Production process of high-strength environment-friendly liner cardboard paper

A liner containerboard and production process technology, applied in papermaking, paper recycling, textiles and papermaking, etc., can solve the uneven quantity and quality of recycling, affect paper web forming and paper quality, and limit the production capacity of containerboard and other problems to achieve the effect of avoiding insufficient supply, improving strength and burst resistance, and high degree of fiber separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The production process of a kind of high-strength environment-friendly linerboard of the present embodiment comprises the following process steps:

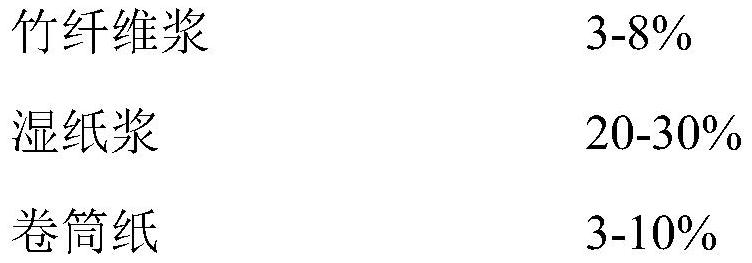

[0033] Step S1, raw material selection: use domestic bamboo fiber pulp, imported wet paper pulp, imported roll paper and national waste as raw materials, and the weight ratio of each raw material is:

[0034] Bamboo fiber pulp 5%

[0035] wet pulp 24%

[0036] Web 6%

[0037] Class A national waste 5%

[0038] Class B national waste 60%.

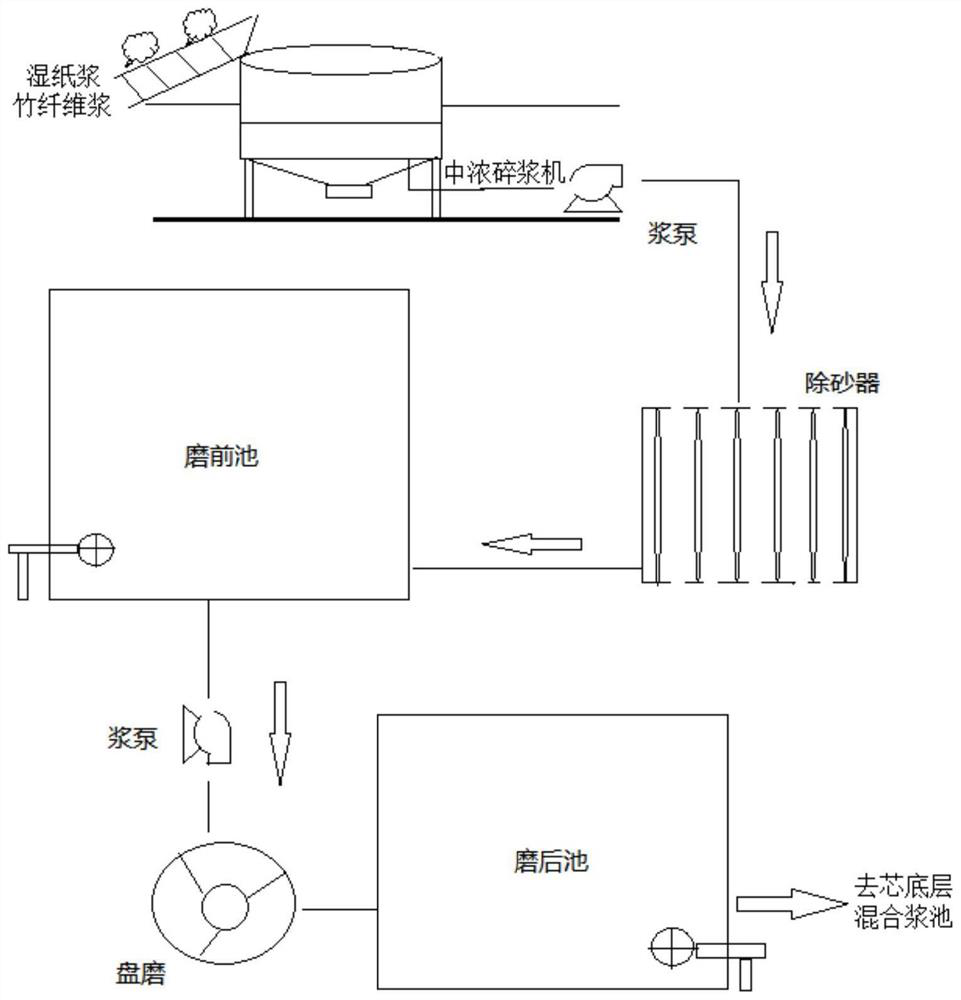

[0039] Step S2, medium consistency pulping line: refer to figure 1 , put the wet paper pulp and bamboo fiber pulp into the medium-concentration pulper for mixing and crushing, and then sequentially pass through the desander, the pre-grinding pool, the disc mill and the post-grinding pool to obtain the first mixed pulp of bamboo fiber pulp and wet paper pulp. slurry, and then pump the first mixed slurry to the mixed slurry pool at the bottom of the core.

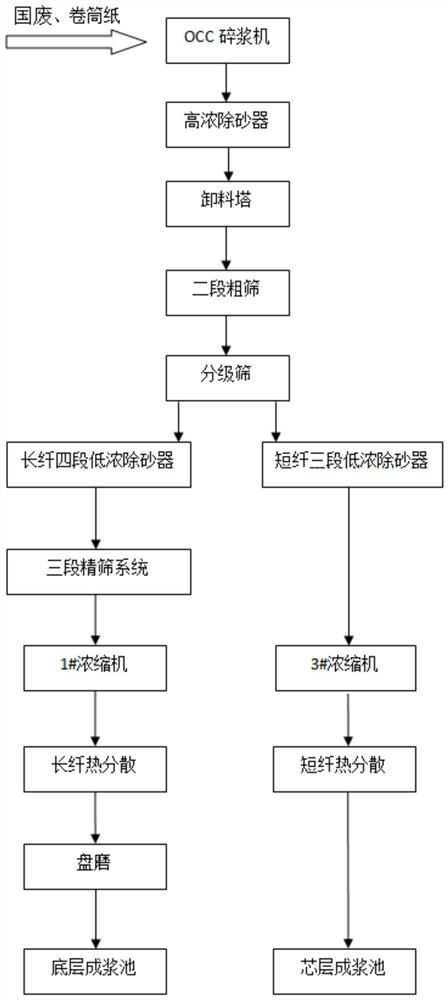

[0040] Step S3, OCC pulping...

Embodiment 2

[0046] A kind of production technology of high-strength environment-friendly linerboard of the present embodiment, specifically with reference to embodiment 1, its difference with embodiment 1 is:

[0047] In step S1, the weight ratio of each raw material is:

[0048] Bamboo fiber pulp 3%

[0049] wet pulp 24%

[0050] Web 10%

[0051] Class A national waste 3%

[0052] Class B national waste 60%.

Embodiment 3

[0054] A kind of production technology of high-strength environment-friendly linerboard of the present embodiment, specifically with reference to embodiment 1, its difference with embodiment 1 is:

[0055] In step S1, the weight ratio of each raw material is:

[0056] Bamboo fiber pulp 7.6%

[0057] Wet pulp 30%

[0058] Web 3%

[0059] Class A national waste 9.4%

[0060] Class B national waste 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com