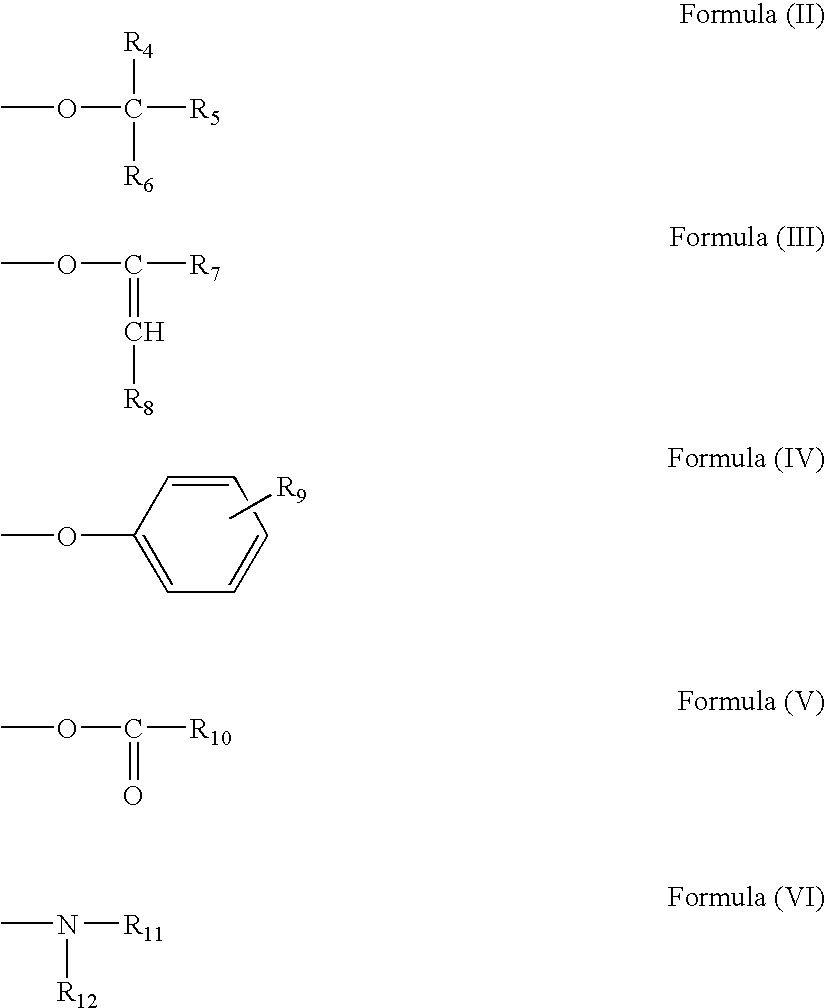

Polyester production method, polyester composition, and polyester fiber

In a polyester production method, a titanium compound having a radical selected from a carbonyl group, a carboxyl group, or an ester group, and a phosphorous compound having a structure illustrated in Formula (I), are addedThis yields a polyester composition which does not exhibit increased filter pressure when forming, which has excellent filament and film forming properties, and which has a polymer color tone superb to that of conventional products.

Owner:TORAY IND INC

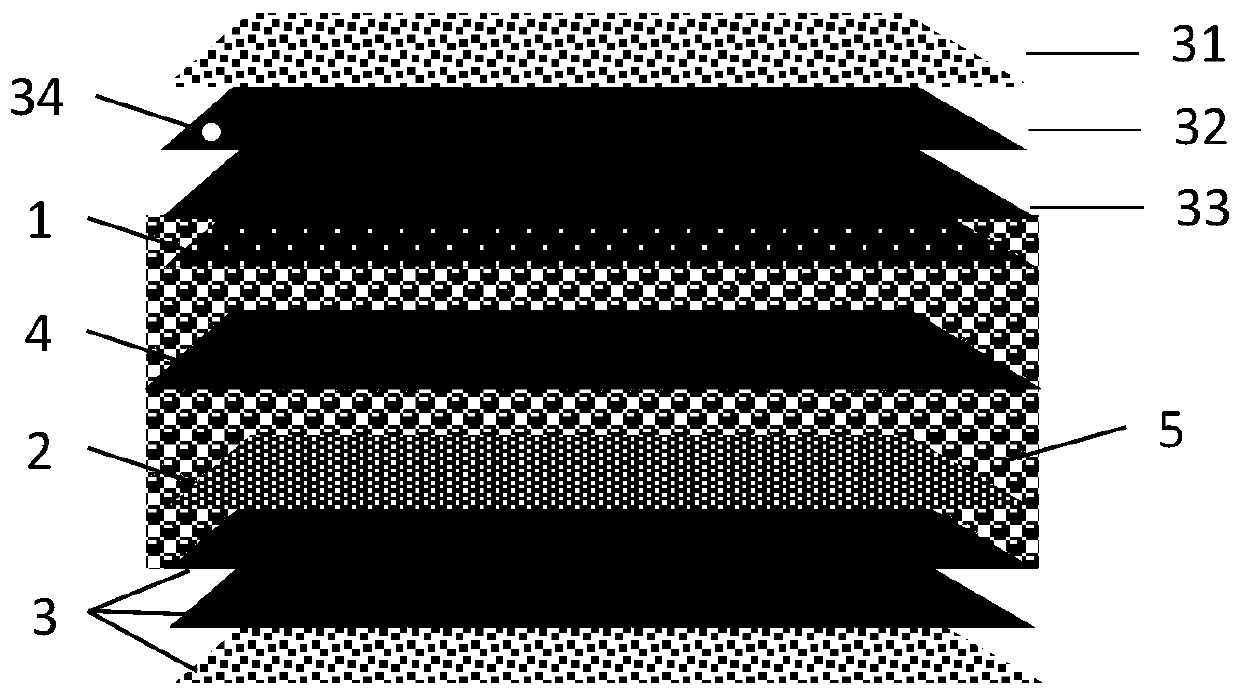

Multilayer and high-density heat insulation wadding sheet and preparation method thereof

The invention discloses a multilayer and high-density heat insulation wadding sheet and a preparation method thereof. The preparation method of the heat insulation wadding sheet includes the steps: 1)sufficiently and uniformly mixing superfine denier fibers or / and superfine denier profiled fibers, low-melting-point fibers and common fibers, and performing opening and cleaning on mixture; 2) carding opened and cleaned fibers into a sheet, and heating the sheet to perform single-layer heat setting to obtain sheet fibers; 3) laying and forming the multilayer sheet fibers, heating the multilayersheet fibers to perform overall heat setting and cutting to obtain the heat insulation wadding sheet. The heat insulation wadding sheet is of a multilayer structure, high in density, good in heat insulation effect and wearing effect, soft and simple in preparation process, a single-layer wadding sheet net is thin, and fibers are fine.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

Saccharum officinarum tail top Baijiu residue protein feed and preparation method thereof

The invention discloses a saccharum officinarum tail top Baijiu residue protein feed and a preparation method thereof. The protein feed is prepared from saccharum officinarum tail tops, Baijiu residues, molasses, corn flour, soybean meal, wheat bran, rice bran and a composite zymocyte agent. Domestication bacteria used in the protein feed are from nature, are obtained through enrichment, screeningand domestication and have super-high cellulose decomposition capacity; the prepared composite zymocyte agent is high-efficiency in fermentation and good in stability, the crude fiber content of rawmaterials of the saccharum officinarum tail tops, the Baijiu residues and the like can be effectively reduced, high molecular carbohydrates which are difficult to digest and absorb by animals, including crude fibers, lignin and the like, are converted into low-molecular substances which can be absorbed and utilized, and the digestion and utilization rate of the animals can be increased; the prepared fermented feed is more comprehensive in nutrition and high in feed conversion rate; and besides, the content of crude protein in the fermented feed is increased, the nutrition and the palatabilityof the feed are increased, the usage of antibiotics can be avoided in the fermentation process, and the feed is safe and environmental-friendly.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Third-stage infant rice flour capable of improving immunity

InactiveCN105124384ANutritional diversityImprove autoimmunityClimate change adaptationFood ingredient functionsDiseaseAnimal science

The invention discloses third-stage infant rice flour capable of improving immunity, and relates to the field of food processing. The third-stage infant rice flour is prepared from the following raw materials in parts by weight: 25-32 parts of millet, 30-40 parts of rice, 5-8 parts of fragrant mushrooms, 3-7 parts of blueberries, 2-6 parts of apples, 2-6 parts of haws, 5-8 parts of walnuts, 2-5 parts of goose livers and 3-5 parts of dried small shrimps. The third-stage infant rice flour disclosed by the invention is comprehensive in nutrition, good in brewing properties and convenient to eat; the third-stage infant rice flour has the effects of invigorating the spleen and stimulating the appetite, has a high content of calcium and zinc, can improve the autoimmunity of babies and reduce the occurrence of diseases, is extremely suitable for the growth needs of the babies six months after birth, and provides comprehensive nutrition for the babies.

Owner:尹传华

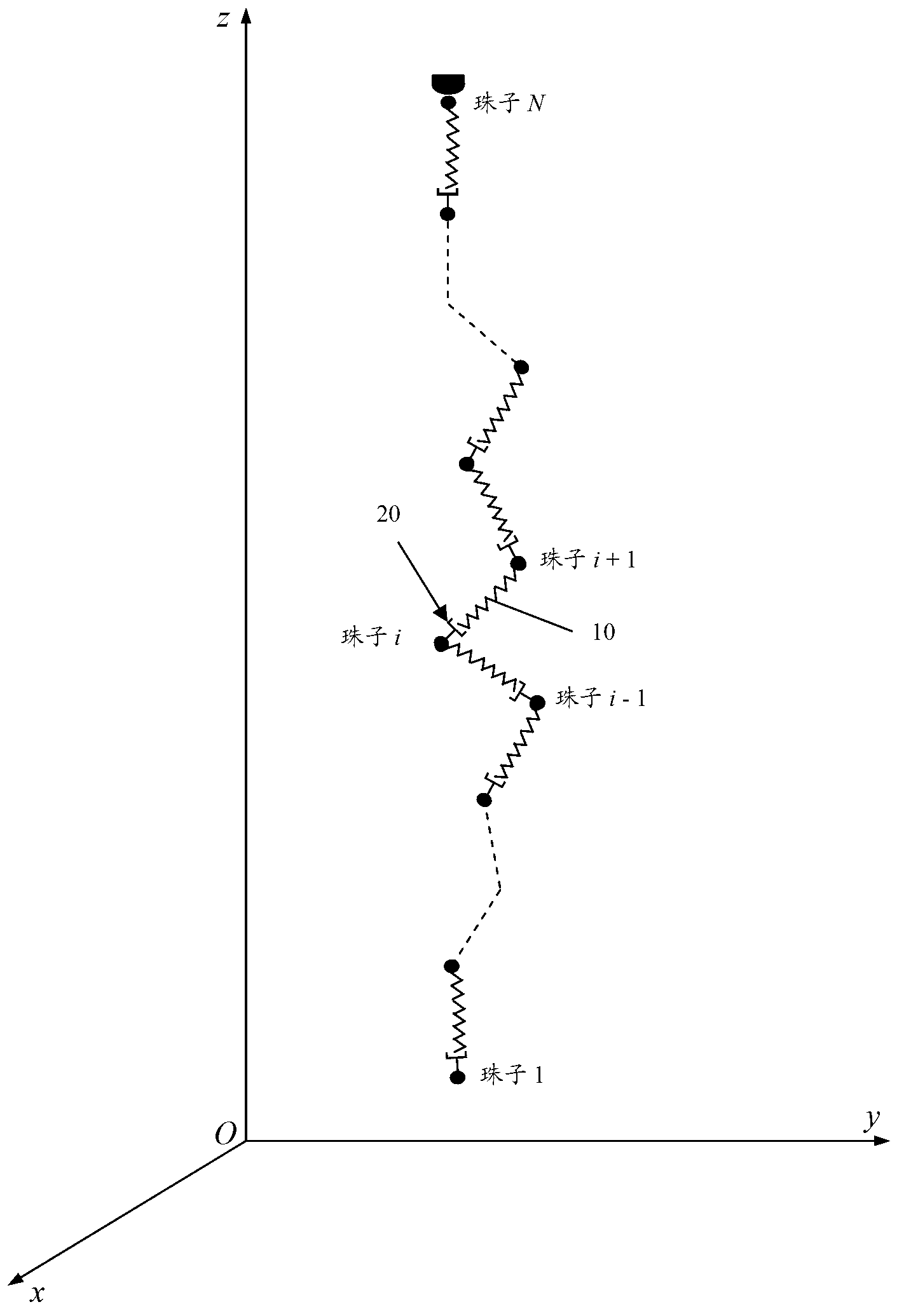

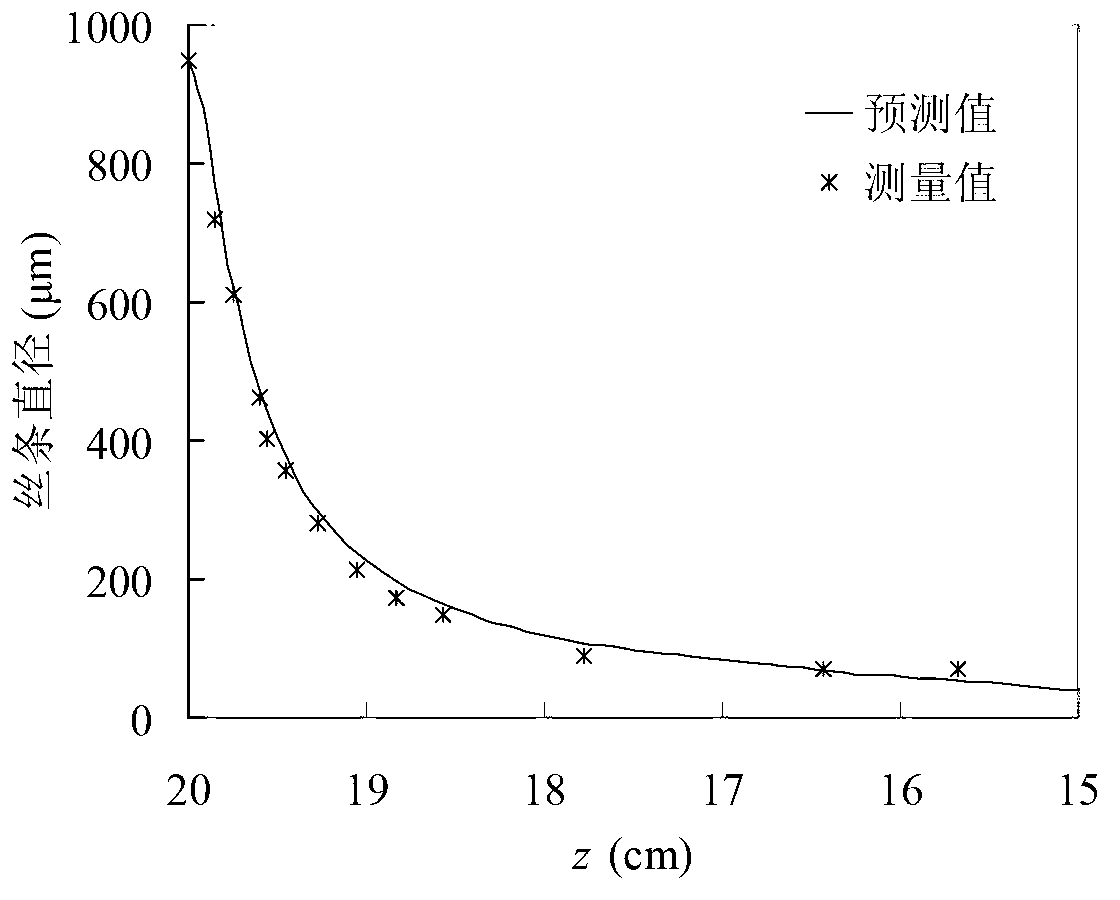

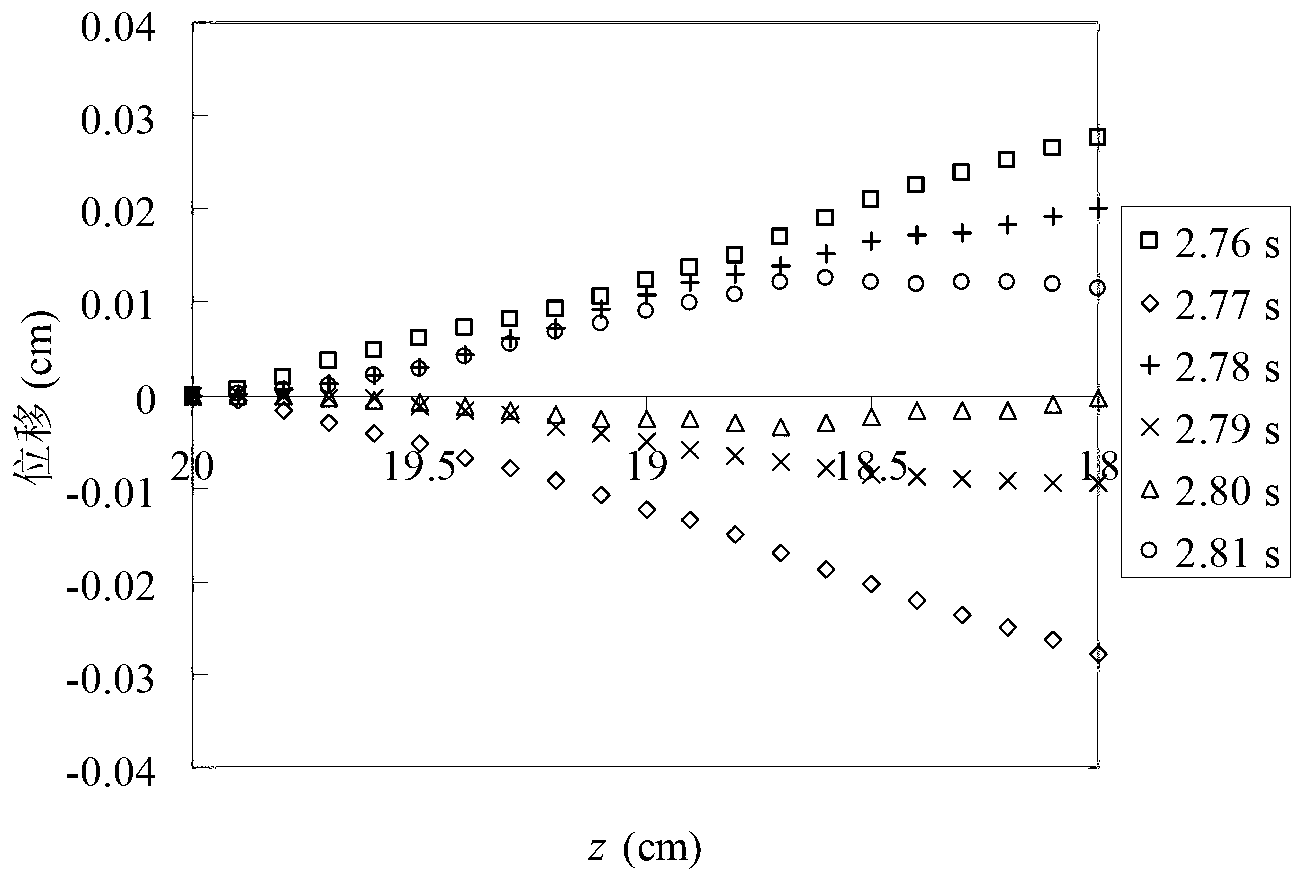

Method for forecasting diameter and lateral motion of melt-blown strand

InactiveCN102799742AReduce consumptionReduce the number of exploratory experimentsMelt spinning methodsSpecial data processing applicationsEngineeringBusiness forecasting

The invention discloses a method for forecasting the diameter and the lateral motion of a melt-blown strand. The method comprises the following steps of: (1) acquiring raw material parameters, equipment parameters and process parameters; (2) calculating air flow speed distribution and air temperature distribution; and (3) calculating the diameter and the lateral motion displacement of the strand by using a melt-blown polymer spinning and stretching model. By the method, the diameter and the lateral motion displacement of the melt-blown strand can be forecast according to the performance of raw materials, the equipment parameters and the process parameters, so that the quality of a melt-blown non-woven fabric product is improved, and a melt-blown non-weaving process and melt-blown non-weaving equipment are optimized.

Owner:SUZHOU UNIV

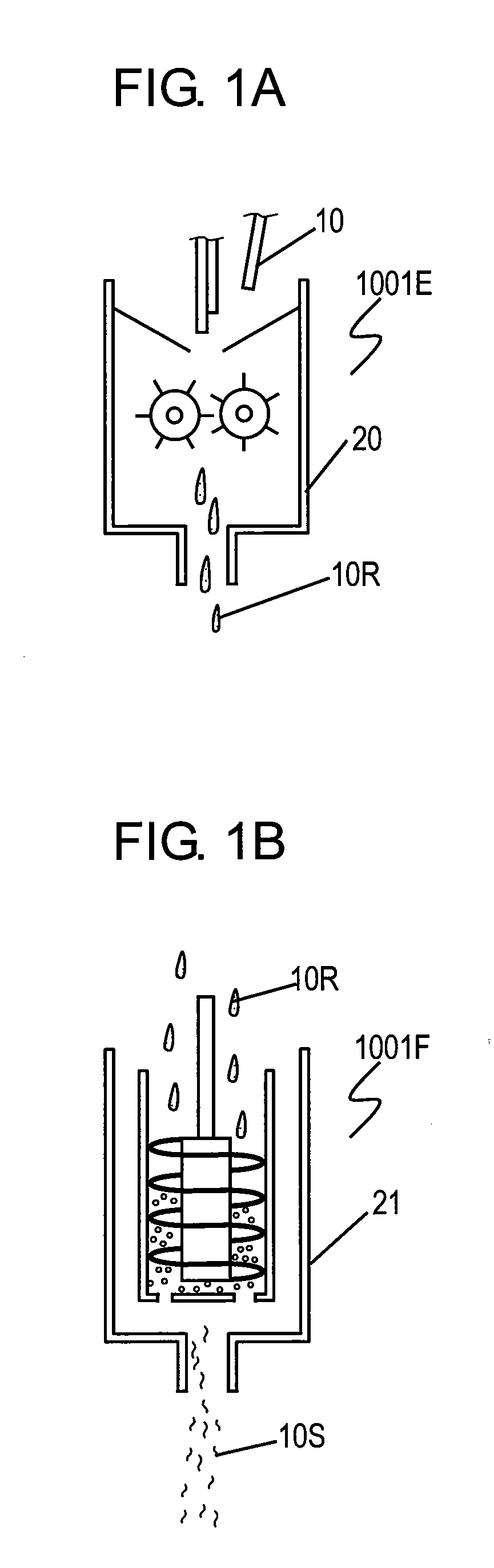

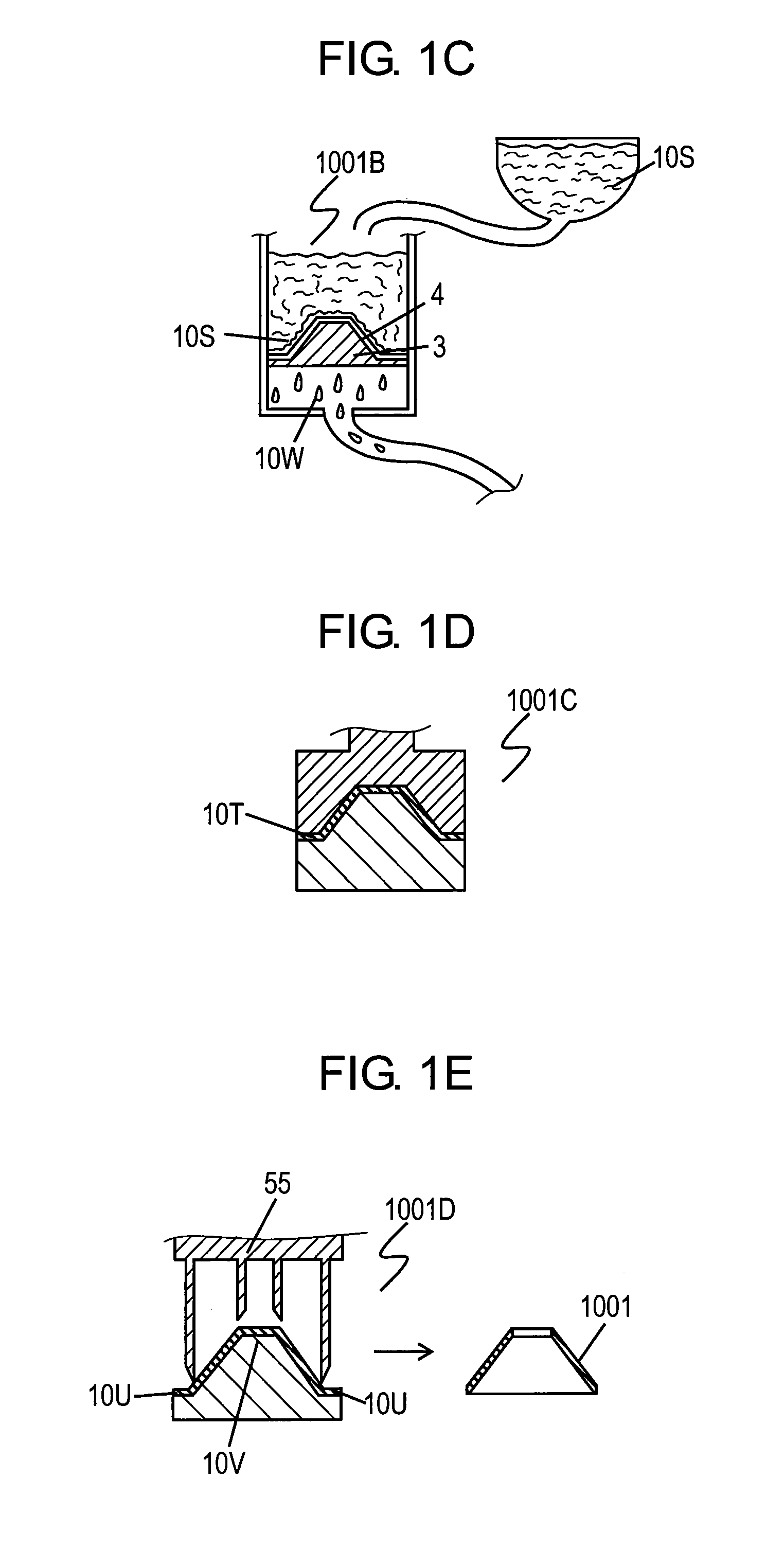

Fine natural fiber and speaker diaphragm coated with fine natural fiber

Natural fiber is beaten with a biaxial kneading machine. The beaten natural fiber is processed finely with a bead mill so as to allow the processed natural fiber to have a BET specific surface area not smaller than 1 m2 / g. This method provides fine fiber in a short time to form a rigid paper component.

Owner:PANASONIC CORP

Eucommia ulmoides paper

InactiveCN103628348AHas acid and alkali resistanceFine fiberNatural cellulose pulp/paperFiberPulp and paper industry

The invention provides eucommia ulmoides paper. The eucommia ulmoides paper comprises pure eucommia ulmoides paper, hybrid eucommia ulmoides paper and composite eucommia ulmoides paper. Materials of the eucommia ulmoides paper comprise wood, leaves, peel and seeds of eucommia ulmoides trees. The eucommia ulmoides contains 1%-18% of eucommia ulmoides paper gum, has acid-base resistance property and fine fibers; while being used for making paper, the eucommia ulmoides can improve strength, luminosity and softness of the paper and can prolong service life of the paper. The eucommia ulmoides is a rare traditional Chinese medicine material and emits beneficial free molecules in a using process. The eucommia ulmoides paper disclosed by the invention is suitable for making common paper, and also suitable for making special paper for Chinese art paper, wallpaper, book arts, life, electrical products, industrial filters, mechanical industry, agriculture, information, optics and biochemical cutting-edge technology,.

Owner:吴建华

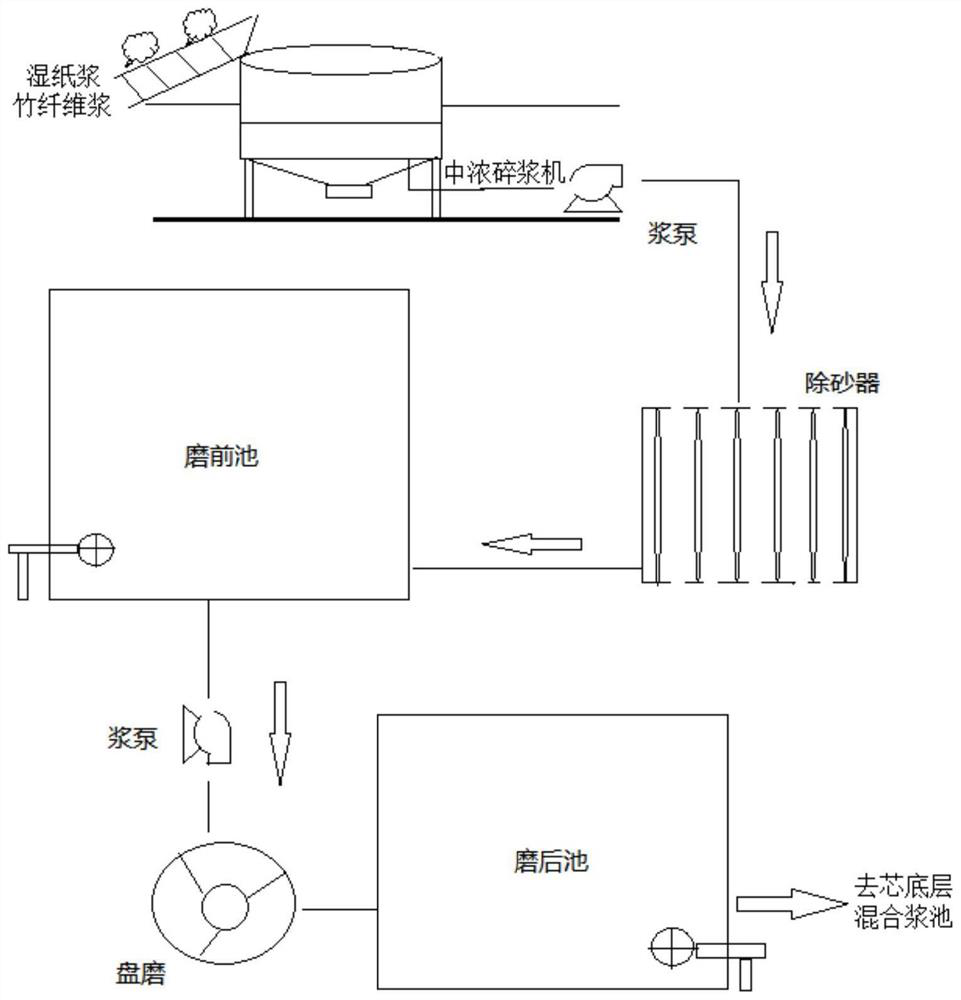

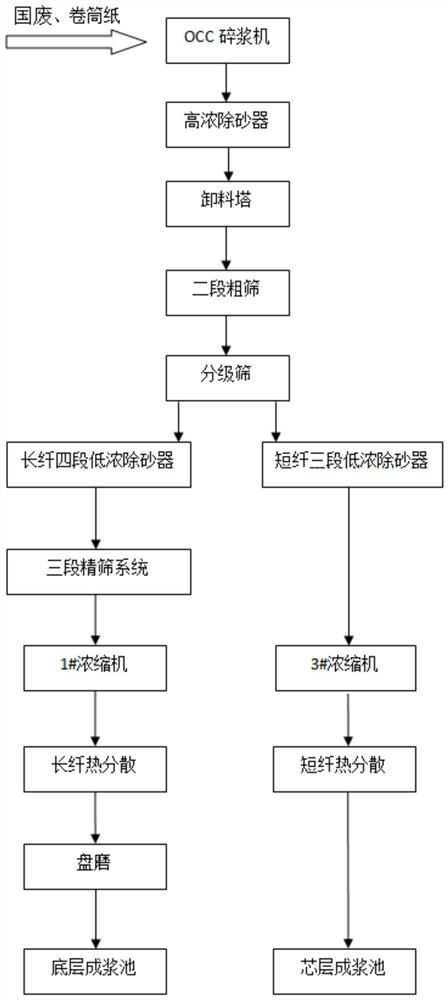

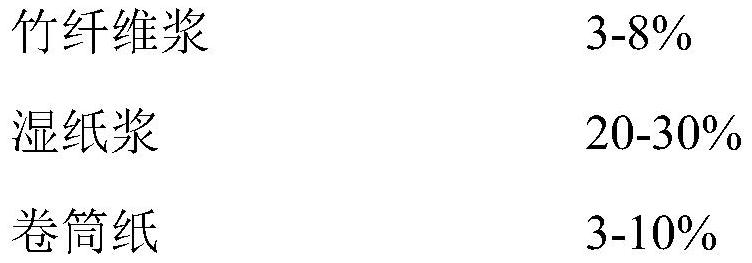

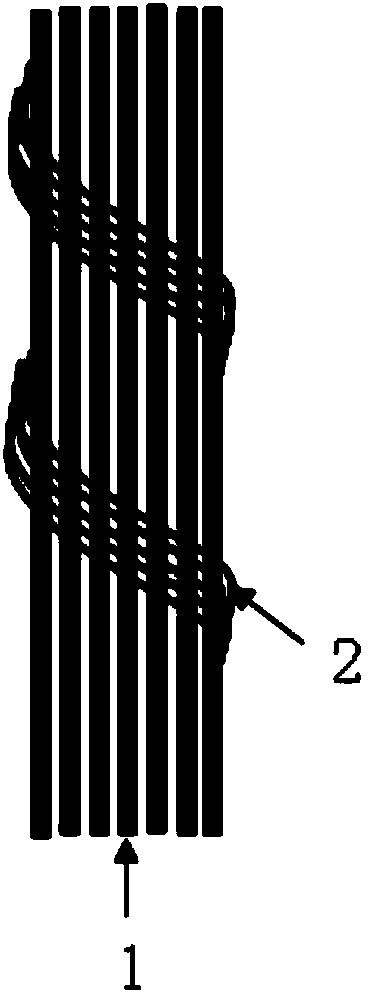

Production process of high-strength environment-friendly liner cardboard paper

PendingCN114293392ASolve limited problemsLow costPaper recyclingPulp beating/refining methodsCardboardFiber

The invention belongs to the technical field of cardboard paper, and provides a production process of high-strength environment-friendly liner cardboard paper, which comprises the following steps: taking domestic bamboo fiber pulp, imported wet paper pulp, imported roll paper and national waste as raw materials according to a specific ratio; the wet paper pulp and the bamboo fiber pulp are mixed and pulped through a medium-concentration pulper, a sand remover, a pre-grinding pool, a disc mill and a post-grinding pool in sequence, and first mixed pulp is obtained; in the OCC pulping line, the cut roll paper and national waste are treated through an OCC pulper, a high-concentration sand remover, a discharging tower, a two-section coarse screen and a classifying screen in sequence to obtain long fibers and short fibers, and then the long fibers and the short fibers are subjected to aftertreatment to obtain long fiber pulp and short fiber pulp; and mixing the long fiber pulp, the short fiber pulp and the first mixed pulp, and performing papermaking to obtain the liner cardboard paper. According to the production process, national waste is mainly used, quantitative roll paper, wet paper pulp and bamboo fiber pulp are matched, and the production process is optimized, so that the cost is reduced, the production efficiency is improved, the quality of finished paper can be improved, and the problem that external waste import is limited is solved.

Owner:东莞理文造纸厂有限公司

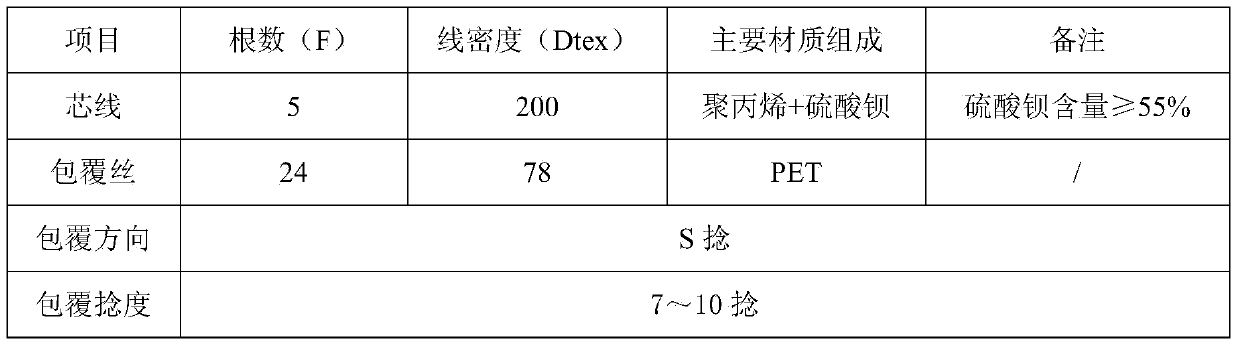

Medical X-ray detectable sewing thread

The invention discloses a medical X-ray detectable sewing thread. The medical X-ray detectable sewing thread comprises a sewing thread body, wherein the sewing thread body comprises a plurality of core threads and covered filaments, the core threads are formed by complex fibers made of barium sulfate and high polymer materials, the covered filaments are formed by a plurality of chemical fiber filaments, and the covered filaments cover outer surfaces of the core threads along the direction of S-twist, Z-twist, or a cross of the S-twist and the Z-twist; covering twists of the covered filaments are 2-16 twists; the cross section of the sewing thread is round or oval; the content of the barium sulfate in the complex fibers is larger than or equal to 55%. The medical X-ray detectable sewing thread can be weaved or sewed (or welded by using ultrasonic waves) into a gauze or an operation towel, whether the gauze or the operation towel is left in the body of a patent can be found through X-ray examination after operations, and medical negligence caused by the gauze or the operation towel left in the body of the patent is avoided.

Owner:浙江川本卫生材料有限公司

Polyester, production method thereof, fibers therefrom and catalyst for polymerization of polyester

InactiveUS20070093637A1Controlled crystallization rateReduce in quantityMonocomponent polyesters artificial filamentPolyesterFiber

There are provided a polyester with a controlled crystallization rate which forms fibers stably even in high-speed spinning in the present invention. There are also provided a polyester obtained in the presence of an antimony catalyst comprising: (i) diantimony trioxide, and (ii) 1 to 10 wt % of diantimony tetraoxide and / or diantimony pentaoxide based on diantimony trioxide, a production method therefor, fibers formed therefrom, and a catalyst for polymerization of the polyester.

Owner:TEJIN FIBERS LTD

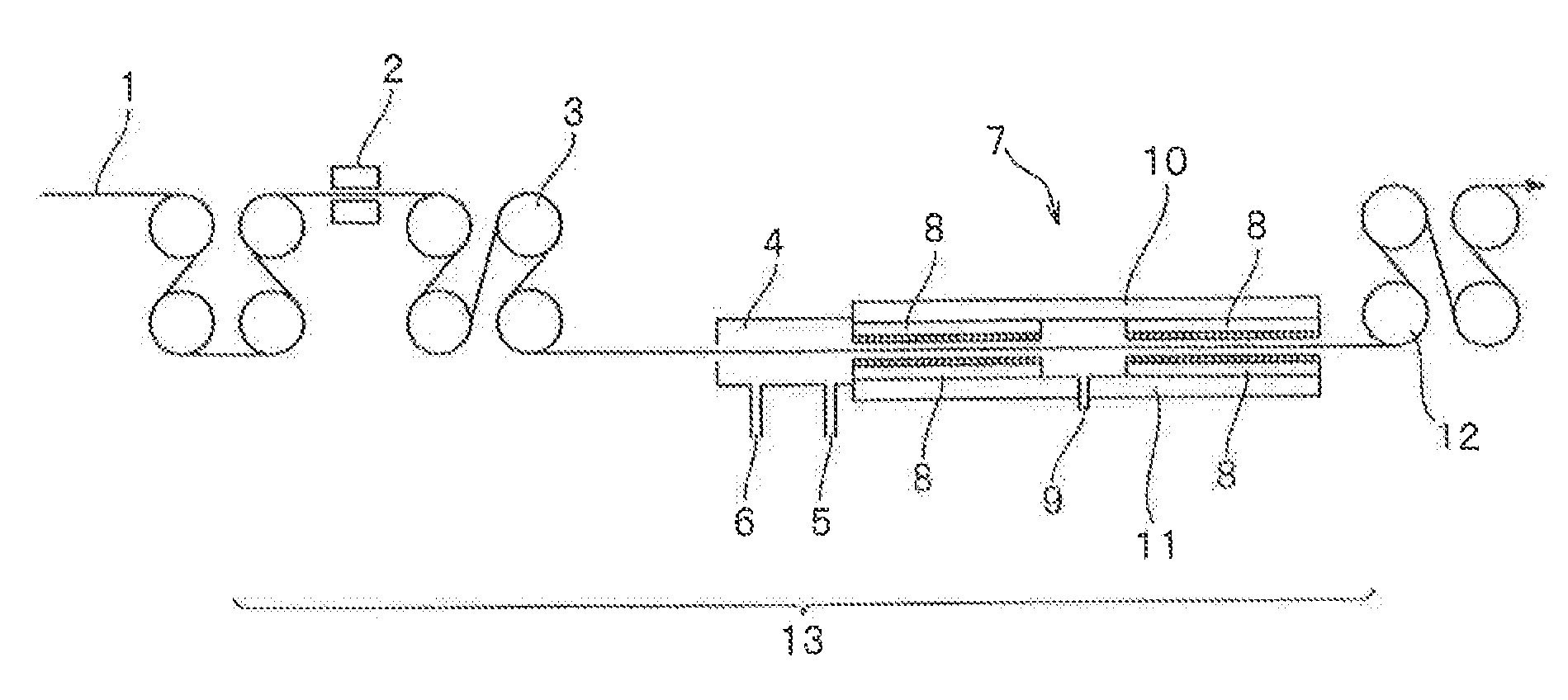

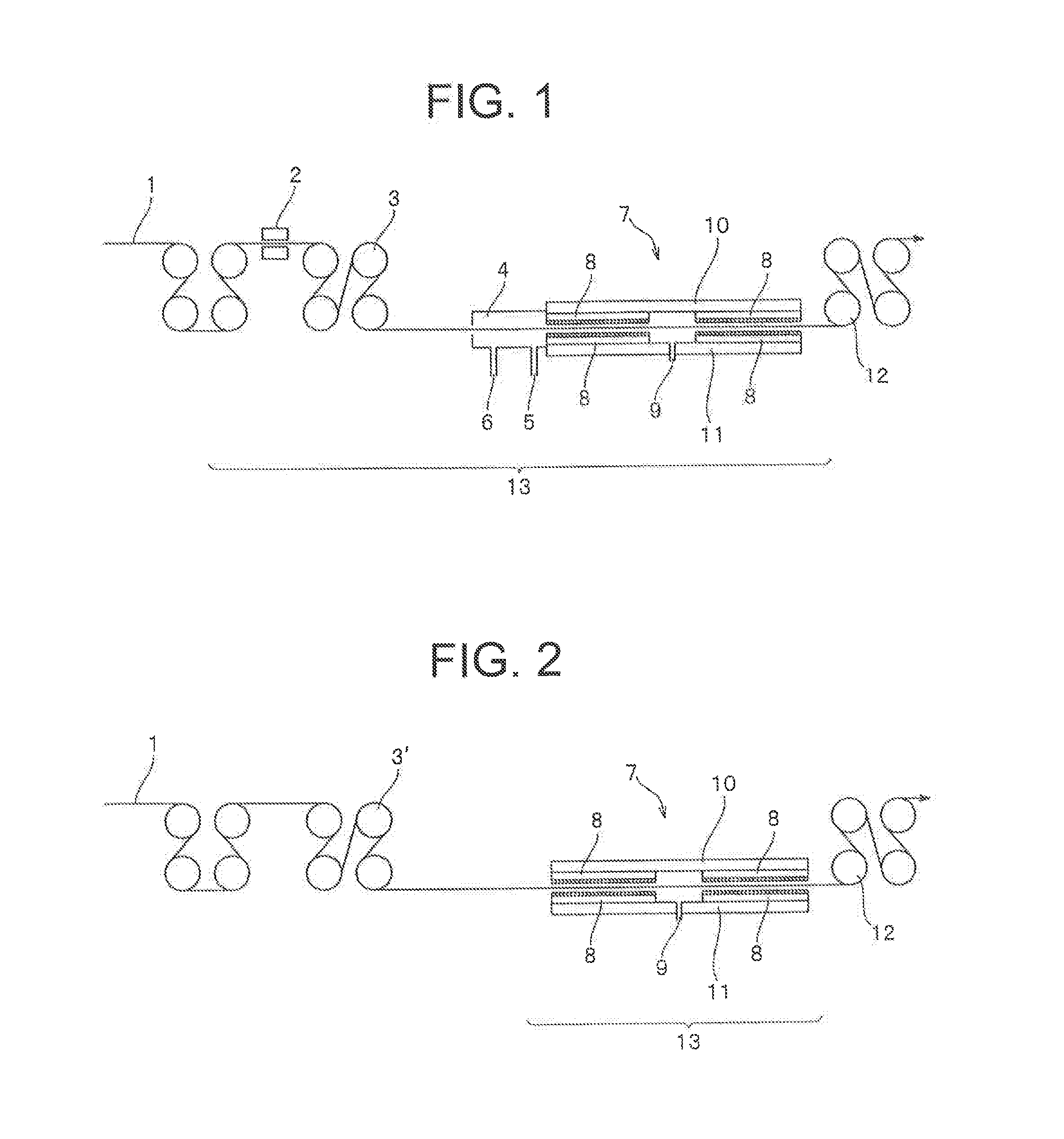

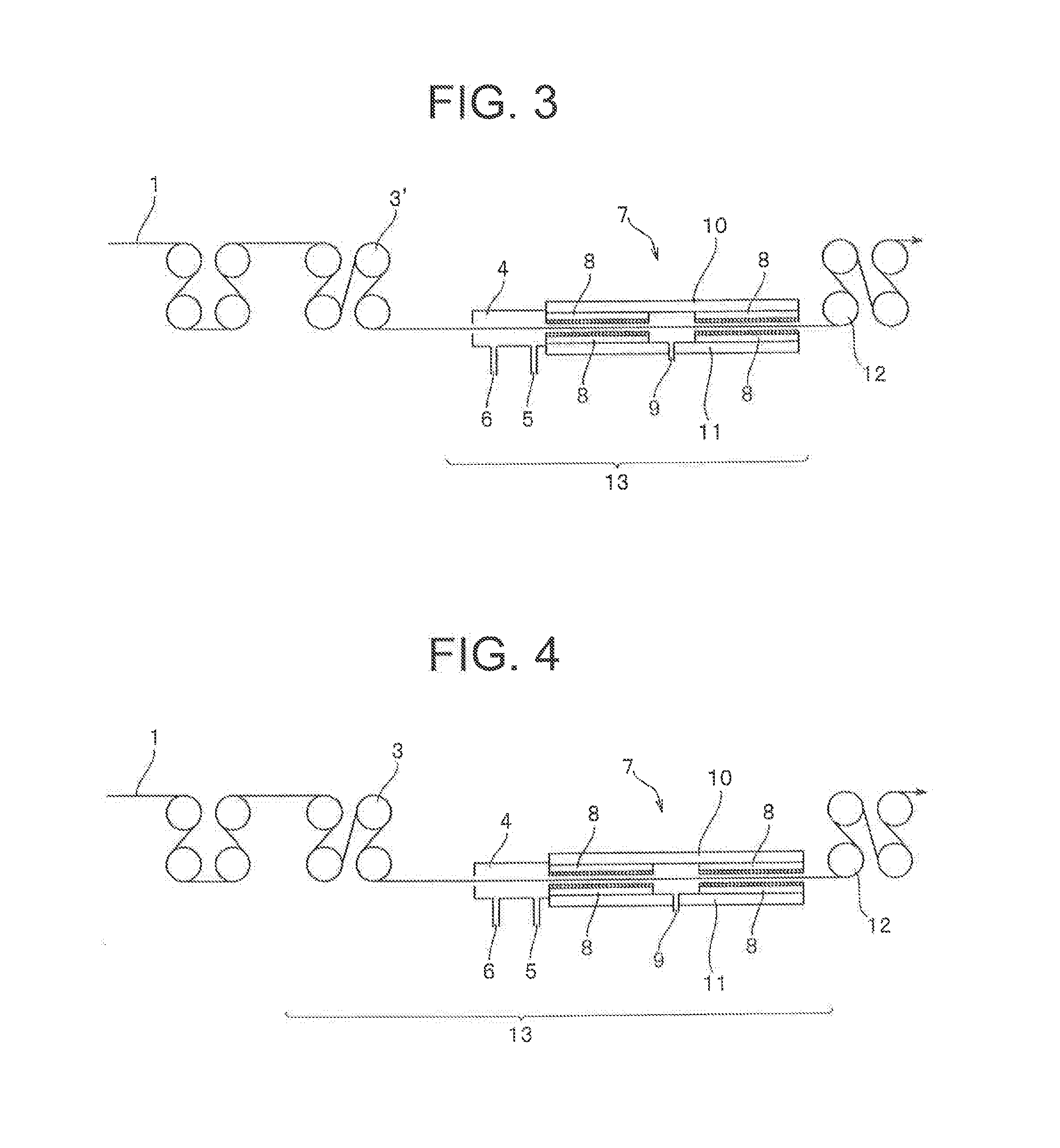

Process for manufacturing carbon-fiber precursor acrylic fiber bundle and steam drawing apparatus

ActiveUS20160151959A1Improve plasticizing effectTrouble with breakage can be preventedFilament manufactureCeramic shaping apparatusCarbon fibersFiber bundle

This process for manufacturing a carbon-fiber precursor acrylic fiber bundle and this steam drawing apparatus are characterized in that the drawing of an acrylic fiber bundle with a pressured-steam drawing apparatus is conducted by: opening an acrylic fiber bundle by blowing a fluid thereto; supplying humidifying steam to the opened acrylic fiber bundle at a fiber temperature of 80 to 130° C. to adjust the water content of the fiber bundle to 3 to 7%; and thereafter drawing the resulting acrylic fiber bundle in a pressurized-steam atmosphere. Thus, the present invention can prevent the breaking of a single fiber, the fluffing of the fiber bundle, and the breaking of the whole of the fiber bundle, though such defects are susceptible to occurring in a case where an acrylic fiber bundle is drawn by steam drawing at a high draw ratio, at a higher speed, or into a fiber having a small denier.

Owner:MITSUBISHI CHEM CORP

Manufacturing method for pulp picture foiled with faithful depiction background

PendingCN107187263AIt is not easy to solve the perspective relationship between far and nearDifficult to solve large and difficult problemsSpecial ornamental structuresIndustrial engineeringManufacturing engineering

The invention discloses a manufacturing method for a pulp picture foiled with a faithful depiction background. The manufacturing method comprises the steps that a bottom plate and pulp are prepared, the pulp picture is manufactured and shaped, and follow-up processing is conducted. Specifically, a faithful depiction background picture is printed on a canvas, a pulp-painting-area blank is reserved in the faithful depiction background picture, a pulp painting contour line is printed in the blank area, figures or characters representing pulp colors are marked within the contour line, and thus the bottom plate is prepared; a paper making pulp board with the whiteness being 70-92% is adopted to prepare pulp with the beating degree being 14-42 degrees SR and water content being 21-40% through a pulping machine, pigment and white emulsion are added to prepare pulp with needed colors, each bottom plate is equipped with pulp of the corresponding amount and corresponding colors, and the pulp colors are marked with figures or characters; according to color marking on the blank position of the bottom plate, the blank position of the bottom plate is filled with the pulp of the corresponding colors, the thickness of the pulp is adjusted, the pulp is shaped, and then the target pulp picture is obtained; and the pulp picture is dried, mended, trimmed and mounted, and thus manufacturing of the whole pulp picture is completed.

Owner:敦化市金兴纸制品有限公司

Feed additive for promoting digestion of chicken

The invention discloses a feed additive for promoting digestion of chicken. The feed additive for promoting digestion of chicken is prepared from, by weight, 20-25 parts of apples, 10-15 parts of hawthorn fruits, 30-40 parts of highland barley powder, 5-8 parts of cocoa powder, 7-9 parts of Chinese prickly ash, 20-25 parts of apricot kernels, 30-35 parts of glutinous rice, 40-50 parts of asparagus, 15-20 parts of fresh peach leaves, 3-4 parts of white vinegar, 4-5 parts of baijiu, 5-6 parts of white sugar, ethyl maltol, lactic acid bacteria and a proper amount of water. The feed additive has good palatability, can promote feed digestion of the chicken, is high in feed conversion, facilitates improvement of the survival rate and reduces the production costs.

Owner:安徽科瑞达禽业有限公司

Hatched chicken feed additive capable of improving disease resistance

InactiveCN106071290AIncrease appetitePromote secretionAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention discloses a hatched chicken feed additive capable of improving disease resistance. The feed additive is prepared from the following raw materials in parts by weight: 10-13 parts of caraway, 5-6 parts of fresh fennel, 30-35 parts of soybeans, 10-13 parts of green bean starch, 7-9 parts of Chinese prickly ash, 20-25 parts of apricot kernels, 30-35 parts of polished glutinous rice, 40-50 parts of asparagus, 15-20 parts of fresh peach leaves, 3-4 parts of white vinegar, 4-5 parts of Baijiu, 5-6 parts of white sugar, an appropriate amount of ethyl maltol, an appropriate quantity of lactic acid bacteria and an appropriate amount of water. The feed additive disclosed by the invention is scientific in formula, can improve the immunity and the diseases resistance of hatched chickens and promote quick growth of chicks, is free from hormones, and facilitates human health.

Owner:HUAINAN SONGWANG HIGH QUALITY GRAIN PLANTING FARMERS SPECIALIZED COOPERAIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com