Wire rope composite fiber core and production method and application thereof

A composite fiber and wire rope technology, applied in textiles and papermaking, textile cables, elevators, etc., can solve the problems of increasing the vibration and noise of elevator wire ropes, fluctuations in the length direction of the diameter of the rope core, and uneven thickness of a single fiber, to avoid diameter The effect of large fluctuation, uniform rope diameter and good oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The method for preparing a composite fiber core of a steel wire rope comprises the following steps:

[0026] 1) Pretreatment of jute yarn: The purchased jute yarn is soaked in oil at high temperature for 20-25 hours, and then oil-controlled for 20-25 hours, so that the jute yarn can absorb oil evenly and saturated;

[0027] 2) Preparation of a single strand of composite fiber core: the pretreated jute yarn and polypropylene yarn in step 1) are loaded on a single twisting machine, uniformly arranged through a splitter, and after passing through a sizing die, twisted into a center It is the main core 1 of jute, and the outer layer is a single strand of composite fiber core of polypropylene outer core 2; when twisting, the pay-off tension of the jute yarn is greater than that of the polypropylene yarn, so that the polypropylene yarn is tightly wrapped in the jute yarn. The outer side of the main core 1;

[0028] 3) Plying of the composite fiber core of the steel wire rope...

Embodiment 1

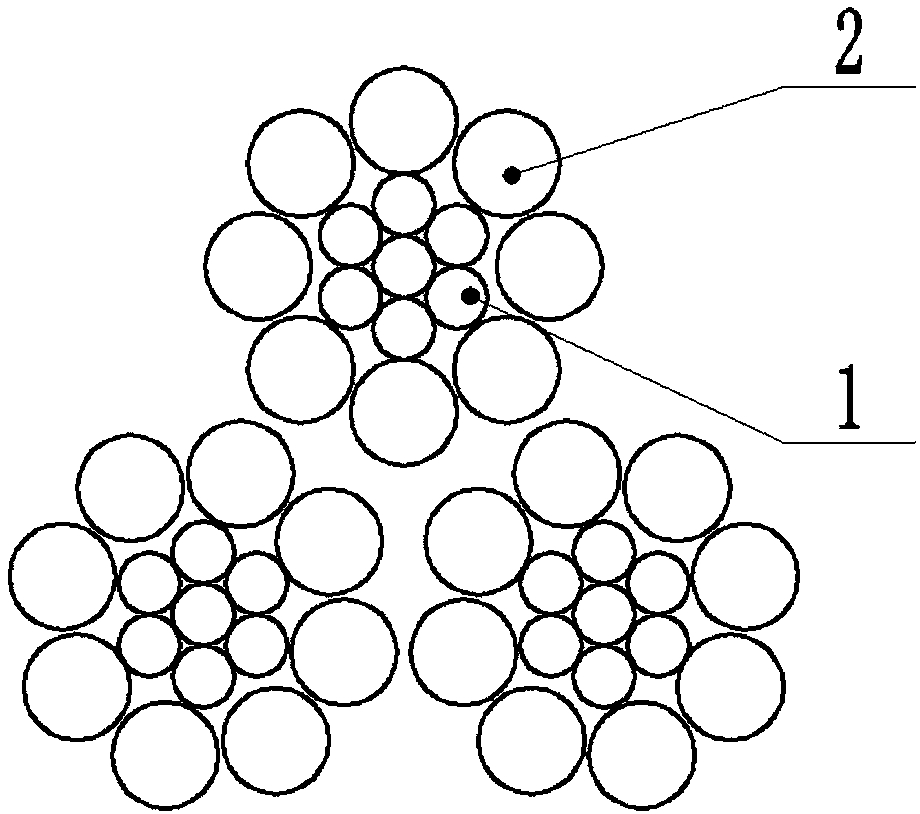

[0032] like figure 1 As shown, in this embodiment, the composite fiber core of the steel wire rope is made of 3 composite fiber cores twisted in a single strand, and each composite fiber core single strand includes a jute main core 1 and a polypropylene outer core 2; the jute main core 1 is composed of 1 central jute yarn and 6 outer jute yarns, and the 6 outer jute yarns are evenly wrapped on the outside of the central jute yarn; 8 polypropylene filaments form the polypropylene outer core 2 and are evenly wrapped in Outside of main jute core 1.

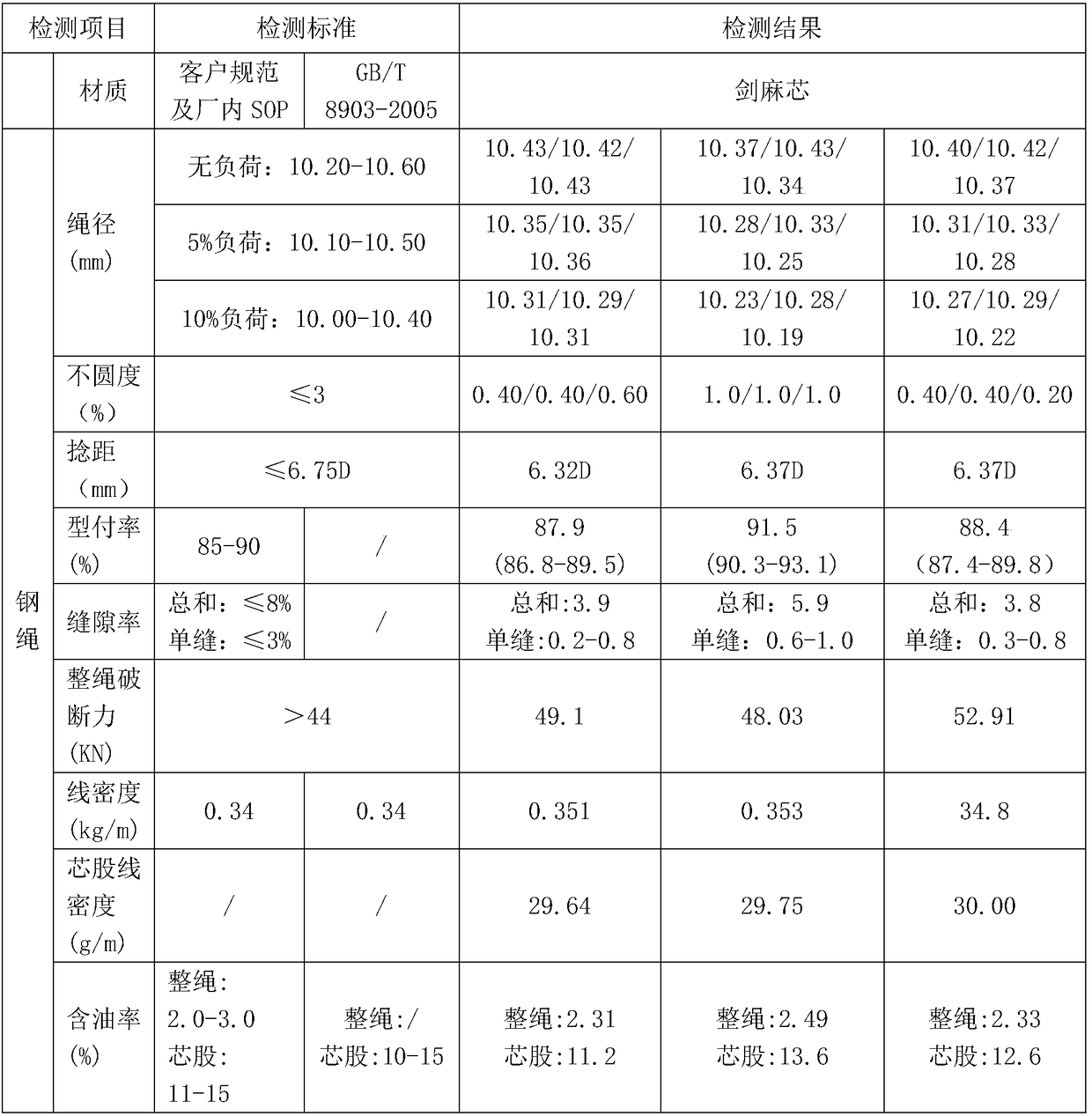

[0033] As shown in Table 1 and Table 2, the test data comparison table of the present embodiment, on the basis of reaching the national standard, the out-of-roundness and the gap rate of the steel wire rope prepared by the method of the present invention are all better than the sisal core whole rope. As shown in Table 3, when using the special fatigue testing machine of Mitsubishi and OTIS to carry out the fatigue test, the wire bre...

Embodiment 2

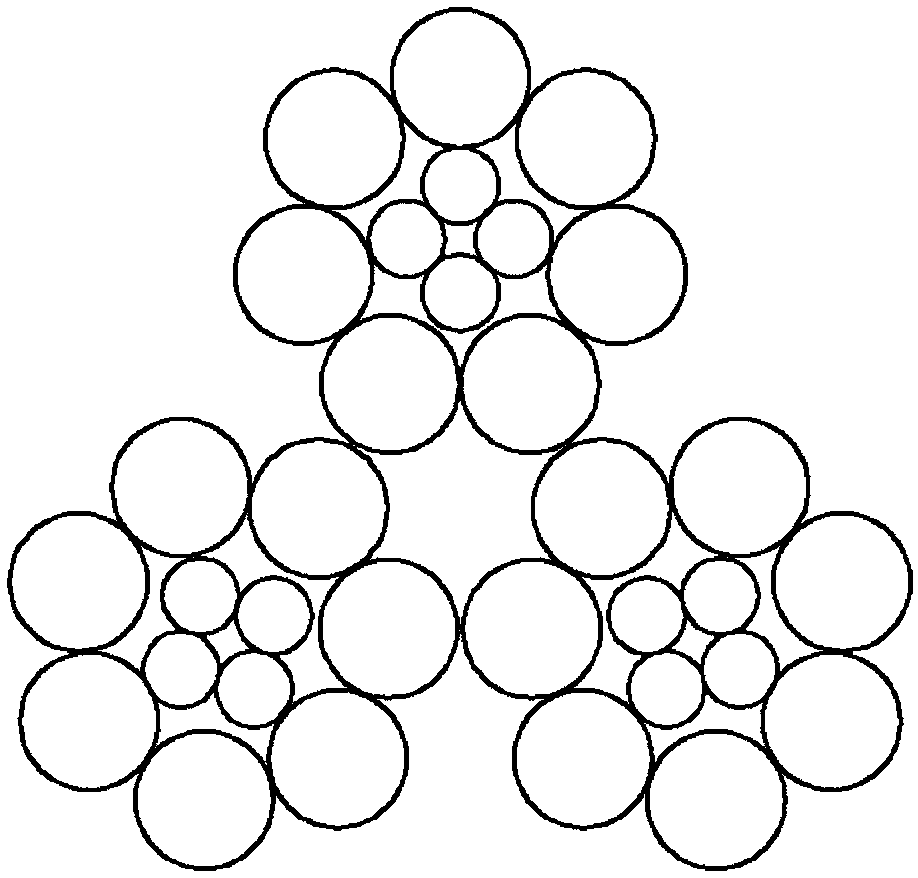

[0041] like figure 2 As shown, in this embodiment, the composite fiber core of the steel wire rope is made of 3 composite fiber cores twisted in a single strand, and each composite fiber core single strand includes a jute main core 1 and a polypropylene outer core 2; the jute main core 1 is composed of 4 jute yarns twisted together; 7 polypropylene filaments form a polypropylene outer core 2 and are evenly wrapped on the outside of the jute main core 1.

[0042] As shown in Table 4 and Table 5, comparing the detection data of this example, on the basis of reaching the national standard, the out-of-roundness and the gap ratio of the steel wire rope prepared by the method of the present invention are all better than the whole rope with sisal core. As shown in Table 6, when using the special fatigue testing machine of Mitsubishi and OTIS to carry out the fatigue test, the wire breakage rate and corrosion resistance of the wire rope prepared by the method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com