Manufacturing method for pulp picture foiled with faithful depiction background

A production method and pulp technology, applied in special decorative structures, decorative arts, etc., can solve the problems of not being able to make large and complex pulp paintings, affecting the appearance of pulp paintings, and rough surfaces of pulp paintings, so as to achieve bright colors, improve viewing and popularization Sexuality, strong effect of three-dimensional picture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention should not be limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

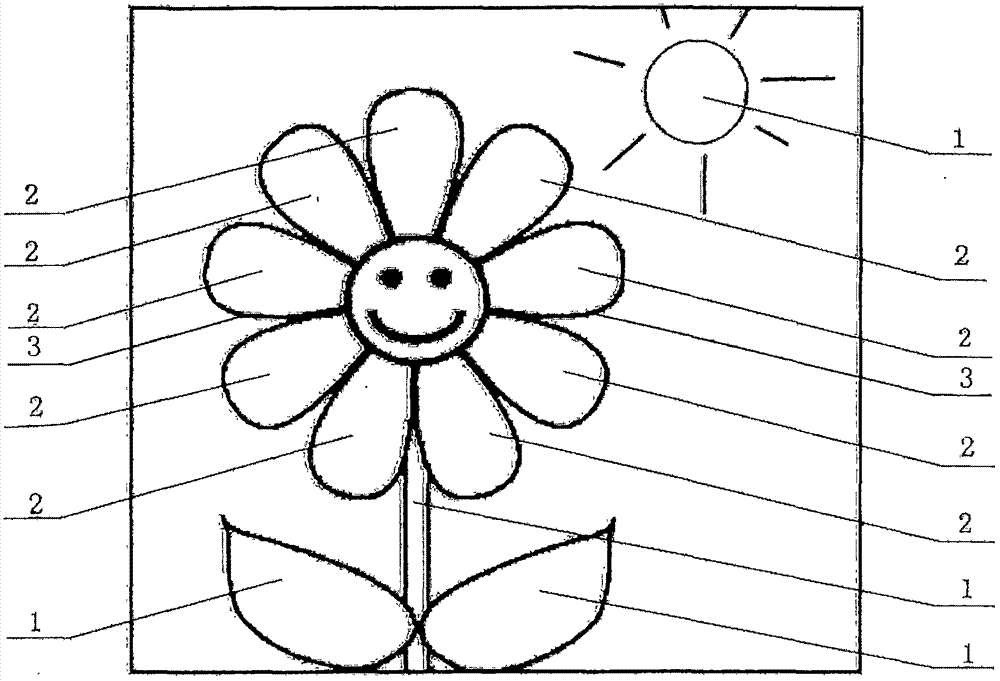

[0012] First use the computer to design the pattern, divide a picture that needs to be made into pulp painting into the background photo area picture (1 in the picture) and the pulp modeling painting area pattern (picture 2), the background photo area picture retains the background photo picture in the original picture (Figure 1), use the theme picture of the whole picture as the pulp painting modeling area (Figure 2), reserve a blank space in the pulp modeling painting area, and use a computer to draw out the pulp painting graphic contour lines in the blank space (Figure 2). Middle 3), mark the required pulp color with numbers or words in the contour line, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com